Small arms ammunition with sub-caliber bullets

To overcome this obstacle in the armor-piercing bullets of small arms, the core is often made of a composite tungsten carbide alloy with cobalt of the BK8 type with grains less than 1 μm, the flexural strength of which is 2 GPa with HRA 4 units of hardness. Even more promising is a metal alloy of tungsten of the type VNZh85, by analogy with the cores of armor-piercing artillery shells. However, SIBZ plates also have a reserve for increasing durability both by increasing the percentage of boron carbide in the composite, and due to the thickness of the plates (taking into account the tendency of transition to the use of passive exoskeletons as part of infantry equipment).

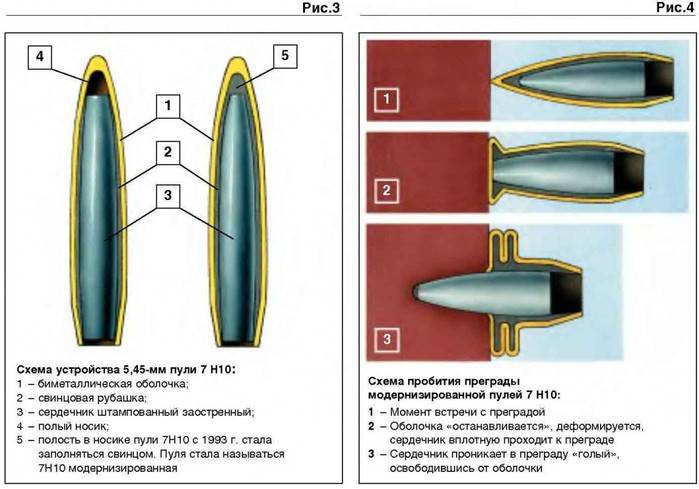

In addition, the classic ogival shell bullet is a highly inefficient carrier of an armor-piercing core, since it requires the use of a lead shirt to pass along the barrel bore without destroying them upon contact with a hard alloy core. As a result, the mass of the core itself is reduced to a minimum. For example, the bullet cartridge 7H24М caliber 5,45х39 mm with bimetallic sheath, lead shirt and armor-piercing core made of alloy BK8 weighs 4,1 gram, of which the weight of the core is only 1,8 gram. In addition, when colliding with a SIBZ plate, part of the kinetic energy of the bullet is spent on collapsing the bimetallic shell, breaking through the armor-piercing core and tearing off the lead shirt

A more effective method of increasing the armor penetration rate of small arms bullets is to increase their initial velocity and reduce the cross-sectional area. The first measure increases the kinetic energy of the bullet, the second increases the specific load in the contact patch of the bullet with the barrier. The speed of the bullet is limited by the maximum pressure of the powder gases in the barrel, which currently reaches 4500 atmospheres and is determined by the strength of the barrel steel. This restriction is overcome by reducing the mass and diameter of the bullet while maintaining the diameter of the barrel bore - that is, by moving to sub-caliber bullets. To drive the sub-caliber bullet in the barrel bore, developed leading belts are used on the surface of the core or a polymer pallet, the density of which is X times less than the density of brass or lead in 9-11.

The first constructive solution in this area is the German Harold Gerlich bullet, developed in the first third of the 20 century and equipped with two leading tapered tape. The bullet in flight was stabilized by rotation, the rifled barrel had a variable diameter tapering towards the end, which allowed achieving even more efficient use of the energy of powder gases. As a result, a 6,5 gram bullet accelerated to the speed of 1600 m / s and punched a steel plate with a thickness of 60 mm at the distance of 12 mm. However, a rifled barrel of variable diameter was too expensive to produce, and the accuracy of shooting with bullets with leading belts crushing during a shot left much to be desired.

The second constructive solution in the field of sub-caliber bullets is the developments of the American company AAI, led by its leader Irwin Barr, who in 1952 developed the 12-caliber rifle cartridge, equipped with 32 swept striking elements, placed in the container-type pushing pallet. Tests have shown that arrow-shaped bullets have a great destructive effect, but they have low accuracy of shooting due to the impossibility of ensuring the specified direction of the flight of bullets after their group departure from the barrel.

