On the way to the T-80: tank gas turbine engines

First projects

The idea to make a tank with a gas turbine power plant appeared even when no one was thinking about the T-80 project. Back in 1948, the turbine production design office of the Leningrad Kirov Plant began work on a project for a tank horsepower engine with a capacity of 700 horsepower. Unfortunately, the project was closed for hopelessness. The fact is that the 700-strong engine, according to calculations, consumed an extremely large amount of fuel. Consumption recognized too large for practical use. A little later, attempts were repeatedly made to design other engines of this class, but they also did not give any result.

In the second half of the fifties, Leningrad designers created another engine that reached the prototype assembly stage. The resulting GTE-1 was not equipped with a heat exchanger and gave out power up to a thousand horsepower with fuel consumption in 350-355 g / hp. Soon, on the basis of this engine made two modifications: GTD1-Gv6 with a stationary heat exchanger and GTD1-Gv7 with a rotating. Unfortunately, despite some progress, all three GTE models had fuel consumption higher than estimated. It was not possible to improve this parameter, therefore the projects were closed.

In general, all of the early GTE projects for land, including tracked, vehicles were not particularly successful. All of them could not get to mass production. At the same time, during the development and testing of new engines, it was possible to find many new original technical solutions, as well as to collect the necessary information. By this time, two main trends had formed: attempts to adapt the aircraft engine for use on tank and make a special gas turbine engine.

In the early sixties, there were several events that positively affected the whole direction. First, the Research Institute of Engines (NIID) proposed several variants of the engine compartment for the T-55 tank. Two variants of a gas turbine engine were proposed, differing from each other in power and fuel consumption. In April, the corresponding order of the country's leadership was issued by 1961, according to which NIIED had to continue work on the projects started, and a special design bureau was established at the Chelyabinsk Tractor Plant, which was exclusively engaged in the subjects of the CCD.

Chelyabinsk engines

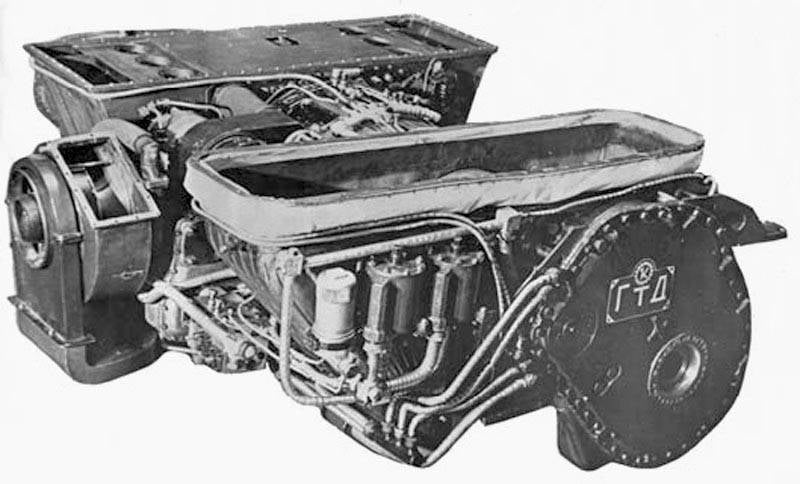

The new bureau received the OKB-6 index and joined forces with the Engine Institute. The result of the design was the project of the CCD-700. With power up to 700 HP This engine consumed 280 g / hp.h, which was close to the required values. Characteristics so high for their time were due to a number of original solutions. First of all, it is necessary to note the design of the heat exchanger, the channels of which were optimized in terms of cross-section and gas flow rates. In addition, a new single-stage cyclone-type air cleaner, which detained up to 97% dust, had a beneficial effect on the operation of the engine. In 1965, the testing of the first two GTE-700 samples began. The operation of the engines on the stand showed all the advantages of the applied solutions, and also allowed to identify and correct the problems in time. Soon, three more GTD-700 engines were assembled, one of which was later installed on the experimental tank “Object 775T”. In March, the first launch of a gas turbine engine on a tank took place on 1968, and sea trials began a few days later. Until April next year, the experimental tank traveled about 900 kilometers with an engine operating time of about 100 hours.

