Machine guns Beardmore-Farquhar (UK)

Already in the 1918 year, after the appearance of an order for serial rifles, gunsmith designer Mobrey J. Farquhar decided to continue developing new small arms. The new goal of the engineer was to create a light machine gun with the lowest possible weight and high performance. The design of such weapons was completed in 1919. The designer decided to cooperate with the company of William Berdmore Beardmore Engineering Co., which was to undertake the manufacture of new weapons. The surname of the manufacturer and developer promising machine gun called Beardmore-Farquhar.

Back at the end of the zero years of the 20th century, M.J. Farquhar proposed an original automation based on a rolling barrel using a buffer spring, which accumulates a recoil impulse and transfers it to the mechanisms of automation. Such a variant of the weapon turned out to be quite complicated, because of which a self-loading rifle with gas automatics was later created, in which the buffer spring was again used. Despite the considerable complexity of the design, such a weapon interested the army and was put into service, although it was not widely used.

In the new project of automatic weapons, it was again planned to use the already existing mechanics, which had been tested at the test sites and on the battlefield. At the same time, the project required to implement several new ideas related to its main tasks. So, the new weapon had to belong to the class of light machine guns and, as a result, have the corresponding weight characteristics. Reducing the mass of the structure also allowed the use of a machine gun as an aircraft armament. The need to reduce the weight in the end led to the fact that the new machine gun had an unusual appearance, formed by a number of parts of a small section.

Because of the need to fulfill the requirements specific to machine guns, a new sample for the authorship of M.J. Farquara should have been noticeably different from the previous design. A long rifled barrel was retained, under which was placed the casing of the gas engine and the buffer spring. The breech part of the trunk connected with the receiver of a small section. Below a similar receiver, there was a thin and narrow hollow plate, in the back of which the details of the firing mechanism were mounted. Behind the main metal parts was attached wooden butt and pistol grip.

Initially, the new machine gun was designed to use .303 British cartridges (7,7x57 mm R). The weapon received a rifled barrel with a length of 660 mm (86 gauges) with a chamber of the required dimensions. Behind the first third of the barrel on its lower surface there was a vent hole for pressure relief to the piston. The barrel was fixed in its place rigidly and motionless, but if necessary it could be removed. Barrel mounts were designed to be replaced after long firing, resulting in heat with loss of performance.

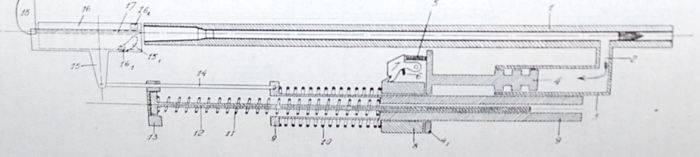

Scheme of automation. Figure Alternalhistory.com

Directly under the barrel were placed the gas engine and the node of the buffer spring, responsible for reloading the weapon. These units were placed inside a common casing, made in the form of an elongated tube with enlarged front and rear parts. There was a gas piston in the front bulge and a buffer spring in the rear bulge. A gas piston with a long stroke was used, the back of which passed through the casing and interacted with the buffer spring. In addition, the piston had its own return spring, less strong than the buffer one.

The cylindrical buffer spring at both ends carried special blocks with latches. While the machine gun was operating, the latches had to alternately engage with the case and block the spring movement, ensuring the correct course of reloading the weapon. The latches were controlled using their own projections and guides on the inner surface of the casing.

Behind the barrel of a machine gun Birdmore-Farquara had a receiver box of the original design. As in the case of the previous rifle, this part of the weapon had a small cross section, and on its outer surface there were longitudinal guides for the slide frame. On top of this unit was the receiving window for the cartridges, as well as the means of holding the magazine. Next to them there was a mount for the frame sight.

The bolt of the machine gun was made in the form of a cylindrical part with an internal cavity for the drummer and several lugs in the front. The shutter was placed inside the movable frame, which also served as the casing. During the reciprocating movement of the bolt group, the shutter had to rotate around its axis, making the barrel locked. The bolt group was equipped with its own return spring, placed inside the receiver. The casing-frame had two tubular cocking handles drawn on both sides of the weapon.

