Samara Region: OJSC Kuznetsov

01. Passage factory. From 1927 to 1994, the company was called “Plant No. 24 named after Frunze”, therefore the bust of MV Frunze is located at the entrance. From 1994, the plant was renamed Motorostroitel OJSC, and a bit later, Kuznetsov OJSC, in honor of Nikolai Dmitrievich Kuznetsov, an outstanding designer of aircraft and rocket engines.

02. Directly in Samara, the plant has been located since 1941, where it was urgently evacuated from Moscow. During the years of World War II, the company produced more than 45 of thousands of AM-38, AM-38F, AM-42 engines.

03. In 1950, the serial production of the first domestic turbojet engine VK-1, designed by V.Ya. Klimov. In April, 1954 launched the Aviation Engine TV-12 into mass production, in 1955 it was given the name NK-12 (Nikolai Kuznetsov). The TU-12, TU-95, TU-126, Antey military transport AN-114 military aircraft flew on the NK-22 engines and their modifications, and the TU-95MS (modification of the TU-142 aircraft) continue to fly. The NK-12 engine is still the most powerful turboprop engine in the world.

04. Memorial plaque M. Wands - the first director of the plant in Kuibyshev (was director from 1941 to 1950 year)

05. Space page in stories The enterprise was opened at the end of the year. By the decree of the Central Committee of the CPSU and the Council of Ministers of the USSR, the enterprise was ordered to reconstruct production and master a fundamentally new type of equipment — liquid rocket engines (LRE) for 1957 and 1 stages of the intercontinental ballistic missile R-2 OKB S.P. Queen.

12 April 1961, the PH "Vostok" with LRE-107 and RD-108 launched into space orbit the first cosmonaut of the earth, Yuri Gagarin. These engines and their modifications are available on the company already 54, and are considered unsurpassed in reliability.

06. Shop number XXUMX - here is the assembly of rocket engines. I will say right away that this and other workshops belong to the defense industry, it’s not very easy to get here, so there will not be many photos.

07. In the 1962-1967 years, bench bench tests of the LK-15, NK-15B, NK-19 and NK-21 LREs were created and successfully completed; in 1969-1973, the modified NR-33 LREs of the NK-43 and NK were developed. 39 and NK-31.

08. The LK-33, NK-43, NK-39 and NK-31 LRE engines were planned to be used in the NXNX-LZ rocket-space complex (RSC) for a manned moon flight, but in May 1, the lunar program was closed.

09. An instruction was given to destroy these engines, but ND Kuznetsov, at his own risk and risk, was able to save a batch of engines by immuring them in one of the shops.

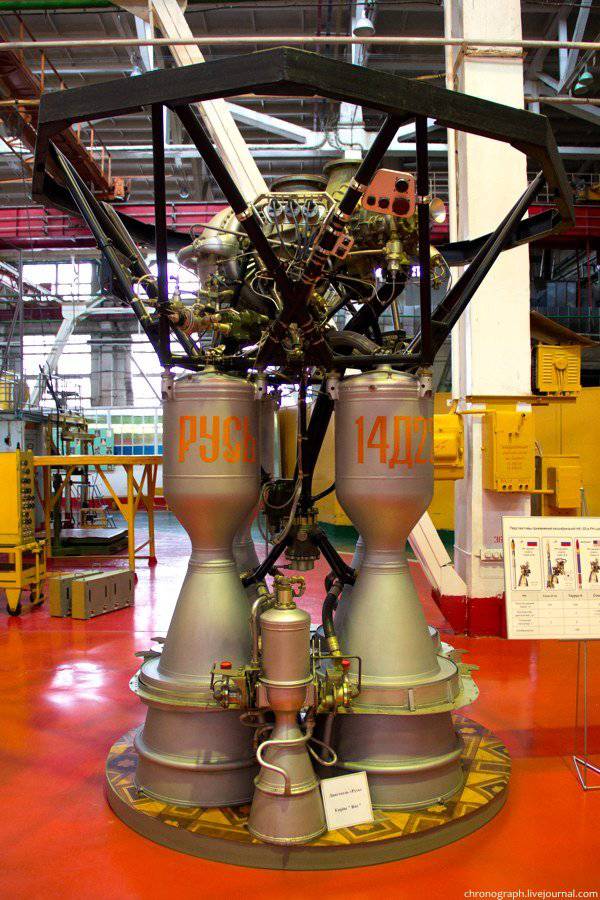

10. Rocket engine "Rus" 14Д22 (modification РД-108) for Soyuz launch vehicles with enhanced energy characteristics are considered the most reliable in the world (engine thrust at ground-79,1 t, specific impulse in void-320 s, height- 2865 mm , diameter- 2578 mm, mass- 1115 kg, probability of trouble-free operation (99,8%)

