Blocking the path of the enemy. Mine spreaders and barriers. Part one

One of the most important tasks of the engineering troops for combat engineering is the installation of mine-explosive obstacles that make it possible for the enemy to cause losses, to delay his advancement, to impede maneuver by forces and means. In the offensive, mining is done to cover the flanks, repelling the enemy’s counterattacks, while securing the captured lines. In defense - to cover the positions of troops, their flanks and junctions between units not occupied by the troops of the gaps, and, if necessary, important objects in the depth of their defense in order to make it difficult for the enemy to deploy forces and attack the front edge.

Both in the offensive and in the defense in the direction of the enemy’s breakthrough, mining is carried out by specially designated engineering - sapper units or mobile detachments of the barrier.

The article will deal mainly with minelayers, which lay mines on the ground (in the ground) directly behind them, in contrast to remote handlers, which scatter mines at a certain distance.

PART ONE

Mining was widely used in the first and especially in the second world wars, mainly by hand or with the help of the simplest improvised devices.

After the First World War, at the beginning of the 1930's. For military specialists, it became apparent that minefields were one of the effective means of anti-tank defense. In the USSR, a special minelayer based on the T-27 tankette was developed in this direction, called MZ-27. By the autumn of 1934, complex tests and a batch of special mines were prepared for accumulating operating experience and practicing the tactics of using a minelayer, and they could be equipped with both combat and training charges.

The minelayer MZ-27 was to be used as a means for the device of anti-tank obstacles immediately before the passage of the terrain by the enemy in the directions of attack or movement of his tank groups. In defense, the MZ-27 was supposed to be used to block the movement of enemy tanks in an unexpectedly detected direction (breakthrough, bypass, etc.), and in the offensive - as a means of protecting the flanks and rear from sudden actions of enemy tank groups.

MZ-27 included a special device for mining, which included: easily removable drum welded construction of 10-mm armor placed inside a rotating cage with cells for mines (the drum had a removable wall, fastened with bolts); swivel gear with a worm shaft, mounted in a drum on a hollow wooden axis; a roller with a cable wound on it; a pen; anchor and cable for opening the door.

The device for mining was attached to the rear. The device for mining was driven without stopping the movement of the machine by dropping the anchor and its engagement with the ground (any load of 5 — 6 kg weight could act as an anchor). There were three ways of mining: in one row, in two rows, as well as mining of certain sections of the road (for more details, see Technique and Armament No. 8 for 2012.).

The design of an experienced mine layer MZ-27 based on T-27 tanket shoes did not receive further development. However, the experience of its design, testing and operation was in demand when creating subsequent machines of similar purpose.

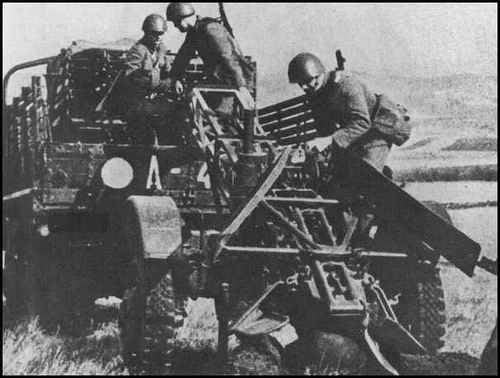

During the Great Patriotic War, in 1942, a mine spreader was developed on the basis of a ZiS truck, which was manufactured by the troops. The marker was a truck, to the body of which are mounted 1-2 wooden trigger tray. In the trays of mines stacked sappers in the back of the car. In the back of the mines are laid parallel to the side walls one upon the other on the edge with the handle up: mines TM-46 in two rows, mines TMD-B, TMD-44 in two or three rows. The back of the body, about 70 cm from the edge, does not load with mines and is a working place for sappers who lay mines in trays. In working position, the vehicle travels at speeds up to 5 km / h. Such a system allowed to increase the speed of mining in 1,5 - 2 times.

Only after the war in the engineering troops of the Soviet army, mine spreaders and barriers are developed and widely distributed.

Here it is necessary to clarify that the mine stacker places mines only on the ground surface, and the minelayer - in the ground (snow) with a disguise or on the ground surface.

