Ampulmet Forgotten weapons of the Second World War?

The available information about ampoulelets of the Red Army is extremely scarce and is mainly based on a couple of paragraphs from the memoirs of one of the defenders of Leningrad, the description of the structure in the manual for the use of ampulets, as well as some conclusions and common conjectures of modern search engines. Meanwhile, in the museum of the Iskra II capital plant named after I.I. Kartukov for a long time, with dead weight, lay in the amazing quality of a specific series of front-line years. The text documents to it are obviously buried in the depths of the archive of the economy (or scientific and technical documentation) and are still waiting for their researchers. So, when working on a publication, it was necessary to summarize only known data and analyze references and images.

The existing concept of "ampoule" as applied to the combat system developed in the USSR on the eve of World War II, does not reveal all the possibilities and tactical advantages of this weapons. Moreover, all available information refers only, so to speak, to the late period of serial ampouletes. In fact, this “pipe on the machine” was capable of throwing not only ampoules of tin or bottle glass, but also more serious ammunition. And the creators of this simple and unpretentious weapon, the production of which was possible almost “on the knee”, undoubtedly deserve much more respect.

Simple mortar

In the flamethrower system of the Red Army land forces, the ampulometer occupied an intermediate position between knapsack or easel flame throwers, firing short distances with a jet of liquid fire mixture, and field artillery (barrel and rocket), which occasionally applied incendiary shells with solid incendiary mixtures of the type of military incendiary Grade 6. According to the intent of the developers (and not the requirements of the customer), the ampulometer was mainly (as in the document) intended to combat tanks, armored trains, armored vehicles and fortified firing points of the enemy by firing at them with any ammunition of suitable caliber.

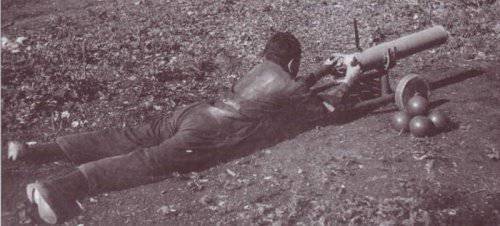

Experienced 125-mm ampoulet during 1940 factory testing.

The opinion that the ampoulomette is a purely Leningrad invention is obviously based on the fact that this type of weapon was produced in besieged Leningrad, and one of its samples is exhibited in the exposition of the State Memorial Museum of Defense and Siege of Leningrad. However, they developed ampoulemets (as, incidentally, infantry flame throwers) in the pre-war years in Moscow in the experimental design department of the plant No. XXUMX named after SM. Kirov (chief designer of the plant - I. Kartukov), consisting of the Commissariat of the USSR Aviation Industry. The names of the designers of ampouletami, unfortunately, are unknown to me.

Transportation experienced 125-mm ampoulelet in the summer when changing the firing position.

It has been documented that, with ammunition from ampoules, the 125-mm ampoule was tested in field tests and military in 1941, and was adopted by the Red Army. The description of the ampoule-meter construction given on the Internet is borrowed from the manual and only in general terms corresponds to the pre-war prototypes: “The ampoule consists of a barrel with a chamber, a bolt-gate, a shooting device, sighting devices and a pad with a fork.” In the version supplemented by us, the barrel of a serial ampoule was a steel seamless pipe from a Mannesmann rolled product with an internal diameter of 127 mm, or rolled from sheet 2-mm iron, plugged in the breech. Barrel staff ampoule freely relied pins on the lugs in the fork wheel (summer) or ski (winter) machine. Mechanisms of horizontal or vertical guidance was not.

An experienced 125-mm ampoule with a rifle-type bolt in the chamber was used to lock the blank cartridge from a hunting rifle of a 12 caliber with a folder sleeve and a 15-gram sample of black powder. The launching of the firing mechanism took place when the left thumb was pressed on the trigger lever (forward or down - there were various options) located near the handles similar to those used on heavy machine guns and welded to the breech.

125-mm ampoulet in combat position.

In the case of a serial ampulets, the firing mechanism was simplified due to the manufacture of many parts by stamping, and the trigger lever was moved under the thumb of the right hand. Moreover, the handles in mass production were replaced with steel pipes, curved like ram horns, constructively combining them with a piston gate. That is, now for loading the shutter was turned with both handles to the left and with the support on the tray pulled to itself. The entire breech with handles along the slots in the tray slid off to the rearmost position, completely removing the cartridge case of an 12-caliber cartridge.

The sights of the ampule launcher consisted of a front sight and a folding stand of the sight. The latter was designed for shooting at four fixed distances (obviously, from 50 to 100 m), indicated by the holes. And the vertical slot between them allowed us to aim at intermediate distances.