11. Vladimir Konstantinovich, Head of Workshop No. XXUMX, has been working at the enterprise for about 4 years, a great specialist in his field. Even as a teenager, Vladimir Konstantinovich saw the arrival of Yuri Gagarin in Kuibyshev, he remembers how warmly and joyfully he was met by a huge crowd of people.

12. RD-107A engine

13. Engine NK-33, one of those that was planned to destroy. The engine is easy to operate and maintain and at the same time has high reliability. At the same time, its cost is two times lower than the cost of existing engines of the same class in terms of load. In the 1995 year, after long-term storage, two NK-33 engines were delivered to the USA, where they successfully passed a fire test complex at the Aerojet stand. The Americans were greatly impressed with the quality of these engines, which were launched by 30-40 years ago.

Characteristics - engine thrust at the ground - 154 t, specific thrust impulse in the void - 331 s, height - 3705 mm, diameter - 1490 mm, mass - 1240 kg, probability of trouble-free operation - 99,8%

14. Current prospects for the use of engines NK-33

15. A few fragments of the workshop №4

16.

17.

18. In 1963, Yuri Gagarin spoke here and thanked the workers for their excellent rocket engines.

19. In the corridor hang portraits of all of our astronauts, delivered into space with the help of rocket engines, released at OAO Kuznetsov.

20. The office of the foreman №4

21. Stella "Continuity of Generations" (1987 year)

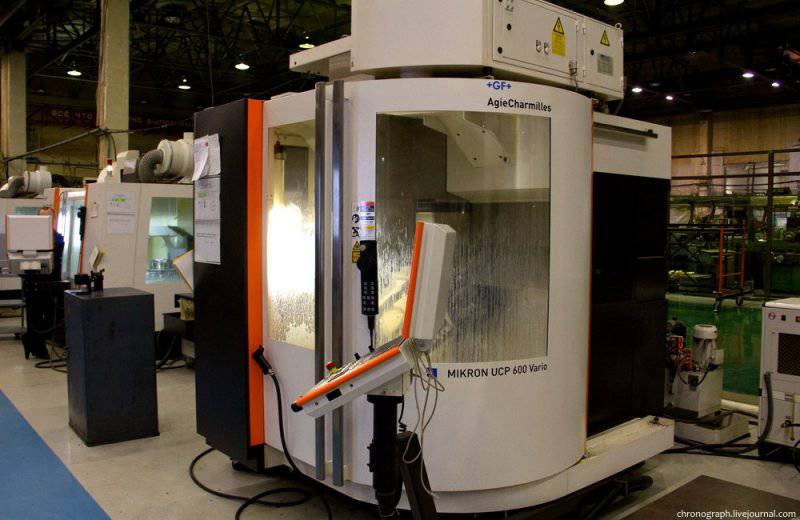

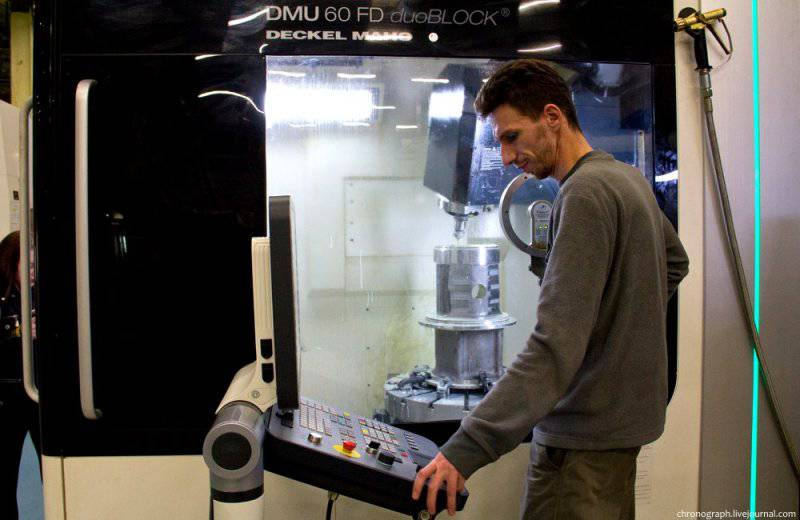

22. Shop №10 - here produce parts for aircraft and rocket engines.

23. Recently launched a new, modern line of machine tools.

24. The productivity of new machines is many times more than old ones, plus they need less equipment, and therefore they take up less space.

