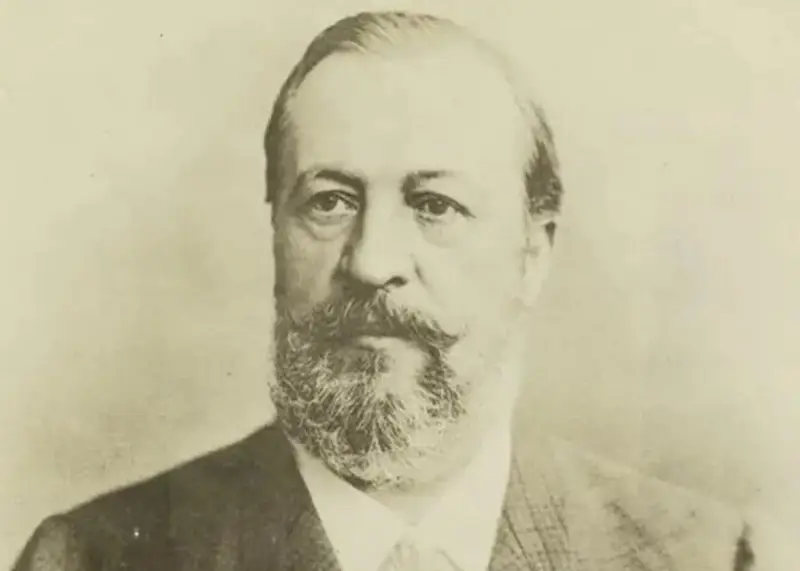

Nikolaus Otto - a businessman who became the inventor of the first mass-produced 4-stroke internal combustion engine

The beginning of the life path

Nikolaus Otto made an enormous contribution to the development of engine technology in the 19th century. In some publications he is even called the father of automobile engines, which is not entirely true in essence.

He was born on June 10, 1832 in the small Prussian town of Holzhausen. His father, a small landowner and head of the post office, August Otto, did everything possible to make his son a good businessman. He sent the child to a real school and, upon graduation, placed the 16-year-old boy in a large trading company. After completing 3 years of practice, the young businessman became a clerk at a large trading enterprise in Frankfurt am Main. Then, after working in several more companies, Otto moved to Cologne, where he continued his commercial career.

According to the generally accepted legend, one fine day 30-year-old Nikolaus opened a magazine and found a small advertisement in which the advantages of the Lenoir gas engine were described in enthusiastic terms.

This day became a turning point in stories engine building - the note unexpectedly struck some hidden chord in the merchant’s soul, and soon the gas engine completely captured the merchant’s imagination. Otto quite reasonably assumed that if it were possible to build a gas engine that was superior not only to Lenoir’s machine, but also to the steam engines of those years, it would cause a real revolution in industry and bring fame and good income to the person who carried out such a bold enterprise.

The most amazing thing was that in those years Otto not only had never seen a Lenoir engine, but did not even have the most primitive technical knowledge. Soon, despite the ridicule of his friends who considered his idea a whim, Nikolaus ordered one of the Cologne workshops to produce a small model of the Lenoir engine and devoted all his free time to practical experiments with this machine.

And so the businessman began to gradually turn into a researcher; with his mind and literally by touch he comprehended the mysteries of the operation of heat engines. Otto literally fell ill with his engine and, sitting up all night, rotated the flywheel, admitting gas into the cylinder in various proportions with air and igniting the mixture with a spark in various positions of the piston stroke.

And suddenly (according to Otto’s stories) during one of his many experiments, he let a flammable mixture into the cylinder and, thinking, squeezed it tightly, and then caught himself and gave a spark. And then a strong explosion occurred in the cylinder, and the unexpectedly high gas pressure strongly pushed the piston and quickly spun the flywheel (flywheel). Having repeated this experiment, Otto was convinced that if the mixture is pre-compressed before ignition, then during its combustion more energy is generated than during combustion without compression, which significantly increases the useful effect of the engine. This is how (according to him) quite by accident, a technically illiterate Cologne businessman discovered a new stroke in engine operation - preliminary compression of the mixture before its ignition.