The photographs show that the prototype ampoule was used by a roughly-made wheeled machine welded from steel pipes and an angle profile. It would be more correct to consider it as a laboratory bench. At the machine ampoule, proposed for service, all the details are more carefully trimmed and supplied with all the attributes necessary for operation in the troops: handles, coulters, slats, brackets, etc. However, the wheels (rollers) on the test and serial models provided for solid wood , upholstered with a metal strip along a generator and with a metal sleeve as a sliding bearing in the axial bore.

In St. Petersburg, Volgograd and Arkhangelsk museums there are later versions of an ampoulometr of factory production on a simplified light wheelless non-folding machine with a support of two pipes, or without a machine at all. Tripods made of steel rods, wooden decks or oak crosses as gun carriages were adapted to ampouletae in wartime.

The guide mentions that the ammunition wearable with the calculation of the ampoule was to make 10 ampoules and 12 expelling cartridges. On the machine of the pre-production version of an ampoule, the developers suggested to install two easily removable tin boxes with a capacity of eight ampoules each in the transport position. Two dozen rounds of one of the fighters, obviously, endured in a standard hunting cartridge case. In a combat position, ammunition boxes were quickly removed and placed in a shelter.

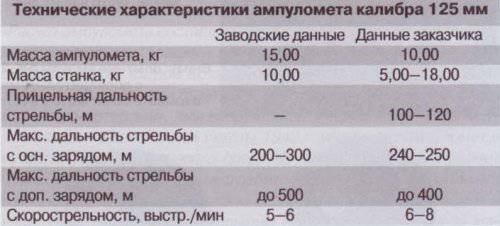

On the trunk of a pre-production version of an ampoule, two welded swivels were provided for carrying it over a shoulder strap. Serial samples were devoid of any "architectural excesses", and the trunk was carried on the shoulder. Many note the presence of a metal grille divider inside the barrel, in its breech part. On the prototype this was not. Obviously, the grille was needed to prevent the cardboard cartridge and felt wad of the idle cartridge against the glass ampoule. In addition, it limited the movement of the ampoule to the breech to the stop, since the serial 125-mm ampoule had a chamber in this place. Factory specifications and specifications for the 125-mm ampoule are somewhat different from those described in the descriptions and application guidelines.

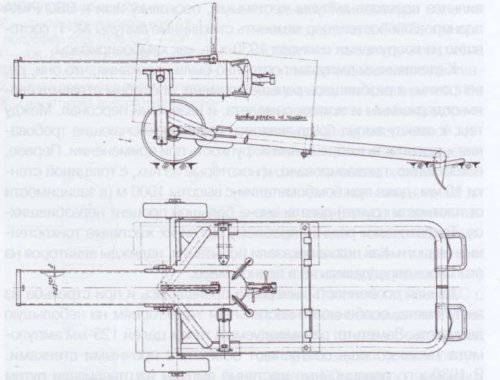

Drawing of a serial 125-mm ampoule offered for serial production in 1940.

Rupture of an 125-mm vial filled with a CS auto-inflammable liquid in the target area.

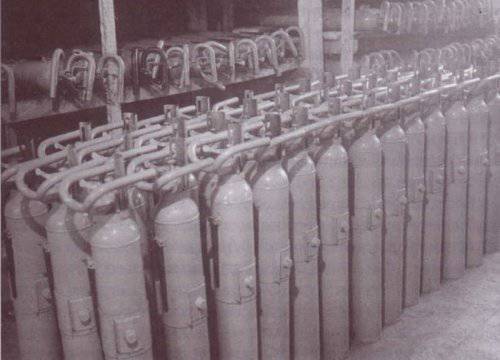

The warehouse of finished products of the workshop for the production of ampoules at the plant №455 NCA in 1942,

Incendiary Ampoules

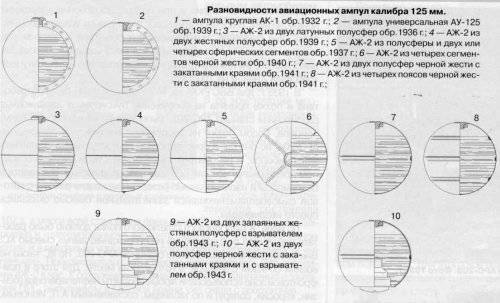

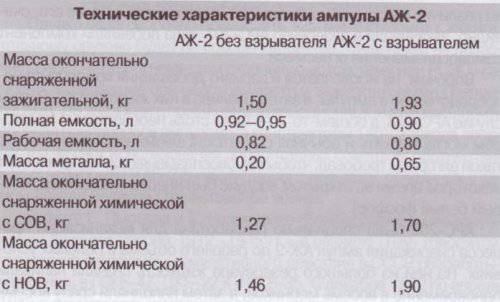

As indicated in the documents, the main ammunition for the ampoule was aviation tin ampoules АЖ-2 of 125 mm caliber, equipped with a self-igniting variety of condensed kerosene grade KS. The first tin spherical ampoules entered mass production in 1936. At the end of the 1930s. they were also improved in the OKO of the 145th plant (in evacuation, this is OKB-NKAL of plant No. 455). In the factory documents, they were called aviation liquid ampoules АЖ-2. But still

it is more appropriate to call the ampoules tin ones, since they were planned to gradually replace the AK-1 glass ampoules, which had been in service with the beginning of the 1930s, in the Red Army Air Force. like chemical ammunition.

