The Swedish army chose Mjölner self-propelled mortars

December 23, the procurement department of the Swedish military department Försvarets Materielverk and BAE Systems Corporation, announced the signing of a contract for the completion of the development and subsequent construction of serial armored vehicles for the benefit of the Swedish armed forces. According to the terms of the contract, at the beginning of 2019, BAE Systems will transfer to the customer the first new type of 40 machines ordered. Thanks to the implementation of the recently signed treaty, the Swedish army will be able to significantly renew the fleet of self-propelled mortars, without resorting to unacceptably high costs.

The only official image of the self-propelled mortar BAE Mjölner

A promising self-propelled mortar for Sweden was named Mjölner ("Mjölnir" - the hammer of the Scandinavian Thunder god of Thunder). As part of the Swedish army, this technique will be operated under the official designation Granatkastarpansarbandvagn 90120 (Grkpbv 90120). The cost of the recently signed contract is 575 million Swedish kronor - about 68 million US dollars. Thus, the price of one mortar was determined in 14,4 million crowns or 1,7 million dollars.

The recently signed contract was the result of a competition held over the past few years. The Mjölner machine, the modified AMOS self-propelled mortar, the Finnish Patria NEMO system (a simplified single-barreled AMOS version), and the 120-mm mortar installation project in the CV 90 armored vehicle compartment with a large sunroof. Based on the results of a study of the four proposals, the army chose the Mjölner project. The proposed architecture of the machine allows to obtain quite high performance with relatively simple design.

As part of the fulfillment of the signed contract, the Swedish side and BAE Systems Corp. should organize a joint venture HB Utveckling AB, which is a subsidiary of BAE Systems Bofors AB and BAE Systems Hägglunds AB. The main task of the joint venture will be the installation of new equipment and weapons on existing tracked chassis. Thus, the new project Mjölner provides for the maximum possible localization of production.

The order of BAE Mjölner self-propelled mortars can put an end to the lingering stories with the selection and purchase of equipment of similar purpose. The program to create a promising self-propelled mortar with enhanced characteristics, designed for the Swedish army, was launched in the mid-nineties. Then the company BAE Systems Hägglunds together with the Finnish Patria began work on the AMOS project. A prospective mortar was supposed to have a number of characteristic features, but the fine-tuning of this system was seriously delayed. As a result, mass production was limited to the release of 18 gun turrets for the Finnish army and several experimental products for Sweden.

Initially, it was assumed that Sweden would acquire 40 self-propelled mortar AMOS on the crawler CV 90. Nevertheless, difficulties with the project implementation have led to the fact that in 2009, they refused from such plans. Built chassis, and not equipped with towers with weapons, were sent for storage. At the same time, however, the need to purchase self-propelled mortars did not disappear, which is why later several new projects were launched, including Mjölnir. In the medium term, this project should lead to the beginning of the re-artillery units.

At the moment, the developer has announced some information about the technical appearance of a promising self-propelled mortar. At the same time, much of the data is not disclosed. In addition, some of the previously published data may contradict each other. In such conditions, the exact determination of the appearance of a new combat vehicle is not an easy task. Interestingly, some of the data available on the Mjölner system suggests the use of ideas previously proposed for use in the AMOS project.

At the moment, we can only speak with confidence about the type of chassis offered for use as a base for a self-propelled mortar. Mjölner mortars will be built on the basis of a modified CV 90 tracked infantry fighting vehicle chassis, created by BAE Systems in the early nineties. Four dozen such machines in the past were built to implement the AMOS program, but the abandonment of this project left the equipment out of business. Now remaining in storage chassis is planned to be used in a new project.

The CV 90 or Stridsfordon 90 is a tracked infantry fighting vehicle with a combat mass up to 25 T. The machine is built according to the standard layout for such equipment with a front engine compartment and aft landing compartment. Diesel engines with power up to 810 hp are used, depending on the modification. The hull of the machine is able to protect the crew from various threats, up to the shells of 30-mm automatic guns. BMP for the Swedish army were equipped with turrets with 40-mm automatic guns. Export equipment carries 30- and 35-mm guns.

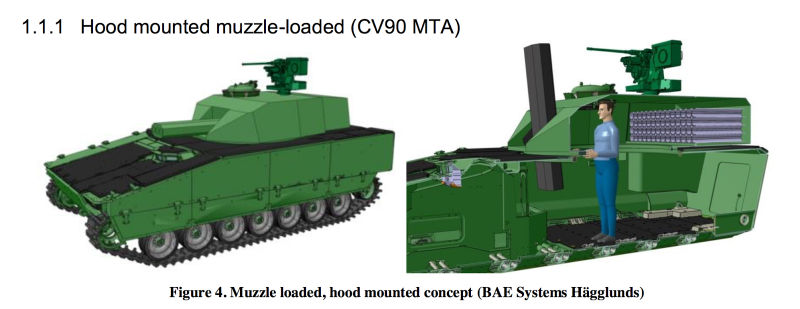

The draft AMOS proposed to deprive the existing standard chassis of the tower and the troop compartment. On the roof of the hull it was proposed to mount a swiveling tower with a double-barreled mortar. In this connection, the central and aft compartments of the corps were assigned to the combat compartment and the laying of ammunition. In the new project BAE Mjölner, as follows from the available data, a similar layout will be used. Probably, the geometric and layout features of the combat module of a new type were determined in accordance with the parameters of the previous project, thanks to which the Mjölnir towers could be mounted on the already built chassis.

