Self-loading rifle Farquhar-Hill (UK)

This weapon was named after the names of its creators. At the beginning of the 20th century, British designers Mobrey J. Farquhar and Arthur H. Hill began studying the problem of creating self-loading weapons. Soon, they developed their own version of automation, which was patented in 1908 year. The first version of the Farquar Hill self-loading rifle, which, however, was not tested in practice, implied the use of recoil barrel with a long stroke in combination with some unusual mechanisms.

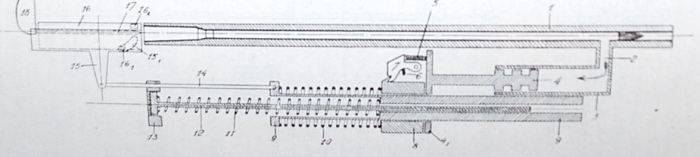

The main feature of the weapon proposed by the British designers was the absence of a direct connection between the moving barrel and the mechanisms responsible for reloading. After the shot, the barrel had to go back, without disengaging from the bolt, and then they came back together. When moving the barrel and the bolt back, the buffer spring should be compressed, which was locked in the maximum compressed position. Only after returning the barrel to the extreme forward position, the buffer spring should be unlocked under the action of a separate return spring. After that, she unlocked the barrel, moved the bolt, and recharged.

The automation system proposed in 1908 was able to solve the assigned tasks by independently reloading the weapon. At the same time, such a system was too complex and could hardly show the required reliability. For this reason, M.J. Farquhar and A.H. Hill refused to manufacture the prototype, its testing and refinement. It was decided to continue work on promising automation systems and look for a system with acceptable reliability. In some sources it is mentioned that the designers still produced and tested the sample of the rifle, working on the recoil energy, but there is no worthy evidence of the existence of such a system.

In 1911, gunsmith designers again applied for a patent. This time, the subject of the patent was a self-loading weapon using gas-engine-based automation. At the same time, the new project retained the characteristic feature of its predecessor in the form of a buffer spring block. The use of this system and some other unusual solutions led to the formation of a non-standard look of the weapon, which has interesting differences from the samples that existed at that time.

Unusual automatics affected the overall appearance of the perspective rifle. While maintaining the overall layout, “traditional” for rifles of the time, this sample should have had the uncharacteristic form of individual parts. In addition, the proposed new solutions related to ergonomics.

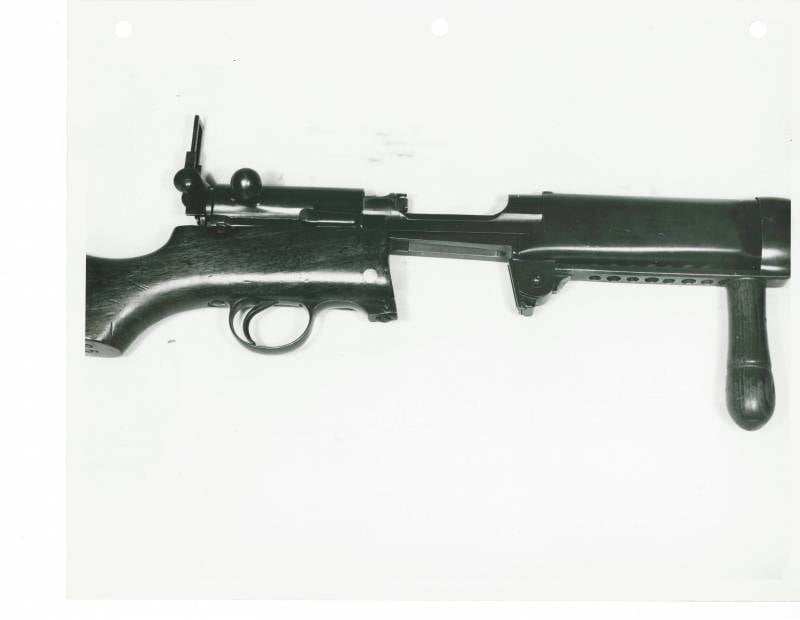

The main part of the weapon was a receiver of great length, part of which actually consisted of a removable cover covering the barrel and the gas engine. Due to a nonstandard automation system with a buffer spring, the box had a long front part, inside of which the barrel breech was placed. In front of this part of the receiver, it was proposed to mount a perforated casing that covered some of the automation components and part of the barrel. The back of the receiver, fastened with a wooden butt, had a relatively small height and width. This feature of the weapon was associated with the original design of the bolt. In the middle part of the receiver, under the shutter in its neutral position, there was a receiving device for the store.

