The state-owned company in the defense industry is the Norwegian experience. The Kongsberg Gruppen evolution is a great example for Russia

The decline in the state's ability to finance defense programs will present defense companies with the need to significantly increase production efficiency, diversify production programs, as well as attract private investment and, consequently, enter an IPO. Simply put, we need a transition to development models typical of companies in the military-industrial complex of Western countries. Since there is no talk of the complete privatization of state corporations in the Russian defense industry complex, it would be advisable to first of all turn to the experience of functioning of companies that remain in state ownership. I would like to acquaint readers with one such company - the Norwegian Kongsberg Gruppen. Despite the many differences between the Norwegian and Russian economies, they are related by a significant dependence on oil rent, which in general has a negative impact on the efficiency of the manufacturing industry. And Kongsberg Gruppen is a Norwegian Rostec, a state-owned company that conducts many production programs that are often unrelated to each other. At the same time, the defense division of Kongsberg Defense & Aerospace AS is a modern effective company with strong positions in a number of market niches, even in the global market.

History parent company

Kongsberg Defense & Aerospace AS is a subsidiary of the Norwegian concern Kongsberg Gruppen (it owns one hundred percent of the shares of Kongsberg Defense & Aerospace AS). The concern itself traces its history back to the Kongsberg Vaabenfabrik company founded in 1814 (literally “Armory Kongsberg factory "). It got its name according to its location - the small mining town of Kongsberg (Kongsberg of Buskerud province in southern Norway). Founded in 1624, Kongsberg was for a long time the main center for silver ore mining in Norway (there was also a mint), but after the depletion of its reserves at the beginning of the 1814th century, the kingdom government decided to reorient it to a weapons manufacturing center. Throughout the 1905th century, the Kongsberg factory produced small arms for the small Norwegian army (from 1886 to 1892, Norway was in union with Sweden and the Swedes bore the brunt of the defense of the union). The fame at the Kongsberg factory was brought about by the activities of its director and weapons engineer, Ole Krag. In collaboration with the factory gunsmith Eric Jorgensen, he managed to develop and present in 1894 one of the most successful models of a shop-mounted rifle with a longitudinally-sliding bolt. At the end of the 1904th century, the Krag - Jorgensen rifle entered service with the armies of Norway and Denmark; these rifles were also supplied in significant quantities to arm the army of the Republic of South Africa (Transvaal) and earned an excellent reputation for accurate and convenient weapons during the Boer Wars. The greatest export success for the Krag - Jorgensen rifle came in 1903, when she won the competition for the main infantry weapon for the American army. About half a million of these rifles were manufactured under license from the Springfield Armory in Massachusetts between 1903 and 1905. Until 1914 (adopting the MXNUMX Springfield), the Norwegian rifle was the main infantry weapon of the US Army. After Norway gained independence in XNUMX, Kongsberg Vaabenfabrik remained the country's main arms factory. During the Second World War and the German occupation, the factory continued to produce Krag - Jorgensen rifles, as well as (under license) Colt MXNUMX pistols, which were used by the militarized wing (Hirden) of the pro-Nazi party of Quisling.

The present heyday for Kongsberg Vaabenfabrik began in 50-s after the formation of NATO (Norway was among the founding members of the alliance in 1949-m) and the beginning of the implementation of the Marshall Plan. Since the factory in Kongsberg was among the few any significant industrial enterprises in the country, whose main source of income remained fishing and whaling, it was chosen as one of the locomotives of industrial development in Norway. An important factor was the discovery of oil fields in the North Sea in the 60s. The Kongsberg Vaabenfabrik shipbuilding division in Horten became one of the main suppliers (along with other state-owned companies of Norway - Kv Aner and Aker) of oil-producing offshore platforms, and the head company in Kongsberg was a supplier of mining and pumping equipment for the oil-producing (and later gas-producing) industry of the country.

