Machine gun "Lewis"

In 1913, the Lewis machine gun was adopted by the Belgian army (it also became the first country to use it in battle, in 1914, during its retreat). At the same time, Russian specialists became interested in the machine gun. In early July, the Belgian Society of Automatic Weapons sent a sample of a machine gun to St. Petersburg. In the course of the tests conducted in the Officer Rifle School, the lack of knowledge of the system was revealed. The main claims concerned the cooling of the barrel, which did not allow more 600 shots to be fired. Despite this, GAU made a proposal to purchase for the tests in 1914 10 guns Mac Klen-Lewis, 3 Hotchkiss machine gun (for airplanes) and 2 machine gun Bertier (Bertier Pasha). Military Council 25 July 1913, this purchase approved. With the outbreak of the First World War, the funds allocated to Bertier and Hotchkis were allowed “to strengthen the funds of the military fund”, and interest in the Lewis, apparently, remained. After the 10 "Lewisov" tests were conducted at the Officer Rifle School, the Head of the GAU ordered them to be sent to the Officer Cavalry School. In turn, the officer's cavalry school refused to machine guns, and they were transferred "to the airborne corps." The positive feedback given by the Head of GAU inspired the company to offer 8 of August - after the start of the war - the supply of 5 to thousands of lightweight machine guns having 56 magazines. However, to issue new orders then did not. And when the need for such weapons became obvious, supplies had to wait until the end of 1915. In 1914, with the beginning of the war, the machine gun was adopted by the British army. Initially, the contract was signed with BSA (Birmingham Small Arms), and although the production of Lewis took 6 times less time than the easel Vickers and was cheaper than 5, the company could not start production weapons in the required scale. In this regard, the contract was transferred to the American company "Savage Armz Company." And only after stable production was established, part of the contract was “ceded” to Russia.

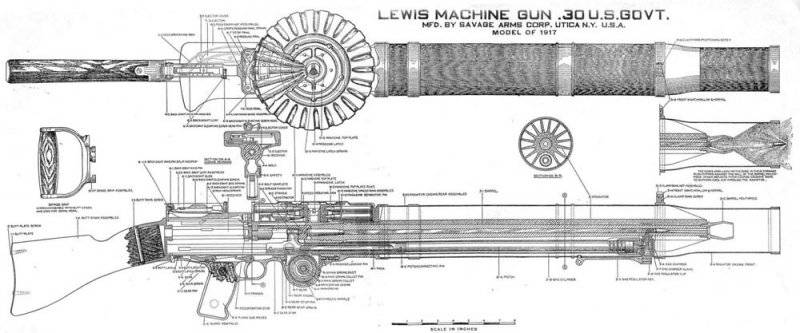

The machine gun had a gas engine automation. Powder gases were discharged through the transverse hole located below the barrel. The piston rod had a long stroke. The barrel is locked when the bolt is turned. The characteristic features of the machine gun were a helical (cochlear) reciprocating combat spring, a disk magazine of relatively large capacity (there was no feeder spring), and air cooling of the barrel.

The original siphon circuit is implemented in the cooling system. An aluminum radiator with high longitudinal ribs covered by a cylindrical casing was worn over the barrel. The casing in front narrowed, going beyond the muzzle of the trunk. During the shot powder gases in the muzzle of the vacuum was formed, as a result of the air from the breech was blown through the radiator.

Gas chamber - closed. From below, a regulator having openings of different diameters was screwed into the gas chamber, which alternately stood opposite the transversely located outlet opening of the chamber. The regulator turned the lower key. On the piston rod there were obturating belts, and on the piston - a cup-shaped notch. The back and front of the bolt carrier (stem) are rigidly connected with pins. In the back there was a rack, rack and combat platoon. The reloading handle was inserted into the stock on the left or on the right. The recoil-combat spring was in the special box from the bottom and put the gear in rotation, which was coupled with the toothed rack of the piston. This solution left a free space in the receiver, protected the spring from heating, but it was unnecessarily complicated.

Four lugs were in the rear of the bolt body, and two spring ejector mounted in the front. The rotation of the bolt was made resistant gas piston, sliding in the screw groove of the core. At the same rack mounted drummer. The non-rotating tail of the bolt inserted into the back of the frame carried guides. The upper ledge set in motion the feeder. The trigger mechanism allowed to conduct only continuous fire. It was assembled in the trigger box, which was attached to the receiver latch and protrusion. The shot from the rear sear allowed to conduct intense fire without danger of igniting the cartridges in the heated chamber. While pushing the trigger, he turned the trigger, while the lever was whispering out of the piston rod. The function of the fuse was performed by the bar, which blocked the slot of the receiver, locking the reloading handle. The mobile system had a stroke equal to 163 millimeters.