25. Further, the details are transferred to the next shop, where the assemblies are assembled, but unfortunately we were not allowed to go there.

26.

27. Half of the workshop # 10 is still occupied by old 50-70 machines, parts are also made here, but gradually, all the equipment will be replaced here. The modernization program has just begun and will last until the 2020 year.

28. In some places there are even 1930's, they are not used now, but they are in working condition. Good exhibits for a museum.

29.

30. On inspection of the workshop №10 we were given quite a bit of time and then we went to the museum of the enterprise.

Brief historical background for aviation enthusiasts:

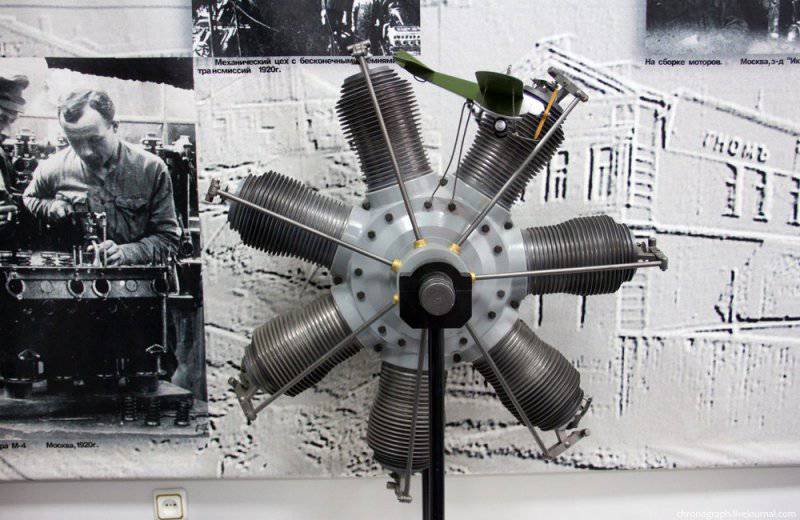

The history of the enterprise began in 1912 year. Then, on the basis of semi-handicraft workshops located on the outskirts of Moscow, on Nikolaevskaya Street (now Tkatskaya), a plant was built for the assembly of seven-cylinder star-shaped aviation engines of the French company “Gnome” with a power of 80 hp. from parts supplied from France. They were installed on Newport-4, Farman-16, and other aircraft. In 1915, the Gnome firm took over the Ron motor company, creating the Gnome and Ron company. In 1915, the Motor plant, which produced the Kalep-80 engines and spare parts for the Gnome and Ron engines, was evacuated from Riga to Moscow. The plant was located in Zamoskvorechye, near Danilovskaya Square.

In 1920, the nationalized plants “Gnome and Ron”, “Motor” and “Salmson” were assigned numbers by the State Aviation Plants - GAZ 2,4 and 6, respectively. From 1922, the factory “Gnome-Ron” became known as GAS No. XXUMX “Icarus”. There were changes in 2: the plant No. XXUMX (the former Salmson) was joined to GAZ No. XXUMX Motor. In 1924, the company received the name of M.V. Frunze. Since the territory of the Ikar plant did not allow it to expand more, in 4, the historic decision was taken for Ikar and Motor: to merge the two enterprises into one. The new plant became known as the United State Aviation Plant No. XXUMX and No. XXUMX Frunze. Soon the name was shortened significantly: “Plant number XXUMX them. Frunze.