The present heyday for Kongsberg Vaabenfabrik began in 50-s after the formation of NATO (Norway was among the founding members of the alliance in 1949-m) and the beginning of the implementation of the Marshall Plan. Since the factory in Kongsberg was among the few any significant industrial enterprises in the country, whose main source of income remained fishing and whaling, it was chosen as one of the locomotives of industrial development in Norway. An important factor was the discovery of oil fields in the North Sea in the 60s. The Kongsberg Vaabenfabrik shipbuilding division in Horten became one of the main suppliers (along with other state-owned companies of Norway - Kv Aner and Aker) of oil-producing offshore platforms, and the head company in Kongsberg was a supplier of mining and pumping equipment for the oil-producing (and later gas-producing) industry of the country.Revenues from the supply of equipment for oil production allowed the company to make major investments in the development of production, including the machine tool industry, the shipbuilding industry and even rocket production. The most important success of Kongsberg Vaabenfabrik in the second half of the XX century is connected with rocket science. In 60, the company, jointly with the Norwegian Defense Research Establishment (Forsvarets Forsknings Institutt - FFI), with technical assistance from US and German companies, developed the Penguin anti-ship missile for the Norwegian Navy. Since the use of the radar homing head was considered ineffective in the Scandinavian fjords, the Penguin radar was used for the first time for a rocket weapon of this class to use infrared homing equipment. Initially, the rocket was intended for use with rocket boats and coastal batteries, so it was distinguished by its compact size, which later allowed to use it from helicopters and airplanes. The combination of these factors provided the missile with significant export success - it became the main anti-ship weapon of the short-range action of the NATO countries and was adopted by the US Navy under the designation AGM-119. The launch of the Penguin missiles and the licensed release projects of the American M113 armored personnel carriers were the main production programs of Kongsberg Vaabenfabrik by the end of the Cold War.

However, in general, 80-e years - a difficult period for the company. Affected by the large number of non-core assets, the costs of poor management of the state-owned company, as well as the general stagnation of the Norwegian economy caused by the effects of the so-called Dutch disease (complex consequences of a resource-oriented economy for the manufacturing industries related to rising labor costs, strengthening the national currency, etc.) d.) The penalties imposed as a result of the investigation of the so-called Toshiba-Kongsberg scam were a serious blow to the company. The two companies were convicted of delivering numerical control milling machines to the Soviet Union, which, according to the Americans, were used to manufacture submarine components with reduced noise parameters to bypass the export restrictions in force.

The result was the disbanding of the Kongsberg Vaabenfabrik. Excluded from the company all the assets associated with the production of civilian products. The production of military products was consolidated as part of Norsk Forsvarsteknologi AS. Under this name, it was listed in 1993 on the Oslo Stock Exchange. In total, 50 percent of state-owned assets were sold out (although other Norwegian state-owned companies acquired a significant portion of the assets). In 1995, the company received the modern name Kongsberg Gruppen. Later, the Kongsberg Gruppen absorbed part of the assets sold after the dissolution of Kongsberg Vaabenfabrik, and significantly diversified production due to civilian products.

The structure and current state of the parent company

Kongsberg Gruppen remains a state-owned company. Fifty percent plus a gold share is controlled by the Norwegian Ministry of Trade. In addition, a significant part of the remaining fifty percent belongs to other state-owned companies in Norway. In particular, about seven percent is under the control of the State Insurance Fund (Folketrygdfondet), another eight percent is under the control of the hydropower company Arendals Fossekompani.

The Kongsberg Gruppen business is divided into four main areas.

At the same time, the directions are combined in pairs under the control of two management companies - Kongsberg Defense & Aerospace AS (KDS and KPS) and Kongsberg Maritime (KOGT and KM itself).

