Nuclear technology: when the future is knocking on the door

Compact nuclear plants: the potential is huge

Reactors of significant power, for example VVER-1200, are unlikely to be localized in small countries or in areas where consumers do not have sufficient load. VVER reactors of lower power have a higher cost per unit of power. Compact, low-power reactors that would have good economic performance and be built quickly and easily (for example, in mass production) will be in good demand on the market.

According to the (IAEA) definition, small reactors are those having a power of up to 300 MW and consisting of modules that are manufactured in a factory before delivery and installation on site. Among them are small modular reactors (SMRs).

Now in the world there are already more than 70 projects of compact, multi-purpose reactors of various types and designs. According to estimates from the UK National Nuclear Laboratory, the global market for SMRs by 2035 could reach 65-85 GW and is estimated at £250-400 billion ($300-500 billion).

SMRs can be built to supply electricity to remote areas of the developing world, in the Far North, and in the desert. On their basis it is possible to build factories, oil platforms, army bases, and supply mines.

Floating NPP – “floating” nuclear power plant

And here Rosatom has promising developments - floating nuclear thermal power plants (FNPP). The first nuclear power plant of this type, Akademik Lomonosov, was launched in 2020 in the port of Pevek (Chaunsky district, Chukotka Autonomous Okrug) and in the future will replace the Bilibino NPP. The station consists of a floating power unit (FPU), an onshore site with structures, as well as hydraulic structures that ensure safe parking of the FPU in the water area.

The project has been implemented since 2007. At nominal mode, the Akademik Lomonosov supplies 60 MW of electricity and 50 Gcal/h of heat to the shore. An additional function of the floating nuclear power plant is the desalination of sea water - from 40 to 240 thousand cubic meters of fresh water per day.

RHYTHM-200

RITM-200 is a Russian pressurized water nuclear reactor developed by OKBM im. Afrikantov, made according to a double-circuit scheme. Designed for installation on nuclear icebreakers, floating nuclear power plants produced by ZiO-Podolsk and low-power nuclear power plants. The first power plant with two reactors for the first nuclear icebreaker of Project 22220 type "Arktika" (LK-60Ya) was delivered in 2016. The icebreaker was commissioned in 2020.

RHYTHM-200

US developments

NuScale Modular Reactor

The US Nuclear Regulatory Commission (NRC) announced the completion of the certification process for the first nuclear reactor developed by private company NuScale. The rector is modular, which allows you to assemble blocks from them. Production is carried out using the conveyor method at the factory, from where the reactor, fully ready for operation, is delivered to the customer at the site of operation.

Two versions of the modular mini-reactor have been created, with a capacity of 50 MW and 60 MW. Both installations have a steel body measuring 23 meters long and 4,5 meters wide. The first version is undergoing certification in a configuration of 12 modules, providing a total of approximately 600 MW of electricity. Such a module is capable of producing almost 50 tons of hydrogen fuel per day from water.

NuScale Modular Reactor

eVinci microreactor

Another project is Westinghouse's eVinci microreactor.

eVinci power ranges between 200 kW and 15 MW. They plan to use pellets with uranium enriched to 19,75% as fuel. The fuel campaign lasts 10 years, then the reactor is sent to the manufacturer for reloading.

Westinghouse expects to build the first eVinci in 2024.

China

The ACP-100 reactor (Longxing) is a project being developed by the Chinese corporation CNNC.

Integral modular pressurized water reactor designed on existing PWR technologies using passive safety systems. Electric power is about 100 MW, service life is 60 years, partial reloading is carried out every two years.

Argentina

Other SMR projects in the final stages of construction include the 30 MW(e) CAREM reactor in Argentina.

The CAREM-25 reactor (Central Argentina de Elementos Modulares) is a low-power modular demonstration reactor. The CAREM reactor vessel, with a diameter of 3,2 meters and a height of 11 meters, was manufactured by the Argentine company IMPSA. It houses 12 vertical steam generators that produce superheated steam.