The initiative work was continued as part of the SALVO research program of the US Army. AAI has developed a 110x5,6 mm single-bullet cartridge with a XHUMXX53 mm caliber cartridge with a high elongation sleeve, equipped with a steel arrow-shaped subcaliber bullet with a diameter of 1,8 mm and a caliber tail. A pulling pallet of magnesium alloy, cut into pieces by a muzzle nozzle after the bullet emerged from the barrel, was used as a master device. Shooting was conducted from small arms with a smooth barrel, the stabilization of the bullet in flight was provided by the tail. Aerodynamic bevels on the plumage planes set a small angular velocity of rotation of the bullet in order to average the effects on the straightness of the flight of manufacturing defects of its manufacture.

During the experiments, an improved version of the 5,77х57В ХМ645 cartridge was developed, which included a composite four-segment pulling tray made of fiberglass with a Teflon coating that was retained on the bullet in the barrel due to friction forces and disintegrated into segments under the influence of air pressure after the bullet departed from the barrel. The length of the cartridge was 63 mm, the length of the arrow-shaped bullet - 57 mm, the weight of the bullet - 0,74 gram, of the pallet - 0,6 gram, the initial velocity of the bullet - 1400 m / s

However, in an effort to ensure the greatest elongation of the bullet, AAI had to lengthen the cartridge case, which adversely affected the reliability of the reloading mechanism due to the large friction in the chamber, and also led to an increase in the size and weight of the receiver of small arms.

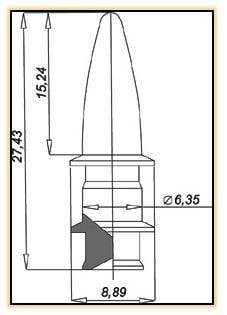

Therefore, in the next program of the US Army under the name SPIW, the 5,6x44 XM144 cartridge developed by the Frankfort arsenal in the form factor of the 5,56x45 low-impulse cartridge mm became the leader. The improved version of the XM216 SFR cartridge had a standard sleeve, the cartridge length was 49,7 mm, the arrow-shaped bullet length was 45 mm, the weight of the bullet was 0,65 grams, the weight of the pallet was 0,15 grams, the initial speed of the bullet was 1400 m / s

Experimental firing using ultra-low-swept sub-caliber arrow-shaped bullets carried out under the SALVO and SPIW programs revealed unrecoverable drawbacks of such bullets - increased lateral drift due to wind and a significant deviation from the target trajectory when shooting in the rain.

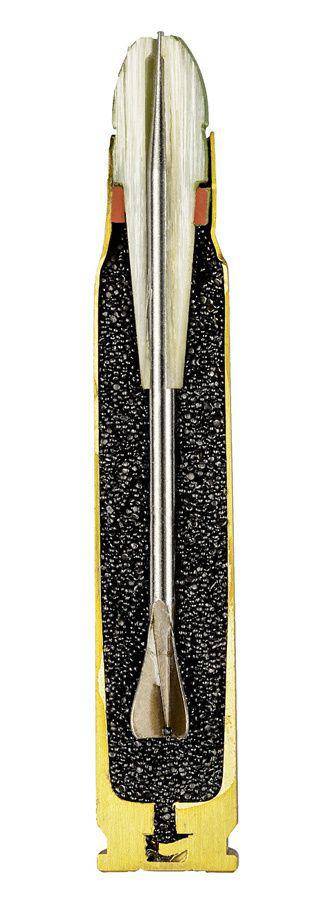

In the Soviet Union, the first 7,62 / 3х54 mm cartridge with a subcaliber arrow-shaped bullet was developed under the direction of Dmitry Shiryaev at the beginning of the 1960-s at the Scientific Research Institute-61 (future Central Research Institute of Musical Instrument Engineering). The arrow-shaped bullet differed from its American counterparts in its greater mass, lesser elongation (3x51 mm), the absence of a narrowing in the area of the tail unit and, most importantly, the method of connecting the pallet and the bullet using a comb applied to the boom shaft. This solution made it possible to provide the necessary grip with a greater pulling force from the side of the pallet for driving the bullets of a multiple greater mass than that of the American counterparts.