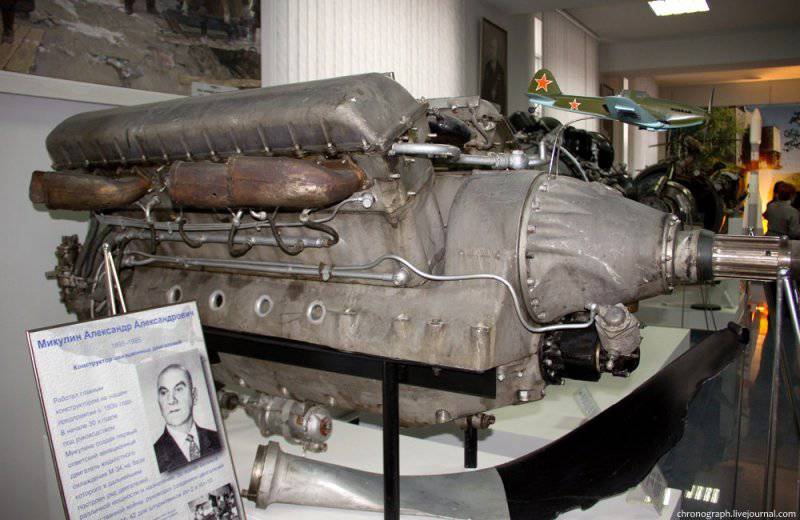

In 1930-s of the last century at the plant. Mv Frunze started the production of liquid-cooled AM-34 piston engines designed by A.А. Mikulin At that time, this engine was the best reciprocating engine in the world and was installed on airplanes TB-3, Р-7, ANT-25, etc. Records of V. Chkalov, M. Gromov, S. Shestakov, A. Yumashev, G. Baidukov, A. Belyaev, S. Danilin, known in aviation, were set on planes with engines produced by the plant, which today is called Kuznetsov OJSC.

31. The museum is small, only some models of engines produced at the enterprise for 100 years are represented here. The photo shows the very first Gnome aircraft engine (1912-1914 years of release, 60 hp, 1200 rpm)

32. On the left is the Calep engine (1912-1916), the right is Ron (1914)

In October 1941, the plant was evacuated to the city of Kuybyshev on the territory of the constructed plant No. XXUMX. In the shortest possible time, the production of the AM-337 engines, begun in Moscow for the Il-38 attack aircraft, was resumed at the new site. During the war years (from 2 to 1941), the 1945 engine AM-25443F, 38 AM-10242 (for IL-42) and the engines AM-10 (for MiG-35) and GAM-1BS (for torpedo boats) were released. ). At the end of 34-x - the beginning of 1940-x. the company launched the VK-1950 turbojet engines, designed by V.Ya. Klimov for the IL-1 and MiG-28 front-line aircraft, and the RD-15 - direct-flow air-jet engines MM. Bondaryuk for the La-900 unmanned target aircraft and the supersonic RD-17 for the intercontinental cruise missile “The Tempest” by S.A. Lavochkin.

From the second half of the 1950-ies, the plant began the introduction into serial production of the family of NK engines developed in the Design Bureau of Chief Designer N. D. Kuznetsova. Since then, for more than 60 years, enterprises have been partnering together: the design bureau has developed engines, a plant for them. Mv Frunze produced them serially. Initially, the design bureau (later OJSC SNTK named after ND Kuznetsov) was established in Kuibyshev in 1946 by order of the Minister of Aviation Industry (No. 228 of 19 on April 1946) by decision of the USSR Council of Ministers (decision No. 874-366 of 17 April 1946) under the name of the State Union Experimental Plant No.2.

From October 1946 to December 1953, the plant number 2 was occupied by German specialists (engineers and technicians) of the Junkers, BMW and Ascania aircraft engine companies with their families. Together with the designers of the enterprise, they worked on the improvement of 004 air-jet engines (based on YuMO-004), 012B (based on YuMO-012), 003С (based on BMW-003) and the 022 turboprop engine (based on YuMO-022).

15 April 1949 of the year to strengthen the technical management of the Chief Designer of the plant number XXUMX appointed and transferred from Ufa Nikolai Dmitrievich Kuznetsov. At the beginning of the 2-s, the enterprise design bureau developed an experienced 50TV-2F engine (later NK-2), hp-powered 12. for the strategic bomber Tu-12500. Since 95 and for more than half a century, this engine and its modifications are NK-1954M, NK-12MB, NK-12MA, NK-12MK, NK-12MP, NK-12MPT (power from 12 12 to 000 HP)) produced at the plant them. Frunze. The engines are installed on Tu-15000, An-142 “Antey” airplanes, on long-range passenger Tu-22, Eaglet “Orlyonok” and other airplanes.