Despite the successes, in the 1969, the testing of the GTE-700 engine was completed. At that time, work on the 775 Object missile tank and, as a result, its gas turbine modification was stopped. However, the development of the engine has not stopped. According to the test results, NIID employees conducted several studies and came to positive conclusions. As it turned out, the design of the CCD-700 allowed to bring the power up to the level of the order of 1000 hp, and reduce fuel consumption to 210-220 g / hp.h. Perspective modification of the engine received the designation GTD-700M. Its design characteristics looked promising, which led to further developments. VNIITransmash (renamed VNII-100) and the LKZ design bureau attempted to install the GTD-700М on the “432 Object” and “287 Object” tanks. However, no practical results were achieved. The engine compartment of the first tank was not large enough to accommodate all the units of the power plant, and the second project was soon closed for hopelessness. On this story engine GTD-700 over.

GTD-3 for the "432 Object"

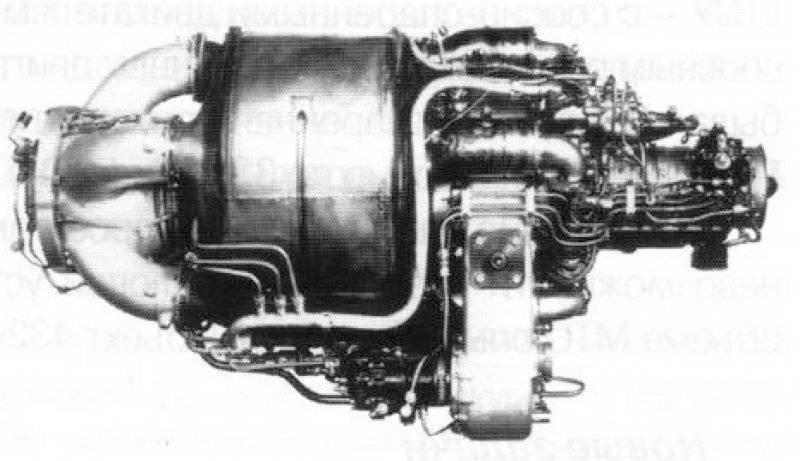

Simultaneously with NIID and Chelyabinsk designers, they worked on their GTE projects in the Omsk OKB-29 (now the Omsk Motor-Building Design Bureau) and the Leningrad OKB-117 (the V.Ya. Klimov Plant). It is worth noting that the main focus of these enterprises was the adaptation of aircraft engines to tank “needs”. This fact is due to a number of features of the resulting engines. The GTE-3 helicopter turboshaft engine developed in Omsk was one of the first to undergo processing. After adaptation for use on the tank, he received a new GTD-3T index and slightly lost in power, from 750 to 700 hp. Fuel consumption in the tank version was 330-350 g / hp.h. Such fuel consumption was too high for practical use of the engine, but the GTD-3T was still installed on the undercarriage layout, the base for which was the T-54 tank. Later, a similar experiment was conducted with the T-55 tank (VNII-100 project) and with the “166TM Object” (the Uralvagonzavod project). It is noteworthy that after testing their prototype Tagil designers came to the conclusion that it would not be expedient to continue work on gas turbine topics and returned to the creation of diesel-powered tanks.

