Shipbuilding in besieged Leningrad

From the first days of World War II, the shipbuilding plants of Leningrad rebuilt their work in relation to wartime conditions. They eliminated combat damage to ships, produced weapons and ammunition, built barges, tenders, dies, armored trains, participated in the creation of defensive lines around Leningrad. The needs of the front demanded the re-equipment of a number of workshops in factories. Some production, which were in close proximity to the front line and subjected to systematic artillery shelling, had to be transferred to more remote areas of the city. After September 8, 1941, Leningrad was in blockade, the ships of the Red Banner Baltic fleet were dispersed along the Neva and included in the general defense system of the city, playing the role of artillery batteries.

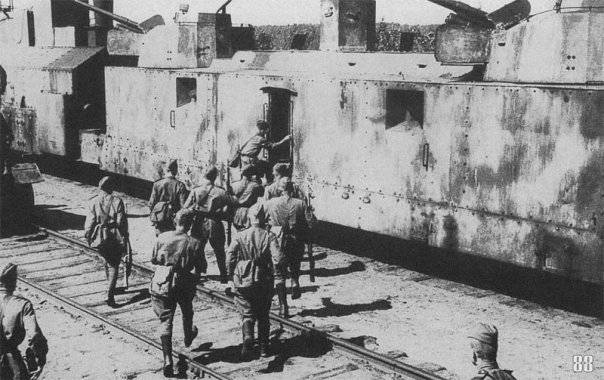

In warehouses there was a large number of different armor, therefore, at the suggestion of the engineer-lieutenant-commander P.G. Kotov, shipbuilders, in accordance with the decision of the Military Council of the Leningrad Front, began the production of mobile means of defense: artillery dots, machine gun points, shelters for snipers, command and observation posts, etc. For a year and a half, from August 1941 to January 1943. , the plants manufactured and installed on the front line more than 7000 armor structures, for the manufacture of which went 18400 t ship armor. Used for the needs of the defense and long-range sea guns. They were installed on railway platforms, protected by ship's armor and sent straight from the factories to the battle lines.

On the destroyers Strict and Stroy, which took combat positions in the Nevsky Forest Park and in the Ust-Izhora settlement, the shipbuilders completed the installation work, which enabled 30 August 1941 of the year to put the ship’s artillery into action. Ships and destroyer personnel had to work under systematic shelling and bombing under heavy blockade times, but in a short time they completed all the necessary work on the ships.

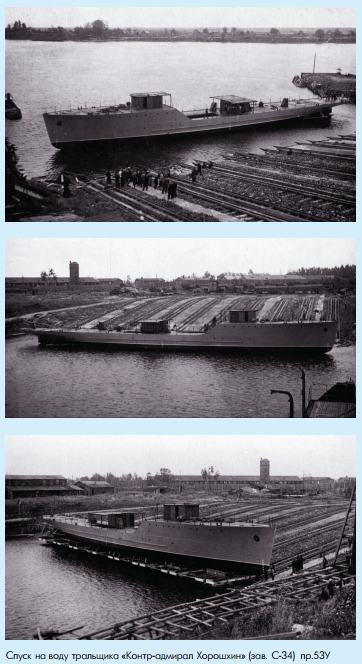

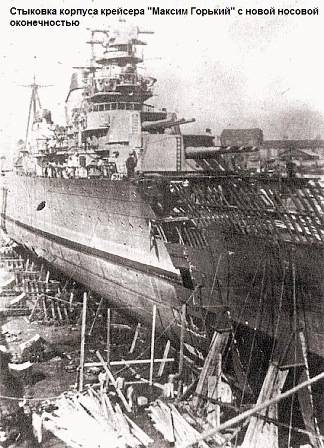

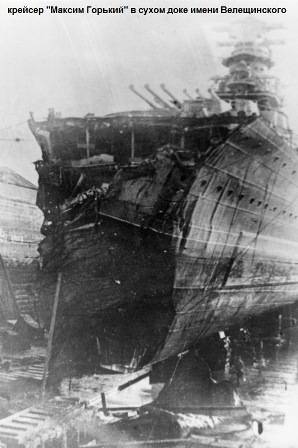

A great achievement of the Petrozavod team during the war years was the delivery of minesweepers to the fleet. Throughout the war, Leningrad shipbuilders carried out a large amount of work on combat repair of ships. So, in 1941-1942, they repaired the battleship "October Revolution" after getting into it aviation bombs were restored by the cruiser "Maxim Gorky" and the destroyer "Terrible", which were blown up by mines, the leader "Minsk", who sank during the enemy bombing. Various kinds of repair work were carried out on the cruiser Kirov, the destroyer Vice-Admiral Drozd, the minelayer Ural, several base minesweepers and submarines.

