Makeevsky Metallurgical Plant: sabotage during construction

Makeevka Metallurgical Plant today

Pre-war industrial construction during the first, second and early third five-year plans was a fascinating epic. It wasn't just success. In those years, a new country was actually built, radically different from what it was before.

However, when you begin to get acquainted with the details, you get a strong feeling that not everyone was happy about such changes, and they tried with all their might to delay, slow down, and disrupt this rapid development. Of course, the very term “sabotage,” which was used in Stalin’s times, subsequently acquired a purely negative semantic connotation: they say that all these were groundless accusations.

Nevertheless, there are actions that can hardly be called anything other than conscious and planned sabotage. In particular, in the construction of a number of facilities at the Makeevka Metallurgical Plant named after. S. M. Kirov in 1940.

Transformation of the plant into a large industrial complex

Makeevka Metallurgical Plant is one of the oldest in Donbass; it was founded in 1898. Even before the revolution, it was a large and well-equipped metallurgical enterprise by the standards of that time.

During the first five-year plan, a plan was developed for a radical reconstruction of the plant and essentially turning it into the core of a large metallurgical plant.

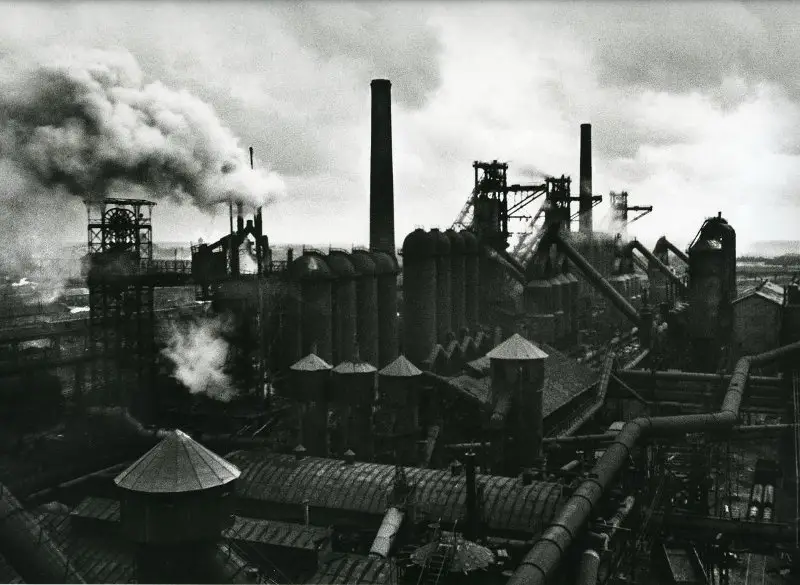

Plant under construction

According to this plan, it was planned to build at the Makeevka Metallurgical Plant:

sintering plant with 5 belts, capacity of 2 thousand tons of sinter;

coke shop with 184 ovens with a capacity of 1 thousand tons of coke;

blast furnace shop consisting of three blast furnaces of 842 cubic meters each and two blast furnaces of 1 cubic meters each;

a new open-hearth shop consisting of nine 15-ton furnaces and a 1-ton mixer with auxiliary workshops;

a new rolling shop consisting of a 1 mm blooming mill, 150 and 630 mm continuous billet mills, a 450 mm checkerboard mill, a 300 mm strip mill, and a 300 mm wire mill.

According to the project, the Makeevka plant was supposed to produce after reconstruction: 2 thousand tons of sinter, 500 thousand tons of cast iron, 2 thousand tons of steel in the new workshop and 240 thousand tons of steel in the old workshop, a total of 1 thousand tons, 600 thousand tons of rolled products .

On the site of the old Makeyevka plant, a new, powerful metallurgical plant was to be built, equipped with the most modern technology at that time and producing much needed products.

Blast furnace shop of Makeevka Metallurgical Plant

Some clarifications.

Agglomerate is enriched iron ore sintered into porous lumps from 5 to 100 mm. Iron ore after beneficiation is fine dust, which, when blast is fed into the blast furnace, is simply carried out of the furnace. Therefore, it is more advisable to agglomerate it to prevent losses. In addition, the sinter charge is well purged, smelting proceeds smoothly and is efficient in terms of fuel consumption.

A sintering plant belt is a sintering machine consisting of a closed chain of sintering carts-pallets, which are passed through an incendiary furnace. We will not consider this in detail, I will only say that this is a complex structure.

Belt sintering machine at the Chelyabinsk Metallurgical Plant

A staggered mill is a rolling mill in which the pre-finishing and finishing stands for the final processing of metal are arranged in a checkerboard pattern. Its advantage is that the length of the mill is quite compact.

A strip is a strip of low-alloy steel that is widely used in mechanical engineering, construction and, for example, in the production of welded pipes.

Napoleonic plans for the reconstruction of the Makeevka plant, however, were not fully implemented during the two pre-war five-year plans. In 1936, the plant smelted 1 thousand tons of cast iron (316% of design capacity), 58,7 thousand tons of steel (1%) and produced 127 thousand tons of rolled products (52,4%). But that was also a lot.

The Makeevka plant in 1936 smelted 9,2% of Soviet cast iron and 7% of Soviet steel.