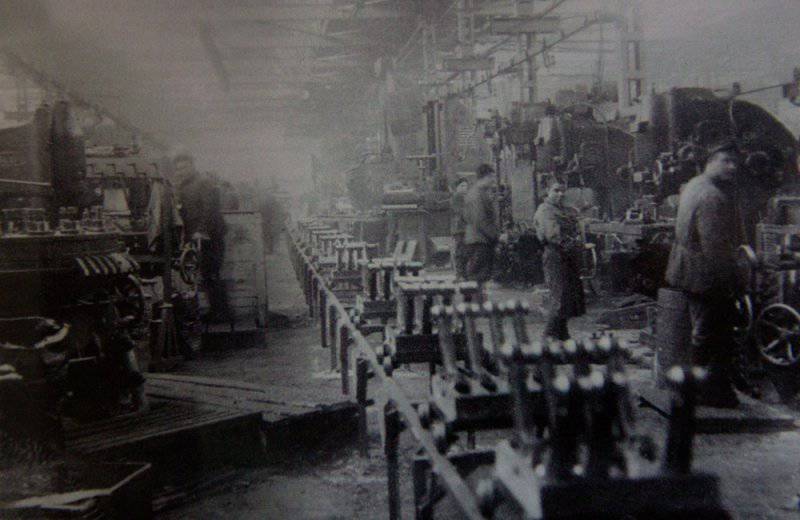

33. In the shop rods 1943 year.

34. Group of complex-shaped tool shop №41 1944 year.

35. Engine AM-38 F, which was installed on the aircraft IL-2. This motor was manufactured in November 1942 of the year and was removed from the aircraft shot down in the battle for the Soviet Arctic (the plane was found and brought to Kuybyshev in the fall of 1970)

27 August 1953, Experimental Plant No.2, renamed Experimental Plant No.276. 12 July 1957 of the year for the creation of the engine NK-12 awarded the Order of Lenin.

Since the beginning of the 1970-ies, enterprises have been developing and serially producing aviation-type gas turbine engines for the gas industry. The first domestic GTD NK-12CT with 6,3MW power was created in 1974 on the basis of NK-12МВ TVD. Currently, these engines are operated at 117 compressor stations as part of 852 gas pumping units GPA-C-6,3. In 1982, on the basis of the NK-8-2U engine (operated on Tu-154B and IL-62 aircraft), the ground-based NK-16CT engine was developed with a 16MW power.

N.D. Kuznetsov was the chief designer of the design bureau until 1994. During this time, 57 original and modified engines were created under his leadership. They include NK-12, NK-4, NK-8, NK-22, NK-25, NK-144, NK-86, NK-88, NK-89, NK-321, NK-93. Development of virtually all engines was carried out in close cooperation with the Samara Engineering Design Bureau (OAO SKBM, formerly Kuibyshev Engineering Design Bureau), founded in 1957 year as a branch of the OKB and gained independence in 1967 year in order to work on improving reliability and resource in mass production and operation of aircraft engines of various types developed by the Kuznetsov Design Bureau.

In 1966, Experimental Plant No. 276 was given the open name “Kuibyshev Engine Plant“ MAP ”. In 1967, I returned the name and the plant to them. Mv Frunze, until this year, he was classified for six years and worked under the name "Organization of the p / i 32".

The next renaming of the enterprise took place only in the 1994 year, when it was transformed into Motorostroitel OJSC. At the same time, the Kuybyshev Scientific and Production Association “Trud” (the name of the Design Bureau with 1981 of the year) was renamed to the OJSC “Samara Scientific and Technical Complex“ NK Engines ”. Two years later, 11 January 1996, the Samara Scientific and Technical Complex was named after N. D. Kuznetsova.

The protracted crisis of the engine-building industry and related industries in the mid-1990 of the early 2000-s. Samara enterprises put on the brink of survival. The serial enterprise still produced engines for the Russian space program and the gas industry, but the volume of orders dropped significantly. In accordance with the orders of the state, new aircraft engines were not actually produced, but only repairs of existing products were carried out.

16 April 2008 was signed by the President of Russia Decree No. 497 “On the further development of OPK Oboronprom OJSC, according to which Motorostroitel OJSC, SNTK im. N.D. Kuznetsova ", JSC" SKBM "and NPO" Volga AviTI ".

In 2009, the enterprises came under the control of OAO UK United Engine Corporation (UK UDC). At that time, the total debt load of Motorostroitel OJSC, JSC SNTK im. N.D. Kuznetsova ”, as well as OJSC SKBM exceeded 7 billion rubles. For their withdrawal from the pre-bankruptcy state, the successful implementation of investment projects and further effective development, it was decided to merge the enterprises into one legal entity. It was also decided to include into the composition of the merged company - OAO NPO Povolzhsk Aviation Technological Institute. This enterprise was created on the basis of the Kuibyshev branches of NIAT and NIID and was a multi-branch institute of the Russian Federation.