Fuel campaign – 510 eff. days at fifty percent core overload.

Nuclear micropower plants (MPs)

According to the IAEA, MPs represent ultra-compact nuclear power plants that can be immediately assembled at the factory and delivered to the site by one truck.

Such stations must have self-regulating passive safety systems that do not require a large number of maintenance personnel. They can not be tied to the electrical network, can be transported from place to place and used in different conditions.

Power - about 10 MW (e) with a minimum fuel loading period of 10 or more years in a round-the-clock and continuous mode provides electricity to more than 5 homes.

Currently, private companies and research groups in different countries of the world are developing more than a dozen MR projects.

Russia: microreactor projects

Project "Shelf-M"

Rosatom plans to build the world's first 10-megawatt Shelf-M microreactor in Chukotka by 2030. Shelf is being developed by NIKIET.

Project SVET-M

"Gidropress" is developing a fourth-generation reactor for low-power nuclear power plants (LNP) "SVET-M" (Lead-bismuth reactor with natural coolant circulation - modular).

According to the head of the Gidropress department, Sergei Lyakishev, options are being developed in a wide range of electrical power: from 1 to 50 MW. The most developed design is for 10 MW.

The height of the reactor is about 5 m, which allows the reactor to be delivered by any type of transport. The coolant is a eutectic alloy of lead and bismuth. The body is a monoblock in which both the core and steam generators are located. Water enters the housing and superheated steam exits. The reactor operates on natural circulation; there are no pumps in the primary circuit. The housing is not loaded with pressure and has passive cooling of the core.

The lead-bismuth alloy is located in the reactor vessel at atmospheric pressure; it does not chemically interact with either atmospheric air or water.

SVET-M belongs to the fourth generation of safety reactors.

Aurora reactor (USA)

One of the projects nearing completion is the 1,5 MW(e) Aurora fast spectrum reactor, which is being developed by Oklo.

The reactor is designed on the principle of functioning and self-regulation primarily due to natural physical processes, which implies the use of a very small number of moving elements in it - in order to increase safety. It will use reprocessed fuel with high content of low-enriched uranium (HALEU), and the nuclear power plant will be able to operate for decades without the need for refueling.

There is another specific area of AE - for military needs. This direction is reflected in the material on VO: “Option for the military: low-power nuclear power plants.”

Problems of the conventional (open) nuclear fuel cycle: shortage of uranium-235

Most current nuclear power plants operate on thermal (or slow) neutrons using water as a coolant.

The fuel used is uranium-235, which is rarer in nature (less than 1%), which is fissioned under the influence of thermal neutrons. The more common uranium-238 cannot support a chain reaction due to the fact that when it fissions, fewer neutrons will appear with each generation than in the past: the reaction will die out.

A diagram of a typical open nuclear cycle is shown in the following figure:

There is currently a shortage of mined uranium in the world. According to the Red Book 2020 (Red Book, a publication of the Nuclear Energy Agency - NEA - and the IAEA), as of January 1, 2019, uranium mining from mines provided 90% of the world's nuclear energy needs. In 2021, 48,3 thousand tons of uranium were extracted, while the demand of operating nuclear power plants was 62,4 thousand tons (77,4%).

The deficit is covered by uranium from the reserves of the state and companies, through the reprocessing of spent nuclear fuel; low-enriched uranium produced by diluting highly enriched uranium, as well as uranium from re-enriched enrichment tails. Uranium tails - depleted uranium hexafluoride - are a by-product of processing uranium hexafluoride into enriched uranium.

The previously used gas diffusion technology for separating uranium 235 was less efficient compared to the modern gas centrifuge technology. Therefore, up to half of its natural volume remained in the uranium tails.

The IAEA estimates that by 2040, depending on the pace of nuclear energy development, global uranium demand could range from 56 tons of uranium per year in a low demand scenario to 640 tons of uranium per year in a high demand scenario.