The Farquhar-Hill rifle was supposed to use an .303 British cartridge (7,7x57 mm R). A rifled barrel with a length of 686 mm (89 gauges) caliber 7,7 mm with a chamber of the required size was developed. The barrel was rigidly fixed in the receiver. In the lower wall of the barrel, in its front third, there was a gas outlet connected to the gas chamber.

Under the barrel was a tube with a gas piston long stroke. The piston was connected to two springs with different characteristics. A less powerful return spring was used to move the piston to the neutral position, as well as a stronger buffer, directly responsible for reloading the weapon.

Under the breech of the trunk were placed buffer spring and its mechanisms of the original design. The spring was equipped with two latches at both ends, which could engage with grooves on the inner surface of the receiver. The task of the latches was to fix the front or rear end of the buffer spring in the required position at one or another stage of the recharge cycle. With its rear part, the buffer spring was in contact with the slide frame.

The Farquara-Hill project envisaged the use of a bolt group of unusual design. The bolt itself could rotate inside its frame, interacting with the guide on its inner surface, and locked the barrel with a set of combat stops. Inside the gate there was a movable drummer. The bolt carrier was made in the form of an elongated part of variable cross-section with a reload knob on the right side. The slide frame was literally put on the back of the receiver and could move along its outer rails. In addition, inside the receiver were protrusions of the frame, designed to interact with the buffer spring. Inside the rear of the receiver was located its own return spring bolt. An interesting feature of the new rifle was the use of the bolt carrier as a movable cover of the receiver covering the internal mechanisms.

Schematic diagram of automation. Figure Alternalhistory.com

The trigger mechanism of the rifle was to be built according to the kurkov scheme and located inside the front part of the wooden butt. When the trigger hooks were pressed, the trigger was unlocked, which, under the influence of its own combat spring, struck the bolt strike. There was a manual fuse.

The rifle was supposed to use 19 drum magazines specially designed for it. The shop was a truncated cone shaped product with spring plates on both bases. With the help of these parts that engage with the projections on the rifle, the magazine had to be held in place. A curious feature of the store was the original holding device, which made it possible to eliminate the loss of cartridges, as well as to compensate for the relatively large force of the spring of the pusher.

On the rear wall of the store, to the right of the axis, there was a lever that operated a special stopper. When the stopper was raised, cartridges could not be placed in the store, but they could not fall out. Releasing the stopper, it was possible to place cartridges in the store. After installing the magazine on the rifle, it was also necessary to release the cartridges to carry the weapon inside.

The rifle received traditional for that time sights in the form of a fly on the muzzle of the barrel and a frame sight mounted on the rear section of the receiver. In the transport position, it was laid back and down, for firing it went up. It was possible to change the position of the rear sight in accordance with the firing distance.

Due to the use of a long metal receiver, consisting of several parts, the Farquhar-Hill perspective rifle received relatively simple wooden fittings. A wooden butt with a pistol protrusion was to be attached to the receiver at the back. For a more comfortable holding of weapons, the butt had a front part in the form of a section of a standard rifle box that reached the magazine intake. Handguard was not provided. At the same time, for convenient holding with both hands, the rifle received a front vertical grip. The handle was screwed into the holes on the bottom surface of the front of the receiver. The presence of several such holes allowed the shooter to choose the most convenient position of the handle for him.

Transport weapons offered with a belt. Swivels for him were placed on the front of the barrel casing (left) and on the bottom surface of the stock.

Rifle designs M.Dzh. Farquara and A.H. Hill had a total length of the order of 1040 mm and weighed around 6,6 kg, excluding rounds. Used automation allowed to fire with a technical rate of fire to 700 rounds per minute. The firing range and the main firing characteristics were at the level of other systems chambered for .303 British.

Rifle Farquhar-Hill arr. 1911 was supposed to be different from other samples of that time by a number of characteristic features. For example, the process of equipping a drum shop required constantly turning on and off the locking mechanism. Thus, when filling the store, it was necessary to lock the mechanisms, then place the cartridge in the upper window, and then move the control lever to the “open” position and return it to its original position. The same manipulations were required in the case of the remaining 18 cartridges.

Before installing the store, it was necessary to pull the handle of the bolt band and move it to the back position, where it was held up by the trigger. Only after that it was possible to insert a magazine into the weapon, after which it was required to disconnect the last stop. The freed cartridge under the action of the spring of the store rose into the receiver, and in its place became the next.

