Photo report from the Progress Aviation Plant, which produces the famous "Alligators"

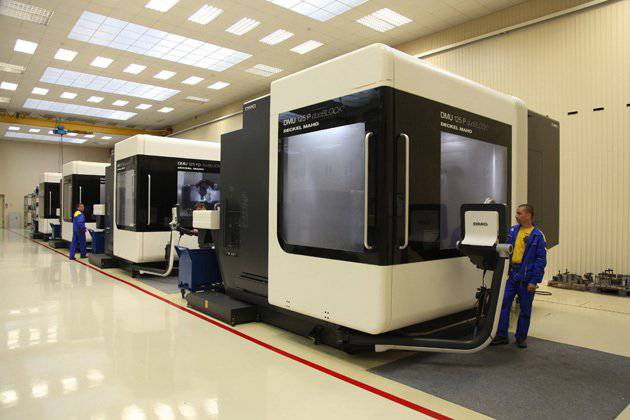

We start with a mechanical production workshop that looks unexpectedly modern. As part of its modernization, DMG, Mazak, Valter equipment with numerical control was installed here. In total, Russian Helicopters invested in various forms (cash contributions to the authorized capital, state guarantees for loans, subsidies for paying interest rates) of the order of 8 billion rubles in technical re-equipment.

8 billion rubles - serious money, more than the plant's revenue for 2010 a year. What are the "Helicopters of Russia", they have invested? The holding itself is part of the Oboronprom corporation, which, in turn, is owned by Russian Technologies. This is the only developer and manufacturer of helicopters in Russia, which includes 5 helicopter factories, as well as two component manufacturers and two design bureaus. And they all demanded money for technical re-equipment. It was carried out, as a result, mainly in debt (in the photo: mechanical production shop).

As a result, by the end of 2010, the net debt of Russian Helicopters was already 28,4 billion rubles. At the same time, capital investments at the level of 2011 billion rubles were planned for 16,5 year, and 2012 billion rubles more for 12,8. They decided to attract money for development on the London Stock Exchange: in early April, the holding unexpectedly announced plans to hold an IPO in May. The company, surprising at the very high EBITDA margin compared to other helicopter manufacturers, rated itself in the $ 1,8 – 2,3 billion range (in the photo: Walter equipment).

In the meantime, we turn to laser processing of parts. The use of a cutting complex Tru Laser 3530 for machining parts allows you to achieve a unique accuracy of their performance. The machine operates in the automatic mode for a given program. He is able to cut sheet metal, replacing almost a whole workshop of closers. The laser cuts metal up to 5 mm.

Modern equipment allows using the software control to create helicopter parts in compliance with the most accurate parameters. After data entry, the intelligent mechanical processing complex creates parts with minimal human involvement.

A little more observe the work of the masters and, at the same time, back to the IPO. Russian Helicopters launched a significant advertising campaign. The highlight was the placement of congratulations to Prince William with the wedding in the newspaper The Times. The advertisement took an entire strip, which showed the Mi-26 helicopter hanging over Buckingham Palace with a large gift package. And the slogan: "One famous pilot from a famous manufacturer of helicopters." A simple puzzle: Prince William is familiar with helicopters. So, in 2008, he even landed a royal air force helicopter in the courtyard of Kate Middleton’s future wife. However, congratulations to the prince did not help the Russian Helicopters. IPO failed.

The next workshop is foundry. At Progress, a foundry, unique for Russia, has been created on the basis of advanced Italian production lines, including low-pressure casting machines and a line of cold-hardening mixtures.

The new foundry complex of the Italian company IMF, which has significantly improved the quality of castings, was commissioned in the 2010 year. Progress receives orders for the performance of foundry works from other enterprises of Russian Helicopters, developing inter-plant cooperation of the holding.

The process of building a helicopter from the manufacture of the first parts to the beginning of the flight tests takes about 9 months. In the final assembly shop of a variety of parts, components, components and assemblies, including the latest VK-2500 engines, developing emergency power to 2400 HP, gyro-stabilized optical-electronic station GOES-452, the radar complex "Arbalet-52", Ka-52 is created for the navigation complex, the radio communication equipment complex, the self-defense complex, the emergency evacuation complex and many other important systems.

Why did the IPO attempt fail? It is not only unfavorable market conditions that are to blame. In the end, in July, the Phosagro holding held a placement on the LSE, and the IPO of Yandex on the Nasdaq turned out to be very successful for investors. Perhaps the reasons lie in the structure of the transaction. Russian Helicopters planned to place shares worth more than $ 500 million. But only $ 250 million was part of the additional issue. The remaining funds were intended by the defense industrial complex Oboronprom, which did not disclose what they would do (in the photo: the final assembly shop).

And this is how “Alligators” are painted in a protective green color.

The next stage after the assembly of the helicopter - testing. The plant checks the operation of all the systems of each new helicopter, its flight performance, and flight quality. Progress test pilots usually conduct several flights, each of which operates according to a specific program aimed at measuring and evaluating the performance of a particular system. After factory testing, the helicopter is subjected to bearer tests, during which the customer must verify the quality of the machine. And then comes the stage of acceptance tests, where already military pilots themselves evaluate the car in flight before it is delivered to the troops.

Ka-xnumx on firing practice. "Alligators" are capable of hitting air and ground targets. The range depends on the type used weapons. An automatic gun with high accuracy will reach the enemy at a distance of up to 4 km. The Whirlwind anti-tank missile is capable of destroying the target at a distance of 8 km, and the Igla anti-aircraft missile will catch an air target at a distance of up to 4 km.

The first batch of Ka-52 “Alligator” serial helicopters was delivered to the Ministry of Defense in May 2011. These combat helicopters were transferred to the line of the army aviation on the territory of the Eastern Military District.

And in the coming years, a naval version of the Ka-52K will appear, which can be based on naval ships, including Mistral-type amphibious ships, which Russia plans to produce jointly with France. A feature of the "rifle" helicopter will be the folding rotor blades, inflatable ballonets for an emergency landing on the water and the navigation complex.

Information