Solid foam against fire

How Russian chemists became revolutionaries in fire fighting

Fire fighting is a complex and responsible area, and it seems even more surprising to see how slowly technologies are developing in this area. The extinguishing foams, the use of which began more than a century ago, have changed little over the past time - but, perhaps, a real revolution will soon begin in this area. In any case, the new development of the Petersburg chemists of the ITMO University and the NGO “SOPOT” looks revolutionary from all sides, from the idea to the environmental safety. Alexander Vinogradov, Deputy Head of the Laboratory “Solution Chemistry of Advanced Materials and Technologies” at ITMO University, answered the questions of the Russian Planet.

- Alexander, where did the idea of creating a new fire extinguishing foam come from? From your chemistry classes, from business order or something else?

- There will need a little insight into the current situation in the market of extinguishing materials. Such materials should always be evaluated on three main parameters: the effectiveness and versatility of extinguishing various materials, including solid and liquid combustible materials; the cost of the foam itself; finally, the environmental safety of the application. And if we analyze all these parameters in the complex, we will see that the market itself is huge, but at the same time it is rather poor in terms of choice. There are not so many truly universal, effective and safe fire-fighting foams in the world.

Russia in this regard is a very interesting market. Our largest consumers, oil and gas giants, use fire extinguishing equipment and technical equipment supplied from the USA and designed to work with mixtures based on fluorine-containing synthetic frothers (AFFF). Indeed, the ability to localize and eliminate the source of ignition AFFF are the most effective among all similar drugs. On the other hand, they have to be purchased in the same America either in finished form or in the form of raw materials. And most importantly, AFFF toxic and extremely negative impact on the environment.

Their half-life in nature is at least 40 years. The products of semi-decomposition fluorosynthetics accumulate in plants and animals, enter the human body. In short, it is not possible to use AFFF-based foams, unless then a whole set of measures is being taken on utilization of residues and restoration of ecosystems.

Therefore, a convention banning the use of fluorosynthetic drugs was adopted a few years ago both in the USA and in Europe. The use of AFFF is virtually stopped everywhere, but is still allowed in Russia. In the rest of the countries, they took the path of banning AFFF, there they use similar drugs - if not so effective, but not so dangerous.

So, when last year we opened our laboratory in ITMO and got acquainted with the company SOPOT, the task arose almost by itself. This company is the largest developer of fire extinguishing agents and a leader in the production of foam generating devices; it is active not only in Russia, but also in some foreign markets, for example, in China and Cuba. They have their own staff who develop and implement new technologies in this area.

However, SOPOT does not develop and produce its own frothers preparations. Therefore, when our team of chemists spoke with colleagues from this company, we immediately noticed that all existing blowing agents — and their production has been going on for more than 100 years — are derivatives of organic substances.

From the point of view of thermodynamics, carbon – carbon, carbon – hydrogen and other bonds existing in organic compounds are unstable at high temperatures. It is impossible for them to remain intact when heated above 300 ° C, but inorganic substances in this sense give much greater freedom. So the idea to try inorganic foam arose almost immediately.

- And how does this foam look like? What is she like?

“Our material is two-component, consisting of the most common foaming agent, plus a new composition based on silica nanoparticles, which ensures the curing of the foam, translating it into a ceramic phase.

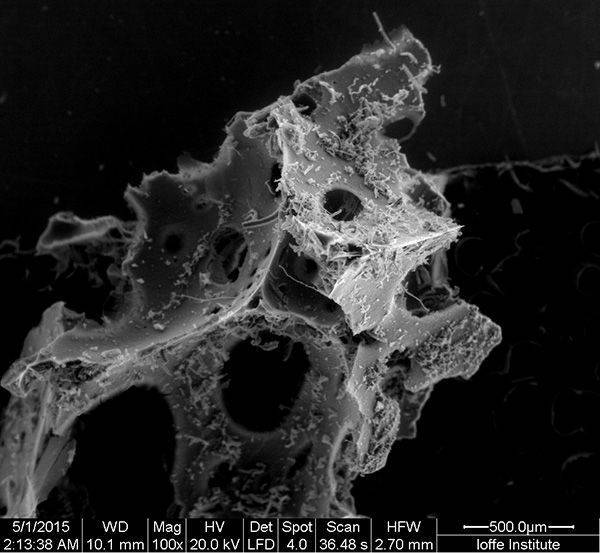

Silica is a common silicon oxide (IV), which is familiar to everyone, for example, in the form of quartz. Its particles can polymerize in a matter of seconds (we can vary this time from 5 to 30 seconds) and force the foam to adhere quite firmly to any burning surface. Experiments have shown that our foam can even be fixed on ordinary polished glass and harden, turning into something like a porous ceramic sponge, which reliably isolates the surface from fire and high temperatures. Nothing of the kind has ever been offered close to it, and no one has done anything of the kind.

The effectiveness of fire extinguishing with such foam is easy to understand. Imagine that your room is on fire, and you pour ordinary wall and ceiling over the foam. Foam quickly flows down, no more than 5% lingers on vertical surfaces, and even if you extinguish these surfaces, they soon risk burning again. Firefighters have to “spill” the building again and again. The hardening effect here can play a key role.

