Pully Kacheeva - the future of ammunition

Speaking about the development of weapons, for some reason they always forget about ammunition to them, and in fact the cartridge has always been the basis for any weapon and determined its basic parameters. Of course, the most well-developed cartridge will not be able to show good results when using a barrel made of a water pipe, but an ideal weapon will show far from the best results if you charge it with poor quality cartridges. It turns out that modern firearms already, if they did not reach their ceiling, came very close to it, but for some reason they do not improve the cartridges - although the weapon is being developed for a cartridge.

Speaking about the development of weapons, for some reason they always forget about ammunition to them, and in fact the cartridge has always been the basis for any weapon and determined its basic parameters. Of course, the most well-developed cartridge will not be able to show good results when using a barrel made of a water pipe, but an ideal weapon will show far from the best results if you charge it with poor quality cartridges. It turns out that modern firearms already, if they did not reach their ceiling, came very close to it, but for some reason they do not improve the cartridges - although the weapon is being developed for a cartridge.Of course, the cartridges are developing too, but for some reason most manufacturers rest on classic designs. Ideally, they strive to create a cartridge that can be used in the existing and common samples, with minimal adaptation of these samples. Nevertheless, I believe that the creation of new, more advanced ammunition can significantly advance the effectiveness of handguns and that any costs are justified.

Naturally, the work on the development of new ammunition is underway, but since everything depends on the financial issue, these works are more likely a reserve for the future, and not for mass production — they are not yet ready to lay out money for higher characteristics of ammunition.

Naturally, the work on the development of new ammunition is underway, but since everything depends on the financial issue, these works are more likely a reserve for the future, and not for mass production — they are not yet ready to lay out money for higher characteristics of ammunition.Since the cartridge can be divided into four components (primer, cartridge case, powder charge and bullet), the designers work on them. The most obvious option to improve the performance of the cartridge is to work with the powder charge, since it is his gases that, when burned, set the speed of the bullet, and the higher the speed, the greater the energy of the projectile. Various variations with gunpowder have already given their maximum results, because in the first half of the twentieth century, work began on the replacement of gunpowder. They didn’t shove them into the liner and didn’t force them to burn ... There were even such exotic options, where instead of gunpowder two gases were used that ignited when combined, but, as we see, it didn’t bring any special results and we use the same powder. With a cartridge cartridge cap, everything is ambiguous. On the one hand, this is the simplest device, the main task of which is to ignite the powder, so that it doesn’t seem to affect the characteristics of the ammunition. But this is only when viewed superficially. We can give the following example of how the capsule can affect the characteristics of an ammunition. If two tracks are made of gunpowder on a flat surface, one is set on fire from one side and the other from the middle, it is obvious which of them will burn faster. Accordingly, the faster the whole thing burns, the faster the powder gases will form, pumping pressure in the barrel, on which all the same speed of the bullet directly depends. True, in the cartridge itself this advantage will not be as significant as can be seen by removing the powder charge from it and striking the primer. So a really significant result will be only with those cartridges where the powder charge is large enough, that is, in cartridges with a large volume of the sleeve or if the sleeve is thin and long. Variations with a sleeve are basically attempts to make the cartridges cheaper to produce. At the moment, the use of polymers can be considered the only justified option. The options for caseless cartridges do not have the advantages over similar ammunition with a sleeve, they require weapons of non-standard design. At the same time, they are cheaper and make it possible to reduce the weight of cartridges, which is important, especially for machine guns, or rather machine gunners, only the cost of new weapons for these munitions covers these positive points.

So only the bullet remains, but ideally, of course, the entire structure should be completely modernized to maximize the performance of the ammunition. Actually on the bullets and work mainly all large weapon companies, changing the materials of the bullet, applying a coating of molybdenum and so on, but, practically, without changing the shape of the bullet.

But not only large weapon companies are busy working on such projects, and we have not translated yet and we have designers who are able to make a new ammunition alone, surpassing existing ones in their characteristics. So, Vasily Ivanovich Kacheev not only was able to improve the performance of bullets, and accordingly ammunition, but also developed a different production technology, which is simpler and more accurate than what Western designers offer in similar projects.

But not only large weapon companies are busy working on such projects, and we have not translated yet and we have designers who are able to make a new ammunition alone, surpassing existing ones in their characteristics. So, Vasily Ivanovich Kacheev not only was able to improve the performance of bullets, and accordingly ammunition, but also developed a different production technology, which is simpler and more accurate than what Western designers offer in similar projects.The main idea, which is used in new ammunition, is to reduce the friction force of the bullet surface on the bore, as well as on the air during its flight. The idea is not new, goes back in the fifties of the last century, it was then that the first studies on this issue began, which are still ongoing and quite productive. Known KTW bullet coated with Teflon. Nevertheless, almost everything depends on the production technology of Teflon coating, which is quite complex and expensive, because such ammunition, although mass-produced, is quite expensive. It is with the increase in bullet speed that all those bikes that were widespread in the last century are connected, that a bullet with Teflon coating can penetrate any body armor. In fact, the armor-piercing properties of a bullet do increase, due to an increase in its speed, so there is some truth in this, but this is just any body armor, any bullet is of course a figment.

Consider the options of ammunition, which offers Vasily Ivanovich, as well as, if possible, comparable to ammunition having a Krupp form bullets (Krupp) sample 1881 of the year.