The trigger type trigger mechanism was placed inside the lower bar of the receiver, as well as in its rear part and block, which served as a gate guide. The trigger was removed on the bottom surface of the weapon and covered with a safety bracket. The task of USM was automatic cocking with his descent after pressing the hook. In this case, the design of the mechanism was modified in comparison with the previous rifle. Thus, the opportunity arose shooting not only single, but also bursts. The control of triggering was carried out with the help of a trigger, a fuse and a translator of fire.

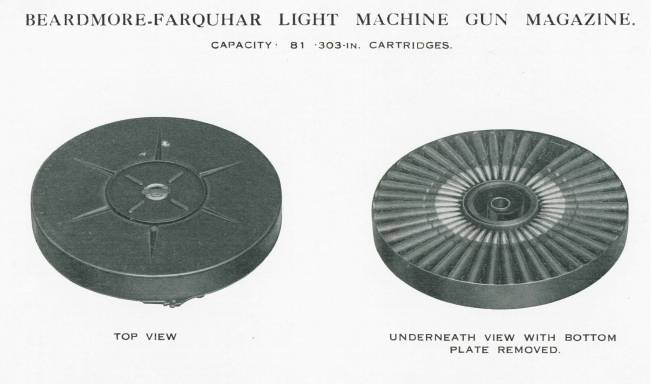

For the new machine gun were developed two types of stores. The first and main - detachable double row disc. Inside the cylindrical body with rotating parts, the 81 British 303 cartridge was placed. In the lower lid of the store there was a hole for feeding cartridges inside the receiver of the weapon. The magazine was fastened using the vertical axis of the receiver, which is included in the central part of its body, and the latch at the rear. Fixation was made by turning the magazine around the vertical axis in a clockwise direction. Later it was found that the existing design of the store does not fully meet the requirements for reliability. Because of this, in order to avoid problems, no more than 75-77 cartridges had to be charged.

A small-capacity auxiliary store has also been developed. A small detachable device with a capacity of all 5 cartridges was installed horizontally between the latch and the axis of a regular magazine. Such shops had the opportunity to equip without removing the machine gun. To do this, you should use the standard clips used with British rifles of the time.

Machine gun Beardmore-Farquhar received extremely simple fittings. Behind the units was attached wooden butt. Also provided for a pistol grip fire control. This structure of additional equipment allowed to reduce the overall weight of the structure, as well as to simplify the production of weapons.

The machine gun retained sights, similar to those used on the previous model rifle. A folding stand with an adjustable front sight was placed above the muzzle of the barrel. The back of the receiver had a mount for a frame sight folding design. To conduct aimed fire, the frame had to be raised to a vertical position and then put the rear sight on the desired position.

From the new weapon it was possible to shoot both with hands, and with an emphasis on a two-legged folding bipod. This device was hinged to the front of the casing of the gas engine. In the transport position, the fry was folded backwards and laid along the casing.

Carry the gun should be using a belt. One swivel for its installation was placed immediately before mounting the bipods, the second - at the junction of the trigger guard with the receiver. To reduce the dimensions in the stowed position, it was necessary to fold the bipod and sights.

The Berdmore-Farkuar machine gun chambered for .303 British had a total length of 1,21 m and weighed only 7,3 kg of ammunition. Due to the use of the original design with the minimum necessary dimensions of those or other units containing the main parts, it was possible to minimize the weight of the weapon. In this parameter, the new model was significantly ahead of other similar systems in its class. For example, the Lewis light machine gun under the same cartridge weighed almost 12 kg. Applied automation allowed the machine gun to do up to 450 shots per minute.

Despite all the changes in the design, the general principles of operation of the new machine gun corresponded to the previous development of M.J. Farquara. The machine gun used automatics with a gas engine and an indirect connection between the gas piston and the bolt group. Due to this, it was possible to a certain extent to reduce the negative impact of strikes of weapon parts against each other and to improve the general characteristics.

Machine gun shop. Photo by Alternalhistory.com

Preparation of weapons for firing was quite simple. The magazine should have been placed in cartridges, then the bolt was retracted to the extreme rear position and fixed. After that, it was possible to fix the store in its place and, turning off the fuse, pull the trigger. Unlike the previous rifle, which, when first pressed, released the bolt and allowed it to go forward, send the cartridge and lock the barrel, the machine gun could shoot from the open bolt.