At the end of 1940-x - beg. 50 – s The first version of the PMR-1 mine spreader was tested with the simplest trigger trays and their lateral location relative to the tractor case. But the lateral arrangement of the trays and their design were found to be unsatisfactory both from the side of laying accuracy of mines and the convenience of working the calculation. Further improvement of the tagger resulted in PMR - 2which was adopted in 1954

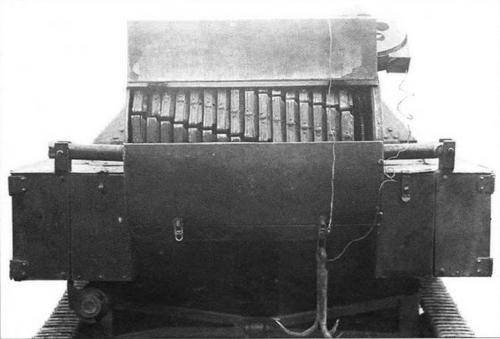

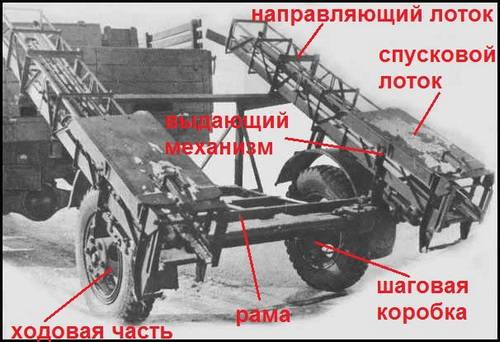

PMR trailer mine spreader - 2, mounted on a single-axle trailer and towed when mining with a truck (tractor).

The marker consisted of a running gear with an actuation mechanism, a frame with a drawbar, two guide trays with trigger trays, two issuing mechanisms with a step box and a chain transmission, and electrical equipment. Frames - trays were separated from each other in width by 2 m, mines moved along them under the action of their own weight. Unlike the previous simplest trays, in this case, for the first time, a pin counting mechanism with a drive from the trailer chassis was used in them.

The PMR-2 trailed mine spreader was designed for laying anti-tank mines on the surface of the ground when building minefields.

The equipment of mines with fuses, posting to the required distances and their installation into the ground with camouflage are performed by demining units manually. At the same time, mines (TM-46, TMD-B, TMD-44) were laid out on the surface of the ground in two rows with the 2 or 4 mining step. The set of mines was placed along the sides of the car.

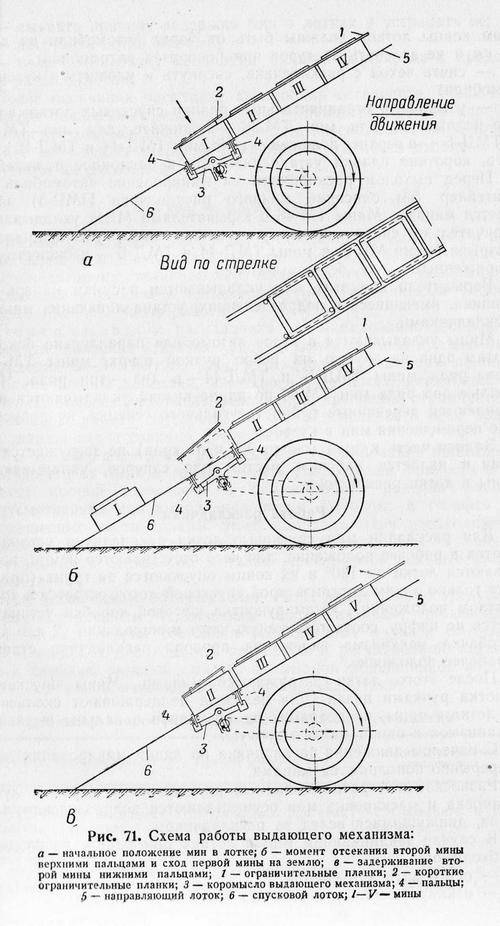

Work spreadsheet. To work the marker clings to the rear hook of the car or armored personnel carriers. The mines are placed in the trays of the spreading place by the sappers that are in the back. Mines under the weight of their own weight slide on the rollers of the trays down. The issuing mechanism through the mechanism of activation from the right wheel of the stacker works in such a way that in one tray the mine will be stopped by the lower fingers of the issuing mechanism, and in the other by the upper fingers (see the figure below). Further, when the lower fingers of the issuing mechanism are lowered and the upper fingers are raised, the first mine slides to the ground, and the second mine is cut off. Then the fingers of the issuing mechanism again change position, and the second mine takes the place of the first. The cycle is repeated. In the other pan, the same thing happens, but mines are delivered between the movements of the mines in the first pan. In this way, a width interval is established between the mines in the row of a minefield, and the mines themselves are laid in a checkerboard pattern.

To lay the mines on the ground, the launch trays are released from the straps holding them and with their ends are lowered to the ground. Then the step box knob is set to the corresponding mining step, that is, opposite the number 2 or 4. Then the trays are loaded with mines handles back. Two sappers support the sliding mines, protecting them from strikes against the fingers of the issuing mechanisms and one against the other.