Delays, changes and reductions

The planned but unfinished facilities of the Makeevka Metallurgical Plant moved to the third five-year plan. They were already dealt with by the Yuzhmashstroy trust, which was part of the construction trusts of the People's Commissariat for the Construction of the USSR or Narkomstroy, formed in mid-1939.

And this is where things started to get interesting.

For 1940, the Makeevka office of the Yuzhmashstroy trust, which was directly involved in construction work at the Makeevka Metallurgical Plant, had a plan:

• construction of an open-hearth furnace worth 9 thousand rubles;

• construction of sintering belt No. 4 worth 6 thousand rubles;

• construction of rolling shop No. 1 with mills 450 and 250 costing 2 thousand rubles.

It would seem that the management of the Makeevka Metallurgical Plant, which was given a specialized construction office to expand production, should be interested in the speedy completion of construction and the launch of new facilities. But it was not there.

An article in the Stroitelnaya Gazeta dated May 24, 1940 described how the capital construction department of the Makeevka Metallurgical Plant went to any lengths to delay construction.

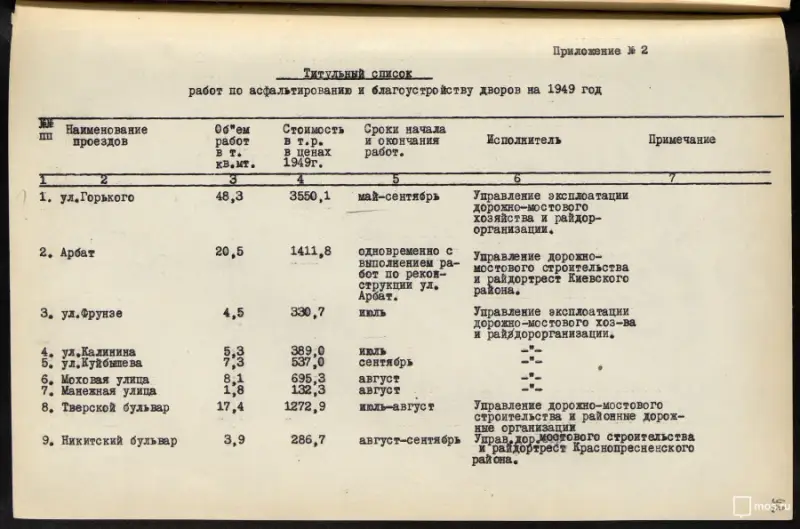

For example, according to the order of that time, the plant had to draw up and approve title lists of construction projects indicating the cost. This is a list of what needed to be built. It seems that the task was not too difficult, but the capital construction department changed the title lists for 1940 four (!) times.

Example of a title list from that time

Then the plant had to enter into a contract agreement with the construction organization, on the basis of which construction work would begin. In theory, the agreement for 1940 should have been concluded somewhere in December 1939. But the capital construction department of the plant formalized the contract only on April 26, 1940, and with an unspecified construction cost.

After this, the plant had to draw up and submit drawings to the builders. This also had to be done in advance. Failure to submit drawings on time was a typical problem in construction at that time. But the capital construction department of the Makeyevka plant went much further. He not only delayed the delivery of drawings, but also replaced some drawings with others, making amendments to them. The builders wrote this in the newspaper - the endless replacement of some drawings with others. That is, this was done not once, not twice, not three times.

In the first quarter of 1940, builders built a gas pipeline to the facilities under construction. But at the beginning of May 1940, the plant’s capital construction department handed over new gas pipeline drawings to the builders and canceled the old ones. Everything that was built according to old drawings turned out to be unusable. This, by the way, is a loss for the construction organization, since an object not accepted by the customer is not paid for.

Finally, the capital construction department of the Makeevka plant allocated much less funds for the construction of facilities than was required. 6 thousand rubles were allocated for the open-hearth furnace, that is, 850 million rubles less; for belt No. 3 - 4 thousand rubles, that is, 1 million rubles less, and for the rolling shop - 070 thousand rubles, or 1,6 million rubles less.

This put the builders in a difficult position. Either the construction organization had to compensate for the shortfall at its own expense, that is, build at a loss, or not complete the construction, that is, disrupt the continuation of the reconstruction of the plant.

As a result, having a plan for 1940 of 18,4 million rubles or 4,6 million rubles per quarter, the Yuzhmashstroy office made only 1940 million rubles in the first quarter of 2.

Sabotage or not?

How else can this be explained, if not by carefully thought out and organized sabotage? All these “pranks” caused enormous damage to the national economy.

Firstly, the money invested in unfinished construction was wasted; if the plant did not produce the planned metal, then the money invested in the construction of factories and plants that were supposed to consume and process this metal was also wasted.

Secondly, builders and machinery were at the construction site, but did little; their strength and skills were wasted uselessly, since during this time they could have built something else.

Thirdly, unfinished metallurgical plant facilities do not produce metal, which is not converted into machine tools, equipment, machinery, as well as weapons, ammunition and military equipment.

Therefore, slowing down or even disrupting the construction of a metallurgical plant is a powerful blow to a number of industries and to defense capabilities in general, and a long-term one, slowing down the development of the national economy for many months and years, which could lead to the cancellation of many important plans that could not be implemented due to shortages. metal

My opinion is that this case, far from being the only one of its kind, was the result of organized sabotage.

But I will ask the readers a question: How would you evaluate this conflict that arose in 1940 at the Makeevka Metallurgical Plant named after. S. M. Kirov?

Information