At the end of December 1941 of the year, six base sweepers of the “Werp” type approached the wall of Petrozavod and took part in the evacuation of the garrison from the Hanko Peninsula, which was held in harsh ice conditions. Two ships had large damage to the nasal tips from the stem to the bulkhead of the fifth frame, captured the underwater part of the hull to a considerable depth. The Military Council of the Red Banner Baltic Fleet took only three and a half months to carry out all the work. In the absence of a dock, the only correct decision was made to repair the nasal tips with caissons. It should be emphasized that during the years of the Great Patriotic War, shipbuilders and military sailors created an extensive caisson farm and gained a great deal of experience in using caissons. They were used on many unequipped bases to ensure the repair of the underwater part of the hulls of various ships. In total, about a hundred ships and auxiliary vessels were restored with the help of caissons during the war period.

Petrozavod made two wooden caissons of the same size. They had a transverse set of pine bars, on top of which a pine planking was installed horizontally. To ensure watertightness, the grooves between the cladding boards were pierced and poured; In addition, the skin was covered with a canvas on the red surik. The cut-out in the rear wall of the caisson was made on a template with a plaza. So that the seawater does not penetrate at the junction of the hull of the minesweeper and the caisson, a felt pad cushioned with a canvas was installed over its section. Due to the fact that they worked in winter conditions, they had to cut ice around the nasal extremities and make lanes for factory caissons. In the stern of each caisson (along the contour), a steel panel was installed with butts on the deck and steel cables were wound, with which the entire structure was compressed tightly. In order to keep the caisson on an even keel, after loading and unloading water under the ship, in its nose part there were two wooden beams that were missed into the side anchors; in addition, a ship's anchor chain was laid on the deck of the caisson.

It was impossible to restore the nasal tips of the riveted hulls of the minesweepers in their original form, since there were no riveters in the plants. Electric welding was used, and all work was carried out by ship personnel under the guidance of factory craftsmen. Repair of six minesweepers was completed exactly by the deadline, and in the spring campaign of 1942, they entered combat trawling.

During the war, the ships of the Red Banner Baltic Fleet often had to sail in ice conditions, which inevitably led to damage to the propeller blades. Due to the heavy workload of the docks, the repair and replacement of screws was carried out in most cases by trimming the ship. It was especially widely used on ships of small displacement. So, for example, in 1941 and 1943, at Petrozavod, with the help of offsetting, screws were replaced on trawlers like Verp; the aft tips were lifted with a stationary coastal boom equipped with hoists and two 3 t lifting cargo winches. To increase the trim, liquid ballast was taken into the ships' bows, and solid was placed on the forecastle. The stern rose to the point until the propeller hubs were shown out of the water. Then a special raft was brought in, the buoyancy of which was enough to accommodate a crew of mechanics with the necessary tools and devices and the propellers themselves. The method of trimming to replace the propellers during the war years was widespread, both on warships and on ships of the merchant fleet.

To repair the bottom-overhead reinforcement and eliminate local damage to the hull at a small depth from the waterline, the ship was inclined by taking water, pumping fuel or laying solid ballast on the deck at the edge of the corresponding side. Using this method, the citizens of Petrozavodsk in the year 1943 installed on the electric welding overhead sheets on the ice belt of the outer skin of the minesweepers of the “Verp” type; as a result, ships were able to sail in harsh ice conditions.

The short time allotted for repair work, the acute shortage of materials and other difficulties of the blockade time constantly forced shipbuilders to look for ways out of critical situations. So, for example, the Balts, while restoring the bow end of the destroyer “Watchdog”, cut off by a torpedo explosion, used the hull set of the tip of a destroyer of another project, which was close to the contours of the repaired ship. The bow end of the Maxim Gorky cruiser was also restored.