The posting of mines on the ground, the passage of the holes, their installation and disguise is carried out by soldiers of the demining unit, who follow the marker.

The main tactical and technical data of the PMR-2:

The types of mines laid out by the handler are the finally equipped TM-46 mines with MVM fuses, the unfinished TM-46, TMD-44 and TMD-B mines intended for equipment with MB-5 fuses;

Minning pitch in the row - 2 or 4 m;

The number of rows of folding mines - 1 or 2 (depending on the number of trays used);

Distance between trays (rows min) - 2 m;

The speed of movement of the marker at work - up to 5 km / h;

The speed of movement of the spreader on the roads in the trailer behind the car - up to 40 km / h;

Time required for 300 min layout:

- at the step of mining 2 m and using two trays - 5 — 7 min

- at the step of mining 4 m and using one tray - 15 — 20 min .;

Time for loading and laying 300 min:

- to the car body in one compartment with a toe for the distance to 30 m - 12 — 20 min .;

The time required to prepare the marker for work - 5 — 7 min;

Slopes of the area at which the normal layout of mines

- rise - up to 15 °

- descent - 7-9 °

- slope - 5-15 °;

Spanner sizes:

- length - 4,3 m

- width - 2,5 m

- height - 2,1 m;

Spreader Calculator - 4 people

Spreader weight - 900 kg.

In 1956, a more advanced trailed mine layer appeared in service PMR - 3 on a single axle trailer. It was first used without a plow-masking device (PMU), which allowed to install anti-tank mines (PTM) in the ground (snow) with their disguise. This halved the work of the sappers.

Mines in a single pass were placed into the ground in a single row to a depth of 6 - 8. To transfer the mine fuses to the firing position in the transfer line of the minelayer that received movement from the support wheels of the trailer undercarriage, an active transfer mechanism of the fuses was used. His spring-loaded rod made a reciprocating movement, pressing the buttons of the mines' detonators before leaving them at the SMU.

Work spreader.

When the spreader is moving, the rotation from its wheels is transmitted to the driving and driven shafts of the issuing mechanism, which passes one mine at set intervals - 4 or 5,5. The work of the issuing mechanism proceeds in the same way as in the PMR - 2 mine spreader. When the plow is working, mines from the guide tray fall into the open furrow and are masked by turf, which is laid back with sod or filled with the plow backflash in loose soil. When the plow is idle, the mines are laid on the ground or in the snow.

To install the mines with a spreader, it is necessary to turn on the clutch with the start of the plow movement and deepening to the required depth and then continuously supplement the tray with mines.

Bringing mines to the final curb condition, pulling out a safety check from fuses (for TM-46 mines with their partial digging) and additional masking are performed in the manual engineer unit after laying the mines with a spreadsheet. When all the mines are used up by the conveyor, the trailer loops to another conveyor loaded with mines.

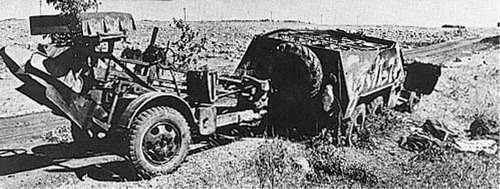

Baptism of frontier PMR - 3 passed during the Arab - Israeli wars, but there is no information about the effectiveness of their use.

Main TTX - PMR - 3:

The types of mines laid out by the handler are the finally equipped TM-46 mines with MVM fuses, the unfinished TM-46, TMD-44 and TMD-B mines intended for equipment with MB-5 fuses;

Minning pitch in the row - 4 or 5,5 m;

The number of rows of mines laid out - 1;

The speed of movement of the marker in work - 3 - 8 km / h;

The speed of movement of the spreader on the roads in the trailer behind the car - up to 50 km / h;

Time required for 200 min layout:

- calculated from 4 people. - 16 min

- calculated from 6 people. - 10 min;

The time required to prepare the marker for work - 1 min;

Slopes of the area at which the normal layout of mines

- rise - up to 15 °

- descent - 10 °

- slope - 10 °;

Spreader dimensions in working position:

- length - 5,25 m

- width - 2,0 m

- height - 2,2 m;

Spreader Calculator:

- at installation of finally equipped mines - 5 people.

- when installing unloaded mines - 8 people.

Spreader weight - 1300 kg.

Later, in the middle of the 1970's, the PMR - 3 was modernized. The transmission was slightly changed: now in the guide tray the mines were forcibly moved by a chain conveyor, which made it possible to simplify the transfer of fuses and to perform it in the form of a spring-loaded plate. Upgraded version received name PMZ - 4 - “trailed minelayer”, which is more consistent with its purpose. Additional equipment (elongated pipes and plow) were also put into the design for mining by mines controlled by wires, as well as for laying the main wire into the ground to a depth of 20. The mines themselves were laid along the side of the car body in cartridges of 100 pcs.