27 June 2011 of the year a record was added to the Unified State Register of Legal Entities (Unified State Register) of the merger of three enterprises to OJSC Kuznetsov: OJSC SNTK im. N.D. Kuznetsova ", OJSC" Samara Machine Building Design Bureau "and OJSC" NPO "Volga Region AviTI". Thus, now the enterprises of the Samara engine-building complex have fully completed the legal process of reorganization. Currently, OAO Kuznetsov is an integrated structure in which all phases of the technological chain of engine creation are concentrated: development — production — marketing and sales — logistic support during operation at the customer.

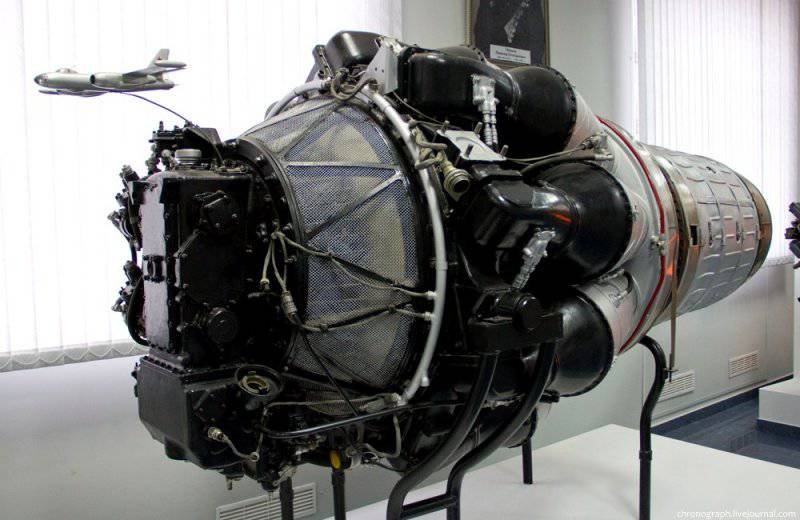

36. VK-1 engine (installed on IL-28, MIG-15, MIG-17) aircraft

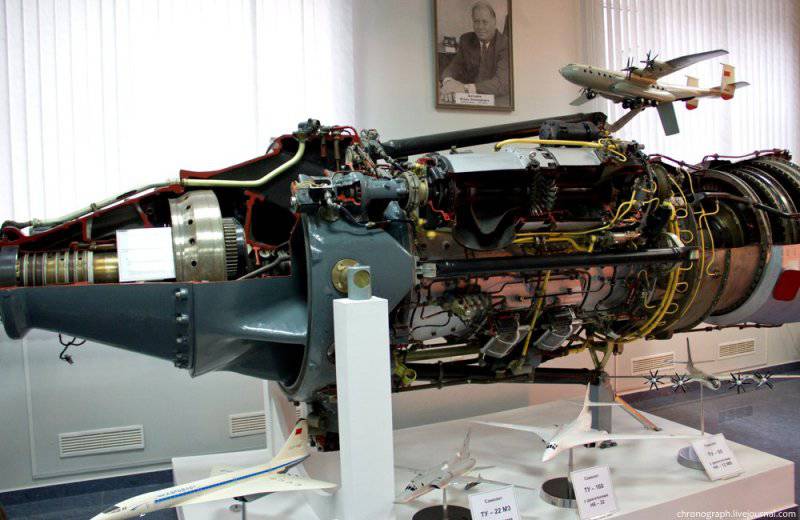

37. Engine NK-12МВ (developed in 1962, installed on TU-114 and AN-22 aircraft)

38. Model aircraft AN-22 "Antey".

39. NK-12MV engine section

40. More models of aircraft with engines of JSC "Kuznetsov"

Today, OAO Kuznetsov is the main supplier of drives for gas pumping units of main gas pipelines for OAO Gazprom. A new direction in the development of OAO Kuznetsov is the production of mechanical drives of the GTE-8,3 NK power unit for the traction section of the main gas-turbine locomotive based on the NCD-361 GTE. Relatively recently, the engine passed the first stage of testing, which resulted in a record haulage of freight train weighing thousands of tons in 15, consisting of 159 cars.

Information