As of January 1, 2019, proven reserves of uranium worldwide amount to 8 tons. Conclusion: in the foreseeable future, the world's uranium reserves will be sufficient for the development of global nuclear energy.

At the same time, the revival of nuclear energy has now encountered the problem of a local uranium shortage. In 2023, uranium prices jumped 30% to around $62 per pound, making uranium an attractive asset. As profinance.ru writes:

Waste processing and mixed uranium-plutonium fuel (MOX fuel)

Spent nuclear fuel (SNF) accumulates in special storage facilities for decades and is only partially reprocessed.

Only a few countries in the world reprocess spent fuel (RAW) on an industrial scale - Russia, France, Great Britain, India, and a number of countries have mastered these technologies.

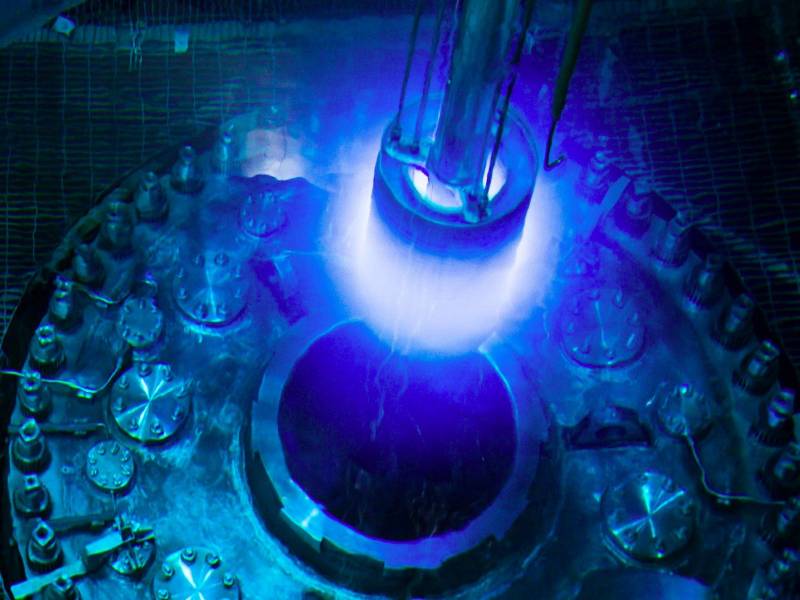

Mayak SNF reprocessing plant (Russia)

The main task of nuclear energy is to use uranium-238, which makes up more than 99% of natural uranium, in the fuel cycle through the production of plutonium from it.

Fast neutron reactors are designed for this, where, in addition to uranium-235, uranium-238 can also be used, which, when fissioned, turns into a fissile isotope of plutonium, suitable as fuel for both thermal and fast reactors. But there are few such reactors in the world (see below).

Scheme of formation of plutonium 239 from uranium 238

Another way to use uranium-238 is MOX fuel (Mixed-Oxide fuel), which no longer uses scarce uranium-235. It consists of a mixture of several types of oxides of fissile materials, mainly a mixture of oxides of plutonium and natural uranium, enriched uranium or depleted uranium - (U, Pu) O2. The PuO2 content can vary from 1,5 wt. % up to 25–30 wt. % depending on the type of nuclear reactor.

The raw material for the production of MOX fuel pellets is plutonium dioxide, obtained during the processing of spent nuclear fuel (irradiated nuclear fuel), and uranium-238 oxide, produced from secondary “tails” of enrichment production.

MOX can be used as an additional fuel for conventional light water thermal neutron reactors, but its use is more effective in fast neutron reactors (BN), in which Russia has an undisputed lead.

MOX ensures the “burning” of plutonium and spent fuel waste, the use of nuclear waste and the expansion of the fuel base (saving uranium ore).

In September 2022, Rosatom tested innovative MOX fuel at power unit No. 4 of the Beloyarsk NPP with the BN-800 reactor, reaching 100 percent capacity.