To the glass ampoules were constantly complaints that they, de, fragile, and breaking ahead of time, can poison with their contents and the crew of the aircraft, and ground personnel. Meanwhile, mutually exclusive requirements were imposed on the glass of ampoules - durability in circulation and brittleness in use. The first, of course, prevailed, and some of them, with a wall thickness of 10 mm, even when bombing from a height of 1000 m (depending on the density of the soil), gave a very large percentage of undivided. Theoretically, their tin thin-walled counterparts could solve the problem. As tests showed later, the aviators' hopes for this were also not fully justified.

This feature probably also manifested itself when firing from an ampoule, especially on flat trajectories at a short range. Notice that the recommended type of targets for the 125-mm ampoule is also completely made up of objects with strong walls. In 1930's rm. aircraft tin ampoules were made by stamping two hemispheres of thin brass 0,35 mm thick. Apparently, with 1937 (with the beginning of austerity of non-ferrous metals in the production of ammunition), their transfer to white tin with a thickness of 0,2-0,3 mm began.

The configuration of parts for the production of tin ampoules varied greatly. In 1936, at the 145 plant, the design of Ofitserov-Kokoreva was proposed for the manufacture of AF-2 from four spherical segments with two variants of roll-up of the edges of parts. In 1937, the production even included an AJ-2 hemisphere with a filling neck and a second hemisphere of four spherical segments.

At the beginning of 1941, in connection with the expected transfer of the economy to a special period, technologies for the production of AF-2 from black tin (thin rolled 0,5-mm decapitated iron) were tested. From the middle of 1941, these technologies had to be used to the full. Black stamping was not as plastic as white or brass, and deep drawing of steel made it difficult to manufacture, so AF-2 was allowed to be made of 3-4 parts (spherical segments or belts, as well as their various combinations with hemispheres) as the war began.

Below: experienced ampoules AJ-2 with additional fuses. Photo 1942

Soldering seams of products from black tin in the presence of special fluxes then also turned out to be a rather expensive pleasure, and the method of welding thin steel sheets with a continuous seam academician E.O. Paton introduced ammunition into production only a year later. Therefore, in 1941, the details of the AF-2 cases were joined by rolling in the edges and embedding the seam flush with the contour of the sphere. By the way, before the birth of ampoule masts, the filler necks of metal ampoules were soldered outside (for use in aviation, it was not so important), but with 1940, the necks began to be fixed inside. This made it possible to avoid the different types of ammunition for use in aviation and ground forces.

The filling of ampoules AJ-2X, the so-called “Russian napalm” - condensed kerosene KS - was developed in 1938 by A.P. Ionov in one of the capital's research institutes with the assistance of chemists V.V. Zemskova, L.F. She-Velkina and A.V. Yasnitskaya. In 1939, he completed the development of the technology for the industrial production of OP-2 powdered thickener. How the incendiary mixture acquired the properties instantaneously self-igniting in air while remains unknown. I am not sure that the trivial addition of white phosphorus granules to the thick incendiary mixture based on petroleum products here would guarantee their self-ignition. In general, be that as it may, already in the spring of 1941 in the factory and field tests of the 125-mm ampoule AJ-2KS normally worked without fuses and intermediate igniters.

According to the original concept, AJ-2 was intended to infect from aircraft of the area with persistent toxic substances, as well as damage to living forces with persistent and unstable toxic substances, and later (when using them with liquid fire mixtures) to ignite and smoke tanks, ships and firing points. Meanwhile, the use of chemical warfare agents in ampoules on the enemy was not excluded from using them from ampouletes. With the beginning of the Great Patriotic War, the incendiary purpose of the munition was supplemented by the smoking of manpower from field forts.

In 1943, for guaranteed operation of AJ-2SOV or AJ-2NOV when bombing from any height and at any carrier speed, the developers of ampoules supplemented their designs with fuses made of thermosetting plastic (resistant to acid bases of toxic agents). As conceived by the developers, such modified munitions have already worked on the living force as fragmentation-chemical ones.

Ampulary fuses UWP (universal percussion fuse) belonged to the category of all-slaughter, i.e. triggered even when the ampoules fell sideways. Structurally, they were similar to those used on aviation smoke grenades of the AH, but it was no longer possible to shoot such ampules from ampulets: from overloads, a fuse of a non-protective type could work directly in the barrel. In the war period and for incendiary ampoules in the Air Force, sometimes they used shells with fuses or with plugs instead.

