Uralvagonzavod is being modernized

As a separate branch of engineering was formed in the 18 century. The development of mechanical engineering has accelerated significantly to the 19 century - first in the UK, then in Western Europe and the USA. In Russia, the first plants of this profile appeared in the 18 century.

Currently in Russia there are more than 2 thousands of large and medium-sized enterprises of mechanical engineering.

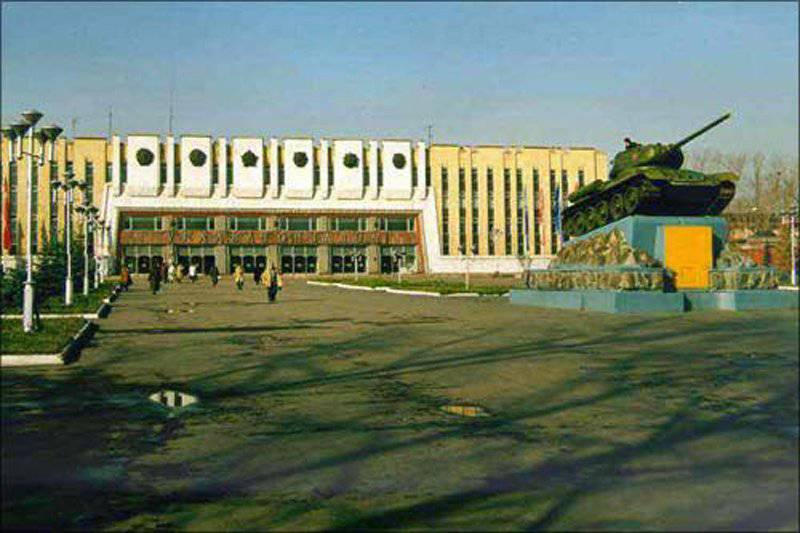

The largest corporation Uralvagonzavod (UVZ) is one of the leading enterprises in this industry, including more than 20 factories, research institutes and design bureaus.

In 2011, UVZ celebrated its 75 anniversary.

The company began operations in 1936. The new plant launched the first freight gondola cars. During the Second World War, the plant switched to the production of military products: Tanks T-34, corps for IL-2 attack aircraft, air bombs. It is no exaggeration to say that workers and engineers literally forged the great victory of the Soviet people in the most terrible war of the 20th century. It also belongs to them the victory at Stalingrad, which broke the back of the German army, the success in the battle of Kursk, the triumph of the liberation of Prague and Vienna.

Using technology, experience gained during the war, the plant in the late forties turned into a diversified company producing not only civilian products (freight cars, isothermal tanks, agricultural and construction equipment), but also military products. In the 50-ies, the plant began to produce new tanks T-54 and T-55, which were considered the best fighting machines of the time. They are still in service with some countries of the world.

The Russian government has appreciated the activities, and most importantly, the development prospects of this research and production corporation. It was taken into account that UVZ has extensive experience in the production of armored vehicles. And the fact that the scientific potential of the corporation allows us to bring the enterprise of the defense complex to a new higher level of technology for creating the newest models of military equipment.

But to achieve the goals, it is necessary to modernize and equip the production facilities and the entire infrastructure of the UVZ.

In this regard, the other day, the Minister of Science and Industry of the Sverdlovsk Region, Alexander Petrov, made a statement that in the current year NPK Uralvagonzavod intends to begin construction of a new foundry. Recall, according to a study of the Stockholm International Peace Research Institute, UVZ is one of the largest manufacturers of 86 weapons in the world. The reconstruction of Uralvagonzavod is one of the largest projects in the machine-building complex. To date, three punching lines have already been reconstructed.

According to Petrov, today there is preparation for drafting a new enterprise, the construction of which will be funded by both the research and production corporation itself and the state budget. It is planned that the state for this purpose will allocate 103 billion rubles. At the same time, Petrov did not specify whether 64 included in this amount the billion rubles that it was planned to invest last summer. Petrov noted that the construction of a new plant is necessary because the metallurgical and foundry production available at this time is outdated. And without the reconstruction of the foundry, it will be impossible to create new types of equipment and modern weapons.

The main production site of the corporation, as mentioned above, was built in the 1936 year, so there is no doubt about the need for modernization. Especially since almost half of the production is occupied by products for civilian needs - freight cars, gondola cars, cargo trucks. It should be noted that thousands of units were manufactured in 2011 in the year alone, which is an absolute record for the whole period of the plant’s existence.

But the tanks that are produced by the UVZ, including the latest modification of the T-90C and T-90AM, the Russian military department categorically refused to buy. And the point is not that they are poorly made. The fact is that the Ministry of Defense is not satisfied with the very concept of this vehicle, which is based on the Soviet T-72 tank (which, by the way, for the period from 1974 to 2005, the year was shipped to more than 50 countries of the world). The situation is very similar history with the rejection of Kalashnikov assault rifles, which the Ministry also rejected. Despite the fact that he will give odds to the majority of similar weapons in the world - he does not fit into the ideas of the General Staff about the concept of modern warfare.

But unlike “Izhmash”, UVZ allocate quite a decent amount for modernization. The reason for this lies primarily in the fact that the enterprise should present in 2013, and by 2015 and launch into mass production new Armata tanks, equipped with an armored capsule for the crew, uninhabited by a turret, retractable barrel. The price of a new type of equipment remains unknown, but the supply of almost 2,5 thousands of new cars to Russian troops is already recorded in the state armaments program.

In the near future, the plant plans to change the entire range of tanks, will be implemented combat platform, universal for all types of weapons.

Over the past year, the development budget of the UVZ amounted to more than 3 billion rubles. Some of these funds were aimed at the development of more 60 projects, in particular, the modernization of production, technical re-equipment, research in the field of creating new types of products and new technologies, as well as social programs.

Last year, Uralvagonzavod significantly increased its production, one of the prerequisites of which was the modernization of production. The main results of the 2011 modernization were: the launch of the most powerful, not only in Russia, but also in Europe, unique complex of rolling stock preparation and painting; the launch of the wheel set shop, the capacity of which is up to 200 thousands of blanks annually; the launch of the Clearing-5500 press, the NG 5222 press shears, as well as the general modernization of the pressing equipment; automation of production in the car assembly shop, which contributes to the maximum improvement of product quality by reducing the presence of the human factor. In addition, the company develops the production of new products, in particular, mobile drilling rigs, is developing a program for the disposal of cars.

Foreign buyers are invariably interested in the entire product line of the leading Russian defense industry enterprise, Uralvagonzavod.

And the development of new types of weapons requires constant improvement of production. The enterprise itself cannot cope with this tremendous work; therefore, the financial support of the Federal Authority, which is now received by the UVZ, is so important and vital for it.

Information