At the end of 2022, experimental fuel assemblies for the BN-600 reactor with fuel rods of the BN-1200 type were manufactured and accepted at the Siberian Chemical Combine in Seversk (JSC SCC). TVELs contain mixed dense nitride uranium-plutonium fuel (SNUP-fuel), and they are planned to be tested in 2023 at the BN-600 reactor at the Beloyarsk NPP.

France, to limit the accumulation of waste, uses spent fuel reprocessing and produces MOX fuel assemblies, but this fuel is significantly more expensive than fuel made from enriched natural uranium.

SNF reprocessing plant, France

Development of pressurized water reactor technology: VVER-S and VVER-SKD (Rosatom)

Among the disadvantages of nuclear power plants is lower efficiency. For the VVER-1200 project, the efficiency is 36% (NPP-2006 project). At the same time, the French EPR-1600 (European Pressurized Reactor) has an efficiency of 37%, and the Chinese reactor of the 4th generation SHIDAO BAY (see below) has an efficiency of 44%.

As atomicexpert writes:

Rosatom is developing new VVER projects:

1. “VVER-S” – reactor with spectral regulation (developed by OKB “Gidropress”). Neutron losses in water are largely determined by the ratio of the volume occupied by water to the volume occupied by uranium, which is called the water-uranium ratio. Spectral regulation (SR) is the abandonment of liquid boron regulation and control of the reactor by changing the water-uranium ratio in the core by introducing and removing displacers there during the fuel campaign.

SR makes it possible to create a harder neutron spectrum at the beginning of the campaign and spend neutrons, which are absorbed in conventional VVERs, on the production of new fissile materials. In VVER-S, instead of being absorbed in boric acid, excess neutrons are absorbed in uranium-238, resulting in plutonium, which is used as a new fuel, which is a step towards creating a “closed cycle”. As the core burns out, the displacers are removed and replaced by water. At the end of the fuel campaign, VVER-S operates like a regular VVER.

VVER-S can operate in both open and closed fuel cycles. Currently, in light water reactors, no more than 50% MOX fuel can be loaded into the core. CP allows a light water reactor to be loaded with a core consisting entirely of MOX fuel.

The world's first VVER-S will be built in Russia beyond the Arctic Circle not far from the existing Kola Nuclear Power Plant by 2035. This technology can reduce the cost of constructing nuclear power plants by 15% and fuel consumption by 30%. The reactor can be fully loaded with MOX fuel.

2. An equally ambitious project is the creation of VVERs with supercritical coolant pressure parameters in the primary circuit - these are VVER-SKD, classified as 4th generation reactors.

Among the advantages: higher burnup coefficient, optimization of natural uranium consumption; increase in efficiency up to 44−45%; an increase in heating in the core from 280 to 540 °C and, as a consequence, a decrease in coolant flow; reduction of specific capital costs for the construction of a power unit.

The main problem is to find suitable materials and technical solutions. The reactor can also be fully loaded with MOX fuel. It is planned to create a low-power SKD reactor. Due to space limitations, a review of the Russian nuclear program is made in a separate material.