Pressing the trigger led to triggering and firing. The powder gases passing through the vapor outlet of the barrel, acted on the piston and forced him to move backward, compressing the buffer spring. At the beginning of the piston movement, the rear end of the spring was locked, which led to its compression. After reaching the maximum compression, the front latch was automatically activated, which allowed the piston to return forward using its own return spring.

Simultaneously with the inclusion of the front latch occurred unlocking the rear, because of which the buffer spring could straighten and push the bolt group back. The bolt turned around its axis, went back, pulled out and threw the sleeve, cocked, and also compressed its return spring. Under the action of the latter, the bolt group returned to the forward position, producing a new cartridge, locking the barrel and shifting the buffer spring to the initial position. The weapon was ready for a new shot.

Carrying a machine gun with a belt. Photos Historicalfirearms.info

In 1919, the Beardmore-Farquhar machine gun was tested at a shooting range and then introduced to the military. The representatives of the army studied this development, noted the pros and cons, and then refused to accept it. According to some information, in the future, W. Berdmore and M.J. Farkuar has repeatedly tried to offer his machine gun to the military, however, these attempts were not crowned with success. Potential customer refused. The main reason for such responses to the proposals was the end of the First World War and the lack of a need for new small arms. In addition, the army’s financial capabilities, which did not allow for the mass production of new models, left much to be desired.

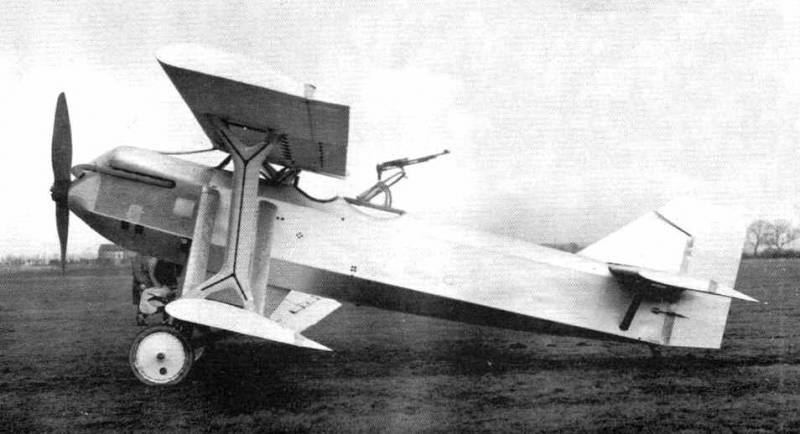

The new machine gun was distinguished by its relatively small size and weight, which allowed it to be used as a weapon for airplanes. After some improvements, one of the weapons was submitted for new tests. 14 November 1919, a crew of flight lieutenants Rea and Pinkkes, lifted the Bristol Fighter aircraft, equipped with a new weapon. The machine gun of Berdmore-Farkuar was installed on the site of an observer pilot using a standard turret. At a given height, the observer pilot Pinkes shot four disc magazines - about 320 cartridges. The rate of fire reached the 420-430 shots per minute. There were no problems during shooting at altitude, there were no delays. The machine gun showed its potential as an aircraft armament.

The authors of the project believed that with the help of some design improvements, the rate of fire could be brought to 1000 shots per minute. In addition, the possibility of installing a synchronizer was declared, which allowed the use of a machine gun as a full-fledged course weapon of fighters. However, these plans were never implemented. Despite all the advantages over existing systems, the Beardmore-Farquhar machine gun was not adopted for reasons of economy and because of the presence of a significant number of other similar weapons.

