Polymers and half measures

The production and use of domestic composite materials has recently been growing at an average annual rate of three to five percent. These are foreign estimates. Very complex technological processes for the manufacture of raw materials, semi-finished products and composites proper cannot be replaced overnight by purely Russian developments, as, by the way, this very product of a very wide range.

For a long time, the relevant technologies and finished products in this area were mainly imported from China and a number of Asian countries (up to 60 – 65%), as well as from the West. Moreover, Soviet composites are estimated to be used at least in 30 non-CIS countries, including NATO members, including France, Germany, Belgium, the USA, and Canada.

It is hardly necessary to prove how important such materials are in the defense complex, in dual-purpose products and in many civilian industries. Therefore, as in the West, we have a demand for maximum self-sufficiency in all components of the composite industry, especially in the part that is used in the defense industry.

Vladimir Putin, in the 2008 year, determined the strategic direction, saying that Russia should not depend on foreign supplies when fulfilling defense orders. This also applies to the composite sector, especially in connection with the increasingly stringent sanctions regime. Naturally, the products and technologies that can be used in the defense industry fall under the embargo.

In July, 2008-th government approved the Federal target program for the production of strategic composite materials (carbon plastics) for weapons and military equipment, providing for the rejection of the purchase of more than 300 types of components for the 2020 year. In the next five years, a “carbon fiber roadmap” was adopted, the government approved a plan for the development of the production of composite materials. In 2012 – 2016, the Russian-Belarusian program “Development of innovative technologies and equipment for the production of competitive composite materials, matrices and reinforcing elements” was implemented.

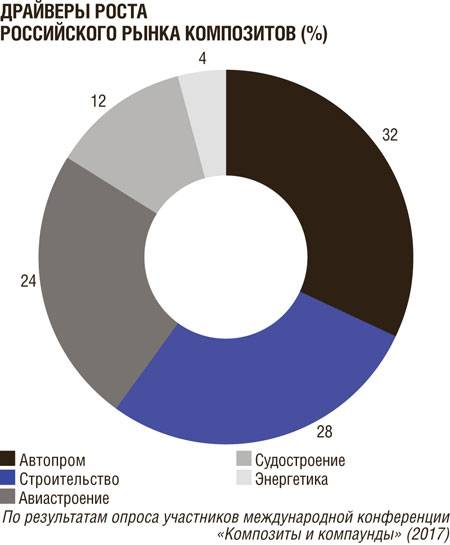

According to estimates made at international forums held in 2017, more than 60 enterprises and no less than 30 specialized research centers are now involved in implementing the decisions taken. Import dependence in the segments related to the production and consumption of composites has decreased over the last 10 years by about 15 percent to 30 – 35 percent. American and British sources estimate it at about 40 percent, noting a decline over the same period by 10 – 12 percent. But in comparison with many Western countries, China, India, Israel, where composites and their derivatives are widely used in shipbuilding, oil and gas production and other material-intensive industries, the demand for carbon plastics in Russia is much lower. This is due to the long-term stagnation in this sector of the domestic economy and, as a consequence, the still low demand, for example, the consumption of composites in the shipbuilding complex of the Russian Federation does not exceed one percent of the global total.

One way or another, the state has seriously taken up ensuring the resource and strategic security of the composite industry (CI). The trends are generally positive, although the oblivion of the problems of the country's manufacturing sectors, experienced in 90, still affects.

One of the main conclusions of the composites forum held at the end of October 2017: among the main reasons hindering active import substitution is the low rate of making changes to the standards related to new materials, the underdevelopment of the domestic market and the lack of personnel understanding the industry.