The bolt during movement back, removed the cartridge case from the chamber and turned the lever reflector, located in the receiver on its left wall. The head of the reflector protruded from the wall, entered the groove of the skeleton of the bolt and pushed the sleeve to the right.

The original power supply system was an attempt to abandon the tape while retaining the drive of the feed mechanism from the moving automation system, as well as to synchronize the operation of the mechanisms. The disk store included a cup, which was divided into 25 sectors by rods and protrusions of the walls. In sectors in two rows along the radius fit cartridges. In the center of the disk there was a sleeve with a central hole and a screw groove. The feeder, mounted in the receiver, had a feeder, a pawl with a spring, two stops and a tongue with a guide plate having a spring. The equipped shop was put on by the central hole on the glass of the receiver (forward arrow). The first cartridge was opposite the stop and the tongue plate. When moving backward, the shutter ledge of its tail moved along the curvilinear groove of the feeder, rotating it to the left. The dog of the feeder shifted the cup of the store, while the left stop restricted its turn, not allowing to take more than one step. The cartridge was wrung out by the tongue plate and moved to the receiving box of the box. When moving forward, the bolt picked up the cartridge, and the feeder, turning to the right, with his little dog, jumped over the next ledge of the cup. The shop spur was wrung out the left stop. The right limiter blocked the rotation of the cup to the right. Since the magazine sleeve was stationary, the cartridges, sliding noses of bullets along the screw slot of the sleeve, went down. Thus, with each turn, a new cartridge was placed under the tongue plate.

Foldable frame sight with diopter pillars and set screw mounted on the cover of the receiver. The triangular front sight was mounted on the casing connecting ring, but this arrangement did not contribute to accuracy. The aiming line was 818 millimeters. The design of the machine gun consisted of 88 parts.

The bipod for the Lewis machine gun was a rigid triangular with a connecting rod with a yoke and fork. Bipod could be mounted with a fork back or forward. When attaching backward, the shelling sector increased (besides, less space was required at the edge of the trench), while mounting backward, stability was increased. Lightweight bipod attached to the coupling ring of the casing on the hinges.

The tripod machine for the Lewis machine gun - the machine was delivered to Russia in small quantities - had two front and one hind legs with openers and boots. The legs were attached to the frame on the hinges, which allowed to change the height of the line of fire. The machine gun on the swivel plate was fastened with a clamp. For vertical rough pickup, there was a mechanism with an arc. Fine targeting was carried out by a screw mechanism, which changed the mutual position of the bar and the arc. Of course, the tripod provided the best accuracy, but did not make the Lewis "universal."

The Lewis machine gun was developed in the United States, and the bulk of the Lewis for Russia was produced there, but we have always considered this machine gun “thanks to the patron and ordering procedure” “English”. In addition to him in service in the Russian army was 37-millimeter automatic cannon Mack Maple, whose main task was to fight with machine guns.

In the UK, the Lewis machine gun of the 1915 model of the year in October 1916 was equipped with a magazine for 47 cartridges and was given the designation Mkl. At the end of the war, he was replaced by the 1923 model of the year. The old "Lewis" remained in the countries of the British Commonwealth, modifications with other calibers were supplied to Japan and Estonia. In December, 1916, the company "Savage" received from the US Army an order for machine guns "Lewis" chambered for .30-06 "Springfield". This order was associated with preparations for the entry of the United States into the war on the side of the Entente. True, in the American army "Lewis" was mainly used as an aviation machine gun. By 1917, the company "Savage" brought the production of "Lewis" to 400 units per week.

Although the "Lewis" was very heavy - almost half of the weight of the easel "Vikkers" - of all the variety of light machine guns used in the First World War, he was the most "long-lived." In the middle of the 20s, he was the only one in Russia to continue to be listed as a standard weapon of rifle subunits. In our country, these machine guns last proved themselves in the first months of the Great Patriotic War, when they were given out to the militia and new formations. However, while the Lewes were used by other armies. The last "big war" of "Lewis" was the Korean War, but later they surfaced in various parts of the world.

