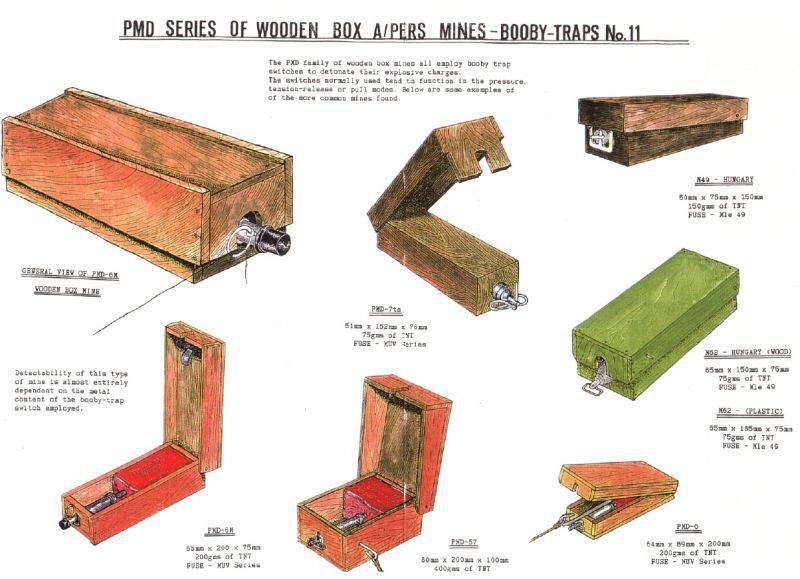

Anti-personnel mines of the PMD-6 family

PMD-6

At the very end of the thirties, new mines of the PMD-6 type (“Anti-personnel mine, wooden”) began to flow into the engineering units of the Red Army. The development of this weapon took into account the current state of the industry, as well as possible difficulties after the start of the war. For this reason, promising ammunition was proposed to be made from the most simple materials and finished products. Due to this approach, the developers of mine mine PMD-6 of various modifications have become one of the main means of creating mine blast barriers designed to protect against enemy infantry.

Mina PMD-6 in the base version received a simple wooden case consisting of two parts. All the main parts of the ammunition were placed in a small elongated box, which was covered with a lid on top. The lid had to perform the functions of a target sensor, for which it was located on an axis located at the rear of the mine. An important feature of the hull design was the ability to manufacture all parts of the available lumber. Depending on the raw materials used, it was necessary to slightly resize some parts, but the general features of the design remained the same.

Depending on the hull material used, the finished anti-personnel mines had a length of about 20 cm, a width of the order of 9-10 cm and a height (in combat position) of no more than 3,5-4 cm. The total weight of the product fluctuated within 550-600 g. , which was the target sensor, measured about 20x10 cm.

The mines of the PMD-6 family were filled with one piece of explosive weighing 200 g. Depending on the manufacturer’s capabilities, the ammunition of different series could receive both TNT blocks and so-called charges. french mix. The Soviet military industry produced several types of 200-gram checkers from the French mix. These were 80 / 20 based on melinite and dinitronaphthalene, 70 / 30 and 50 / 50 from TNT and trinitroxylene (xylyl), as well as other similar compounds. Despite the different compositions and characteristics, all standard pieces weighing 200 g had dimensions 10 xX NUMX x X NUMX. See At the smallest end (5 x2,5 cm) there was a slot for installing a detonator and a fuse.

The checker was placed at the back wall of the box-case. Some mines could receive a small bar set at the bottom of the latter and holding the sword in place. In the front nest of checkers, a fuse of the MUV family was installed. Depending on their capabilities, sappers could use similar fuses of the types available. The mines of the PMD-6 of the early series, for obvious reasons, were completed with fuses of the first model MUV. The tail of the fuse protruded from the body through a round hole in its front wall. In the combat position of the loop T-shaped fuse checks was under the shank of the drummer.