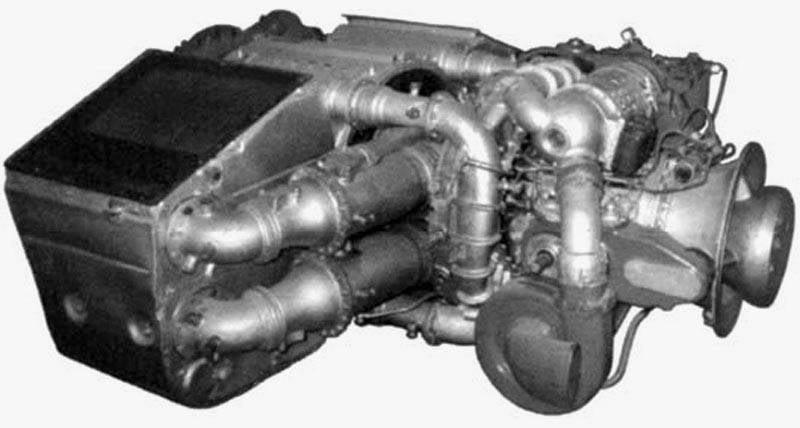

In 1965, OKB-29 and VNII-100 were assigned to modify the engine of the CCD-3T for use on the “432 Object” tank, which was soon adopted under the designation T-64. During this revision, the engine received a new designation of the CCD-3TL and a number of design changes. The design of the compressor and the turbine casing changed, a system of gas by-pass after the compressor appeared, two new gearboxes were created (one in the motor unit, the other was located on the tank body), and the exhaust pipe was altered. Having relatively small dimensions, the GTD-3ТL engine fitted well into the engine and transmission compartment of the 432 Object, while additional tanks fit into the free volumes for 200 liters of fuel. It is worth noting that the MTO tank had to install not only a new engine, but also a new transmission adapted to work with a gas turbine engine. Engine torque was transmitted to the main gearbox and distributed to two onboard planetary gearboxes. In the design of the new transmission, the details of the original 432 Object system were widely used. Due to the specific requirements of the engine for the air supply, it was necessary to re-design the equipment for underwater driving, incorporating air feed and exhaust pipes of a larger diameter.

In the course of designing the GTD-3TL engine, in order to test some ideas, the GTD-55Т engine was installed on the T-3 tank. A tank with a gas turbine engine was compared with a similar armored vehicle equipped with a standard B-55 diesel engine. As a result of these tests, all preliminary calculations were confirmed. Thus, the average speed of an experienced tank turned out to be slightly higher than the serial speed, but this advantage had to be paid in 2,5-2,7 times higher fuel consumption. At the same time, by the time of the comparative tests, the required characteristics were not achieved. Instead of the necessary 700 hp GTD-3TL produced only 600-610 and burned the order of 340 g / hp, instead of the required 300. Increased fuel consumption has led to a serious reduction in power reserve. Finally, the resource in the 200 clock did not reach even half of the set 500. The identified deficiencies were taken into account and soon a full-fledged project of the CCD-3ТL appeared. By the end of 1965, OKB-29 and VNII-100 jointly completed the development of a new engine. The basis for it was not the tank GTE-3T, but the aviation GTD-3F. The new engine developed power up to 800 HP. and consumed no more than 300 g / hp. In 1965-66, two new engines were manufactured and tested on the “003 Object” tank, which was a modified “432 Object”.

Simultaneously with the testing of the tank "Object 003" was the development of the "Object 004" and the power plant for it. It was supposed to use the engine GTD-3TP, which had more power compared to the GTD-3TL. In addition, the motor with the “TP” index was to be placed not across the tank hull, but along, which resulted in the re-assembly of some units. The main paths of development remained the same, but their nuances underwent certain corrections related to the identified problems of gas turbine engines. We had to seriously modify the system of air intake and filtration, as well as exhaust gas exhaust. Another serious question concerned efficient engine cooling. Creating a new transmission, improving performance and bringing the service life to the required 500 hours also remained relevant. When designing the engine and transmission for the “Object 004” tank, we tried to assemble all the units in such a way that they could fit in MTO with minimal modifications.