Shooting from a machine gun. A shot from the newsreel

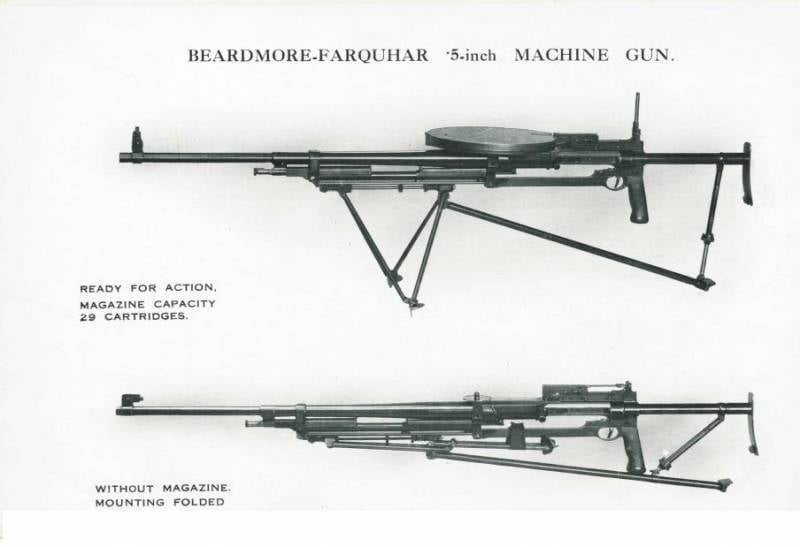

In 1922, a new version of the machine gun was proposed under the designation Beardmore-Farquhar Mk II. It differed slightly from the basic design, primarily by the presence of fasteners for use with machine tools and tumba installations. However, this version of the weapon did not interest the potential customer.

Three years later, work was completed on a large-caliber modification of the machine gun. This weapon was equipped with a barrel chambered for 12,7x81 mm Vickers and, according to the main design features, hardly differed from the basic version. For a large-caliber machine gun, new single-row (29 cartridges) and two-row (52) disc magazines were developed. Also the detachable box magazine on 10 cartridges could be used. The use of the new cartridge forced the project authors to resize the main parts, introduce more powerful springs and apply other necessary changes.

Heavy machine gun received a new butt in the form of a tubular base with a butt pad. A reinforced bipod was used, consisting of two triangular blocks attached to the two hinges of the casing of the buffer spring. There was also a back rest associated with the butt. The stop and the back of the bipod are connected by a long barrage. When folded, the bipod elements were disengaged and laid backwards. The butt stop turned forward.

Large-caliber version of the machine gun Berdmore-Farquhar. From above - in a fighting position with the bipods laid out, from below - in the transport position. Photo by Alternalhistory.com

A new modification of the weapon, designed for a more powerful cartridge, had a length of 1,55 m. The weight of the product without a magazine was 19,5 kg. The rate of fire remained at the same level. It is noteworthy that after the modernization of the weapon design M.Dzh. Farquara was superior to competing designs in terms of size and weight.

Soon after its appearance, the heavy machine gun Berdmore-Farquhar, as well as its predecessor, became the standard weapon of a promising aircraft. By order of Latvia, the company Beardmore Engineering Co. created a biplane fighter WB.XXVI. Two rifle-caliber machine guns with synchronizers were installed near the engine and were intended to fire forward through the plane of the screw. Large-caliber was placed on the turret in the rear cockpit and, if necessary, could be replaced by two machine guns of smaller caliber.

In 1926, the prototype of the fighter was sent to the client country. Inspections showed that the aircraft engine has insufficient power and cannot provide it with the required characteristics. After some trials, limited to only three flights, the plane was returned to the UK. Armament machines, like herself, did not interest the customer.

Over the next few years, the authors of the project tried to develop a machine gun of the original design. Weapons offered to various potential customers. In order to interest them, a number of outstanding weapons qualities were mentioned in promotional materials. The machine gun was called the lightest, easiest to manufacture and use, the cheapest and most reliable in the world. In addition, it was argued that the machine gun is less demanding on the quality of service in comparison with counterparts. However, all this advertising has not helped interest potential buyers.

Attempts to promote machine guns Beardmore-Farquhar without any success continued until the 1936 year. By the mid-thirties, this sample was hopelessly outdated and finally ceased to be of interest to potential customers. As a result, all the work on the project was abandoned. More this weapon was not advertised, not offered to customers and not modernized.

For testing and demonstration by the military, several machine guns of Berdmore-Farquhar of two modifications were fired: the base for a rifle cartridge and the new one for large-caliber ammunition. Due to the lack of orders, the mass production of such weapons did not begin. An interesting and promising sample of small arms has remained only in a few copies. It is known that several such machine guns have survived to our time. Like many other unique samples, they are now museum exhibits.

On the materials of the sites:

//world.guns.ru/

https://forgottenweapons.com/

//alternathistory.com/

//historicalfirearms.info/

Detailed photo review of the machine gun Beardmore-Farquhar:

https://forgottenweapons.com/beardmore-farquhar-photos/

Information