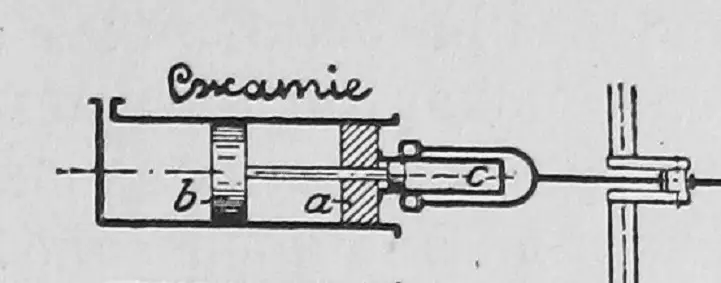

In 1862, Cologne mechanic Zonz, guided by Otto’s sketches, built for him an experimental engine of an extremely sophisticated design.

In those years, the inventors of internal combustion engines began their R&D work with the construction of simple single-cylinder engines. Otto designed a four-cylinder with oppositely located horizontal cylinders, and in addition a four-stroke.

Each cylinder had two pistons: the main a, connected by a connecting rod to the main shaft, and an additional b, the rod of which passed through the main piston. Gas pressure was transmitted to the piston b, and that one through the “air buffer” с moved the piston a. An air buffer was introduced to protect the cranks from "explosion shock". And four cylinders were provided to ensure uniform operation and the ability to develop more power.

When familiarizing yourself with the operating principle of this heat engine, strong curiosity arises: how could a technically ignorant businessman independently come up with such a complex and ridiculous design?

Otto tinkered with his brainchild for a long time, but was unable to curb his temper: the explosive nature of the combustion of the mixture put strong stress on the mechanism parts, and the inventor was unable to establish smooth and uninterrupted operation of the motor.

As his contemporary, the German engineer G. Guldner, later wittily noted, “...shortcomings of knowledge and experience prevented Otto from assessing the beginnings of success, and so obscured the already close goal of his efforts that he completely lost sight of it and deviated from the promising path he had just found».