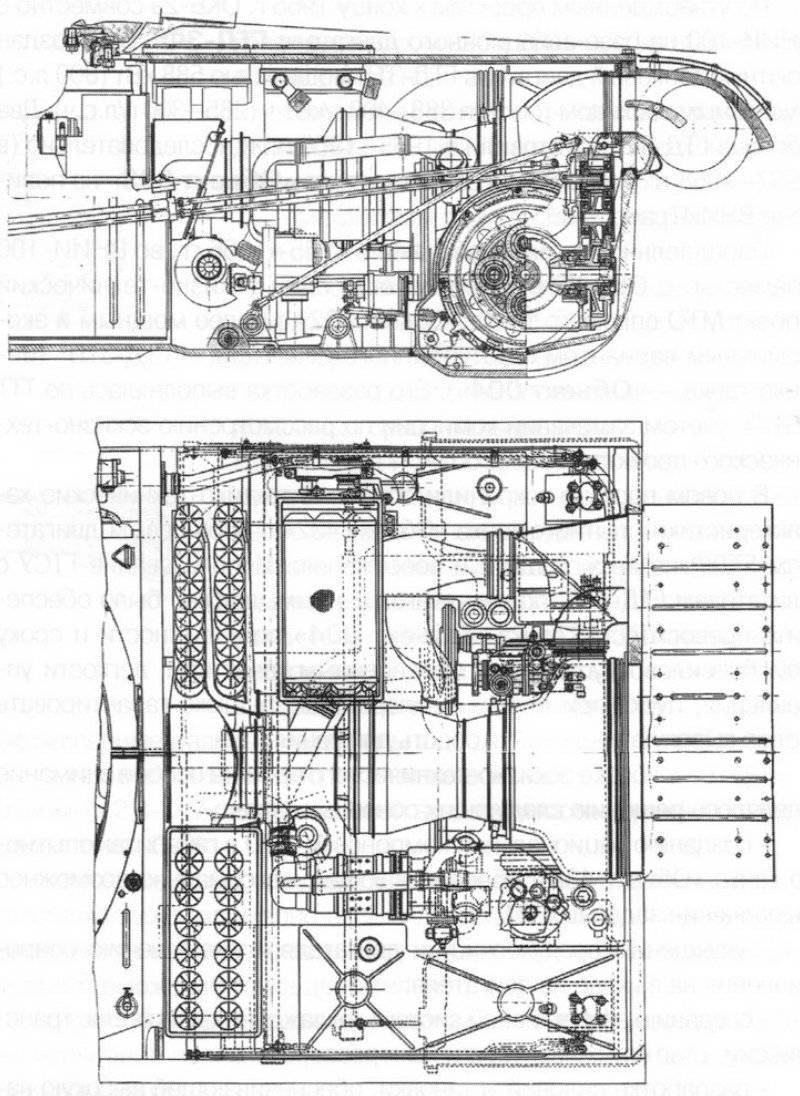

The roof of the engine compartment and the stern sheet of the armored hull underwent the greatest changes. The roof was made of a relatively thin and light sheet with windows on which the air intake louver was placed. In the stern there were holes for the emission of engine gases and air from the cooling system. To increase the survivability of these holes covered with an armored cap. The engines and some transmission units were mounted on a newly developed frame, which was mounted on an armored hull without any modifications to the latter. The engine itself was installed longitudinally, with a slight shift from the axis of the tank to the left. Next to it are the fuel and oil pumps, 24 straight-flow cyclone air cleaning systems, a compressor, a starter-generator, etc.

The GTD-3TP engine could deliver power up to 950 hp. at fuel consumption in 260-270 g / hp, h. A characteristic feature of this engine was its scheme. Unlike previous engines of the GTD-3 family, it was made on a two-shaft system. The engine was coupled with a four-speed transmission, designed taking into account the typical loads for a gas turbine engine. According to calculations, the transmission could work for the entire life of the engine - up to 500 hours. The onboard gearboxes were the same size as the original “432 Object” and were placed in the original locations. Drives of control units of the engine and transmission in most of them were located on the old places.

As far as is known, the “004 Object” has remained on the drawings. In the course of its development we managed to solve several important issues, as well as determine plans for the future. Despite the decrease in the visibility of the tank with the CCD in the infrared spectrum, the improved quality of air cleaning, the creation of a special transmission, etc., the fuel consumption remained at an unacceptable level.

GTD from Leningrad

Another project that began in 1961 was Leningrad research into the prospects for the GTD-350 turboshaft engine. Leningrad Kirov Plant and Plant them. Klimov jointly began to study the question posed to them. As the stand itself for the first research the serial tractor K-700 was used. The GTD-350 engine was installed on it, to work with which it was necessary to modify the transmission a little. Soon another experiment began. This time the armored personnel carrier BTR-50П became the “platform” for the gas turbine engine. The details of these tests did not become public, but it is known that, based on their results, the GTD-350 engine was recognized as suitable for use on land vehicles.

