Liquid "armor" to protect people

The main problem of modern body armor is the ratio "weight - quality of protection." In other words, a more reliable body armor turns out to be heavy, and one that has an acceptable weight has too low a class of protection. By the way, it was this problem that Kevlar had to solve. In the course of research in the 70 of the last century, it was found that the dense weaving Kevlar fabric, laid in several layers, effectively dissipates the energy of the bullet across its surface, so that the bullet cannot penetrate the entire Kevlar package. In combination with a plate made of a suitable metal (for example, titanium), this property of Kevlar fabric made it possible to create relatively light body armor with the same protective properties as all-metal.

However, the Kevlar-metal body armor has its drawbacks. In particular, it still has considerable weight and considerable thickness. In the case of a soldier’s combat work, this can be of great importance: the fighter has to carry extra weight on his shoulders, which could be used to take more ammunition or supplies. But in this case, you have to choose between the payload and health, if not life. So the choice is obvious. Scientists of the whole world have been fighting over the solution of this problem for more than a decade, and there are already some successes. In 2009, almost sensational news. A group of English scientists led by R. Palmer developed a special gel called D3O. Its peculiarity lies in the fact that when a significant force strikes, the gel becomes harder while maintaining its relatively small weight. In the absence of any effects, the gel bag remained soft and flexible. D3O gel was proposed to be used in body armor, special modules to protect transport and even as a soft lining for soldiers' helmets. The last moment looks particularly interesting. According to Palmer, a helmet with such a lining will be bulletproof. Doesn’t he know what price the soldiers of the First World War paid for bullet-proof helmets? However, the British Ministry of Defense became interested in the gel and allocated a grant to Palmer’s lab in 100 thousand pounds. In the past three years since, news of the progress of work has regularly appeared, photos and videos from the tests of the next version of the gel, but have not yet shown a finished helmet or vest with D3O.

A little later, a similar gel was demonstrated to representatives of the agency DARPA. The American equivalent of D3O was developed by Armor Holdings. It works on the exact same principle. Both gels, in essence, are what are called non-Newtonian liquids in physics. The main feature of such liquids is the nature of their viscosity. In most cases, these are liquid solutions of solids with relatively large molecules. Due to this property, a non-Newtonian fluid has a viscosity that is directly dependent on the velocity gradient. In other words, if a body interacts with it at a low speed, then it will simply sink. If the body strikes a non-Newtonian fluid at a sufficiently high velocity, then it will be inhibited or even rejected due to the viscosity and elasticity of the solution. Such a liquid can even be made at home from plain water and starch. Such properties of some solutions have been known for a very long time, but the use of non-Newtonian fluids in protection against bullets and fragments came relatively recently.

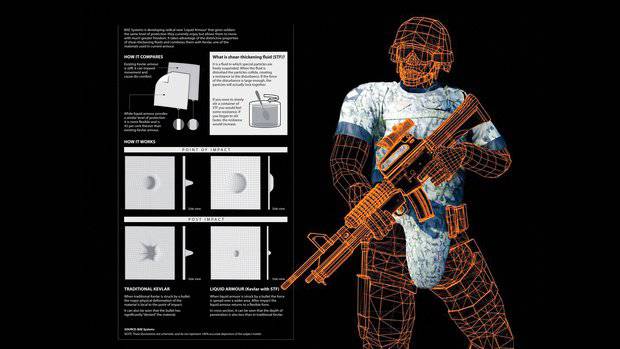

The latest successful liquid armor project was created by the British branch of BAE Systems. Their composition Shear Thickening Liquid (working name bulletproof cream - bulletproof cream) appeared in 2010 year and is planned to be used not in an independent form, but in combination with Kevlar sheets. The composition of its non-Newtonian fluid for body armor BAE Systems for obvious reasons, do not disclose, however, knowing the physics, we can draw certain conclusions. Most likely, this is an aqueous solution of a substance (s), which has the most suitable viscosity characteristics for strong impacts. In the Shear Thickening Liquid project, it finally came to creating a full-fledged body armor, albeit an experienced one. With the same thickness as the 30-layer Kevlar vest, “liquid” has three times fewer layers of synthetic fabric and half the weight. With regard to protection, the “liquid armor” with STL gel has almost the same protection performance as the 30-kevlar layer. The difference in the number of sheets of fabric is compensated by special polymer bags with non-Newtonian gel. Back in 2010, the tests of the finished, experienced gel-based body armor began. To do this, fired test and control samples. The 9 mm bullet cartridge 9x19 mm Luger fired from a special pneumatic gun with a muzzle velocity of the order of 300 m / s, which is to some extent similar to most types of firearms weapons under this cartridge. The protection characteristics of the experimental and control body armor turned out to be about the same.

However, body armor with liquid protection has a number of disadvantages. The most obvious lies in the fluidity of the gel under normal conditions: it can leak through the bullet hole and the level of protection of the vest will drop significantly. In addition, non-Newtonian fluid or gel can not completely absorb or dissipate all the energy of the bullet. Accordingly, a significant improvement in performance is possible only with the simultaneous use of both Kevlar and liquid bags and metal plates. Obviously, there can be no trace of weight advantages in this case, of course, if we compare such a vest with only Kevlar. At the same time, a small increase in weight can be considered quite adequate payment for the improvement of protective properties.

Unfortunately, so far none of the instances of body armor or other protection using the principles of non-Newtonian fluid has gone beyond the stage of laboratory tests. All research organizations involved in this problem are primarily working to increase the effectiveness of protection of liquids / gels and reduce their density, in order to reduce the overall weight of the body armor or helmet. From time to time, unverified information appears that one or another sample is about to go to British or American units for trial operation, but so far there has not been official confirmation of this. Perhaps, the security forces of foreign countries are simply afraid to trust the lives of the fighters of the new and, to be honest, not yet looking reliable technology.

Information