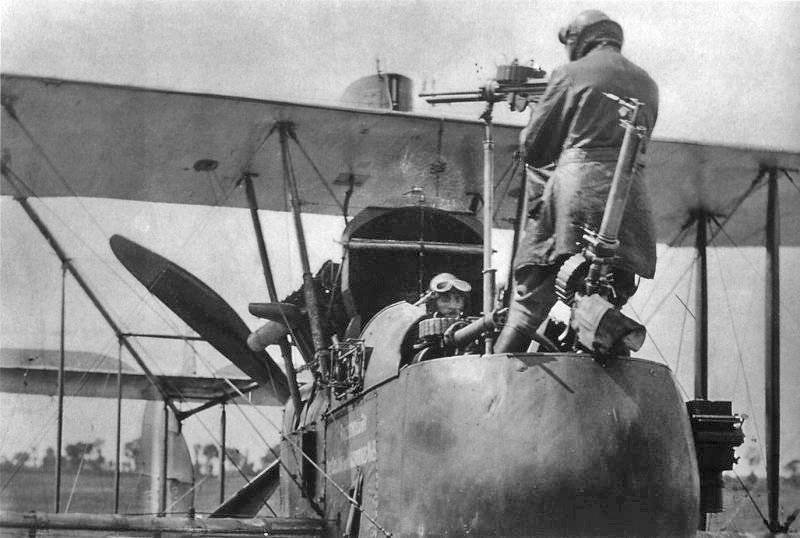

Being the most successful model of the light machine gun of its time, the Lewis machine gun also became widely known as an aviation machine gun. October 11 1915, General Belyaev, Assistant Secretary of War, wrote: "I think it necessary ... to order Lewis companies a thousand machine guns to equip airplanes." That is, the Lewis machine gun was originally purchased by Russia for aviation. General Hermonius 14 on July 1916 of the year reported: “The 50 of Lewis air guns with the mark“ Aviation ”were sent on July 10-23 to the name of the Marine General Staff. In the UK, an aircraft modification of the Lewis MK 2 machine gun was adopted in November 1915 of the year - a month after the land Mkl was adopted (although Lewis was used in air battles from the 1914 year). The 2 MK was distinguished by the presence of a second control knob located at the butt location, a bag-sleeve, an 97-charging magazine, the cover and the radiator were shortened on a part of the machine guns, and a flame arrester was installed. In 1918, the radiator was removed - a counter-flow of air in flight sufficiently cooled the barrel. In May, the 1918 year, "Lewes" began to redo the 2 in the MK with changes in automation components and an enlarged venting hole. Automation has been modified to increase the rate of fire. This machine gun, produced again, received the designation Mk 3. When the aviation "Lewes" in World War II began to be used on the ground, it turned out that a massive radiator is not very necessary for a light machine gun.

The order of unloading machine gun "Lewis": Lowering it down to include located on the left above the trigger guard fuse. Clicking on the latch located inside the opening of the store to separate it. Remove the cartridge from the receiving window (from under the feed lever) of the receiver. Raise the fuse up to turn it off. Clicking the trigger smoothly release the bolt carrier from the platoon.

The procedure for partial disassembly of the machine gun "Lewis":

1. Unload a machine gun.

2. Separate the back plate and butt. To do this, click on the latch located below the pistol grip and turn the butt to the left by turning the 1 / 8.

3. Separated trigger box. To do this, press the trigger to pull the box back.

4. Separated box with recoil-fighting spring and gear.

5. Separate the receiver cover by sliding it back.

6. The feed lever is removed from the cover. To do this, move the feed lever latch forward; turn the lever to the right so that the notch is in the position opposite the ledge on the glass.

7. Remove from the receiver the bolt carrier and bolt. To do this, take back the loading handle. Remove the grip from the frame by moving it to the side. Remove the bolt and slide frame.

8. The shutter is separated from the bolt carrier.

Reassemble in the reverse order. When assembling, it is necessary to pay attention to the fact that during the attachment of the feed lever, the protrusion of the shutter tail enters the curved groove on the feed lever; Before attaching the box, the return spring must be pressed in (partially twisted).

Technical characteristics of the Lewis machine gun:

Cartridge - .303 "British" (7,71 * 56);

The mass of the weapon without the bipod and cartridge - 10,63 kg;

Weight of the equipped shop - 1,8 kg;

The length of the weapon is 1280 mm;

Barrel length - 660 mm;

Grooves - 4 right;

Initial bullet speed - 747 m / s;

Sighting range - 1850 m;

Rate of fire - 500-600 rounds per minute;

Combat rate - 150 shots per minute;

Magazine capacity - 47 cartridges;

The height of the line of fire on the bipod - 408 mm;

Type of machine - tripod;

Machine weight - kg 11,5;

The angles of vertical guidance of the machine gun on the machine - from -62 to + 42 degrees;

The angle of the horizontal guidance of the machine gun on the machine - 360 degrees.

Based on: S. Fedoseev - Machine Guns in the First World War

Information