Unusual, and taking into account the accumulated experience, even a strange one, a feature of the Farquair-Hill rifle was a way to bring a weapon into a combat position. To move the bolt forward, then send the cartridge and lock the barrel, you had to pull the trigger. At the same time, the bolt group was released and, under the action of its own return spring, went forward, preparing the rifle for firing. The shot, however, was not made.

To fire a shot, you should aim the rifle at the target and pull the trigger again. After that, the trigger was released, beat on the drummer. Passing through the barrel, the bullet allowed the powder gases to get into the gas chamber of the automation system. The gases pressed the piston and forced it to move backward, compressing the return and buffer springs. At the same time, the rear end of the buffer spring was automatically blocked by a latch and could not move. With the rearmost position of the gas piston, the front end of the buffer spring was automatically locked. The piston was able to go into the neutral front position with its own return spring.

Simultaneously with the latching of the front end of the buffer spring, the rear end was released. Straightening, the spring worked on the slide frame and forced it to go back. The bolt unlocked the barrel, removed the sleeve and threw it out when you roll back. Also produced a new cocking hammer. After the gate has passed a certain distance, the front latch of the buffer spring was turned off. At this point, the return spring of the bolt was straightened, which led to the forward movement of the bolt, sending a new cartridge and returning the buffer spring to its place under the rear of the barrel. After all parts returned to neutral, the rifle was ready for a new shot.

After receiving the patent in 1911, the duet of designers continued to develop their weapons. For example, at a certain stage it was proposed to use a new cartridge of its own design. It was made from a sleeve without a welt, borrowed from the cartridge 7,65x53 mm, and the bullet of the standard .303 British. A prototype weapon was manufactured for such ammunition. The use of a sleeve without a welt allowed to significantly increase the reliability of the automation while maintaining acceptable combat qualities.

After the outbreak of the First World War, M.J. Farquhar and A.H. Hill offered their army development. The military was interested in a new self-loading rifle, but it was not without claims and criticism. So, the army immediately abandoned the use of new cartridges. The military was interested in the rifle only under the standard .303 British ammunition. Also, at the request of the military, some minor changes were made to the weapon design.

In 1916-17, it was decided to manufacture a small batch of Farquhar-Hill rifles in order to conduct field and military tests. This weapon was made and sent to the troops participating in the battles of the First World War. The experience of the military operation of the new system was considered positive. At the very beginning of 1918, the Farquara-Hill rifle was officially adopted by the British Army, giving it a new designation Rifle .303 inch, Pattern 1918. It was also decided to place an order for the production of 100 thousand units of such weapons for supply to the army.

In 1918, we managed to find a contractor who was to make new weapons. However, by the end of the year fighting on the fronts of the First World War actually stopped. In the foreseeable future, a peace treaty was to appear, putting an end to the conflict. Such a change in the situation led to the cessation of the production of new weapons. The army managed to get some Farquhar-Hill rifles, after which their production was discontinued.

According to others, until the very end of 1918, the army unsuccessfully tried to find a company that could manufacture and supply new weapons. Weapon factories were loaded with work, because of which no one wanted to take a new order. The search for the contractor continued until the beginning of 1919, when it was decided to abandon existing plans. According to this version, the army received only rifles intended for military trials.

According to some sources, the Rifle .303 inch, Pattern 1918 rifles found limited use in the army and in the Royal Flying Corps. Due to the possibility of self-reloading, such a weapon had certain advantages over other systems. At the same time, in aviation parts of Great Britain already had a significant number of self-loading rifles of other types. As a consequence, M.J. Farquhar and A.Kh. Hilla could not noticeably affect the firepower and combat effectiveness of the fighters.

The total number of Farquhar-Hill rifles produced, according to various sources, did not exceed a few hundred. The weapons were limitedly used by the troops, after which they went to the warehouses. In the future, much of these rifles were disposed of as unnecessary. Several samples have survived to our time and are exhibits of museums and private collections.

Unable to initiate any noticeable rearmament of the army, Mobrey J. Farquhar began to develop his ideas in order to create new types of small arms that could be offered to customers. In 1918, the designer, together with William Berdmore, began to develop the design of a promising machine gun. The design of this weapon should have been used all the main developments from the project of a self-loading rifle.

On the materials of the sites:

http://world.guns.ru/

http://forgottenweapons.com/

http://historicalfirearms.info/

http://alternathistory.com/

http://secretprojects.co.uk/

Information