Self-loading rifles by V. Madsen and J. Rasmussen (Denmark)

In 1883, Army Officer V. Madsen and Director of the Copenhagen Arsenal J. Rasmussen (later changed his name to Bjarnov) began work on creating a new weapon capable of independently performing basic operations in preparation for firing. In view of the absence of serious alternatives, it was decided to use automatic systems that use barrel recoil. Already in 1886, two gunsmiths completed the development of a promising project, and then offered it to a potential customer in the face of the Danish army.

The new project involved the creation of a self-loading rifle under the newest unitary cartridge 8х58 mm R, designed for the Krag-Jorgensen rifle. It was a central ignition cartridge with a propellant charge of smokeless powder and a bullet with a rounded head (a version with a pointed bullet later appeared). This munition had a fairly high performance, and was also devoid of the disadvantages characteristic of cartridges with black powder. As a result, it was very convenient for use in new self-loading weapons, and had a certain impact on the successful completion of the project.

During the creation of a new self-loading rifle, V. Madsen and Y. Rasmussen proposed a new original version of automation, using the recoil of the barrel. A new system of their development was implemented when creating a new rifle, and later was taken as the basis for developing a new machine gun, which later entered service with several countries. It is noteworthy that automatics, which from the current point of view looks very unusual, has gained quite a lot of popularity. The mode of operation of the automation led to the appearance of the corresponding project name. According to some information, the new rifle until a certain time was designated as Forsøgsrekylgevær (“Experimental rifle using recoil”).

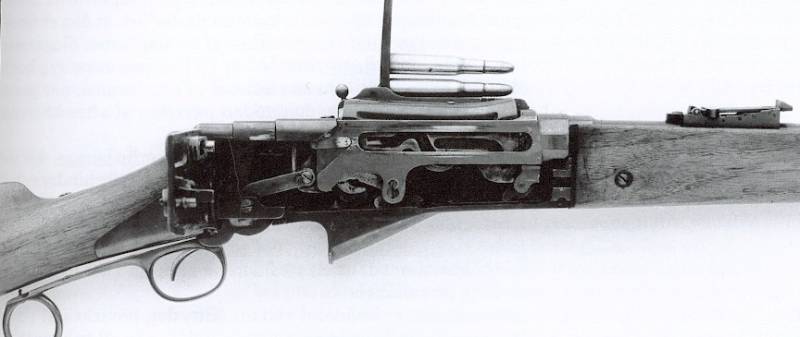

The Madsen-Rasmussen rifle was made according to the standard for that time scheme, but had some differences associated with the use of original automation. The main part of the weapon was a metal receiver connected to other units. The trunk was movably connected to it in the front, and fastenings were also provided for the wooden forearm. On the back of the receiver there was a frame for the details of the firing mechanism, and fasteners were installed for the stock with the neck without a pistol protrusion.

The receiver was made in the form of a rectangular unit with a movable lid instead of the right wall. For mounting the parts and servicing the mechanisms, the cover could fold back and side. In the closed position, the lid was fixed with a latch. On the bottom surface of the box was provided a triangular nozzle for ejection of spent cartridges. The left wall of the box was equipped with a rectangular receiving shaft of the ammunition system.

Inside the receiver it was proposed to place a set of various parts of complex shape with numerous protrusions, teeth, etc. In addition, on the inner surface of the receiver provided for a number of guides, grooves and protrusions. With the help of the interaction of different sections of different parts, the correct operation of the mechanisms was to be ensured according to a rather complex algorithm.

Rifle Madsen-Rasmussen of the first version received an unusual system of filing cartridges. Ready-to-use cartridges should be placed in the holder (due to the nature of the weapon’s work, this part can also be called a pack) inserted into the grooves of the receiving shaft. Under its own weight, the ammunition should have been lowered inside the mine. At a certain point in the reloading cycle, a special lever placed inside the shaft, interacting with other mechanisms, was supposed to push the cartridge and feed it to the dispensing line. At the next reload, the mechanism allowed the new cartridge to fall under its own weight inside the shaft, after which it pushed it into the receiver. There were no protective covers for cartridges or springs to feed them into the weapon. The authors of the project considered that in this case the system will have the required performance.