In 1943-1944 Azh-2SOV or NOV ampoules have been tested for long-term storage in curbed condition. To do this, their enclosures inside were covered with bakelite resin. Thus, the resistance of the metal body to mechanical stress increased even more, and fuses were necessarily installed on such ammunition.

Today, on the ground of past battles, “diggers” can only have the AK-1 or AU-125 ampoules (AK-2 or AU-260 - an extremely rare exotic) made of glass in a conditional form. Thin-walled tin ampoules almost all decayed. You should not try to defuse the glass ampoules, if you can see that inside - the liquid. White or yellowish cloudy - this is the COP, which has by no means lost its ability to self-ignition in air, even after 60 years. Transparent or translucent with yellow large crystals of sediment - it is SOW or NOV. In the glassware, their combat properties can also be maintained for a very long time.

Ampulets in combat

On the eve of the war, the units of backpack flame-throwers (flame-throwing teams) were organizationally part of rifle regiments. However, due to difficulties in defense (extremely short range of flame throwing and disguise signs of the ROX-2 knapsack flamethrower), they were disbanded. Instead, in November 1941, teams and companies were set up, armed with ampouletates and rifle mortars for throwing at tanks and other targets of metal and glass ampoules and incendiary bottles. But, according to the official version, ampoule guns also had significant drawbacks, and at the end of 1942, they were removed from service.

The refusal of rifle-bottle mortars was not mentioned. Probably, for some reason they did not have the disadvantages of ampoule. Moreover, in the remaining divisions of the rifle regiments of the Red Army, bottles with a CS were thrown at tanks solely by hand. But the flame throwers of the flamethrower teams, obviously, discovered a terrible military secret: how to use the aiming bar of the Mosinskaya rifle for accurate shooting with a bottle at a predetermined distance determined by sight. As I understand it, the rest of the illiterate infantrymen simply had no time to teach this “tricky business”. Therefore, they themselves fitted a three-inch cartridge case for cutting a rifle barrel and “outside the hours” themselves were trained in sighting bottle throwing.

When meeting with a strong barrier, the body of the ampoule AJ-2X was broken, as a rule, along the heel-joint seams, the incendiary mixture was splashed out and ignited in air with the formation of a thick white

th smoke. The temperature of combustion of the mixture reached 800 ° C, which, when hit on clothing and exposed areas of the body, caused the enemy a lot of trouble. No less unpleasant was the meeting of the sticky KS with armored vehicles - from changing the physicochemical properties of the metal with local heating to such a temperature and ending with the indispensable fire in the engine-transmission unit of the carburetor (and diesel) tanks. It was impossible to clean off the burning CS from the armor - all that was needed was the termination of air access. However, the presence of a self-igniting additive in the CS did not preclude the spontaneous ignition of the mixture again.

Here are a few excerpts from the military reports of the Great Patriotic War, published on the Internet: “We applied the ampoulelets. From an obliquely mounted tube mounted on a sleigh, a shot of the idle cartridge pushed out the glass ampoule with the combustible mixture. It flew along a steep trajectory over a distance of 300-350 m. Crashing when it fell, the ampoule created a small but steady firing of the fire, hitting the enemy's living strength and setting fire to his dugout. The pivotal ampoule company under the command of Senior Lieutenant Starkov, which included 17 calculations, released 1620 ampoules during the first two hours. ” “Ampumeletters have moved here. Acting under the cover of infantry, they set fire to an enemy tank, two guns and several firing points. ”

By the way, intensive shooting with black powder cartridges inevitably created a thick layer of carbon on the walls of the barrel. So after a quarter of an hour of such cannonade ampoule meters would probably find that the ampoule rolls into the barrel with great difficulty. Theoretically, before this, soot would, on the contrary, somewhat improve the obturation of ampoules in the barrel, increasing the firing range of them. However, the usual range marks on the sight bar, for sure, "floated." About bananas and other tools and devices for cleaning the barrels of ampouletes, probably, it was mentioned in the technical description ...

But quite an objective opinion of our contemporaries: “The calculation of the ampoule was three people. The loading was done by two people: the first number of the calculation was inserting a cartridge from the treasury, the second one inserted the ampoule into the barrel from the muzzle. ” “Ampulets were very simple and cheap“ flamethrower mortars ”, they were armed with special ampoulet platoons. 1942 g. Infantry combat regulations mentions ampoule launcher as a regular infantry fire weapon. In combat, the ampoule gun often served as the core of a group of tank destroyers. Its use in defense was, on the whole, justified itself, while attempts to use it in an offensive resulted in large losses of calculations due to the small firing range. True, they were not without success used by the assault groups in urban battles - in particular, in Stalingrad. ”

There are also memories of veterans. The essence of one of them comes down to the fact that at the beginning of December 1941 on the Western Front, in one of the battalions of the 30 Army, Major-General DD. Lelyushenko delivered 20 ampouletams. The designer of this weapon also came here, as well as the commander himself, who decided to personally try out new equipment. In response to the designer's comments on loading the ampule launcher, Lelyushenko grumbled that it was sly and painful for a long time, but the German tank would not wait ... At the very first shot, the ampule broke in the barrel of the ampulets, and the whole installation burned down. Lelyushenko already with the metal in his voice demanded the second ampoule. It all happened again. The general “fidgeted” by switching to profanity, forbade the fighters to use such an unsafe weapon for calculations and crushed the remaining ampulets with a tank.