Leningrad shipyards did not stop working for the needs of the front, even in the most difficult months of the blockade. The winter of 1941 / 42 was especially cold and hungry. Urban transport did not work, and the weakened people who lived far from their enterprises could not get to work. A job for the repair of ships, for production weapons and ammunition continued to flow. Under these conditions, the administration of the factories organized trips to workers' homes; completely weakened, they were sent to factory hospitals, where they received enhanced nutrition, after which they returned to work. So, on the Petrozavod in the middle of January, 1942 of the year could be used by just 13 people, by February 1 - 50; By the middle of April, when the supply of food to the city improved somewhat, 235 people were already employed in repairing ships. No difficulties and deprivations could prevent the workers from carrying out the tasks assigned to them to ensure the combat capability of the ships.

Frequent power outages from the city network forced the shipbuilders at each enterprise to solve this problem in their own way. The Balts, for example, used floating crane diesel generators with a total power of 2000 kW; and a backup power plant with 800 kW power was equipped under a large slipway. At some factories, electricity to the shops and to the stocks was supplied from ship generators. So, using shipboard diesel diesel generators of direct current for the production of electric welding works at minesweepers, at Petrozavod they achieved the characteristics required for welding using ballast resistors. When performing pneumatic work used ship compressors.

In the heavy blockade winter 1941 / 42, the main supply of Leningrad was carried out along the icy Road of Life. But how will it be possible to ensure the mass transportation of goods with the onset of spring, when the ice melts, especially since there were clearly not enough ships available on Ladoga? Having considered this issue, the State Defense Committee in March 1942 ordered the Leningrad shipbuilders to build an appropriate number of barges. Since the enemy occupied the left bank of the Neva at the Ivanovsky thresholds, ready-made vessels could not be transported to Ladoga. Therefore, we decided to assemble sections in Leningrad, deliver them by rail to Ladoga, and then weld them at the slipway in the Golsman bay. Shipbuilders built the first barge in just 20 days. In April, construction of small self-propelled vessels began at almost all shipbuilding enterprises in Leningrad.

Those that were built, for example, at Petrozavod, received the name of the tender and had a load capacity of 10 t (length 10,5, width 3,6, depth of the board 1,5 m). To simplify the technology of metal processing and assembly of sections, the tender had rectified lines; The body of the welded structure was assembled on the stocks from large sections: bottom, side, stern, fore and deck. A waterproof bulkhead divided the ship into two compartments — the aft (engine compartment) and the bow (cargo hold). The engine used was a ZIS-5 automobile engine with a capacity of 75 l. s., providing speed around 5 knots. The team consisted of a motorman and helmsman. 1 June 1942, the first tenders and scaffolds were demonstrated to members of the Military Council of the Leningrad Front. Before the end of the year, Leningrad shipbuilders handed over to seafarers only tenders over 100 units. The Ladoga military flotilla, reinforced by built ships, transported about 1 million tons of cargo and almost 1 million people, including 250 thousand soldiers and officers, in the summer of the same year.

During the blockade of Leningrad, the front line ran four kilometers from the territory of the Ust-Izhorsk shipyard, so its main production had to be transferred to the city. The great need for trawling forces forced the Military Council of the Leningrad Front to mobilize all possible resources for the early commissioning of minesweepers. A number of Leningrad plants received an order for the construction of small minesweepers. In the fall of 1942, in the Ust-Izhora shipyard in the year, a large group of military sailors with hull experience was sent to help small shipbuilders.

During the period of preparation for the complete defeat of the fascist troops near Leningrad, there was a question about the secret transfer of the 2 shock army of the Leningrad Front to the Oranienbaum bridgehead. In this important operation, which began in November 1943 of the year and ended in January of 1944, minesweepers, network barriers and other vessels took part. Its implementation was complicated by the heavy ice situation and the inability to use icebreakers because of the shallow depths of the Petrovsky Canal, which was used for guiding ships behind the coasts occupied by the enemy. The role of the icebreakers was assigned to the small-set base minesweepers, on which they not only reinforced the hulls, but also replaced the regular propellers with special ones intended for navigation in ice. On the ice belt of the outer skin they welded overhead steel sheets, and near the waterline, on the bulkheads and frames in the forward tip, they placed the wooden bars. The shells of minesweepers reinforced in this way weathered well under sail in ice conditions.