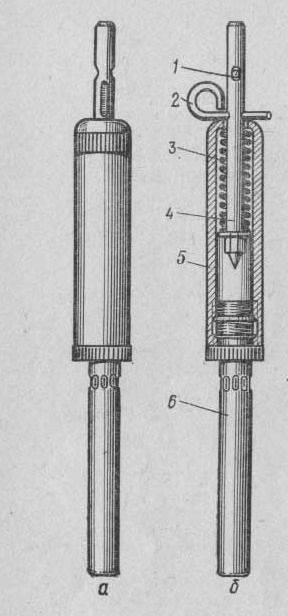

The fuses of the series MUV had a fairly simple design. Inside the metal or bakelite case were placed combat spring and drummer. The shank of the latter protruded from the hull. In the firing position the drummer was kept with the help of checks. To use the fuse in the composition of the push munition was used T-shaped check. To install the "stretch" was required to use the P-shaped check. When preparing the fuse for use, the sapper had to insert a special pin into the hole of the firing pin, pull the firing pin out and fix it with a check. At the bottom of the fuse, a standard MD-5 fuse and a detonator No. 8 were attached.

It should be noted that the first model MUV fuse was dangerous to handle. To extract the checks was enough effort just over 2 kg. For this reason, the miners had to work very carefully, risking blown up on their own ammunition. Due to these problems, the fuse MUV-2 was later created. He received an elongated body with a temporary fuse placed in an additional tube. The new fuse differed from the basic version by the presence of safety checks, which made it possible to transport it in the cocked state. The time fuse consisted of a soft metal rod and a wire loop. The loop was attached to the shank of the firing pin, inside it there was a rod. After the mine was installed, a safety check was removed, as a result of which the wire loop fell onto a metal rod. Within a few minutes, the wire cut the spring under the action of a spring, after which the fuse was only held by the combat check.

Fuse scheme MUV-3

Later, the fuses MUV-3 and MUV-4 were developed, which were modified versions of the MUV-2 with a temporary fuse. Mines PMD-6 could be equipped with various fuses available in the engineering units. It is noteworthy that the fuses series MUV used for a long time. Production of products MUV-4 lasted until the seventies of the last century.

The PMD-6 mine cover was box-shaped. A vertical slot was provided in its front wall. It was assumed that when closed, the cover with its front wall would rest on the fuse's check. The axis in the back of the case allowed the lid to swing freely and when pressed with the necessary force to squeeze the pin.

PMD-6 anti-personnel mines with the first model MUV fuses were dangerous enough for sappers. Be careful when installing this weapon. In addition, over time, the original method of cocking mines appeared with a significant reduction in the probability of damage to the miner. In this case, a stud tied to a cord several meters long was put on the shank of the installed miner of the installed mine. On the hairpin down cover. After that, it was possible to disguise the mine, and then, having retired to a safe distance, gently pull the pin. If excessive sensitivity of the fuse and led to an explosion, then the sappers remained intact and unharmed.

For the enemy, the PMD-6 mines were no less dangerous than for the miners. Even the “tightest” instances of MUV fuses were triggered when pressed with a force of no more than 15-20 kg. It was enough to undermine a person’s foot or vehicle wheel. In addition, some mines could explode from the pressure exerted by demining dogs.

Most anti-personnel mines from World War II were equipped with an explosive charge weighing about 200-250. This amount of TNT, pentrite, melinite or French mixture was enough to permanently disable or even kill an enemy fighter. Exploding directly under the enemy's foot, mine PMD-6 inflicted severe damage to the limb, up to traumatic amputation. The blast wave and shell fragments (in the case of some modifications) had an additional effect on the enemy. In case of late first aid, the victim was doomed. Death came from great blood loss and pain shock.

Mines PMD-6 in a wooden case could be installed in the ground and on the ground, in the snow, etc. The service life was limited only by the time of softening and decomposition of the hull. Usually mines of this model could retain their properties for several months. A curious feature of these mines was the fact that the destruction of the hull did not make them safer. Sufficiently sensitive fuses of the MUV family did not impose special requirements on the strength of the hull.