The use of APC-203 for filling ampoules of AJ-2 with chemical battle preparations. The inclined fighter pumps out the excess fluid, standing near the tripod sets the plugs on the filling mouths of the AF-2. Photo 1938

Quite likely story, although not very pleasant in the general context. As if the ampulets did not pass the factory and field tests ... Why could this happen? As a version: the 1941-th winter (all eyewitnesses mentioned this) was very frosty, and the glass ampoule became more fragile. Here, unfortunately, a respected veteran did not specify what material those ampoules were from. It may also affect the temperature difference of thick-walled glass (local heating), fired when fired with a flame of gunpowder charge. Obviously, in severe frost, it was necessary to shoot only with metal ampoules. But “in the hearts” the general could easily ride through the ampoules!

Filling station ARS-203. Photo 1938

Front Cockpit Fire Cocktail

It is only at first glance, the pattern of use of the ampoulomett in the army seems to be primitively simple. For example, the calculation of the ampoule in a combat position shot off a portable ammunition and pulled the second ammunition ... What is easier - take it and shoot. Vaughn, the senior lieutenant Starkov’s two-hour unit expenditure exceeded one and a half thousand vials! But in fact, when organizing the supply of troops with incendiary ampoules, it was necessary to solve the problem of transporting long distances from factories from the deep rear of incendiary ammunition that was far from safe in circulation.

Tests of ampoules in the pre-war period showed that these munitions in final form could withstand transportation no further than 200 km along peacetime roads in compliance with all the rules and with the complete elimination of “road adventures”. In wartime, everything became much more complicated. But here, no doubt, the experience of the Soviet aviators was useful, where ampoules were equipped at aerodromes. Prior to the mechanization of the process, pouring the ampoules, taking into account the unscrewing and wrapping of the choke plug, required 2 man-hours per 100 pieces.

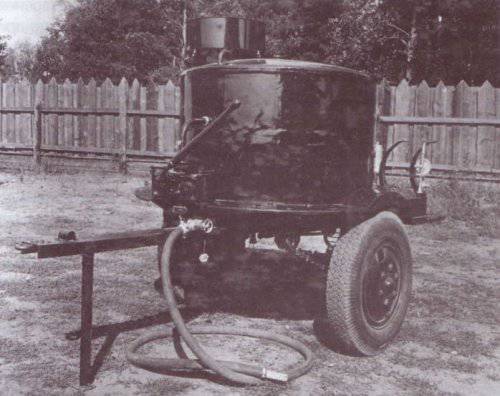

In 1938, for the Red Army Air Force, the NKAP 145 plant was developed and later adopted by the towed aircraft filling station ARS-203, made on a uniaxial semi-trailer. A year later, the ARS-204 self-propelled machine entered service, but it was oriented towards servicing pontoon aircraft, and we will not consider it. ARSs were mainly intended for filling combat chemicals into ammunition and isolated tanks, but they proved to be simply irreplaceable for working with the finished self-igniting incendiary mixture.

In theory, in the rear of each rifle regiment a small unit was supposed to work on equipping ampoules with a mixture of COP. No doubt, it had an APC-203 station. But the COP also did not carry the barrels from the factories, and prepared on the spot. For this, any refinery products (gasoline, kerosene, solarium) and according to the tables compiled by A.P. Ion, added to them a different amount of thickener. As a result, despite the difference in the initial components, the QS was obtained. Further, it was obviously pumped into the APC-203 reservoir, to which the auto-ignition component of the fire mixture was added.

However, the option of adding the component directly to the ampoules, and then pouring the CS liquid into them, is not excluded. In this case, ARS-203, in general, was not so necessary. And the usual soldier's aluminum mug could serve as a dispenser. But such an algorithm required the self-igniting component to be inert outdoors for some time (for example, wet white phosphorus).