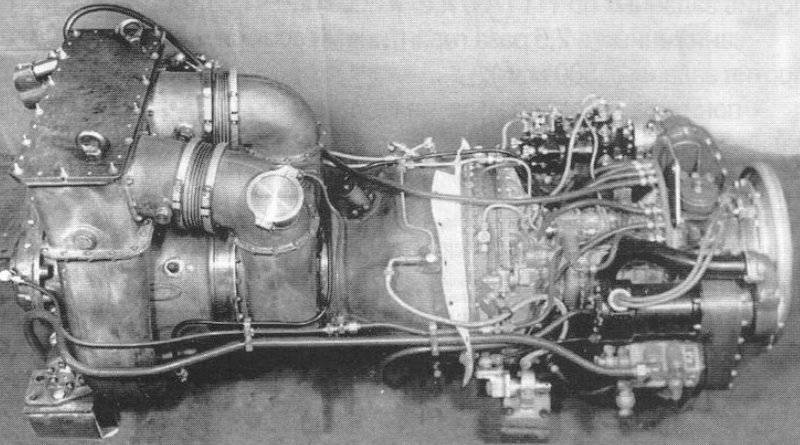

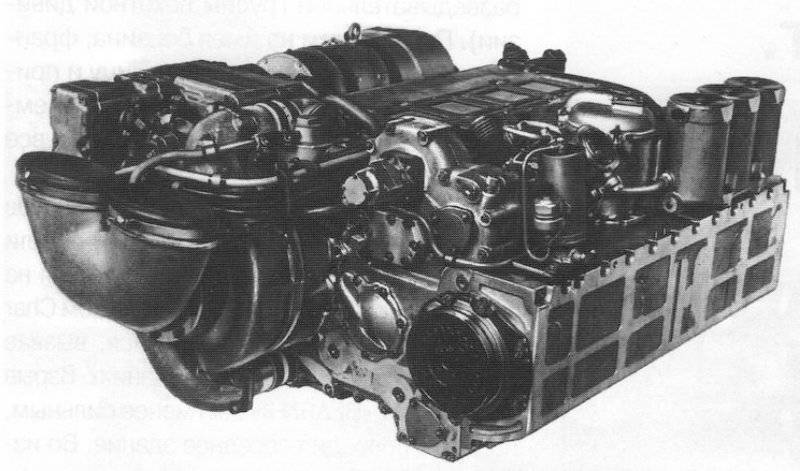

At its base, two variants of the engine GTD-350T were created, with and without a heat exchanger. Without a heat exchanger, a twin-shaft gas turbine engine with a free turbine developed power up to 400 hp. and had a fuel consumption of 350 g / hp. The version with a heat exchanger was significantly more economical - no more than 300 g / hp, although it lost in the maximum power of the order of 5-10 hp On the basis of two variants of the GTE-350T engine, power units for the tank were made. At the same time, in view of the relatively low power, variants with the use of one or two engines were considered. As a result of comparisons, the unit with two GTE-350T engines located along the tank hull was considered the most promising. In 1963, the assembly of a prototype of such a power plant began. It was installed on the chassis of an experimental 287 Object missile tank. The resulting machine was called the “288 Object”.

In the 1966-67 years, this tank was factory tested, where it confirmed and corrected the design characteristics. However, the main result of trips to the landfill was the understanding that the prospects for the twin engine system are dubious. The power plant with two engines and the original gearbox turned out to be more difficult to manufacture and operate, as well as more expensive than one GTE of equivalent power with a conventional transmission. Some attempts were made to develop a two-engine scheme, but in the end the designers of the LKZ and the Plant named after them. Klimov stopped work in this direction.

It should be noted that the GTD-350T and “288 Object” projects were closed only in 1968 year. Until that time, at the insistence of the customer in the person of the Ministry of Defense, comparative tests of several tanks took place at once. They were attended by diesel T-64 and "Object 287", as well as gas turbine "Object 288" and "Object 003". The tests were severe and took place in different locations and in different weather conditions. As a result, it turned out that with the existing advantages in terms of dimensions or maximum power, existing gas turbine engines are less suitable for practical use than diesel engines mastered in production.

Shortly before the termination of work on the subject of twin engines, designers LKZ and Plant them. Klimov made two draft designs that implied the installation of a paired installation on the “432 Object” tank with advanced GTD-T engines with an 450 HP power. Various options for locating engines were considered, but in the end both projects did not continue. The twin power units were inconvenient for practical use and were no longer used.

Engine for T-64A

Adopted in the sixties, the T-64A tank, with all its advantages, was not without its drawbacks. A high degree of novelty and a few original ideas caused technical and operational problems. A lot of complaints caused the engine 5TDF. In particular, and because of them, it was decided to seriously engage in promising GTE for this tank. In 1967, a corresponding resolution of the country's leadership appeared. By this time, there was already some experience in equipping the 432 Object tank with a gas turbine power plant, so the designers did not have to start from scratch. In the spring of 1968 year at the Leningrad Plant them. Klimov turned design work on the engine GTD-1000T.

The main issue facing the designers was to reduce fuel consumption. The remaining nuances of the project have already been worked out and did not need so much attention. They proposed to improve efficiency in several ways: to increase the temperature of gases, to improve the cooling of structural elements, to modernize the heat exchanger, and to increase the efficiency of all mechanisms. In addition, when creating the CCD-1000T, an original approach was applied: a combined group of 20 from their employees, representing each organization, was responsible for coordinating the activities of several enterprises involved in the project.