PMD-6 products were not equipped with anti-handling devices. However, the sensitive fuse did not allow enemy sappers to disarm such mines. Clearing minefields with PMD-6 mines could only be carried out by detonating detected ammunition. Manually neutralize such mines forbidden by all instructions. Thus, the lack of special anti-slack devices was compensated by the design of the fuse. It is also necessary to note the possibility of installing anti-personnel mines together with mine-traps, which further complicated the work of enemy sappers.

"Anti-personnel mines, wooden" were delivered to the troops disassembled. Empty enclosures were packed in wooden boxes of 100 pieces. Explosive checkers and fuses were supplied in separate containers. Shells were equipped with checkers already in parts, before the sappers went to mining. The fuses were installed directly during the laying of mines.

PMD-6M

The PMD-6 anti-personnel mine was extremely simple and could be produced in large quantities. However, the used MVU fuses were too sensitive and thus significantly complicated the work of the sappers. To preserve the life and health of the personnel of the engineering units, a modification was developed under the name PMD-6M.

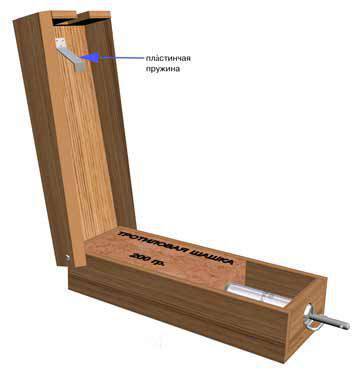

The PMD-6M product was designed with the need to reduce the sensitivity of the target sensor. The development of a new fuse was inexpedient, which was why it was decided to refine the design of the mine itself. In this case, the Soviet gunsmiths managed to achieve the goal by introducing into the design of the ammunition only one detail. The actuation force was increased by adding a special leaf spring.

The construction of mines PMD-6M. Figure Saper.etel.ru

On the inside surface of the lid of the PMD-6M mine, a small metal plate of a special shape was attached above the fuse. With the lid closed, it rested against the fuse body. It was assumed that by pressing the mine cover the spring will create a certain resistance, thanks to which the force of the ammunition will increase. To undermine PMD-6M mines, pressure was required with a force of at least 6-8 kg.

The remaining structural elements, components, etc. remained the same. The combat qualities of the product have not changed either. In fact, PMD-6M was a basic PMD-6 with a small spring under the cover.

According to some reports, mine PMD-6M has not yet been decommissioned. Such ammunition, having an extremely simple design, can be manufactured at any enterprise or even in field workshops. At the same time, mines have rather high characteristics and do a good job with their tasks.

PMD-6 in the metal case

According to some reports, by the end of 1941, some enterprises of the Soviet Union had mastered the production of anti-personnel mines in the new building. After the war, similar weapons were found in the vicinity of Sevastopol, which could be evidence of the production of such mines in the besieged city.

The overall architecture of the mines in the metal case remained the same. However, some changes have been made. Thus, the explosive charge was held in its place by a special metal loop installed in front of it. In addition, a tube in which the fuse was located was attached to a hole in the front wall of the case. Due to the use of a relatively thin metal (roofing iron or tin) instead of fairly thick boards, it was possible to slightly reduce the size of the ammunition. The length of metal PMD-6 did not exceed 16 cm, width - 5-5,5 cm, height - not more than 4-4,5 cm. The total weight of the ammunition was 450-500 g.

Mines PMD-6 in a metal case were a necessary measure. Apparently, during the defense of Sevastopol, local enterprises did not have the desired resources, including boards. The result was the appearance of weapons with a body made of tin or roofing gland.

According to its characteristics, PMD-6 mines in a metal casing obviously did not differ much from other products of the family. The 200 gram explosive bomb is guaranteed to hit the enemy unit. In addition, the effect of the blast wave could be enhanced by shards of the metal body. However, due to the use of relatively thin metal parts, the fragmentation of the mines was small.

“Slate mine arr. 1942 of the Year

In the summer of 1942, the production of another anti-personnel mine on the basis of PMD-6 began. A new version of the ammunition was developed, the production of which could involve the cement industry enterprises. As the material for the body was offered the usual slate. An interesting fact is that mines with slate hulls did not receive their own designation. Until the very end of operation, they were designated as “Slate mines arr. 1942 of the Year.