The two-piece pallet was made of aluminum alloy, so when expanding after leaving the barrel, it was a certain danger to the neighboring shooters. In addition, aluminum intensively adhered to the surface of the bore, which required dry cleaning of the barrel every 100-200 shots. But the most negative property of arrow-shaped bullets turned out to be their low killing effect in manpower — high-speed bullets pierced armor perfectly and, like needles, passed through soft tissues without causing shock shock and without forming a large-diameter wound channel.

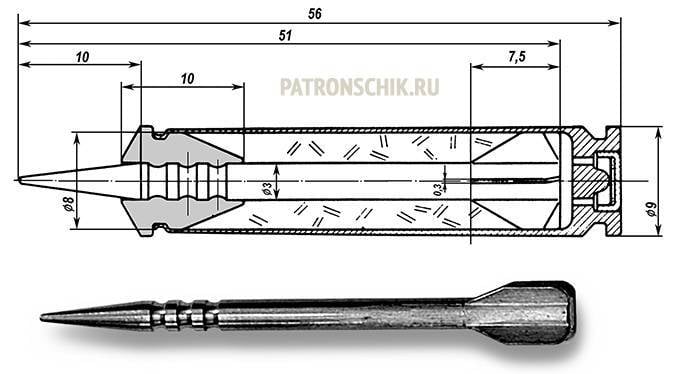

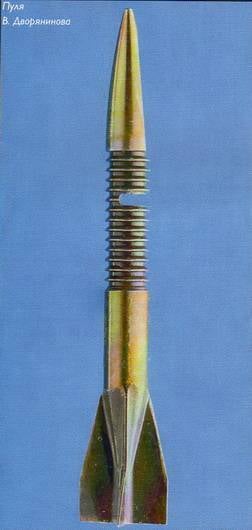

In connection with these circumstances, in the year 1965, under the leadership of Vladislav Dvoryaninov, the development of a new 10 / 4,5x54 mm caliber cartridge with an arrow shaped bullet of a modified design with a weight increased to 4,5 was started. During the development, a polymeric material was used to manufacture the pallet, which did not contaminate the bore during the shot, tailing of the shaft was used (as in the American counterparts) to increase the ballistic coefficient, and transverse propyl of the shaft was formed in the area of the comb and flat on the tip of the bullet. according to constructive weakening of the bullet for breaking into two parts and tipping the bullet in the process of breaking through the soft tissues

These technical solutions allowed to increase the slaughter effect of arrow-shaped bullets, but at the same time reduced the degree of penetration of infantrymen’s individual armor protection means, since the bullet undergoing a solid obstacle is experiencing including flexural stresses (increasing with an increase in the angle of the bullet meeting the obstacle), which lead to the destruction of the bullet shaft , twice weakened (comb and propyl) in the most critical section, directly adjacent to the tip. The gain in the slaughter action and the loss in the breakdown action did not allow the articulate arrowhead bullets of the Dvoryaninov and co-authors construction to be adopted.

The study of the flow around various bodies in a wind tunnel with supersonic air flow revealed that swept bullets of any design have a non-optimal aerodynamic shape - they generate five shock wave fronts at once:

- head front;

- front at the point of transition of the point into the shaft;

- front on the front edges of the tail;

- front on the rear edges of the tail;

- the front at the place of the tail narrowing of the shaft.

For comparison, the caliber bullet of ogival shape at supersonic speed generates only three shock wave fronts:

- head front;

- front at the point of transition of the tip into the cylindrical part;

- tail front.

The most optimal from the point of view of supersonic flight aerodynamics is the conical shape of a bullet without a fracture of the generatrix surface and without tail unit, which generates only two shock wave fronts: the head and tail. In this case, the opening angle of the head front of a conical bullet is a multiple of the opening angle of the head front of the swept bullet due to the smaller opening angle of the tip of the first compared to the opening angle of the second cone. In addition, an arrow-shaped bullet fired from a smooth bore and unwound in flight (in order to compensate for manufacturing defects) at the expense of tail tails, is also distinguished by increased braking due to the selection of part of the kinetic energy for unwinding a bullet.