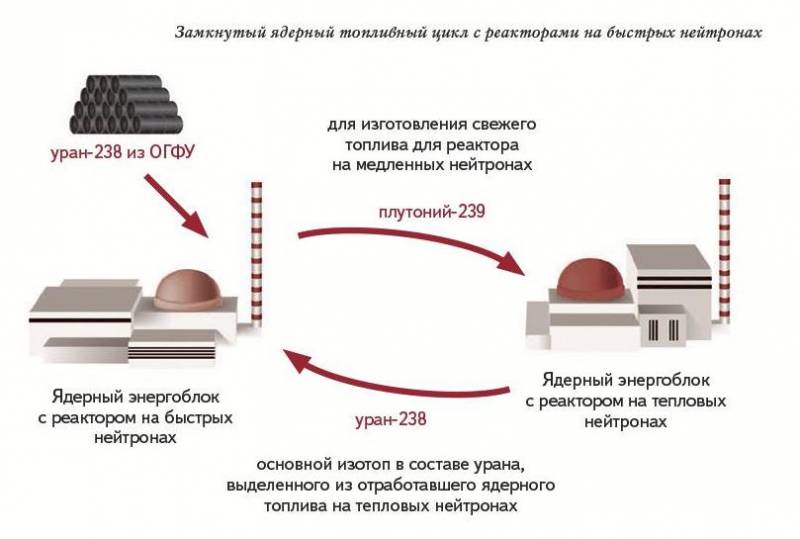

Two-component nuclear power with a closed nuclear fuel cycle (CNFC)

According to the Rosatom concept, two-component nuclear power, combined with a closed nuclear fuel cycle (CNFC), will provide a fundamental solution to two main nuclear energy problems: handling spent nuclear fuel, radioactive waste (RAW) and increasing the efficiency of use of natural uranium.

To solve this problem, Rosatom plans to create an energy complex of two types of reactors: water-cooled reactors with spectral control (VVER-S) and fast neutrons (BN): pilot-demonstration (BREST-OD-300) and power (two options are being developed: BN‑1200M with sodium coolant and BR‑1200 with lead coolant).

The use of VVER-S will ensure savings in natural uranium during the operation of nuclear power plants, and BN reactors will make it possible to effectively use spent fuel, reprocess it and produce new fuel (MOX, SNUP).

The task of creating a CNFC is solved by our fast neutron reactor projects at the Beloyarsk NPP and the Breakthrough project, which connects two types of thermal and fast neutron reactors (BN) in one energy complex.

Project "Breakthrough"

On the basis of the Siberian Chemical Combine, an Experimental Demonstration Energy Complex is being built, where a fuel fabrication and processing plant and a unique innovative fast neutron reactor with lead coolant BREST-OD-300 will be built. The BN-1200 sodium fast neutron reactor is also being developed.

But all these projects require the development of new, extremely complex technical and design solutions.

Closed fuel cycle – CNFC (ideals and reality)

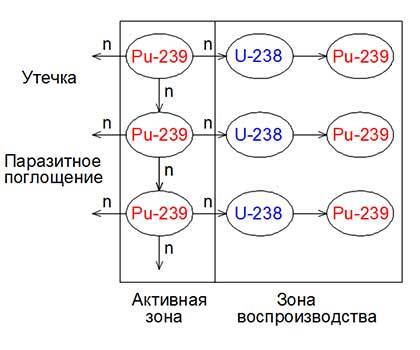

Reproduction of nuclear fuel in the CNFC can only be organized in a fast neutron reactor, where uranium-238 can be used.

If plutonium-239 is loaded into the reactor core and surrounded by a breeding zone of uranium-238, then when neutrons flying from the core are captured, uranium-238 turns into “new” plutonium-239.

Scheme for the reproduction of plutonium-239 from uranium-238 in reactors at BN, Source: proatom.ru

But everything is not so simple here.

Water, which is used as a coolant in conventional reactors, is not suitable here - since it slows down neutrons, and fast particles are needed.

A substance that would be liquid at the temperatures existing in the reactor and would not absorb or moderate neutrons could be liquid sodium, which is usually used in BN reactors as a coolant. But the use of sodium greatly complicates the technology, makes construction more expensive, and the problem of nuclear proliferation arises. weapons due to the production of plutonium.

To close the cycle, a process of processing and manufacturing new fuel assemblies from highly radioactive spent fuel assemblies is necessary, which is quite expensive and complex (requires remote, automated and specialized processing).

According to a number of experts (Professor I. N. Ostretsov, S. V. Korovkin, JSC Atomenergoproekt, etc.), this scheme has a number of difficulties. To obtain plutonium, it is also needed in significant quantities in the initial assembly, and the rate of “generation” of new plutonium is quite low. Consequently, the production of plutonium is limited by its reserves, which can be obtained either from the reprocessing of spent nuclear fuel or from weapons stockpiles.