APC-203 was specifically designed to mechanize the process of equipping AJ-2 ampoules to working volume in the field. On it, from a large reservoir, the liquid was first poured simultaneously into eight measuring tanks, and then eight ampoules were filled at once. Thus, in an hour, it was possible to equip 300-350 ampoules, and after two hours of such work, the 700-liter reservoir of the station was emptied, and it was again refilled with CS liquid. It was impossible to accelerate the process of pouring the ampoules: all flowing liquids passed naturally, without a pressurized container. The filling cycle of eight ampoules was 17-22 with, and 610 l was pumped into the working capacity of the station using a Gard pump in 7,5-9 minutes.

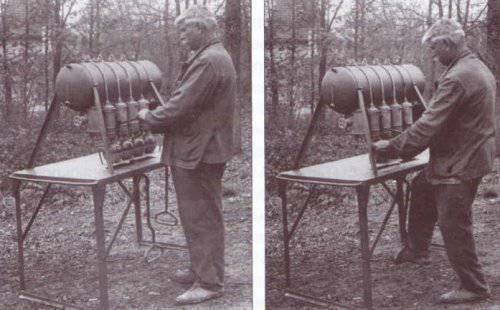

The ORS station is ready for filling four ampoules of AJ-2. The pedal is depressed, and the process has begun! Refilling incendiary mixtures allowed to do without a gas mask. Photo 1942

Obviously, the experience of operating the ARS-203 in the ground forces was unexpected: the performance of the station, focused on the needs of the Air Force, was recognized as excessive, as, indeed, its dimensions, weight and the need to tow a separate car. The infantry needed something smaller, and in 1942, in the OKB-NCAP of the 455 plant, Kartukovtsy developed a field station for the IRS. In its design, the measuring tanks were abolished, and the filling level of opaque ampoules was monitored with the help of the SIG-Extremely Simplified Glass ORS Tube. for use in the field. The capacity of the working

The volume of the tank was 107 l, and the mass of the entire station did not exceed 95 kg. The ORS was designed in a “civilized” version of the workplace on a folding table and in an extremely simplified, with the installation of a working capacity “on the stumps”. Station performance was limited to 240 ampoules AJ-2 per hour. Unfortunately, when the CPD testing ground ended, the ampouletales in the Red Army had already been removed from service.

Russian reusable "faustpron"?

However, it will not be entirely correct to categorize the 125-mm ampoulomet incendiary weapon unconditionally. After all, no one allows himself to consider the receiver artillery system or the Katyusha MLRS, which fired incendiary ammunition if necessary, as flamethrowers. By analogy with the use of aircraft ampoules, the designers of the 145 plant offered to expand the arsenal of ampoule launchers through the use of modified Soviet anti-tank bombs PTAB-2,5 of cumulative action created at the very beginning of World War II.

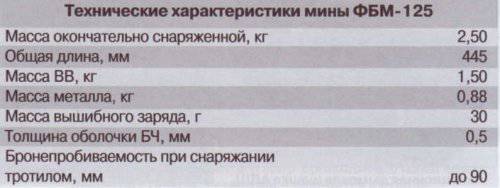

In the book of E. Pyr'ev and S. Reznichenko, “Bombing Armament of Russian Aviation 1912-1945” in the PTAB section, it says that small aerial bombs of cumulative action in the USSR were developed only in GSKB-47, CDB-22 and SKB-35. From December 1942 to April, 1943 was able to design, test and work out the full program 1,5-kg PTAB of cumulative action. However, at the 145 plant I.I. Kartukov dealt with this problem much earlier, back in 1941. Their 2,5-kg ammunition was called a high-explosive armor-piercing mine of AFBM-125 caliber 125 mm.

Outwardly, such a PTAB strongly reminded the high-explosive aerial bombs of Colonel Gronov of small caliber from the time of the First World War. Since cylindrical tail wings were welded to the body of an aviation munition by spot welding, it was not possible to dispense with the use of a mine in the infantry to simply replace its tail. A new mortar type plumage on the bombs was installed with an additional propelling charge built into it in the capsule. The ammunition was fired as before, with a single gun cartridge cartridge of the 12 caliber. Thus, as applied to the ampoule, the system was obtained in a certain Stepemin MF. 125 without the additional active-reactive. fuse contact fuse.

For quite a long time, designers had to work on improving the reliability of arming the contact fuse of a mine in a trajectory.

Mina BFM-125 without additional fuse contact fuse.

Meanwhile, the problem is in the above-mentioned episode 1941 with the commander of the 30 th army DD. Lelyushenko could also have arisen when shooting high-explosive-armor-piercing mine mines from the SBM-125 early models. Lelushenko’s grumbling indirectly points to this: “Everything is sly and painful for a long time, the German tank will not wait,” since investing an ampoule and loading a cartridge into a conventional ampoulometom did not require any special wisdom. In the case of the use of PBM-125, before firing at the ammunition, it was necessary to unscrew the safety key, opening fire access to the powder pressing of the safety mechanism holding the inertial impactor of the contact fuse in the rear position. For this, all such ammunition was supplied with a cardboard cheat sheet with the inscription "Unscrew before shooting", tied to the key.