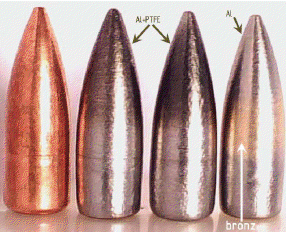

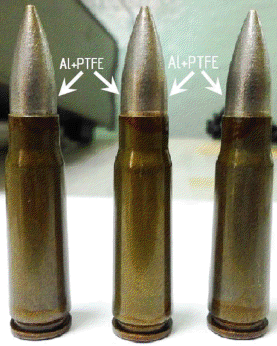

First of all, consider the 7,62 × 39mm hunting cartridges of gross production. After deposition of a two-layer coating on gross bullets containing an aluminum alloy underlayer, and on top of it a layer of fluoroplastic-4, which is also known under the trademark Teflon. Further, the designation Al + PTFE for such a coating will be used. The result of the shooting of such experienced hunting cartridges was obtained not the most impressive in accuracy - it grew by only 5,7%. This, of course, is also a result, but it will not be enough. Although we should not forget that the cartridges of gross production, and some companies, when the result of a three percent improvement in accuracy, scream at the top of their heads about their uniqueness and genius.

First of all, consider the 7,62 × 39mm hunting cartridges of gross production. After deposition of a two-layer coating on gross bullets containing an aluminum alloy underlayer, and on top of it a layer of fluoroplastic-4, which is also known under the trademark Teflon. Further, the designation Al + PTFE for such a coating will be used. The result of the shooting of such experienced hunting cartridges was obtained not the most impressive in accuracy - it grew by only 5,7%. This, of course, is also a result, but it will not be enough. Although we should not forget that the cartridges of gross production, and some companies, when the result of a three percent improvement in accuracy, scream at the top of their heads about their uniqueness and genius.But in an ideal ammunition, not only accuracy is important, but also the time of approach to a moving target. The reduction of this value is quite possible by the Al + PTFE coating. Fluoroplastic-4, in its essence, is used here as a dry lubricant, helping the pool to pass the bore of the weapon with less friction and, consequently, with greater speed. The air resistance in flight of the bullet can also not be discounted, since this factor seriously affects the same speed of the bullet (flight time).

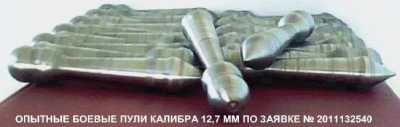

Next, the designer suggested for large-caliber sniper rifles. its version of the bullet, which is recognized by the invention.

Monolithic bullet design V.I. Kacheeva - a combination of balls and transitional volumes of such a shape, which ensure the mixing of the center of gravity to the bullet tip. In addition, the diameter of the head is equal to the caliber (the size of the trunk along the fields). The bullet is centered by the headline strictly along the axis of the barrel bore - thus eliminating the bullet misalignment - the "slanting" of the bullet along the cuts (as the professional arrows say).

The main feature of his bullets Vasily Ivanovich distinguishes not their armor-piercing properties, but the fact that they will be cheaper in production than bullets of classical designs. The designer proposes to apply the well-known technology of cross-wedge rolling in the manufacture of their bullets. It should be noted that the bullets that will be manufactured using the cross-wedge rolling technology have a smaller weight dispersion compared to cores that are machined on automatic lathes, which is especially important for ammunition used in high-precision weapons. The technology was developed at one of the institutes of the National Academy of Sciences of Belarus.

The main feature of his bullets Vasily Ivanovich distinguishes not their armor-piercing properties, but the fact that they will be cheaper in production than bullets of classical designs. The designer proposes to apply the well-known technology of cross-wedge rolling in the manufacture of their bullets. It should be noted that the bullets that will be manufactured using the cross-wedge rolling technology have a smaller weight dispersion compared to cores that are machined on automatic lathes, which is especially important for ammunition used in high-precision weapons. The technology was developed at one of the institutes of the National Academy of Sciences of Belarus.  The technology was tested in the manufacture of steel cores of shell bullets - during the Soviet era. The coating of aluminum and fluoroplast-4 designer also offers a very original patented method - steel bristle brush, which is environmentally friendly - compared with the electrochemical method (electroplating).

The technology was tested in the manufacture of steel cores of shell bullets - during the Soviet era. The coating of aluminum and fluoroplast-4 designer also offers a very original patented method - steel bristle brush, which is environmentally friendly - compared with the electrochemical method (electroplating). Plus, the speed of applying these coatings increases many times, which reduces the cost of bullets. The Al + PTFE coating made using this technology is a replacement for either a sub-caliber hunting bullet or a shell on a Krup-shaped bullet of a model 1881 of the year. Thus, we get more “fast”, cheap and accurate bullets than those that are now common.

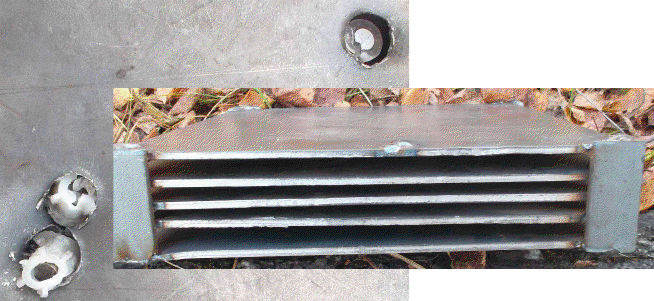

We will consider this the first introductory article. In the following, we will try to disassemble the results of the shooting below of the depicted experienced hunting cartridge containing a hardened bullet with an Al + PTFE coating and a composite powder charge of the development of the Ph.D. M.A. Sour - on the plate of the bulletproof vest.

Information