Anti-personnel mines in slate cases had a length of about 17 cm, width about 7 cm and a height of no more than 4-4,5 cm. The total weight of such ammunition reached 500 g. From other products of the Slate mine arr. 1942 r. "Differed only in body. All other components remained the same. 200-gram checkers and fuses of the MCU line were placed in the body.

In terms of combat qualities, mines with a slate case did not differ from other ammunition, primarily from weapons in wooden cases. There was a slight advantage over the base PMD-6. Unlike wood, slate did not rot and did not soften with time. Thus, the service life of the new weapon was significantly increased. However, the slate hulls were too fragile. Despite all the precautions, a large number of such products cracked during transportation.

“Slate mines arr. 1942 g. ”Were produced until the second half of 1944. The manufacture of such weapons was curtailed due to the improvement of the situation at the front and the restoration of the potential of the industry. Now it is possible to produce mines in wooden hulls that meet the requirements for strength.

PMD-6f

Resource problems also affected the supply of explosives. Due to the lack of the required amount of TNT, anti-personnel mines often had to be equipped with other types of explosives. Already in 1941, ammonium nitrate and the like went into action. explosives. For the use of such charges had to develop another version of the mine called PMD-6f.

In the name of the new modification was reflected its main feature. The letter "F" means "Flacon". To protect explosives from moisture, it was suggested that they be placed in a glass vial. Especially for PMD-6f mines, production of rectangular glass bottles was launched, the dimensions of which corresponded to the size of the internal cavity of the base mine hull. In addition, a special cork was produced, consisting of two tubes of different diameters with a sealed bottom.

When making mines, an explosive charge of up to 150-200 g was placed in the bottle, depending on the type of explosive. The bottle was sealed with a cork. Glass parts assembly should be installed in the case. The internal dimensions of the tubular plug corresponded to the dimensions of the MVU fuses. The principle of operation of mine PMD-6f remained the same.

A glass bottle made it possible to protect the explosive charge from moisture and thus preserve it for a sufficiently long time. The service life of PMD-6f mines reached several months. Moreover, the service life was mainly limited by the capabilities of the case and the fuse. For some time, decomposed the wooden case. Metal parts were subject to corrosion. If the glass bottle was properly sealed, the explosive charge could be the most enduring component of a mine.

In terms of combat qualities, PMD-6f mines could differ significantly from basic PMD-6 mines. The destructive effect of such mines depended on the type of explosive used. The effect of the weapon could be enhanced by the fragments of a glass bottle. Nevertheless, the glass during an explosion is usually broken up into small pieces or dust, as a result of which such “striking elements” are unlikely to have a serious impact on the target.

***

The anti-personnel mines of the pressure action of the PMD-6 family were produced and actively used until the end of World War II. Despite the simplicity of the design, such a weapon made it possible to quickly and easily create a mine-explosive barrier in a dangerous direction. A useful feature was the relatively high sensitivity of the fuses of the MUV series. Complicating the work of the miners, this feature of PMD-6 mines almost completely excluded the possibility of demining and making passes in minefields.

The simplicity of the design affected the production volumes. According to various sources, at least several million PMD-6 mines of various modifications were produced. Most of these weapons were used for their intended purpose.

It must be admitted that the mine PMD-6 had a very high modernization potential. The initially simple design allowed the use of various materials and components. As a result, any manufacturer could use the available resources. This feature of mines led to the appearance of products in wooden and metal cases. Thanks to the glass bottle, almost all suitable explosives restrictions were eliminated.

Thus, the simplest Soviet anti-personnel mine since the Great Patriotic War, has become at least one of the most successful developments in this area. Numerous advantages outweighed the existing shortcomings and allowed the engineering units to make extensive use of the PMD-6 mines. Mines of this series, perhaps, can be put on a par with other outstanding examples of weapons and equipment that brought victory.

On the materials of the sites:

http://saper.etel.ru/

http://lexpev.nl/

http://saperka.ru/

http://eragun.org/

http://snariad.ru/

http://weaponplace.ru/

Information