The automatic weapons of the Forsøgsrekylgevær rifle were supposed to work due to the recoil of the barrel during its long course. It was proposed to use the recoil impulse to ensure the operation of automation using the design of the barrel and related parts. In front of the receiver, a rifled barrel of 8 mm caliber was movably attached, equipped with a return spring. The latter was installed inside the wooden forearm and had to retract the barrel to an extremely forward position at the end of the recharge cycle.

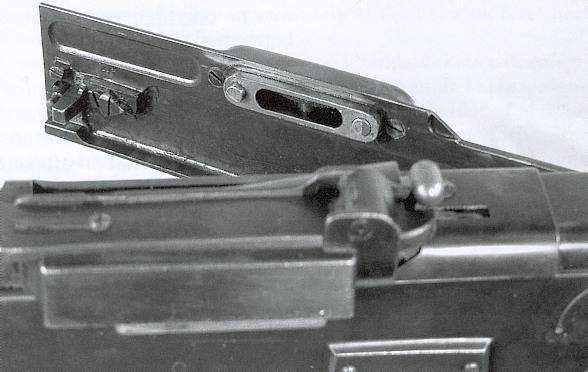

The inside of the receiver cover

To the breech of the trunk rigidly joined detail-frame of complex shape with a set of grooves and protrusions, designed to convert the reciprocating motion of the trunk into the movement of other parts of automation. The main task of the frame, connected to the barrel, was to control the movement of the shutter. The latter was hinged and could swing in a vertical plane. It is noteworthy that during reloading the shutter had to make several movements up and down to remove the liner, dismount the cartridge and lock the barrel. On the left, near the cartridge well, there was a swinging reload knob connected to the gate.

Inside the gate was placed movable drummer with its own mainspring. The drummer was to be controlled by a trigger mechanism, most of the details of which were located on the rear frame of the receiver. The trigger carried to the neck of the butt was connected with other parts with the help of a long thrust. The USM design provided shooting only single shots. A non-automatic fuse was provided to block the descent.

Rifle Madsen-Rasmussen of the first version received a frame sight, marked for shooting at different distances. The fly was placed on the muzzle of the rolling trunk. The rifle was equipped with wooden fittings in the form of a stock and forearm. The use of a bayonet was also envisaged, but it was distinguished by its small length and weight. A larger and heavier blade could disrupt automation.

The Forsøgsrekylgevær product had a total length of 1341 mm with a 860-mm barrel. The weight of the weapon without ammunition reached 4,95 kg. Automatic rifles, given the lack of possibility of firing bursts, had a technical rate of fire at the level of 40-45 rounds per minute.

Before firing from the self-loading rifle Forsøgsrekylgevær designed by V. Madsen and Y. Rasmussen, the fighter had to place a clip / pack with several 8х58 mm cartridges into the slots of the receiving shaft, then pulled the reloading handle, twisting the mechanisms, and turning off the fuse, pull the piece, and pull the piece back piece. After that, the weapon was ready to fire.

In the production of a shot, the powder gases pushed the bullet out of the barrel, and also created a recoil momentum. Moving backward, the barrel, coupled with the bolt, actuated the mechanisms of the weapon. The frame connected to the barrel, when moving backwards, worked on the shutter, moving it upwards. At the same time, the spent cartridge was extracted, which was then fed to the lower branch pipe for discharge outside the rifle. The sleeve had to fall down and back towards the trigger bracket.