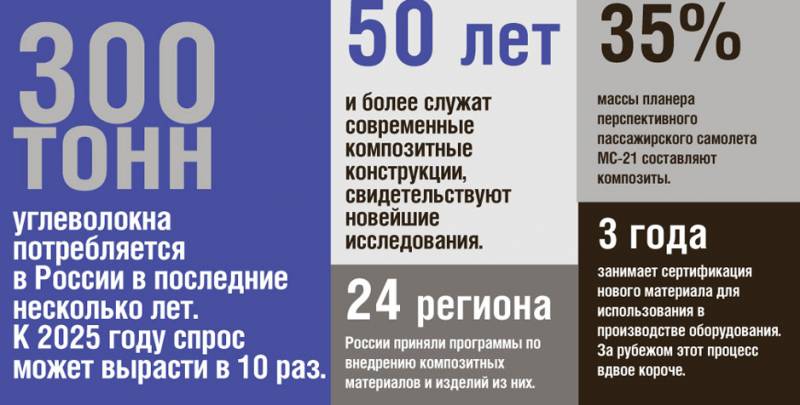

Characteristic is the opinion of Kirill Komarov, director of the development and international business unit of Rosatom State Corporation, expressed on the same forum: the process of certification of new composite material for equipment takes up to three years, twice as much as abroad. In addition, a “more compact procedure for developing standards is needed, research and testing should be carried out not sequentially, but synchronously”. And in order to apply new materials, it is not enough to allow their fixation and description in the regulations - we need trained personnel.

According to the mentioned program documents, by the year 2020 the volume of production of composite materials and products from them should be 120 billion rubles. Provides for the development and adoption of at least 550 regulatory, technical, regulatory and other documents necessary for the development of the industry. At the end of October, 2017, Deputy Industry and Trade Minister Sergey Tsyb stated that 363 has already developed and approved new standards, 25 rulebooks, 4 classifier, 16 estimated standards and 5 professional training programs for the composite industry.

Conspiracy threads?

The highest growth rate shows domestic production of carbon fiber (HC). According to Andrey Ignatiev, Umatex Group sales director, the capacity of the domestic HC market is about 300 tons with the potential for a multiple increase in the near term. In 2015, the largest in the country Alabuga-Fiber plant with an annual capacity of 1400 tons of HC per year was commissioned. By 2030, this enterprise plans to enter the register of the largest hydrocarbon producers. Although the plant already today produces five times more carbon fiber than the Russian market requires, therefore a significant part of the production is exported. However, there are concerns that due to the projected growth in domestic demand for hydrocarbons, export will come into conflict with domestic needs.

As for thermoplastic polymer compositions, Russia has so far only a two-percent share in the world market, the volume of demand in the country is no more than six million tons per year. Meanwhile, according to Polyplastic expert Sergey Kiselev, imports have been at least 25 percent over the past three years and may increase mainly due to the fact that foreign suppliers, especially East Asian, offer low and medium-priced assortment, Russian counterparts are more expensive, although for the most part and better.

Regarding resins for the production of composites there are nuances. At the end of last year, the consumption of unsaturated polyester resins will be at least 45 thousand tons, and about 80 percent - Russian products. But in the epoxy resin segment with the capacity of the domestic 40 – 42 market thousands of tons the share of domestic producers does not exceed 10 percent. This niche is confidently occupied by foreign, mainly Chinese suppliers. Their products are again cheaper, often at the expense of quality. So the pace of import substitution in this sector is due not only to physical growth in production volumes, but also to a decrease in cost.

In the segment of man-made chemical fibers (CVI), nonwovens and products based on them, the situation with import substitution remains difficult. As noted at last year’s forum “Building a Technological Chain for the Production of Synthetic Materials: From Hydrocarbons to the End Product”, unsecured domestic demand for these products remains no less than 60 percent, despite the growth in Russian production in this sector. Among the reasons for the deficit is the almost complete loss at the end of 80's - 90's of small and medium-tonnage chemistry and its raw material base, as well as the dependence of most sectors of the chemical industry on foreign equipment close to one hundred percent. The same dumping products from the PRC and developing countries dominate in commodity imports. Nevertheless, over the past three years, the production of nonwovens using CVIs as a result of demand in the defense industry and other industries increased by one third, which was ensured primarily by the enterprises Kuybyshevazot, Kurskhimvolokno, Gazpromkhimvolokno and Thermopol.

But the largest project in this segment - the polyester complex in the Ivanovo region - has not yet been implemented, the construction start dates are regularly postponed. However, this is a private initiative that does not provide for government funding. Experts note that the non-state status of the project hinders its implementation, and this in turn negatively affects the domestic production of import-substituting chemicals for the chemical industry, including the composite one.