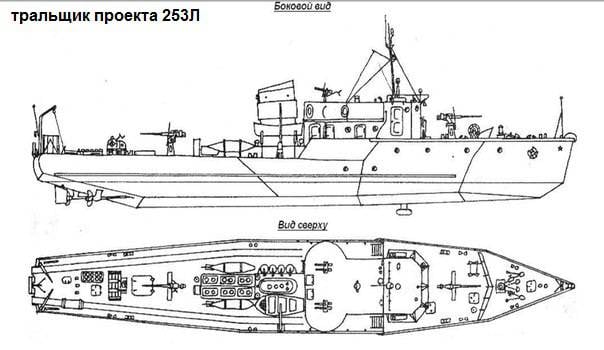

The need for trawling operations in the shallow waters of the Baltic Sea, which the Germans “stuffed” with a multitude of mines of various types, dictated the need to create a small minesweeper. The development of the project started on the mainland in July 1941 year. And in Leningrad, the documentation for the new “sea-sweeper-trawler” of the 253 project came already during the blockade. The artillery weapons developed by the minesweeper were designed, first of all, to fight enemy aircraft and small ships. The ship was supposed to carry sufficiently powerful and diverse trawl armament, which made it possible to destroy all types of mines known at that time in the conditions of shallow water. Displacement minesweeper was 91,2 tons, length 31,78 m.

The main drawback of the project was the fact that the designers did not take into account the specific conditions of Leningrad. The lines of the ship were drawn by classic curved curves, which necessitated the complex, “hot” work on the bending of steel sheets. In addition to obvious technological difficulties, these processes required substantial expenditures of fuel and electricity, which was an unaffordable luxury for besieged Leningrad, since their value was equal to bread. Therefore, the specialists of the design bureau, in which practically all the engineers in Leningrad gathered, started a radical reworking of the project. The displacement of the ship was increased, curvilinear complex nose and aft contours were replaced with multi-faceted, which were formed by flat sheets. The experience of combat trawling accumulated in the Baltic during the first years of the war was also taken into account. This caused significant reworking of the design of the all-welded hull with the equipment, in addition, another tool appeared on the minesweeper’s tank. The result was a new project, which was significantly different from the 253, so the letter L - “Leningrad” was added to the main index. The production of working drawings and the start of construction began almost simultaneously. And when the draft design was sent for approval to Moscow, the first copies of the minesweepers were already afloat, and equipment and weapons were mounted on them.

The head "stotonnik" was put to the test at the very beginning of November 1942. In the same month, the first minesweeper of the 253L project became part of the Baltic Fleet. Sailors noted good seaworthy and firing characteristics of ships of this type and quite acceptable speed, which was little affected by the "blockade" flat lines. The mass production of the "stoton tanks" enabled the Baltic seamen to fully deploy trawling operations at sea in the second half of the war and in the first post-war years. Also in the conditions of the blockade, Leningraders also created such new types of ships as armored sea hunters, skerry monitors. It must be said that the creation of minesweepers proceeded in the extremely difficult conditions of besieged Leningrad and was carried out at the cost of the true labor heroism of the shipbuilders. Suffice it to say that during the time of delivery of the head minesweeper, the personnel of the design bureau lost about two-thirds of its strength, only the most persistent and physically fit were left, who withstood the most severe blockade conditions - hunger, cold, hardship, death of loved ones.

Sources:

Kotov P. Armor belt. // Engineering troops of the city-front. Collection. Leningrad: Lenizdat, 1979. C. 140-144.

Dmitriev V. Baltiysky Zavod in the days of the blockade. Leningrad: Shipbuilding, 1975. C.50-54

Ankudinov V. Leningrad project. // Model Builder. 1985. No.3. C.17-21.

Ilyichev A. Shipbuilders of Leningrad during the Great Patriotic War. // Shipbuilding. 1985. No.5. C.51-53.

Ladinsky Yu. On the fairways of the Baltic. M., Military Publishing, 1973. C.84-86.

Information