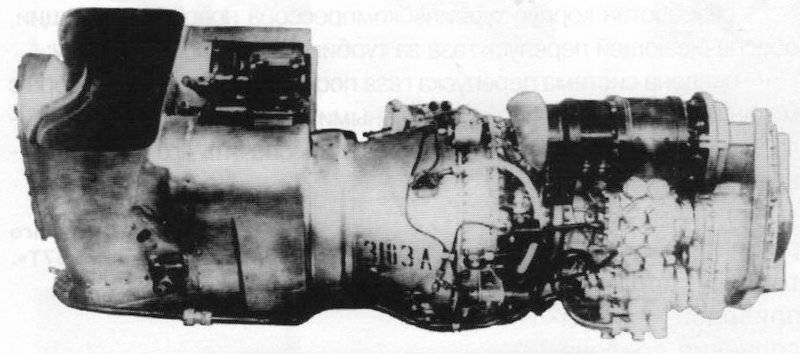

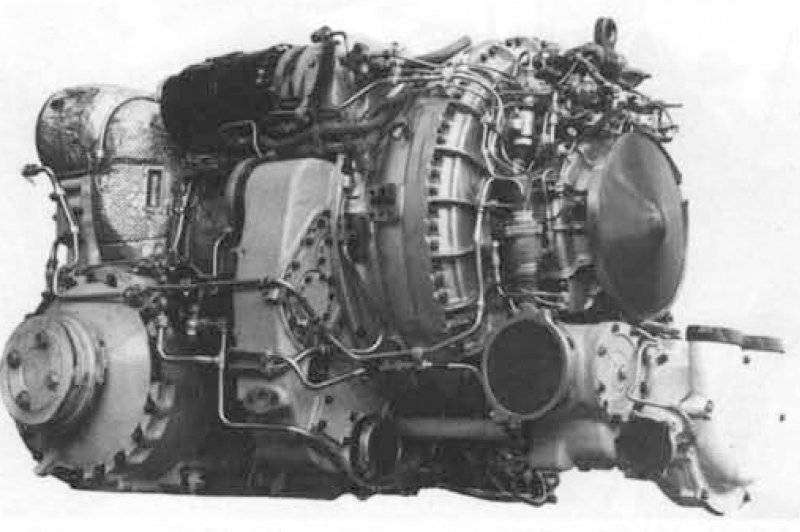

Thanks to this approach, we quickly managed to determine the specific appearance of a promising engine. Thus, the plans included the creation of a three-shaft gas turbine engine with a two-stage turbocharger, an annular combustion chamber and a cooled nozzle apparatus. The power turbine is single-stage with an adjustable nozzle apparatus in front of it. The design of the engine GTD-1000T immediately introduced a built-in reduction gearbox, which could convert the rotation of the power turbine at a speed of about 25-26 thousand rpm in 3-3,2 thousand. Transmission "Object 432" without any extra transmission parts.

At the suggestion of VNIITransmash employees, a block of direct-flow cyclones was used to clean the incoming air. Removal of dust separated from the air was the responsibility of additional centrifugal fans, which, moreover, were blown by oil radiators. The use of such a simple and effective air purification system led to the failure of the heat exchanger. In case of its use, in order to achieve the required characteristics, it was necessary to clean the air by almost all 100%, which was at least very difficult. The GTD-1000T engine without a heat exchanger could work even if up to 3% dust remained in the air.