Attempts to mechanize the installation of anti-personnel minefields and the absence of any means of mechanization for these purposes necessitated expanding the composition of the PMZ-4 additional equipment: a launch chute (long pipe on the left while moving), pushers, and special stands were introduced into it. This equipment allowed to install PMN anti-personnel mines, and the minelayer was given the name PMZ - 4P. In this embodiment, the minelayer carries 1000 pieces of MRP. The PMZ-4P mining step with anti-personnel mines is 2 and 2,75 m, and the mining speed is up to 2 km / h. The simplicity of the design of the PMZ-4P led to its widespread use in the troops, where it is used to this day.

With the help of a minelayer, it is possible to install both permanently and inconclusively equipped mines. The calculation of the minelayer consists of 5 - a person, 7, depending on what mines he places and in what condition - fully equipped or not.

Thus, the calculation of the minelayer during the installation of finally equipped anti-tank mines consists of five numbers:

- The first number - the operator - is the senior of the calculation, is located directly on the barrier and is responsible for the task.

- The second and third numbers - are in the back of the tractor, remove the mines from the container, remove the safety checks and lay the mines on the receiving tray.

- The fourth number is also in the back and delivers one mine each from the receiving tray to the chain conveyor.

- The fifth number - the driver of the tractor - is obliged to strictly observe the speed and the given direction.

When installing inconclusively equipped PTM, the calculation of the minelayer consists of seven numbers.

- The first number - the operator - is the senior of the calculation, is located directly on the barrier and is responsible for the task.

- The second and third numbers - are in the back of the tractor and feed mines from the container to the guide tray.

- The fourth number - searches for mines installed in the ground and reveals a masking layer of soil over them.

- Fifth number - unscrews the plugs min.

- The sixth number - sets fuses in mines, tightens traffic jams, finally masks the place where mines are placed.

- The seventh number - the driver of the tractor.

PMZ-4 and PMZ-4П trailed minelayers are the cheapest, and therefore, massive means of mechanization of mining outside enemy fire, on the rear lines, at night, in poor visibility conditions and in closed areas. This of course does not preclude their use during combat, when, according to the conditions of the situation, it becomes necessary to place mines in front of the enemy’s attacking orders, and there are no other means of mechanization. Their use provides a reduction in labor intensity and installation times of mines in 2-3 times as compared to manual installation.

But with all the simplicity and reliability of the construction of trailed mine-layers, their main disadvantage was the lack of protection for the crew and mines from enemy fire impact, as well as the lack of defensive weapons, which caused the use of barriers only in the depth of the military formations of their troops.

The above disadvantages of trailer barriers were eliminated in the GMZ new self-propelled minelayer.

The main TTX PMZ - 4:

Tractor - car ZIL-131 (ZIL-157), Ural-375, artillery tractors AT-T, AT-L with one section of the container;

Types of mines used:

- finally equipped - TM-62 with fuses that do not allow mechanized installation; TM-57 with fuses MVZ-57; anti-personnel PMN;

- not fully equipped - TM-62 with fuses that allow mechanized installation; TM-57 with fuses MV-57, MVS-57; TM-46 with fuses MV-62 and BMV;

- without fuses - TMD - B; TMD-44 (fuses in them are installed manually after the mines are placed on the ground;

The total mass of the haulier kit is 1800 kg.

Overall dimensions in working position:

Length - 5,28 m.

Width - 2,02 m.

height - 1,97 m.

Track - 1,75 m.

The maximum transport speed is 45 km/h.

Mining speed:

- anti-tank mines - up to 5 km / h.

- anti-personnel mines - up to 2 km / h.

Mining step:

- anti-tank mines - 4 or 5.5 m.

- anti-personnel mines - 2 or 2.75m.

Ammunition min:

Anti-tank - 200 pcs.

Anti-personnel - 1 000 pcs.

Number of calculation

- when installing finally equipped anti-tank mines - 5 people.

- when installing not fully equipped anti-tank mines - 7 people.

- when installing a fully equipped anti-personnel mines - 7 people.

The length of the minefield from one ammunition mine

- anti-tank - 800 or 1100 m.

- anti-personnel - 2000 or 2750m.

The time of bringing the minelayer into a combat position - 1 - 2 min.

The charging time of the cassette by mines calculation forces - 10 - 15 min.

The installation time of the controlled minefield set by the sapper department is up to 80 min.

The main weapon of PMR - 3 and PMZ - 4. From top to bottom: TM - 46 anti-tank mines, TM - 57, TM - 62 and anti-personnel PMN.

Information