Earlier, BAE Systems published several images of a promising self-propelled mortar. At the same time, while we are talking only about diagrams and drawings. A full-fledged prototype of the Mjölner machine has not yet been built, which is why the manufacturer simply cannot provide photos of it.

On the existing figures and diagrams depicts a tracked chassis combat vehicle equipped with a large turret or wheelhouse. The tower may have a sloping frontal part, as well as a large central and aft compartment. In the frontal part of the tower / felling should be a gun mount. Aft niche can be used to place stacking ammunition. The free volumes of the fighting compartment are allocated to accommodate the crew. Available data suggest that mortar is not supposed to seat, and they will have to work while standing. Such features of the ergonomics of the fighting compartment are directly related to the unusual approach used in creating weapons and auxiliary systems.

One of the main problems of the previous AMOS project was the unacceptable complexity of the design of the artillery system and their means of control. Because of this, the terms of reference for the Mjölner project provides for the greatest possible simplification of all the main elements of the fighting compartment. So, it is proposed to use hand drives to rotate the turret and vertical guidance of the gun mount. Mortar recharging is also offered manually. Finally, the proposed use of some simplified fire control system. What exactly is its simplification, however, is not specified.

The desire of the customer to simplify the design of the combat vehicle led to the emergence of original ideas and unusual equipment. The main weapon of the Mjolnir machine must be twin mortars of the caliber 120 mm. It is proposed to install two such tools side by side on common brackets and equip them with combined recoil devices. Weapon mounting tools must be equipped with manual vertical drive drives. The muzzle of the barrels, which goes beyond the combat compartment, can be covered with a large casing of a characteristic angular shape, the task of which is to protect the weapon itself and its additional units.

Contrary to the obvious ideas and solutions, in the project BAE Mjölner it is proposed to use the muzzle loading of mortars. To do this, both guns must be equipped with special means of supplying ammunition to the muzzle of the barrels. Thus, the crew’s task will be to carry the mine from laying onto a tray or a movable element of the loading system, which will then feed the shot into the barrel. How exactly this technique will be implemented and how the loading drives will be is not yet specified.

It should be noted that similar loading systems were studied by Swedish experts in the mid-nineties, in the early stages of the AMOS project. Then, in order to carry out the tests, a pilot plant was assembled with two muzzle loaders and mines. Above the trunks were placed two long guides in the form of trays, on the sides of them - rotary axes with cylindrical devices for transporting ammunition. Most of the elements of such a system had hand drives. The principle of operation of the systems was quite simple. Mina was asked to be laid on the tray, after which the corresponding mechanism gave it forward and took it outside the fighting compartment, where it fell from the tray into the cylinder. Then the rotation of the axis moved the cylinder with a mine to the barrel, after which the ammunition under its own weight fell into the gun.

Experimental twin mortar installation with a muzzle loading system

In the full-fledged AMOS project, it was decided to use only mechanized and automated systems, while the manual ones were not of interest to the customer. Nevertheless, in the course of testing and refinement, certain problems of automation were identified, which ultimately was one of the reasons for rejecting such equipment. Given this experience, respectively, the new Mjölner self-propelled mortar should have the maximum possible number of systems with manual control.

In 2019, a joint venture between two Swedish offices of BAE Systems should transfer the first self-propelled mortar of the 40 required to the customer. As part of serial construction, only towers with weapons and some other devices will be manufactured from scratch. They are planned to be mounted on existing tracked chassis, which are the “legacy” of the unsuccessful AMOS project. All this equipment is available and is currently in storage.

Mjölner / Grkpbv 90120 self-propelled mortars are planned to be reduced to batteries of eight cars each. One such unit will be present as part of five heavy maneuverable motorized infantry battalions. Operation of such equipment will begin after the implementation of current plans for reforming the structure of the army. The deadlines for the completion of deliveries of four dozen self-propelled mortars have not yet been specified. Apparently, the supply of equipment will end no earlier than the middle of the next decade.

Currently, the Swedish army does not have self-propelled mortar caliber 120 mm, continuing the operation of relatively numerous towed systems. In the mid-nineties, an attempt was made to create the required technology with high performance, but for almost a decade and a half of work it did not lead to the desired result. As a result, the army was forced to abandon the AMOS project and later issue updated technical requirements, revised to simplify.

Recently, the Swedish army completed an analysis of four proposals, the results of which selected equipment for future purchases. Over the next few years, BAE Systems Corporation and its structural divisions will have to complete the development of the project, and then prepare for the mass production of Mjölner mortars. The first cars of the new type will be handed over to the customer at the end of the current decade.

On the materials of the sites:

http://baesystems.com/

http://fmv.se/

http://defence.pk/

http://cornucopia.cornubot.se/

http://bmpd.livejournal.com/

Information