Arzamas Machine-Building Plant

Arzamas Machine-Building Plant, which is part of Military Industrial Company LLC, is one of the leading enterprises in Russia in the production of wheeled armored vehicles and a leading enterprise in the machine-building industry of the Nizhny Novgorod Region. AMZ was founded in 1972 year as the Arzamas Automobile Spare Parts Plant of the Gorky Automobile Production Association. In 1980, the plant produced the first army armored personnel carrier, and in 1981, it already produced the first batch of special vehicles.

GAZ-233114 Tiger-M multi-purpose assembly line

Multi-purpose vehicle GAZ-233114 Tigr-M from different angles

The plant specializes in the production of wheeled armored vehicles, the most famous models of mass-produced products are rightfully armored personnel carriers BTR-80 and BTR-82, multi-purpose vehicles of the Tiger family, BMM medical vehicles, wheeled repair and recovery vehicles BREM-K, and unified chassis UNM.

AMZ has a wide geography of supplies, Russian armored personnel carriers and armored vehicles of the Tiger family are highly popular in the armies and law enforcement agencies of Algeria, Hungary, China, Congo, Indonesia, Sudan, Djibouti, Vietnam, Sri Lanka, Uzbekistan, Kazakhstan, Azerbaijan, Armenia, Uruguay, Colombia, Venezuela, etc. In some countries, deployed licensed production of armored vehicles.

The Tigr-M armored car is equipped with a YMZ-534 diesel engine with turbocharging and HP 215 power.

The purpose of the visit of Dmitry Rogozin was to get acquainted with the achievements of the largest Russian manufacturer of wheeled armored vehicles, as well as to hold a meeting on the production of light wheeled and armored vehicles.

During the meeting, the Deputy Prime Minister paid special attention to the modernization of the production process of the equipment included in the state defense order, developing rules of the game between the state and business, increasing the share of private capital in the defense industry, creating a fundamentally new scientific and technical background in the industry.

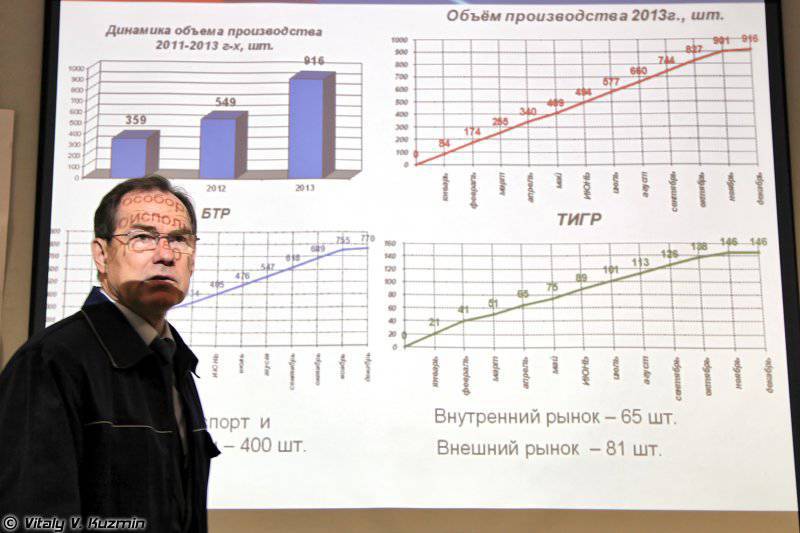

Alexander Zolotarev, Managing Director of AMZ OJSC, said that in 2013, the volume of output would be 916 BTR armored personnel carriers of various modifications and STS "Tigr"

Of the planned 916 products, 770 will comprise BTR modifications, of which 290 are units. will be delivered to the Ministry of Defense of the Russian Federation, 400 pcs. produced by Rosoboronexport and subcontractors and 80 pcs. - repair by technical condition. In the 2013 year, it is planned to release and supply 146 armored vehicles of the Tiger family to customers, of which 65 is on the domestic market and 81 on the outside.

GAZ-233114 Tigr-M during assembly, without wheels

A significant part of the AMZ presentation was devoted to the analysis of complaints and identified defects during the production and operation of armored vehicles. Alexander Zolotarev said that the company had thoroughly investigated the reasons leading to the complaint and took steps to eliminate them. Thus, in 2012, AMZ’s warranty fleet comprised 3425 products, of which 3180 BTR of various modifications and 245 armored vehicles of the “Tiger” family. In this case, 2012 BTR and 567 STS Tiger were advertised in 253.

In 2012, AMZ’s warranty was based on 245 products of the “Tiger” family, and there were complaints about 253 machines.