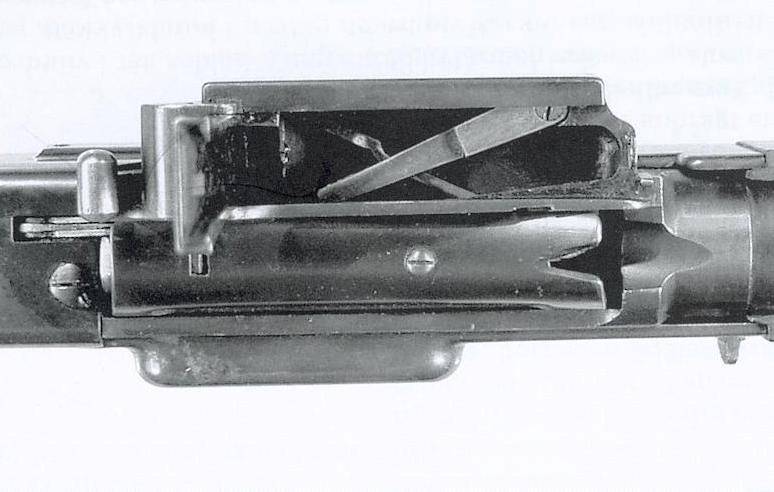

Reception shaft for cartridges, visible feed lever

Next, the automation lowered the shutter, the mirror of which fell below the level of the chamber. At this point, the new cartridge was fed from the mine into the receiver box and then pushed it in the direction of the chamber. At the end of the recharge cycle, the barrel under the action of the return spring had to move forward and return the bolt to the center position. In this form, the bolt locked the barrel and allowed the shot to be fired. The next time you clicked the trigger, a new shot occurred with a repetition of the reload cycle.

Such an operation algorithm allowed the rifle to shoot off all ready-to-use ammunition without manual reloading (in the absence of problems). The intervention of the shooter was necessary only when the cartridges were used up from the holder. In this case, it was necessary to remove the empty clip, install a new one and re-cock automatic, after which the weapon could continue firing until the ammunition was developed.

A new weapon was proposed by the Danish army in 1886. The military got acquainted with the project documentation and showed great interest in it. It was decided to make an experimental batch of Forsøgsrekylgevær rifles, which was planned to be used in tests. In 1888, the Copenhagen Arsenal received an order to assemble a new type of 70 rifles. By year of production weapons received the designation M / 1888. Rifles of the first batch before the end of the year were transferred to the military for testing and trial operation.

The army of Denmark has been testing new weapons for several years. Only in 1892, the command decided to adopt the M / 1888 rifle. An order was placed for two hundred rifles for delivery over the next few years. For various reasons, the Copenhagen arsenal managed to release only 86 M / 1888 products, after which their assembly ceased. All manufactured rifles were transferred to the customer and distributed among some units of the ground forces.

According to others, only about fifty rifles of an experimental batch were manufactured. This weapon was handed over to one of the infantry battalions, which was to check it in the conditions of real service in the troops. According to this version, the military expressed some complaints about the design of the new weapon, after which they did not order its mass production. Not very sophisticated rifle mechanisms were subject to contamination, which is why the M / 1888 rifle could not be fully used by the infantry. At the same time, the arming of such fortress personnel with such rifles was not excluded. Operation in the forts was associated with a lower risk of contamination and therefore did not place particularly high demands on the reliability of the weapon.

Anyway, the production of Madsen-Rasmussen rifles by Forsøgsrekylgevær M / 1888 was limited to only a few dozen pieces - from 50 to 156 units. Serial samples for some time used by the army. At the same time, due to the small number of rifles produced, this weapon could not press down other models that were in service. The main weapon of the infantry of the Danish army was still store rifles with manual reloading.

After the production of M / 1888 rifles was completed, the development of a modernized version of the new weapon started. The authors of the project decided to reduce the size and weight of the structure, as well as to improve various systems and simplify operation. In the new project of a self-loading rifle, the full preservation of automation mechanisms and their principles of operation were implied when some external devices were changed.

