103 Armored Repair Plant

Grew up in the cold war

The 103rd Armored Repair Plant, one of the largest defense enterprises in Siberia and the Far East, began to be built in Transbaikalia in 1942, by the will of the highest military leadership of the USSR. Despite the fact that the construction of a new facility began during the Second World War, he was able to begin his duties only after it. 1946 for BTRZ became historical - the first repaired armored vehicles came off the assembly line.

And the USSR immediately entered the era of another war - the cold. The arms race, organized by the two superpowers, naturally, first of all, touched defense enterprises, whose power was increasing exponentially.

BTRZ, starting with the repair tank T-34, from year to year, mastered new technologies, following the pace with the military achievements of the Soviet military industry. As soon as new armored vehicles entered the armament of the army, the plant was reconstructed and equipped with equipment for its repair. Since the beginning of the BTRZ operation, more than a thousand vehicles have descended from its conveyors, including not only tanks of various modifications, but also infantry fighting vehicles, armored recovery and recovery vehicles, mine minesweepers, universal tractors and others.

Even in heavy 80 for the country and 90 for the 103, the BTRZ felt pretty good. In 1992, the production of old vehicles was completely discontinued, and from 1993, the plant switched to the repair of modern types of tanks: T-72A, T-72B1, BMP-2. At the same time, prototypes of the BTS-5 universal tractor based on the T-72 tank were manufactured, the production of the mine mine sweeper of the BMI Kort-B was mastered.

By the beginning of the 2000-x at the factory mastered the repair of all samples of armored vehicles, which are in service with the Russian army. Given the number of military equipment being repaired and the geographical location of the enterprise, the 103 of the BTRZ alone can serve the two largest military districts of our country - Central and Eastern.

11 June 2009, the 103 th BTRZ officially became an open joint-stock company, in which the state still remains the main owner. The change of ownership did not particularly affect the work of the enterprise. It still executes orders of the Ministry of Defense of the Russian Federation, including for foreign countries. For example, in the 2009 — 2010 years, the T-55М tanks for the Republic of Cuba were repaired at the factory, now a large order is being carried out for Venezuela. At the moment, 98 T-72Б-1 tanks have already been sent to the country of Latin America, for the repair of which the Defense Ministry pays almost 15 million.

Repair is a delicate matter!

The process of repairing military equipment is extremely complicated. A tank that drives into the factory is literally dismantled to the last detail, of which there are about a thousand. Each of them goes to a specialized workshop. Already there it is cleaned, defective, repaired and checked if necessary.

It may be interesting to clean the hull of an armored vehicle’s body, which is made in a special chamber with the help of a cast-iron shot. Parts of the tank literally shelled, so you can get rid of the old paint.

Significantly more subtle process occurs when repairing towers and cannons. There can be no errors in this area, since the accuracy of the gun depends directly on the setting, adjustment and verification of the sight and automatic loader. These operations occur not only in the workshop, but also on the ground during firing.

Surprise and some other details of the design of military vehicles. For example, in a tank there are about two kilometers of wires of different diameters. This is the reason for the existence at BTRZ of a special section for restoration and production of wires.