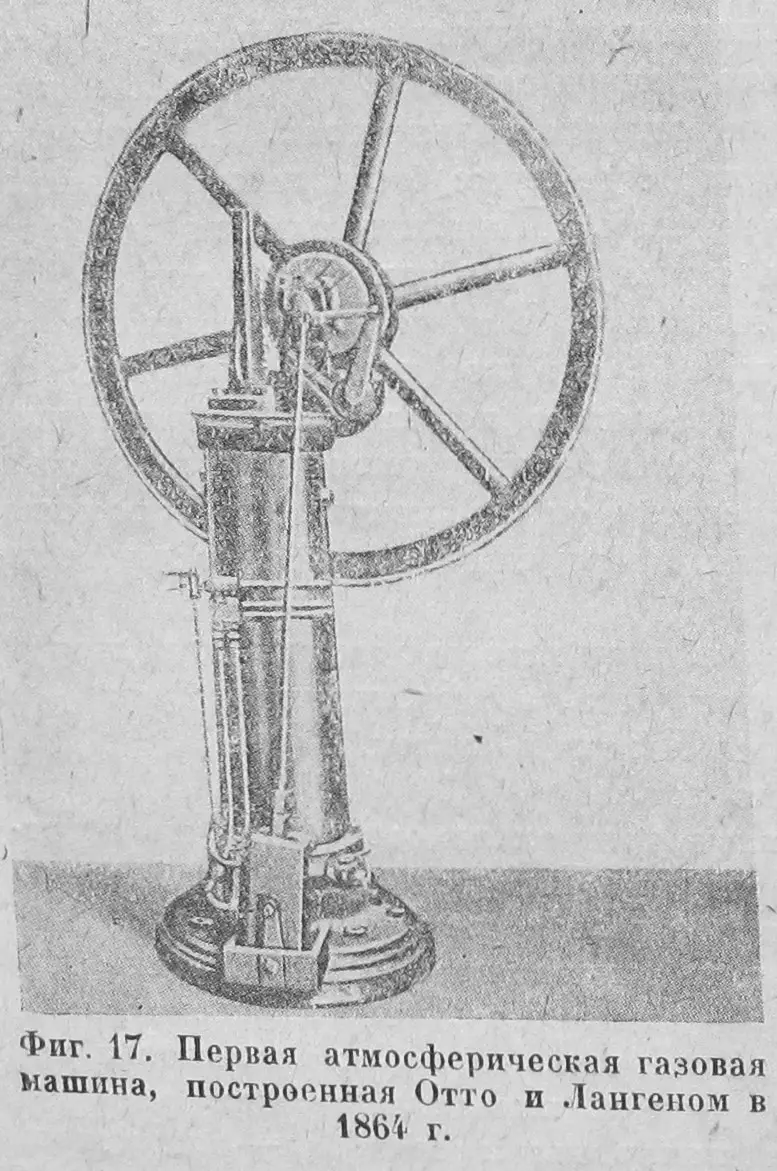

Considering that he was going in the wrong direction, in 1862 the restless inventor abandoned the idea of pre-compression, and the next year he came up with a more flexible engine, operating on a completely different principle without a “compression” stroke, which, according to the classification of those years, was called “atmospheric”. Accustomed to the extravagance of the customer, Conz designed this machine for the eccentric businessman, which Otto brought to a certain perfection, achieving its stable operation. In essence, the invention was a further improvement of Denis Papin's gunpowder machine, built in 1688.

The inventor, delighted with his success, hastened to patent his brainchild in England, Belgium, France and Germany in 1864.

Fateful decision

And then Otto faced a choice of his future path in life. Two roads opened before him: he could either remain a businessman and direct his efforts to trading patents; or establish production and sell the final product - new engines, while simultaneously engaged in their further improvement.

Nikolaus chose the second path; he could no longer imagine his life without constant fiddling with mechanisms. It was under such circumstances that 32-year-old Nikolaus Otto made a decisive turn in his destiny and firmly embarked on the difficult path leading from businessmen to designers.

Otto was not stupid, he really assessed his technical level and realized that he couldn’t carry out his planned business alone; it was necessary to involve people with a technical education in the undertaking. Fate favored the inventor: in February 1864, he met the 31-year-old German engineer Eugen Langen, who by that time had not only extensive production experience at refineries, but also numerous inventions that brought the engineer decent money. Langen, unlike Otto, was not an enthusiastic dreamer; he followed the path of mastering technology gradually and saw in this activity not only the satisfaction of creative needs, but also the improvement of his material well-being.

In the same year, the partners founded the company Otto & Co., which legally secured the creative union of these two talented people, one of whom was burning with ideas, and the other skillfully implemented them.

Langen had never worked on engines before, but this only benefited the overall cause - the engineer’s flexible mind, unfettered by established design schemes, never cast aside the sometimes rather extravagant ideas of his companion, writing them down in advance as fantasies. Everything was carefully studied and double-checked. In addition, Langen contributed money to the foundation of a new production and became its first director.

Subsequently, history somehow undeservedly relegated Eugene Langen to the background, leaving him with the role of Otto’s assistant, which is fundamentally wrong. These were two comrades who walked shoulder to shoulder and jointly built a new path in global engine building. Moreover, it was precisely thanks to Langen’s energy and his numerous connections in the engineering community that the business started by his partners did not die, although at times it was not far from it. And in the technical literature of the beginning of the last century, the results of their joint activities were quite rightly called the “Otto-Langen engine”.

And so, in a rented workshop in Cologne, experimental development work began, but only two years later (1866–1867) through the joint efforts of the partners it was possible to sell several “commercial” atmospheric engines.