The updated rifle received a modified receiver with a top cover. In its place, the lid was fixed with a swivel latch at the rear. Instead of an open receiving shaft for mounting the cage / pack on the left surface of the weapon, a receiving device for a single-row box box store for 10 cartridges appeared. Feed cartridges, as before, should have been carried out under its own weight. There were holes in the walls of the store to control the consumption of ammunition. Instead of a small lever for reloading on the upper side of the weapon, it was now proposed to use a larger part on the right wall of the receiver. To move the bolt and cocking the weapon should pull the lever, turning its axis.

Changed the design of wooden fittings and related units. There was a significant increase in the length of the forearm, as well as the upper trunk pad appeared. At the front cut of the wooden parts was mounted a sleeve on which the fly was fixed. This innovation made it possible to reduce the impact of the movements of the barrel on the guns. Also on the front sleeve there was a ring for attaching the chain. On the latter, it was proposed to place a small trunk lid. To avoid contamination of the weapon, the muzzle of the barrel had to be closed with a special cylindrical cap. A folding bipod was installed under the forearm. In the transport position, it was laid under the forearm by turning back.

To the rear of the receiver, it was now proposed to mount the butt of a new design with a pistol projection capable of improving the usability of the weapon.

After revision, the total length of the rifle was reduced to 1179 mm, the barrel was shortened to 617 mm. The weight of the upgraded product was 4,7 kg. By maintaining the existing automation, the rate of fire parameters remained at the same level. Reliability of work also did not undergo significant changes.

In 1896, the Danish military again became interested in the designs of V. Madsen and Y. Rasmussen. An updated version of the self-loading rifle was tested and was able to attract the attention of the naval commanders. It was decided to buy a new weapon for the armament of the Marine Corps. The Copenhagen Arsenal again received an order, this time it was required to assemble 60 rifles. Soon, the terms of the contract were fulfilled, and the marines were able to re-equip part of their units. A new version of the rifle called Flaadens Rekylgevær M / 1896 - “Naval rifle using recoil arr. 1896

The Madsen-Rasmussen rifles of the two models remained in service until the early thirties. A number of units of the army and marines used such weapons in parallel with other systems, first with older ones, and then with new models. Finally, the M / 1888 and M / 1896 rifles were written off only by the mid-thirties due to complete and hopeless moral and physical obsolescence.

Only a few Madsen-Rasmussen rifles of two models survived to our time. Surviving rifles are stored in several museums and private collections, mainly in Denmark.

After fulfilling the contract with fleet W. Madsen and J. Rasmussen decided to establish their own company, which was supposed to be engaged in the production of new weapons, including for foreign customers. In 1898, Danish Recoil Rifle Syndicate entered the international arms market. The new organization made several attempts to offer its developments to foreign customers, but until a certain time it could not interest anyone.

According to some information, at the beginning of the 20th century an attempt was made to modify the existing design of a self-loading rifle in accordance with the requirements of foreign armies. As a result, there were several modifications of weapons for different cartridges. It is known about the testing of such weapons in a number of foreign countries, but these checks did not lead to the appearance of new orders for the mass production of rifles of a particular model.

In parallel with the work on the self-loading rifle, V. Madsen and Y. Rasmussen were engaged in the creation of a promising machine gun. This weapon had to use the same principles of work and be based on already existing solutions, nodes and units. In the future, the new machine gun Madsen was adopted and went into the series. Soon, these weapons became interested in several foreign countries and became the subject of a number of export contracts. It was created several modifications of the machine gun for different cartridges, which were used until the middle of the XX century.

Madsen-Rasmussen self-loading rifles M / 1888 and M / 1896 were not widely used and were released in quantities of several hundred units. Nevertheless, they allowed to work out and test in practice a new version of automation based on recoil of the barrel, which later found use in the new small arms. Thus, not the most popular and mass rifles opened the way to the promising direction of development of small arms. In addition, the rifles of V. Madsen and Y. Rasmussen were the first weapon of their class, who managed to reach the adoption.

On the materials of the sites:

https://arma-dania.dk/

http://forgottenweapons.com/

http://world.guns.ru/

http://thefirearmblog.com/

Information