The cumulative notch in the front of the mine was hemispherical, and its thin-walled steel lining rather formed a given configuration when pouring explosives, rather than playing the role of a shock core when cumulating the ammunition charge. The documents indicated that PBM-125, when firing from standard ampulets, was intended to disable tanks, armored trains, armored vehicles, vehicles, as well as to destroy fortified fire points (DOTT. DZOTovypr.).

An armor plate 80 mm thick, confidently punched by the PBM-125 mine in the ground tests.

The nature of the outlet of the same punched armored plates.

The grounding tests of the munitions were carried out in 1941. Their result was the launch of mines in pilot production. The military tests of the XFUMX-125 were successfully completed in 1942. The developers suggested, if necessary, equipping such mines with chemical irritants (chloroacetophenone or adamsite), but this did not happen. In parallel with the FBM-125, the OKB-NCAP of the 455 plant developed the BFM-125 armor-piercing mine. Unfortunately, its combat properties in the factory information is not mentioned.

Cover infantry smoke

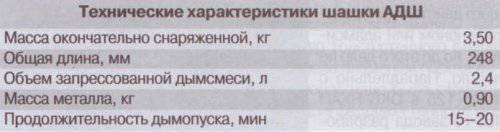

In 1941, the ground tests passed at the factory №145 named after. CM. Kirov Aviation Smoke Bomb ADS. It was intended for setting up vertical masking (blinding the enemy) and poisonous smoke (binding and exhausting enemy combat forces) curtains when dropping drafts from an airplane. On aircraft ADSH loaded into ampoule-bomb cassettes, after removing the fuses safety plugs. The checkers were poured in one gulp when the doors of one of the cassette sections opened. Ampoule-bomb cassettes were also developed at the 145 plant for fighters, attack aircraft, long-range and near-bomber aircraft.

Contact checker fuse has already been performed with an all-slaughter mechanism, which ensured its operation when the ammunition was dropped to the ground in any position. The trigger of the fuse spring prevented the saber from triggering if it accidentally fell, preventing the drummer from pricking the primer-igniter with insufficient overloads (when falling from height to 4 m on concrete).

Probably, it is no coincidence that this ammunition also turned out to be made in the caliber 125 mm, which, according to the developers, allowed the use of APS from standard ampoulelets. By the way, when firing an ampoule, the ammunition received an overload much greater than when falling from 4 m, which means that the bomb began to smoke in flight.

Even in the pre-war years, it was scientifically proven that it was much more effective to cover its troops if it was the army that was fuming in an attack on a firing point, and not its own infantry. Thus, the ampoule would be a very necessary thing when, before the attack, it was necessary to throw a few pieces at a couple of hundred meters to a bunker or a bunker. Unfortunately, it is not known whether ampoule guns were used on the fronts in this version ...

When firing heavy drafts ADS from the 125-mm ampoule, his aiming devices could be used only with amendments. However, great firing accuracy was not required: one ADS created an invisible creeping cloud up to 100 m. And since it was necessary to adapt the ADS

an additional expelling charge was impossible; for firing at the maximum distance, it was necessary to use a steep trajectory at elevation angles close to 45 °.

Regimental propaganda activities

The plot for this section of the article on ampoule was also borrowed by me on the Internet. Its essence was that one day the deputy commander, having come to the sappers in the battalion, asked who could make a propaganda mortar bomb? Pavel Yakovlevich Ivanov was called. He found the tools at the site of the destroyed forge, made the case of ammunition from a chock, adjusting a small powder charge to break it in the air, fuse it from a bi-ford cord, and a stabilizer from cans. However, the wooden mine for a mortar was light and lowered slowly into the barrel without piercing the capsule.

Ivanov reduced its diameter so that the air from the barrel would leave more freely, and the primer on the firing pin would stop falling. In general, the craftsman did not sleep for days, but on the third day the mine flew and exploded. Flyers circled over enemy trenches. Later, for shooting wooden mines, he adapted the ampoule. And in order not to cause a return fire on his trenches, he carried him to a neutral strip or to the side. Result: the German soldiers somehow came over to our side in a group, drunk, in broad daylight.

This story is also quite believable. It is rather difficult to make agitmina in a metal case from improvised means under field conditions, and quite capable of wood. In addition, such ammunition, according to common sense, and should be non-lethal. Otherwise, what kind of agitation! But the factory propaganda mines and artillery shells were in metal cases. To a greater extent, to fly further and not to greatly violate the ballistics. However, before the designers of the ampule launcher hadn’t even thought about enriching the arsenal of their offspring with this kind of ammunition ...

More ampulets, good and different!