Meanwhile, the financial affairs of the company were going from bad to worse, and bankruptcy was clearly beginning to loom ahead. Despite the good characteristics of the engines, it was not possible to organize their mass sales; in those years, the industry was still completely dominated by steam engines and imperfect Lenoir engines, and production workers, due to inertia of thinking, were in no hurry to replace the low-efficiency, but time-tested engines.

The inventors needed to loudly announce their new heat engine to the whole world, but how to do this so that potential buyers would hear them and be convinced of the usefulness of the invention?

Luck and world fame

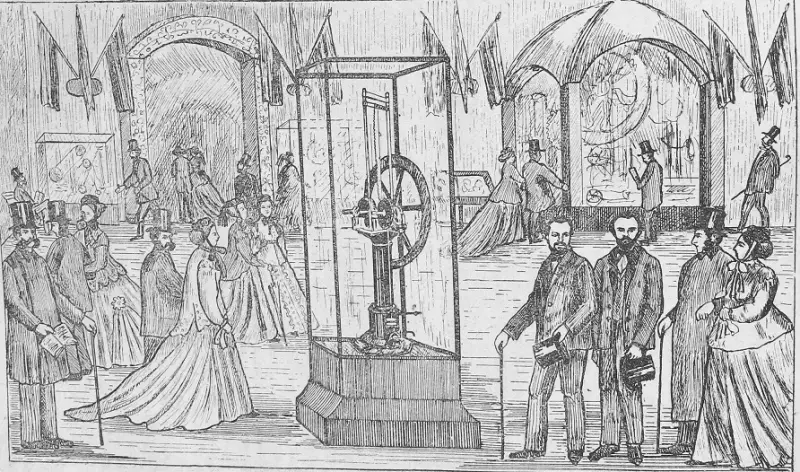

And then the comrades take a desperate step: they exhibit their creation at the Second World Exhibition of 1867, held in Paris.

Their gas engine, which was essentially a further improvement of the experimental engine of the Barsanti-Matteucci design of the 1854 model, was made with a vertical cylinder without a top cover (head). At the beginning of the start-up, the piston was at the bottom of the cylinder. Carried away by the rotation of the flywheel, it went upward and sucked under itself a mixture of illuminating gas and air. Then, at 1/10 of its stroke, the spool closed the inlet and at the same time opened the “ignition channel”, in which there was a burner with an open flame. As a result, the gas-rich mixture instantly ignited and the piston flew up in 0,2...0,3 seconds.

Then atmospheric pressure, trying to eliminate the vacuum formed under the piston, carried it down, and it returned to its original position (which was additionally facilitated by its gravity) and through a complex mechanism, which was a gear wheel, a vertical rack, a coupling clutch and additional lever gears, caused rotation of the drive shaft. When the pressure in the cylinder was compared with atmospheric pressure, the exhaust valve opened, and the piston, unhooking from the drive mechanism, slowly went down under the influence of gravity and pushed out the exhaust gases. Then the valve closed, and the piston, which had returned to its original position, was connected by a cunning coupling mechanism to the flywheel, which helped it begin the next cycle.

Simply put, the machine was a gas engine in which useful work was performed when the piston moved downward, and when the piston moved upward, the drive shaft and wheel were disconnected and rotated by inertia.

It is interesting to note that the inventors abandoned the method of igniting the mixture with a spark, previously used by Lenoir, and used ignition from a “pilot burner” running on the same gas as the engine.

The foregoing indicates that the engine had a complex design, consisting of many gears, and an imperfect ignition system, so it is no wonder that its distribution was associated with such enormous difficulties.

Regulation of speed (power) on the first copies was carried out by reducing the gas supply; later a method was added to change the composition of the mixture.

Since hot gases in the engine performed an auxiliary function - they drove the piston up, and the power stroke was carried out as a result of atmospheric pressure, it went down in history as the first atmospheric internal combustion engine of mass production.