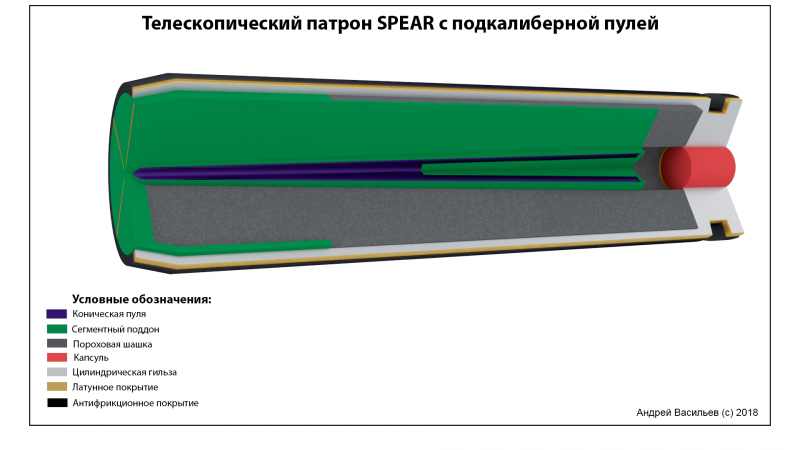

In connection with the indicated disadvantages of arrow-shaped bullets, an innovative cartridge under the title “Spear” / SPEAR, equipped with a sabotted conical bullet with a pushing pallet that does not require the application of a comb to the body of the bullet, is offered to the attention. The cartridge is made in a telescopic form factor in order to minimize the packing volume, which is determined only by the length and the largest diameter of its sleeve. The cartridge is intended as an ammunition for small arms equipped with a barrel with an oval-screw drill for Lancaster-type drill for the purpose of spinning a bullet in the process of passing the barrel bore. A bullet in flight maintains stability due both to the gyroscopic moment and to the forward displacement of the center of gravity relative to the center of aerodynamic pressure by forming an internal cavity in the tail portion of the bullet.

A conical bullet fired from a Lancaster barrel has an improved ballistic coefficient compared to both lively and swept bullets for the following reasons:

- The smallest number of shock wave fronts generated during supersonic flight;

- no loss of kinetic energy for the promotion of a bullet due to the oncoming air flow.

A conical bullet with an internal cavity in the tail section also has an increased penetration ability — during the passage of a solid barrier, the tail section is crushed inwards and the diameter of the base of the cone decreases to the diameter of the bullet at the cross section of the beginning of the cavity. The transverse load of the bullet almost doubles. At the same time, the sharpness of the preserved conical surface of the bullet remains larger than that of an ogival or arrow shaped bullet of equal length. The absence of a comb and transverse cuts on the surface of a conical bullet additionally increases its penetrability in comparison with the arrow-shaped bullet of the Dvoryaninov and co-authors design.

At the same time, a conical bullet with an internal cavity in the tail section has a high lethal effect, since:

- it is on the verge of stability due to the gentle pitch of the screw cutting of the bore of Lancaster;

- after penetration of the armored obstacle, its stability decreases due to creasing of the tail section and displacement of the center of pressure beyond the center of gravity.

The loss of kinetic energy to penetrate the armored obstacle at a conical bullet with an internal cavity is at the level of arrow-shaped and ogival bullets: at the first energy is spent on the body crushing in the cavity, at the second - on the tail section, on the third core.

The body of the conical bullet functionally corresponds to the core of the shell bullet, the lead shirt is absent, instead of a shell made of heavy and expensive brass, a pallet of lightweight and cheap plastic is used. On the other hand, the conical bullet makes the most rational use of the strength characteristics of its structural material in comparison with the arrow-shaped bullet, which is artificially weakened in the place of the comb and transverse cutting. Therefore, the mass of a conical bullet can be significantly minimized compared to an ogival and swept bullet with equal penetrability. This makes it possible to make an economically reasonable choice of the construction material of a conical bullet in favor of a metal tungsten alloy with the highest density.

