Production of the MiG-29 in Moscow

01. MiG-29K / KUB are mass-produced for the Indian Navy and will be delivered in the future by sea aviation Russian Navy.

02. The corporation is currently implementing two contracts with India.

03. The first contract for the supply of sixteen MiG-29K / KUB, which the Indian Navy should receive under the contract for the supply of the aircraft carrier Vikramaditya, will be completed this year.

04. Eleven cars have already been delivered to India, five more will be delivered by the end of the year.

05. In addition, last year, a contract worth $ 1,5 billion was signed to supply an additional batch of 29 aircraft.

06. The initial training of Indian pilots on the MiG-29K / KUB, testing takeoff / landing on the deck of an aircraft carrying cruiser will be held at the Ukrainian complex "NITKA". India also builds its own take-off / landing range.

07. As the head of the engineering center, Vladimir Ivanovich Barkovsky, said, RSK MiG is also currently executing a contract for the supply of 20 MiG-29 to Myanmar and a contract to modernize the MiG-29 of the Indian Air Force.

08. "This is a deep modernization of previously delivered aircraft. New avionics, radar, information control field, and new weapons are installed on the aircraft. 6 aircraft will be modernized in Russia (4 in Moscow and 2 in Nizhny Novgorod) ...

09. ...

after which the modernization technology will be transferred to India, where about 60 aircraft will be upgraded at the Air Force repair base. Under this contract, MiG will supply modernization kits and weapons to India. "

10. The company's CEO Sergei Korotkov told reporters that MiG plans to sign a contract for the supply of MiG-29K / KUB carrier-based fighters for the Russian Navy.

11.

12. The MiG-29K multipurpose ship fighters (single) and MiG-29CUB (double) belong to the generation "4 ++"

13. The aircraft have an advanced airframe with a high proportion of composite materials, a digital integrated electrical remote control system for an aircraft with fourfold redundancy, a significantly reduced visibility in the radar range, an increased fuel system capacity and combat load, and an open-air radio equipment architecture.

14. The MiG-29K / KUB has a modern multipurpose multi-mode pulse-Doppler on-board radar Zhuk-ME, a multichannel optical-radar station and a target designation system for passive homing anti-radar missiles.

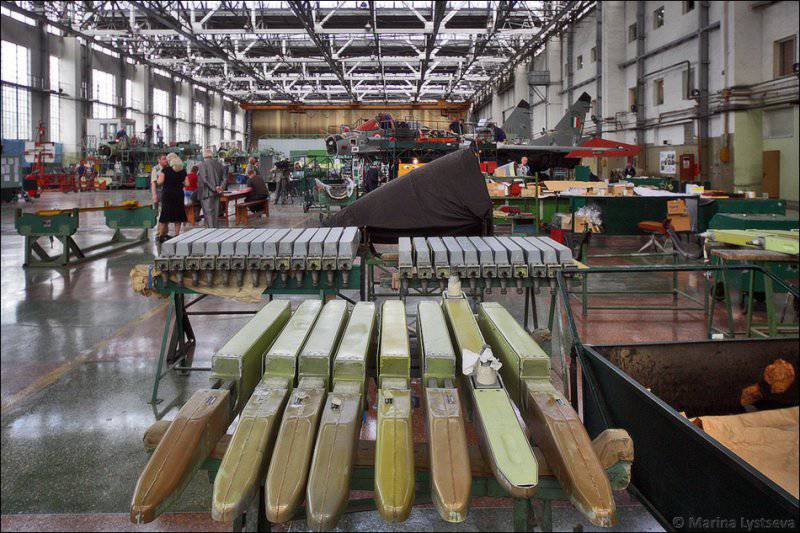

15. The armament complex includes air-to-air and air-to-surface guided missiles, adjustable bombs, unguided missiles, aerial bombs, and an integrated 30-mm gun. In the photo - her layout. This gun did not show us.

16. Nose fairing for the Indian MiG.

17.

18.

19.

20.

Information