The aesthetically elegant machine made an unpleasant impression on visitors to the exhibition: its operation was accompanied by infernal noise and a terrible roar, it seemed that it was about to go crazy and break into pieces.

Otto and Langen at an exhibition near their heat engine

And it is unknown what path the world engine building would have taken if one of the jury members, Langen’s classmate at a technical school, the Frenchman Relo, had not proposed to arrange comparative tests of the machines presented at the exhibition. They were put into operation, the characteristics were taken, and then suddenly it was unexpectedly discovered that the economic efficiency of the Otto-Langen machine was about 14%, while for Lenoir engines it did not exceed 4,6%. And it was also found that a new engine consumes 1 cubic meters of illuminating gas to produce useful work of 0,8 horsepower hour, and Lenoir engines consume 3.

The numbers were inexorable, and the jury, consisting mainly of French engineers who historically disliked the Germans and all their products, was forced to call the Otto-Langen atmospheric engine the best of the 14 heat engines presented at the exhibition and awarded it a gold medal.

Hitherto unknown inventors became famous overnight, their company began to receive orders, and by the end of 1867 they managed to build and sell 22 engines. The partners began to breathe more smoothly and, not far from Cologne, in the small town of Deitz, they founded their own machine-building production.

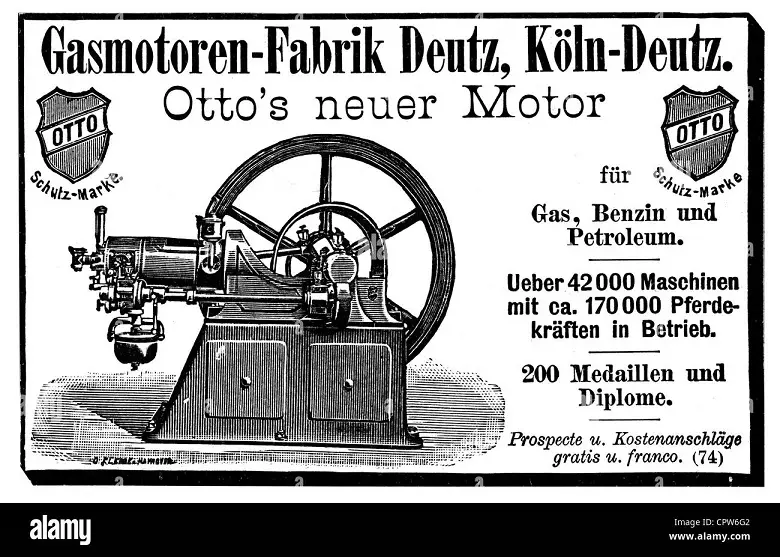

The new business was proceeding with great difficulty and required significant funds, which were constantly in short supply. In order to carry out their plans, the partners were forced to attract new partners to the business, participating in the enterprise only with capital, which led to the establishment in January 1872 of the Joint Stock Company Gasmotoren-Fabrik Deutz (Deutz Gas Engine Factory), which was sometimes informally called “Otto-Deutz”.

The invented engine turned out to be inconvenient. A vertically located cylinder and a high-rising rack required a 1,5-liter motor when installing. With. the presence of ceilings no lower than 3,5 m. And since the size of the entire engine increased with the increase in power, the limitation of the ceiling heights of existing production facilities was a natural barrier to the use of the new engine in large plants and factories. Sometimes it was even necessary to make a hole in the ceiling of the machine room and pass the soaring rail right through. However, on later commercial engines the rack was replaced by a device for directly transmitting the work of the piston to the drive belt.

Another big drawback of this design was its low power - reliable engines with a power of more than 3 hp cannot be built. With. failed.

And so, in the world of motors, a balance was slowly established: steam engines were firmly established in large enterprises, Lenoir engines with a power of about 12 hp. With. on average, and naturally aspirated Otto-Langen engines with a power of 0,5...3 liters. With. (at 40–100 shaft revolutions per minute) are widely used in small industries - printing houses, workshops, and also as water pump engines, and were produced in a total quantity of more than 1 units.