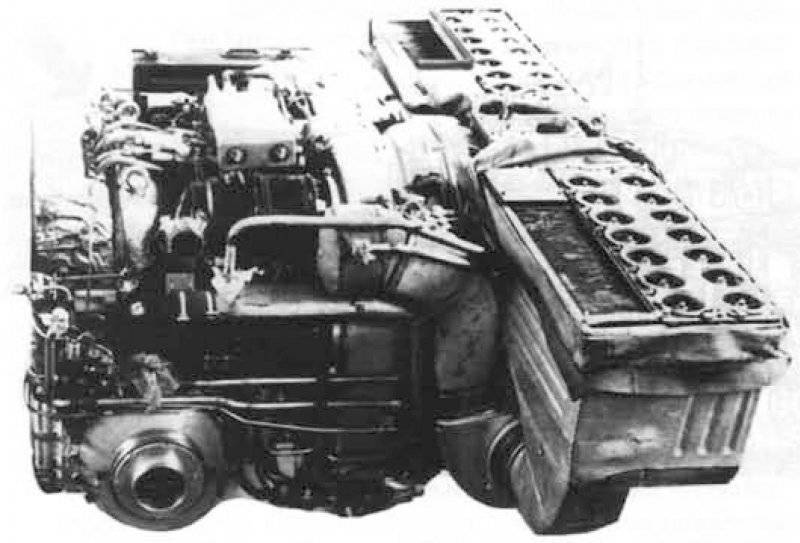

Separately, it is worth noting the layout of the engine. Cyclones, radiators, pumps, oil tank, compressor, generator and other parts of the power plant were installed on the body of the gas turbine unit itself. The resulting monoblock had dimensions suitable for installation in the engine compartment of the T-64A tank. In addition, in comparison with the original power plant, the GTE-1000T engine left enough volume inside the armored hull to accommodate tanks for 200 liters of fuel.

In the spring of 1969, the assembly of prototypes of the T-64A with a gas turbine power plant began. Interestingly, several enterprises took part in the creation of prototypes: the Leningrad Kirov and Izhora Plants, the Zaporozhevsky Plant. Klimov, as well as the Kharkov Transport Engineering Plant. A little later, the leadership of the defense industry decided to build an experimental batch of X-NUMX T-20A tanks with a gas-turbine power plant and distribute them to various tests. 64-7 tanks were intended for factory, 8-2 for landfills, and the remaining machines had to pass troop tests in different conditions.

For several months of testing in the conditions of landfills and test bases, the necessary amount of information was collected. GTD-1000T engines showed all their advantages, and also proved their suitability for use in practice. However, another problem emerged. With power in 1000 hp the engine did not interact well with the existing chassis. Her life was noticeably decreasing. Moreover, by the time the tests ended, almost all twenty experienced tanks needed repair of the undercarriage or transmission.

At the finish line

The most obvious solution to the problem was the finalization of the chassis of the T-64A tank for use with the GTD-1000T. However, such a process could take too much time and LKZ designers took the initiative. In their opinion, it was necessary not to modernize the existing equipment, but to create a new one, originally designed for heavy loads. This is how the 219 Object project came about.

As you know, over several years of development this project has managed to undergo a lot of changes. Almost all elements of the design were corrected. In the same way, the engine of the CCD-1000T and the associated systems underwent modifications. Perhaps the most important issue at this time was to increase the degree of air purification. As a result, a lot of studies chose an air cleaner with 28 cyclones equipped with fans with a special blade shape. To reduce wear, some parts of the cyclones are coated with polyurethane. Changing the air cleaning system has reduced the amount of dust entering the engine by about one percent.

Even during testing in Central Asia, another problem of a gas turbine engine was revealed. There was a high silica content in the ground and sand. Such dust, having got into the engine, was sintered on its units in the form of a glassy crust. It interfered with the normal flow of gases in the engine path, and also increased its wear. They tried to solve this problem with the help of special chemical coatings, injecting a special solution into the engine, creating an air gap around the parts and even using some materials that gradually collapsed and carried away the burnt dust. However, none of the proposed methods helped. In 1973, this problem was solved. A group of specialists of the Plant. Klimova proposed to install a part of the engine that is the most susceptible to contamination — the nozzle apparatus — a special pneumatic vibrator. If necessary, or after a certain period of time, air from the compressor was supplied to this unit and the nozzle began to vibrate at a frequency of 400 Hz. The dust particles were literally shaken off and blown out by exhaust gases. A little later, the vibrator was replaced with eight hammers of a simpler design.

As a result of all the improvements, it was finally possible to bring the engine of the CCD-1000T to the required 500 hours. The fuel consumption of the "Object 219" was approximately 1,5-1,8 times higher than that of armored vehicles with diesel engines. The power reserve has been reduced accordingly. Nevertheless, the aggregate technical and combat characteristics of the tank "Object 219sp2" recognized as suitable for adoption. In 1976, the Council of Ministers issued a decree, in which the tank was designated T-80. In the future, this armored vehicle has undergone a number of changes, several modifications were created at its base, including with new engines. But that's another story.

On the materials of the sites:

magazine "" Equipment and armament: yesterday, today, tomorrow ... ""

http://armor.kiev.ua/

http://army-guide.com/

http://t80leningrad.narod.ru/

Information