Due to the limited internal volume of the telescopic cartridge, it is proposed to use a propellant charge in the form of pressed gunpowder with the addition of HMX (which is smaller than the critical detonation diameter of the explosive) to its composition in order to provide the calculated charge burning rate for the selected barrel length of the small arms. In order to reduce the total weight of the cartridge as a structural material of its sleeve, it is proposed to use a composite alloy of aluminum and dispersed aluminum oxide fiber, protected by a brass electroplated coating and an antifriction polymeric coating with graphite filler, described in the article "Promising cartridges for rifled weapons" ("Military review "From December 9 2017 of the year).

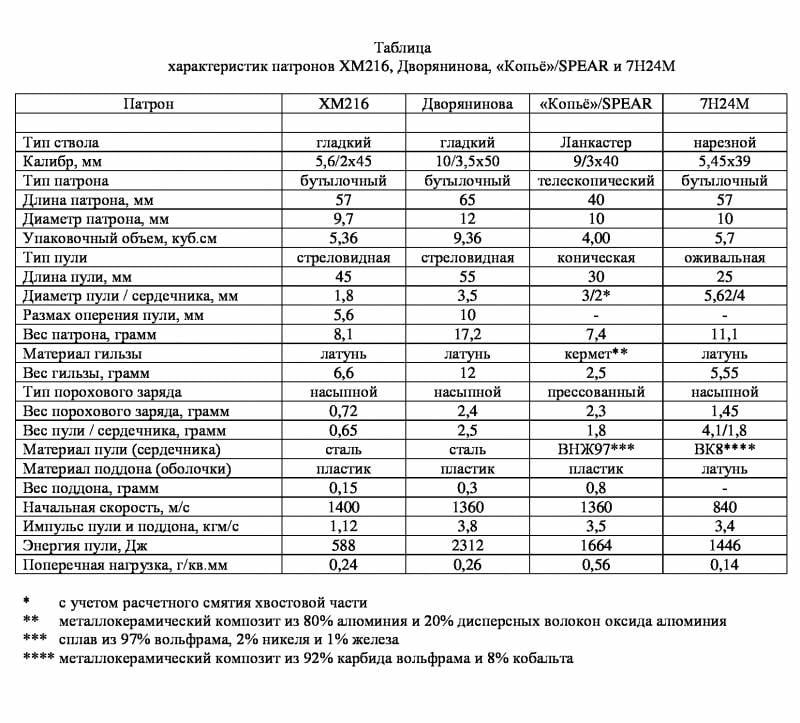

The following table provides a comparative assessment of various types of small arms ammunition and bullets:

As can be seen from the table, the “Spear” / SPEAR cartridge is leading in terms of minimum packing volume, length and weight, as well as in transverse load of the bullet. The total recoil impulse of its bullet, pallet and powder gases by approximately 1 / 3 exceeds the total recoil impulse of the bullet and powder gases of the cartridge 5,45х39 mm while the muzzle energy of the first one exceeds the second one by 1 / 7.

In addition, when shooting with a bullet in a polymer tray from a barrel with an oval-helical drill, there is practically no thermoplastic wear of the bore due to the lack of rifling. In this regard, increasing more than 1,5 times the initial speed of the bullet will not affect the resource of small arms. Moreover, a shotless shot creates a reserve for increasing the rate of firing with fixed bursts to the level of 2000-3000 rounds per minute, which was recommended by the commission of the Main Directorate of the Ministry of Defense of the Russian Federation according to the results of the Abakan competition in order to increase the accuracy of automatic shooting from uncomfortable positions.

In addition to small arms ammunition, the Spear / SPEAR cartridge can be used as a hunting weapon ammunition with Lancaster IZH-27 trunks using standard plastic shells equipped with turned conical steel or brass bullets in a thermolayer molded pallet. If the recoil of the weapon is maintained at the level of firing, the 12 caliber’s standard shotgun sub-caliber bullet weighing 9 grams will accelerate in the barrel with a length of 70 cm to a speed of 900 m / s, which corresponds to the characteristics of the Mosin three-line rifle.

Geometric characteristics of various types of conical bullets (length, angle of opening of the cone, degree of roundness / biconality of the tip, presence of a contact pad for crushing an armored barrier or expansive cavity for slaughter of a large beast, depth and wall thickness of the tail cavity) taking into account specified flight speeds and target targets can be determined on the basis of modeling the passage of bullets of air, gel or solid media using the domestic software product FlowVi sion.

Information