Birth of the first mass-produced 4-stroke engines

Soon, on Langen’s initiative, Gottlieb Daimler was invited to the new rapidly expanding production as technical director, who brought with him the young technician Wilhelm Maybach.

This was the second fateful decision in Nikolaus’s life: Daimler skillfully got down to business, identifying the main goal of increasing engine reliability and improving build quality. He insisted on replacing equipment, fired careless workers, replaced them with experienced craftsmen, and instructed Maybach to focus on simplifying engine designs.

So little by little, the factory formed a friendly, close-knit team of talented German engineers and mechanics, capable of solving technical problems of any complexity.

And these tasks were not slow to arise...

The new business, like a well-oiled engine, was rapidly gaining momentum, the cars were becoming more reliable day by day, orders were pouring in like autumn leaves from the trees. Evgeniy Langen has long moved away from design activities and began to focus on expanding his business. And Otto plunged headlong into the company’s trading activities, essentially becoming commercial director.

And then suddenly, unexpectedly, it was discovered that returning to the profession that he had studied since childhood did not bring satisfaction, did not ignite the brain, like a spark combustible mixture, did not bring the soul into a state of exceptional tension of all creative forces, a state of highest dedication. The established engineer stubbornly refused to turn into a businessman.

As soon as a free moment arose, this respectable 43-year-old man, like a boy, ran to the experimental laboratory to quickly grab his favorite pieces of iron with his hands and once again hopelessly stain his new expensive suit in oil - he could no longer live without designing engines. All his thoughts were constantly tied to this place, where the iron heat engine, nurtured by his hands, was slowly but steadily being further improved.

And then one fine day in 1874, a vision suddenly emerged from the memory of the restless inventor of how 12 years ago, while still a young businessman, he struggled with a four-stroke engine, unable to figure out why it stubbornly refused to work. Now the circumstances had changed: Otto had good technical knowledge and rich practical experience, and most importantly, he had a design team of professional engine builders at his disposal.

The inventor decided to try again, and his first step was the discovery of patent No. 532 dated August 4, 1874 (which will be discussed below).

Otto, 1876

Then the company’s team was given a new important task, and the team did not disappoint.

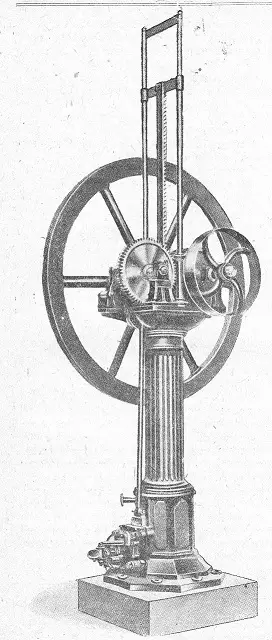

As a result, in 1876, as a result of the joint work of Nikolaus Otto, Gottlieb Daimler, Wilhelm Maybach, Hermann Schumm and many other German mechanics, whose names have not gone down in history, the very famous gas engine was developed, built and tested, which subsequently caused such a stir in the history of world engine building, and its basic design diagram was the basis for the development of automobile engines used today.

Subsequently, analyzing the descriptive part of Otto’s patent No. 532 of 1877, the researchers came to the conclusion that at that time Otto did not yet realize the obvious benefits of compressing the combustible mixture, and he chose the four-stroke stroke to improve the uniformity of the engine. And only after the construction of the first prototypes it became clear that the main advantage of such a technical solution is not balance at all, but an increase in effective efficiency to 17% due to the pre-compression stroke of the combustible mixture.