- How does the process of formation of such a solid foam?

- Imagine: we have the first component, which is responsible for the formation of foam, a multitude of air-filled bubbles. The second component is injected into the first one, just before being applied to the burning surface, and makes the foam harden.

So, the foam enters the burning object, the temperature of which repeatedly exceeds its own. As a result, it cools it sharply - to a temperature below the pyrolysis stage - and after a couple of seconds it hardens, preventing the re-ignition from developing. Roughly speaking, we envelop the burning object with a “ceramic coat”. In comparison with the same AFFF, our efficiency is higher by more than 20 times.

Unlike conventional foams, which due to the enormous temperatures evaporate in a matter of seconds, our foamed silica does not collapse. When water evaporates, crystallization of the amorphous silica particles only intensifies, the crystal frame is compacted - and the foam, like a brick in an industrial furnace, becomes only stronger and more reliable protects our object.

- But what will be the result of such a quenching? Not burning, but generally useless lump of solid foam?

“Although we are talking about solidification, polymerized foam is not solid in the household sense of the word. Rather, it resembles a gel, which in principle can be removed from the surface. On the subject she can last a week or two, in fact, until the first rain. Such foam has a powerful ability to adsorb water, therefore, having absorbed it, it softens and is easily subjected to mechanical destruction. As a result, even once in the drain or sewage system, it will not last long and will disintegrate to silica particles with a diameter of 100 – 150 nm.

- And do these particles themselves have no toxic properties?

- Silica - the material is extremely resistant and chemically inert, its safety has been repeatedly proven. The US Food and Drug Administration (FDA), as well as the European Medicines Agency (EMEA), whose findings are largely guided by our Ministry of Health, prohibits only intravenous and intramuscular use of silica. But orally it is completely safe. You are probably familiar with such a popular drug like Enterosgel? It consists of silica nanoparticles.

We have already managed to get a certificate of compliance with the first class of biodegradability - in general, for the first time in the world for such drugs. Although it is worth noting that such a certificate would more accurately be called a “biocompatibility certificate”: silica particles in nature will not decompose, they are only absorbed and carried by microorganisms without any harm for them, and therefore for the environment.

- It turns out, no restrictions on the use of such a silica foam is not expected?

- Exactly! And this is one of its great merits. Not so long ago, in Surgut, we conducted tests on the use of our preparation for the creation of felting strips. Now for this purpose using phosphate-based products, which are considered quite inexpensive. However, phosphates are water soluble, so they are easily carried away by rain and soil moisture. In addition, phosphates are important fertilizers, in the forest they are quickly recycled plants. Therefore, after such a band has been created, it will not last long.

Our tests showed that the barrier with the use of "hardening foam" lasts much longer, allowing you to localize the fire in the forest and prevent the spread of fire: through such a barrier a few meters wide no fire will "jump". Ideally, firefighters will have up to two weeks in order to arrive at the scene, deliver equipment and organize fire fighting.

- How was your role in creating a fire extinguishing foam distributed? What part of the decisions did you, ITMO chemists, and which part - the developers of the company "Sopot"?

- There was no strict division of labor, although, of course, we were more concerned with solving chemical problems, because this is our profile. They concentrated more on the technological part, which also found a huge number of problems.

It can be noted that technological adaptation has become a key issue for the possibility of generating hardening foams. That is why NPO SOPOT, being a leader in the field of creating foam generating devices in Russia and possessing a huge baggage of experimental experience, was able to solve all the issues that arose, ensuring the stable operation of devices for generating hardening foams. It would be correct to say that 90% success was in the hands of the company that ordered this research and today is the copyright holder of the technology.

Generally speaking, there were a lot of difficult "trifles", it is even surprising that they were solved so quickly. Only 26 November, 2014, the first discussion of our idea took place - and on March 15 a patent application was sent. In May, the development was demonstrated to the Minister of Emergency Situations Vladimir Puchkov and his colleagues from Belarus and Mongolia at the exhibition "Integrated Safety" in Moscow. And already in June, the forest fences were tested using a specially converted MT-LB (light armored multipurpose transporter. - RP.).

- What is the continuation of this stories?

- The market is gigantic, the potential is mad, I can say for sure. And from the business side, the interest in our development is huge. There are proposals for the use of such a two-component foam for specialized applications, such as fire extinguishing in mines and at oil loading stations.

As far as I know, in the company “Sopot” the prospects of this invention were taken very seriously. A specialized chemical laboratory has already been equipped, a fire test capsule has been created, new developments are underway, and the launch of the production of both components is being prepared. But we have nothing to do with it.

Our task is not commerce. We are doing science, and the main focus of our laboratory is basic research, some of which can be quickly turned into practical, practical solutions. This is exactly what we are doing: two-component hardening foam is not the only one of our practical developments.

In the near future, we are planning to register our own startup InnoColloids, it will be engaged in the release of innovative colloidal substances that will find the widest application - from holography to medicine and solar energy. It is difficult to promise something, but I think it will be just a bomb: I can say that now we can increase the brightness of liquid crystals by 20% without any serious efforts, suggest a new technology for printing nanoconstructions, present unique non-invasive biosensors ... It will be a project completely focused on foreign markets. But this is a topic for another conversation.

Information