The reader probably already noticed how the author almost obsessively mentioned 125-mm ampoulelets. And this is no accident ... The fact is that, along with the instrument of low ballistics of this caliber, the factory workers I.I. Kartukov offered for use 100-mm and 82-mm "ampouleme" in the form of anti-tank cumulative mortars. These systems could not be counted as ampulets: the Soviet "defense industry" did not release ampoules of such a caliber and was not planning to set up their production. But with ampoule launchers, these easel anti-tank mortars related only the appearance and the same team of developers.

But back to the anti-tank mortar development "kartukovtsev." 100-mm and 82-mm "ampoulemes" were not an alternative to the 125-mm ampoulemet, just their development took place in parallel. Most likely - to determine the fighting qualities of both systems and select the best sample. The nomenclature of ammunition was limited to only armor-piercing high-explosive mines of mortar type. That is, the expelling cartridge of the 12 caliber was mounted in the tail section of the mines themselves. Mina 82 caliber mm was converted from an experienced cumulative PTAB development OKO

145-th plant NKAP. There is no information about armor penetration of ammunition of both calibers. The anti-tank mortars themselves, as can be seen in the photo, are made according to a similar scheme, the Kazakh 100 "mm mine armor-piercing high-explosive

actions BFM-100.

charge-loaded, with piston shutter. Shooting mechanisms are similar in systems of both calibers.

The artillery mortars "Ampulemet" were not received. According to the classification of artillery systems, samples of both calibers can be attributed to the rigid type mortars. Theoretically, the recoil forces when firing high-explosive armor-piercing mines should not have increased compared with throwing ampoules. The mass of the FBM was greater than that of AJ-2X, but less than that of the ADS. And the expelling charge is the same. However, despite the fact that the Ampulemet mortars fired at more flattering trajectories than the classic mortars and bomb bombers, the first ones were still more "mortar" than the Katyusha guards mortars.

Conclusions

So, the reason for the removal of ampoule launchers from the ground forces of the Red Army at the end of 1942 was officially their insecurity in handling and use. But in vain: in front of our army, there was not only an offensive, but also numerous battles in populated areas. It was there that would be fully useful.

100-mm machine-gun anti-tank mortar in the process of loading.

By the way, the safety of using a backpack flamethrower in an offensive battle is also very doubtful. Nevertheless, they were returned to the “system” and used until the end of the war. There are front-line memories of the sniper, where he claims that the enemy flamethrower can always be seen from afar (a number of signs of unmasking), so it is better to heal him at chest level. Then from short distances the bullet of a powerful rifle cartridge pierces through both the body and the tank with the fire mixture. That is, the flamethrower and flamethrower "can not be restored."

Exactly in the same situation could be the calculation of the ampoulomette when bullets or fragments hit the incendiary ampoules. Glass ampoules generally could smash each other with a shock wave from a close break. And in general, the whole war is a very risky business ... And thanks to the “hustle of generals Lelyushenko”, such early conclusions about the low quality and combat inefficiency of individual types of weapons were born. Recall, for example, the pre-war ordeals of the MLRS Katyusha, mortar weapons, submachine guns, the T-34 tank, etc. Our gunsmith designers in the overwhelming majority were not amateurs in their field of knowledge and no less generals sought to bring victory closer. And they were “dipped” like kittens. The generals are also easy to understand - they needed reliable samples of armaments and with "protection from a fool."

And then, the warm memories of infantrymen about the effectiveness of the COP incendiary bottles vs tanks against a background of a very cool attitude to ampouletames somehow look illogical. Both that, and another - the weapon of one order. Unless the ampoule was exactly twice as powerful, and it was possible to throw it once more in 10. It is not at all clear to what the claims in the infantry were more: to the ampoulemet itself or to its ampoules?

External suspended non-dropable container АБК-П-500 for salvo application of aerial bombs of small calibers from high-speed and diving bomber. In the foreground are the AJ-2X ampoules of four spherical segments with edges sealed from the inside.

One of the variants of a handheld (non-flame) flame-thrower developed by the designers of the plant №145 NCAP on 1942 tests. At such a distance from this “aerosol can”, you can grind piglets.

At the same time, the same “very dangerous” ampoules of AJ-2X in Soviet attack aircraft survived in service, at least until the end of 1944 - the beginning of 1945 (in any case, the assault air regiment of MP Odintsov used them already in German territory for tank columns, sheltered in the forests). And it is on attack aircraft! With unarmored bomb compartments! When the enemy’s infantry is pounded from the ground by what has got it! The pilots were well aware of what would happen if only one stray bullet hit the cassette with ampoules, but nevertheless flew. By the way, a timid mention on the Internet that ampoules were used in aviation when firing from such aircraft ampouletes is absolutely not true.

The author expresses his gratitude to A. F. Nosov, Honored Veteran of the Enterprise, Curator of the Museum of OJSC ICB Iskra named after I. Kartukov, for their full assistance in the preparation of this publication.

Information