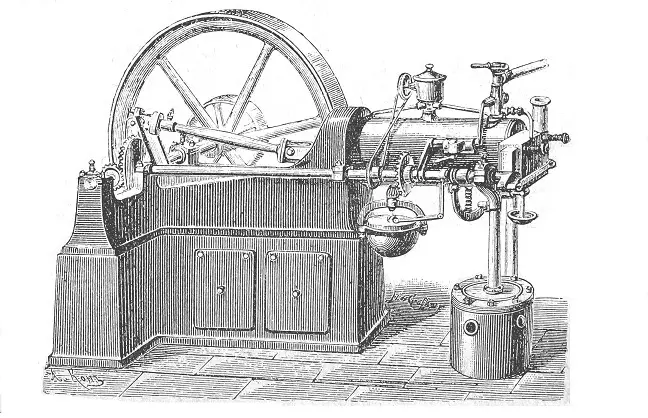

Be that as it may, there is a historical fact: as a result of intense two-year work done by a close-knit team under the leadership of N. Otto, in 1878, at the World Exhibition in Paris, a new single-cylinder four-stroke gas engine with ignition by “flame transfer” was shown, which went down in history under the name “new Otto”.

Unlike the previously made naturally aspirated engine, the new engine had a horizontal cylinder, had a crosshead-type crank mechanism (the flywheel made 4 revolutions in 2 strokes), was characterized by reduced noise, good smooth operation and significantly greater “unit power”.

Gas was supplied to the engine by three tubes: the first provided its supply to form a gas-air charge sucked by the piston into the cylinder; the second supplied gas to the lit burner located outside the cylinder; the third supplied gas to the ignition chamber located in the spool. The movable spool itself was a very complex part and performed the functions of mixture formation, replaced the inlet valve (which appeared much later), and also had an ignition chamber, where a gas-enriched mixture was first formed, then when the spool moved, the mixture was ignited by the burner flame, with its further movement connected to the cylinder and ignited the lean gas-air mixture contained in it. This was the principle of “flame transfer”, from which the name of the ignition system of this type was derived.

The speed of the machine was regulated by “skipping flashes” - the centrifugal regulator closed the gas valve, the gas flow was blocked and the piston drove the air until the speed was reduced to the required value.

From the perspective of today, such a design seems very primitive, but in those early years the engine created a real sensation, was declared the greatest invention in engine building since the time of Watt and glorified the young designers involved in its creation, opening up great prospects for them.

Subsequently, the young eagles Daimler and Maybach, nurtured in this large nest of German engine building, took off on an independent flight and gave the world their own carburetor gasoline engines, which represent the final development of the ideas embedded in the Otto engine of the 1878 model.

Later, the Otto-Deitz factory began producing compact vertical gas engines with a capacity of 0,17–0,5 liters. pp., called “dwarf” (Zwergmotor). They were simple, cheap, initially built without a spool with valve timing and intended for small craftsmen.

Serial horizontal engines of the 1878 model developed a power of 1–4 liters. pp., their best economic efficiency was 12%. The simplified mechanism for transmitting force from the piston to the shaft no longer prevented an increase in power due to an increase in size, and in 1880 the plant already offered consumers engines of 15–20 horsepower, in 1880 - up to 80, in 1889 - up to 100, in 1893 - up to 200 l. With. and up to 600 l. With. - in 1898. Experiments by independent experts conducted with motors produced in 1886 showed that their efficiency has increased and is 14...18% at 140...180 rpm.

Thus, Otto engines not only ousted Lenoir engines from production, they began to attack steam engines on a broad front.

Unexpected blow of fate

It would seem that now Nikolaus Otto can bask in the warm rays of well-deserved fame for the rest of his days. But fate would have it otherwise.

The point was that the patent rights of those years were not only for the benefit of the applicant of the engine patent. The patent was a strong brake on the creative activity of other inventors, who set out to significantly improve his sometimes very imperfect creation, even to the point of completely remaking it. And then they literally slapped their hands, reminding them that such activities at the moment could only be carried out with the consent of the patent holder. And he, at best, sold his consent for a decent amount, and at worst refused, in order to maintain his monopoly.