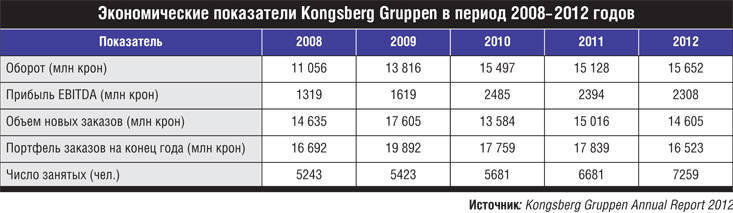

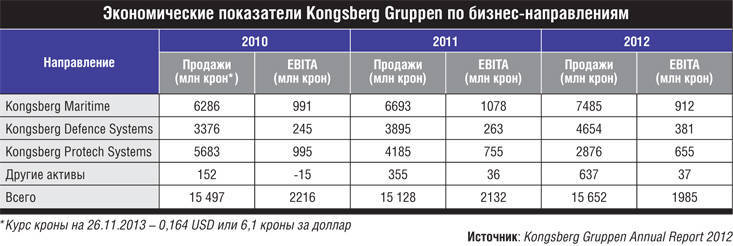

The sectors of production of offshore drilling platforms, gas and oil producing and pumping equipment have been developing most dynamically and consistently in recent years. Advanced Norwegian deepwater drilling technologies are widely in demand abroad. So, Kongsberg Maritime signed a series of contracts for the supply of mining equipment to Brazil and India in 2012. A subsidiary of Kongsberg Maritime China (Shanghai) Ltd. operates in China from 2003, which built and opened in 2012 a plant for the production of shipboard equipment in Zhenjiang County (Jiangsu Province in eastern China). Also in 2012, the Apply Nemo company, which has facilities in Australia, was bought. It was the success of Kongsberg Maritime that allowed the concern to demonstrate stable profit indicators in recent years, although the growth in sales volumes slowed down a bit in 2010 – 2012-m compared to 2006 – 2009's.

In the revenue structure of the Kongsberg Gruppen concern, exports have prevailed since the middle of the 90-s. In 2012, 78 percent of the group's revenue accounted for sales outside Norway. At the same time, the concern’s management seeks to maintain an approximate equality between the revenue shares obtained from sales of military and civilian products. In 2012, civilian products accounted for 56 percent of the Kongsberg Gruppen revenue.

Main production programs of Kongsberg Defense & Aerospace AS

The main program of Kongsberg Defense & Aerospace in the 90st century is the development and production of the Naval Strike Missile (NSM) anti-ship missile to replace the outdated Penguin anti-ship missile. Its development has been underway since the second half of the 2007s. The contract for the supply of NSM missiles for the Norwegian Navy was signed in 2008. Fridtjof Nansen-class frigates and Skjold-class boats will be equipped with them. In addition, like the Penguin anti-ship missile, the missile can be used from coastal installations. In 127, Poland signed a contract worth about $ 2010 million to supply six launchers, as well as missiles and radars to equip one coastal defense battalion. In 38, an additional contract was signed for the supply of 2012 NSM missiles to Poland. In 100, the NSM was adopted by the Norwegian Navy. Technically, it is a two-stage rocket made according to the normal aerodynamic design. Equipped with IR seeker with a database of targets, control on the cruising section is carried out by an inertial navigation system with correction according to GPS signals. The declared maximum firing range is 185 nautical miles (125 kilometers), the missile is equipped with a warhead weighing XNUMX kilograms.

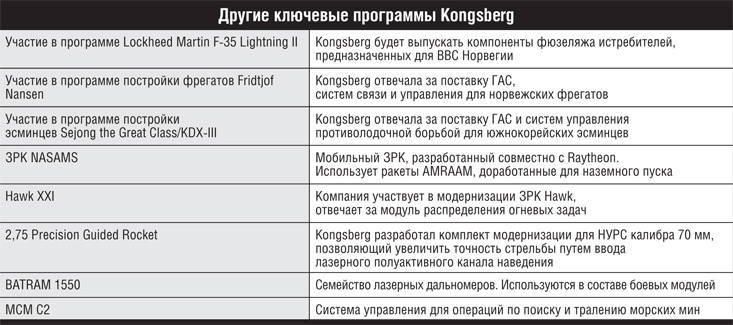

The NSM program was derived from the Joint Strike Missile air-launched anti-ship missile program. It is intended mainly for the armament of F-35A Lightning II fighter jets, which are planning to acquire the Norwegian Air Force (52 units according to the information available). According to the Western media, technical support for the F-35 Lightning II JSM missile launch became a prerequisite for placing an order for the first F-35A for the Norwegian Air Force. According to representatives of the Kongsberg Joint Strike Missile range must reach 200 nautical miles. With the successful development of the programs Naval Strike Missile and Joint Strike Missile, these missiles may well repeat the success of the Penguin RCC. It is worth noting that at the present time, Kongsberg is working on a variant of Naval Strike Missile for equipping submarines.