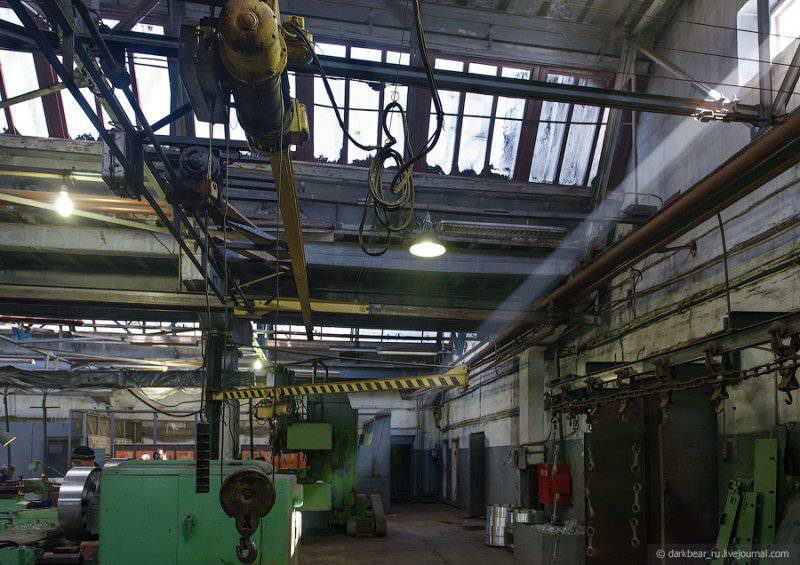

In the huge machine shops located here, everything is repaired, starting from the rollers and ending with the transmissions. By the way, very curious mechanisms exist here at almost every site. For example, the engine after repair is installed on a special equipment, with the help of which it is checked in a running state under different loads with the help of water.

It is also noteworthy that the parts taken from a specific tank are marked with an individual number, thanks to which, upon completion of the repair, they are installed on it. Except for those that are replaced due to breakage.

At the last stage of repair, the machine after assembly is sent to the landfill, located near the plant, where its acceptance takes place. The 100-kilometer run is enough not only to assess the quality of the repair, but also to pretty much stain a freshly painted tank, so it has to be re-washed.

It happens, tanks come to the factory, which are no longer subject to recovery. They are sent to the local "cemetery" - repair park. Previously, parts of old machines were used in the repair, but now they all go to recycling, by cutting them to a state from which restoration is impossible. The territory of the repark and all its contents belong to the Ministry of Defense of the Russian Federation.

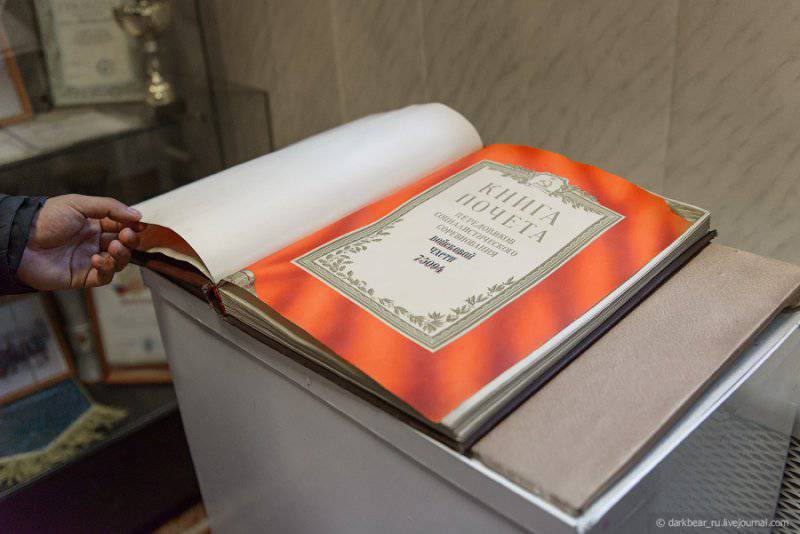

Defense depends on them

Today, more than 700 people of different specialties work at the plant in one shift. With an increase in orders from the Ministry of Defense, an enterprise can go to work in two shifts, increasing the number of employees. Of course, for the people on whom the country's defense capability depends, it is necessary to provide all the necessary conditions for work and rest: a medical center, a canteen, a palace of culture, a museum, a recreation center, and a children's camp on Arakhley Lake.

2012 year for 103-th BTRZ will be historically significant, since this year it marks 70 years. Judging by the number of orders and the amount of financial injections into the plant, there is no need to worry about his fate. In this regard, the workers of BTRZ can only be congratulated on the anniversary and the recent Day of the tankman, and also wish further prosperity to their enterprise!

Information