This happened with the new engine: Deitz Gas Engine Factory JSC did not just patent the engine design. In patent No. 532 dated August 4, 1874, the company itself was assigned 4-cycle operating principle, as first coined by Nikolaus Otto. No one had the right to manufacture any four-stroke engine without the permission of the patent holder.

This caused bitter resentment among engineers who were eager to design and patent more technically advanced 4-stroke engines than the very primitive Otto engine, and also infuriated machine builders who wanted to produce four-stroke engines that were in great demand.

In 1882, angry anti-monopoly fighters living in Germany, Austria, England, France, Belgium and Italy united, filed lawsuits to challenge patent rights, and presented for trial a document raised from the depths of history, published in a small edition (300 copies) in In 1861, a brochure by the French engineer Alphonse Beau-de-Roches, which detailed considerations about the undoubted benefits of running an engine in 4 strokes with preliminary compression of the combustible mixture.

Moreover, it turned out that the first functional four-stroke gas engine was built in 1873 by the Munich watchmaker H. Reitman. The internal working process of this engine was completely consistent with the process of the Otto engine, which he patented in 1877, and the design of the motors was very different from each other. The car served Reitman for almost 8 years as an engine for drilling and milling machines and amazed eyewitnesses with its calm running. It’s just that the watchmaker, out of naivety, considered his heat engine too imperfect to patent it, much less brag about it to all of humanity.

As a result, on January 30, 1886, by the final decision of the court, four-stroke operation became the common property of technology, which undoubtedly only benefited the engine industry and allowed the same Daimler and Maybach, who back in 1882 parted with Langen and Otto, to create with a free hand, and established own business, in 1883 they designed the first gasoline engine, and in 1900 they organized mass production of cars with light, high-speed engines developing up to 500–900 rpm. (for engines of that time, operation at 150–160 rpm was considered normal).

Be that as it may, in fact, only one thing is known for certain: Otto was very worried about what happened, and, although the affairs of his company did not suffer much due to the court decision, the health of the inventor was seriously undermined. The legal battles that lasted 4 years, during which he was constantly accused of appropriating other people's ideas and constructive solutions, greatly frayed his nerves - after this the inventor was destined to live only 5 years...

And literally a week before his death on January 17–19, 1891, he wrote his last letter to his colleague Langen, where he outlined in detail the idea that once came to him under the influence of joint conversations with Beau de Rochas of the working process of an internal combustion engine, in which the piston compresses to 100 atmospheres of clean air, then at the beginning of the 3rd stroke a “stream of fuel” is gradually introduced into the cylinder so that eventually the fuel spontaneously ignites and burns at constant pressure.

That is, Nikolaus Otto (if you believe in the authenticity of this letter) until the last days of his life thought about improving engines and actually came up with an idea, which a year later, on February 20, 1892, Rudolf Diesel outlined in his patent.

But on January 21, 1891, the inventor died, and his idea died with him, because Langen could not understand its importance and considered it the result of clouding the mind of a dying man...

Well, as often happens, as soon as the inventor died, he was immediately declared great. Exactly a month after Otto’s death, a congress of the German Society of Engineers took place, at which the inventor was highly praised and was even posthumously awarded the honorary title of “Doctor Engineer.” And in 1892, for some reason, the University of Würzburg awarded him the honorary title of Doctor of Philosophy for “... the invention of an engine named after him and bringing great benefit in industry.”

In memory of the famous compatriot in Germany, 4-stroke engines with forced ignition are still called Ottomotor.

Four years after Otto’s death, his friend and comrade-in-arms Eugene Langen passed away, and in 1900, 78-year-old Jean Etienne Lenoir, who was not famous for loud scandals and had far outlived his younger colleagues, died quietly, having devoted the last decades of his life entirely to pleasant idleness.

This is how the 19th century, which was so turbulent for engine building, ended...

Использованная литература:

Guldner G. Gas, oil and other internal combustion engines. M., Printing house of T-va I. N. Kushnerev and Co., 1907.

Shpanov N. The birth of a motor. State Energy Publishing House. M., 1934.

Information