At the above forum, it was proposed to develop a comprehensive "roadmap" for the development of domestic production of CVI and related products. And soon, by order of the Ministry of Industry and Trade, an interdepartmental working group headed by Deputy Minister Sergey Tsyb was formed to develop an action plan for the development of the sub-sector of artificial and synthetic fibers and threads for the period up to 2020 of the year. The team includes specialists from 20 specialized companies, including, for example, Gazpromhimvolokno, Union of Composites Manufacturers, Sibur, Composite, NIITEkhim, Balakovo Karbon Production, Khimprominzhiniring, Kazanorgsintez.

Or PAN, or gone

Prospective development is first of all the formation of the inter-regional industrial cluster “Composites without borders”. It is created from 2016 on the initiative of the Umatex Group (part of Rosatom). At the conference “Import Substitution-2017”, the company's general director Alexander Tyunin, introducing the project, noted that the goal is to increase the Russian market for carbon fiber and materials based on it. Now it is 0,5 percent of the global, and by the year 2025 should increase fourfold. The cluster will create conditions for large, medium and small enterprises, as well as for young businessmen who are ready to organize advanced production and develop new high-tech products based on composites. 23 enterprises from Tatarstan, Moscow and Saratov regions confirmed their interest in the project. It is expected that the cluster will be fully formed before the end of this year.

As for composite and related R&D and projects, it is necessary to highlight the technology developed by the Perm Research Technological University for using secondary carbon fiber from polymer composites. These developments are led by associate professor Julia Kulikova. According to her, studies on the extraction of carbon fibers from the composition of polymer composite materials (PCM) by reagent methods have no analogues in Russia, they create the basis for the formation of a new industry for the production of structural and other products. The main goal of the project is to increase the life cycle of PCM products, including in aviation and space industries, in mechanical engineering, through the reuse of resources. A minimal decrease in the mechanical strength of PCM from the secondary product was achieved in comparison with materials from primary fibers. The introduction of such technology is planned at the waste disposal companies Uralplast and Bumatika. In Alabuga, with the help of the Industrial Development Fund, this year the furnace for the production of high-quality fiberglass is being modernized. The project cost is about 900 million rubles, of which 441,5 million will be provided by the FRP soft loan. According to the Ministry of Industry and Trade of the Russian Federation, the demand for the project is due to the fact that fiberglass is among the most competitive reinforcing materials used in the basis of composite products. It is also the main product for the production of materials approved for use in the defense industry. By the way, the global consumption of fiberglass is 85 percent of all used fibers for reinforced composites, and only 13,5 percent falls on other polymers.

As for composite and related R&D and projects, it is necessary to highlight the technology developed by the Perm Research Technological University for using secondary carbon fiber from polymer composites. These developments are led by associate professor Julia Kulikova. According to her, studies on the extraction of carbon fibers from the composition of polymer composite materials (PCM) by reagent methods have no analogues in Russia, they create the basis for the formation of a new industry for the production of structural and other products. The main goal of the project is to increase the life cycle of PCM products, including in aviation and space industries, in mechanical engineering, through the reuse of resources. A minimal decrease in the mechanical strength of PCM from the secondary product was achieved in comparison with materials from primary fibers. The introduction of such technology is planned at the waste disposal companies Uralplast and Bumatika. In Alabuga, with the help of the Industrial Development Fund, this year the furnace for the production of high-quality fiberglass is being modernized. The project cost is about 900 million rubles, of which 441,5 million will be provided by the FRP soft loan. According to the Ministry of Industry and Trade of the Russian Federation, the demand for the project is due to the fact that fiberglass is among the most competitive reinforcing materials used in the basis of composite products. It is also the main product for the production of materials approved for use in the defense industry. By the way, the global consumption of fiberglass is 85 percent of all used fibers for reinforced composites, and only 13,5 percent falls on other polymers.At the beginning of 2017, a cooperation agreement was signed between the government of the Saratov region and JSC NPK Khimprominzhiniring on the implementation of a project for the production of carbon fiber at the Saratovorgsintez site. This company produces the necessary raw materials - acrylic acid nitrile, from which Khimprominizhiring will produce PAN precursor - white fiber, which forms the basis of composite materials. The project was discussed in the regional administration in November 2016. Then it was stated that the investor would invest a billion rubles in the production of 3,5. The capacity of the plant in Saratov will be four thousand tons per year, followed by an increase to 25 thousand. It is planned to implement this project within three years. At the plant in Balakovo (Saratov region) it is planned to manufacture finished products based on a PAN precursor.

Information