Due to difficulties, almost everywhere where breeder reactors (breeders) were built, they were either closed or not built.

Russia is the only country in the world in which two industrial fast neutron reactors with sodium coolant are operating at once - these are the BN-600 and BN-800 reactors at the Beloyarsk NPP. However, the operation of these stations, due to the mentioned technical difficulties, was far from simple.

In addition, an innovative fast neutron reactor with lead coolant, BREST-OD-300, is being developed.

So why all this?

Russia can create such a reactor by developing innovative technologies and being ahead of many countries, but it is not a fact that it will be able to become widespread.

However, China is also following the same path of “developing innovations”.

Xiapu NPP

Xiapu Nuclear Power Plant is a nuclear power plant being built in Xiapu County, Fujian Province, China, on Changbiao Island as part of China's plan to achieve a closed nuclear fuel cycle. This is a demonstration project of the China National Nuclear Corporation (CNNC) Generation IV reactor.

This nuclear power plant is also known by the name of its reactor as CFR-600 (China Fast Reactor 600). “China Fast Reactor 600” is a pool-type BN nuclear reactor with sodium coolant. Construction of the reactor began at the end of 2017. The reactor power will be 1 MW – thermal and 500 MW – electrical. The fuel will be supplied by TVEL, a subsidiary of Rosatom, in accordance with an agreement signed in 600.

At the same site, construction of a 2020 MW CFR-600 reactor began in December 600, and four 4 MW CAP1000 reactors are proposed to be built.

Shidaowan NPP – innovative 4th generation reactor

The Shidaowan NPP, the latest development of Chinese nuclear power plants, should become the world's first fourth-generation nuclear power plant. In 2021, the first SHIDAO BAY power unit was connected to the grid. The unit operates two unique reactors and one turbine. Gas-cooled reactors HTR-PM are used here (in our classification HTGR - high-temperature gas-cooled reactors). For the first time in the world, helium is used as a coolant, and graphite is used as a moderator.

Fuel - loading of 245 balls - spherical fuel rods with a diameter of 000 cm made of graphite interspersed with ceramic uranium fuel, containing 6 g of fuel enriched to 7%. The fuel is capable of storing radioactive contents at temperatures up to 8,5 ° C, which is higher than emergency values .

This is an experimental unit, the total power of the turbine that powers the two reactors is small - 210 MW. The main advantage of this technology is the high coolant temperature, about 750 degrees, which makes it possible to obtain a higher efficiency of the power unit, about 44%. The unit can be used as a heat source for city heating, water desalination or for hydrogen production.

In November 2021, China announced the completion of a chain reaction test in the second reactor of the Shidaowan power plant, and in December 2022, both reactors were brought to full 240-megawatt power.

As stated by Lu Hua Kuan, Chairman of Huaneng Nuclear Research Institute:

In his opinion, these reactors have good export potential for countries and regions with a shortage of fresh water and to countries where local power systems are not suitable for nuclear plants with a capacity of more than 1 MW.

In addition to the HTR-PM, China is offering a larger version, the HTR-PM600, with a single 650 MW turbine powered by six small reactors.

The disadvantages of HTGR, according to atomicexpert, include the volume of spent fuel, which is an order of magnitude larger than that of light water reactors, while the reprocessing of spent fuel is difficult: industrial technologies for separating the moderator from the cores and extracting the fissile material have not been tested. The reactor contains a large volume of irradiated graphite, the disposal methods for which are quite complex.

A general overview of the state of nuclear energy in the world and its prospects is given in the article on VO “Fukushima and Chernobyl, wind turbines and solar panels? Forget: the world is waiting for a nuclear energy renaissance.”

The situation in the electric power industry in general and the problems of developing renewable energy sources (RES) are discussed in the article on VO “Clean Energy” as a geostrategy: will wind turbines and solar panels save the climate.”

Information