In addition, Kongsberg is the main supplier of the Norwegian Armed Forces in terms of communication systems, C4ISR, simulators of various types of equipment.

Production Programs Kongsberg Protech Systems

The most famous military products in the world at present are Kongsberg Defense & Aerospace AS, a kind of business card of the concern - the PROTECTOR family of remotely controlled combat modules. They were put into series production in 2001 and over the following years became the main export success of the Kongsberg military unit in the 1997st century. The first prototype of the PROTECTOR combat module was developed jointly by Vinghøg AS (now owned by the German Rheinmetall) and Kongsberg Protech AS in 1999. After signing the first contract for the supply of modules to the Norwegian Army in 2002, Kongsberg bought the rights to the system. A key success for the program came in 151, when the US Army selected the PROTECTOR (designated XM151) for an experimental installation on the Stryker armored personnel carrier. The modules performed well during the campaigns in Iraq and Afghanistan, and soon PROTECTOR under the designation M1126 was officially chosen as the standard armament for the MXNUMX armored personnel carrier (Stryker version for transporting infantry).

The main advantages of the PROTECTOR modules are versatility (they are capable of being installed on various types of equipment, compatible with various on-board equipment, allow you to mount a wide range of weapons - from machine guns rifle caliber 5,56 mm M249 SAW or 7,62 mm M240B to large-caliber M2, 40-mm MK19 automatic grenade launchers) to large-caliber M151, 2-mm MK151 automatic grenade launchers)) reliability and a wide potential for improvement. Thus, in the course of subsequent upgrades, a stabilized version of the M1A312 module was created, and thermal imagers were introduced into the monitoring tools (starting with the M25A307 version). A possible composition of weapons supplemented with large-caliber machine guns XMXNUMX, XNUMX-mm automatic XMXNUMX grenade launcher with guided explosions, anti-tank systems Hellfire and Javelin, non-lethal weapons. PROTECTOR variants were developed, designed for installation on boats and patrol ships, as well as aircraft.

The main export success of the program was the victory in 2007 in the CROWS contest (Common Remotely Operated Weapon Station - “Standard Remote Controlled Weapons Station”). As a result of the series of contracts that followed, Kongsberg received orders for a total of some 11 PROTECTOR modules worth over one billion dollars. In addition to the M690 BTR, the modules are installed on various versions of the MRAP armored vehicles, as well as in the upgrade kit on Tanks M1A2 Abrams. To produce the modules, the company established a subsidiary of Kongsberg Defense Corporation in Johnston, PA. In addition to the US and Norwegian aircraft, PROTECTOR modules are actively purchased by the Swedish Armed Forces (for installation on Sisu Pasi armored personnel carriers, ARCHER self-propelled guns, RG-32M armored vehicles), various heavy wheeled armored personnel carriers Patria AMV and Piranha, etc. Since 2001, Kongsberg has contracted about 17 modules for delivery to the armed forces and other power structures of 000 countries.

Kongsberg - sample for Russia

Kongsberg is a great example of an efficient modern state-owned company. The components of her success are obvious. Firstly, its transparency, openness to public control. Secondly, a clear niche strategy. Anti-ship missiles and remote-controlled combat modules are the business cards of the concern on the global arms market. Only two key niches, but in them the Norwegians are able to circumvent even the American military industrial complex. Thirdly, an all-out increase in production efficiency, a strategy based on the application of technologies and methods of lean manufacturing. Fourth, rely on innovation. In the case of remote-controlled combat modules, the engineers and the management of the Norwegian company managed to create a new market segment, to prove the viability of potential customers. At the same time, the company does not rely on any government subsidies or preferential loans. State participation is reduced to placing orders for the armed forces and other law enforcement agencies in Norway, as well as the involvement of Kongsberg in the implementation of offset parts of import procurement programs. So, Kongsberg enterprises will receive orders under the Lockheed Martin F-35 Lightning II Norwegian fighter program. Moreover, the participation of Norwegian companies was a necessary condition for the state to join the F-35 program. Thanks to this policy, Norway, a country with excellent relations with the United States, large revenues from the export of hydrocarbons and quite capable of doing without arms imports, has a quite decent military-industrial complex. In the next few years, the Russian defense industry will have to undergo the same evolution in order not to become a burden for the national economy.

Information