After the analysis of the claims of customers and operators, it was established that the main systems failing are (in% of the total number of defects):

- electrical equipment 29%

- Transmission 20%

- body 16%

- brake system 12%

- engine 11%

- hydraulic system 6%

- tire loading system 2%

- power supply system 2%

- wheels 1%

- other 1%

Elements of the front suspension Tigr-M

By the nature of occurrence defects STS "Tiger" are divided into:

1. Production defects 28.5%: presence of air in the brake system, poor quality pumping of the brake system;

2. Defects of suppliers 32.9%: failure to calibrate the SRDVS unit, defects YAMZ;

3. Operational 36.6%: non-observance of the distance of movement, destruction of the winch case in case of improper operation, movement when the bridges are permanently turned on.

In 2011, the detected defects of the Tigger were distributed 36.66%, 26.38% and 36.96%, respectively.

Rear suspension

Salon armored Tiger-M in the assembly process

GAZ-233036 SPM-2 of one of the units of the riot police for warranty repairs

According to the identified defects of various modifications of the BTR, a similar situation develops. 3180 is advertised from the 567 warranty BTR. The main defects in the BTR, identified in 2012 year (in% of the total number of defects):

- Transmission 27.8%

- electrical equipment 24.8%

- engine 17.8%

- hydraulic system 8.5%

- brake system 4.4%

- tire loading system 3.3%

- body 3%

- power supply system 2.3%

- weapons 0.2%

- other 7.9%

BTR-82A

The defects in the production and operation of the BTR in the year 2012 were distributed according to the nature of occurrence as follows (in% of the total):

1. Production defects 23.7%: speedometer, hydraulic lock, axle gearbox, transfer case;

2. Defects of suppliers of components 35.3%: clutch, PZD, automatic protection, starter, electric motor, power steering;

3. Incorrect operation of 40.6%: coolant leaking from the cylinder head, worn clutch discs, gear shift drive is malfunctioning, failure of the circuit breaker and starter failure, destruction of the transfer case shaft and gearbox destruction.

BTR-82A in AMZ assembly shop

According to the representatives of the plant, thanks to the systematic work to improve the quality of the products and components supplied, last year the plant managed to change the ratio of defects by the nature of occurrence. In the 2011, the identified BTR defects were distributed 34.84%, 37.49% and 27.67%, respectively.

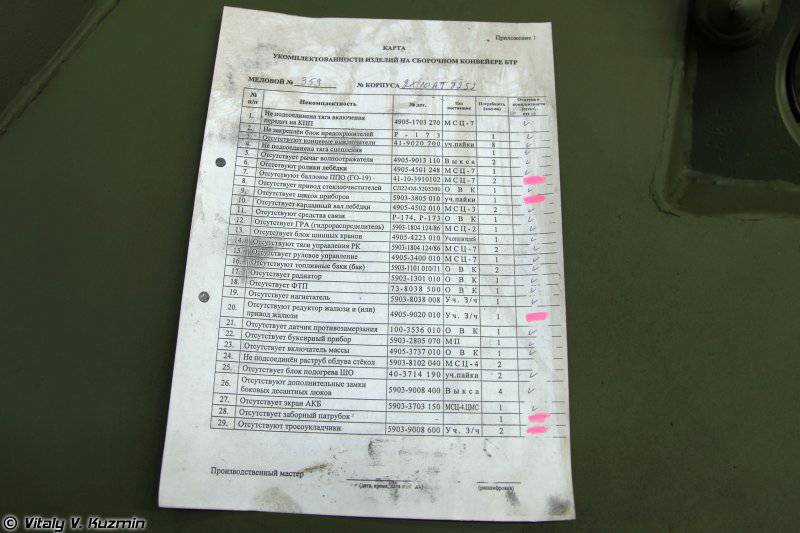

A staffing card is available on each item.

BTR-82А almost ready for delivery to the customer

Particularly attentive can notice a bent wheel and a practically worn tread design on this BTR-82А. These wheels are installed on the machine for movement in the shop.

In addition, during the presentation, representatives of AMZ voiced their proposals for the implementation of imports of a number of components due to the low quality of domestic counterparts and non-compliance with delivery times.

According to AMZ management, at present there is a need to consider options for finding and purchasing in foreign markets the following range of components: electrical connectors, sensors, relays, switches, bearings, clamps, lamps, generators, non-ferrous castings, heaters, oils and lubricants.

BTR-82A, rear view

The process of assembling armored personnel carriers

BTR-80 armored personnel carrier for UN supplies

Chassis elements BTR-80

Salon BTR-80 in the assembly process

Deputy Prime Minister Dmitry Rogozin examines the exhibition at AMZ

Information