The brainchild of the company Oerlikon: artillery installation Searanger 20 will increase the ability to combat small vessels

Searanger 20 paired with the GAM-BO1 installation (in the background) at the Rheinmetall Ochsenboden test site

The development of the omnipresent XA NUMX-mm KAA cannons, the first "hints" which appeared in the distant 20 year, began in the 1914-ies of the last century, the Swiss defense company Oerlikon. Originally designated as Type 50GK, a single-barreled gas-guided KAA cannon with power feed is capable of accepting ammunition from either side. When firing a 204x20 mm projectile, the initial speed reaches 128 m / s and the 1150 firing rate per minute.

The KAA cannon, as part of the well-selling GAM-BO1 shipboard artillery, gained widespread acceptance in the maritime weapon systems market. The lightweight, compact installation of the GAM-BO1 on a swivel plug, created for local control, is usually well suited for two main tasks: as a weapon system for small-size police courts and as an anti-aircraft and anti-submarine defense system for larger ships. After the conflict on the Falkland (Malvinas) Islands 1982, the UK purchased a significant number of GAM-BO1 installations for such tasks.

While GAM-BO1 remains in service with many fleets, Rheinmetall Air Defense’s marine systems division (heir to the Oerlikon brand after acquiring Oerlikon-Contraves in 1999) acknowledged that operational needs and threat dynamics have changed significantly in recent years, especially with the advent of a new generation of small fleet, maneuverable and potentially deadly "asymmetrical" surface threats.

These factors determined the need for an artillery system, which, along with the inherent 20-mm armament, advantages in terms of mass, volume and area, usability and logistics, can provide increased accuracy and increased “stopping power” necessary for hitting high-speed combat boats and other high-speed surface threats at distances of approximately 2000 meters. Rheinmetall Air Defense's response was its new remote-controlled installation Oerlikon Searanger 20 and the corresponding insensitive 20x128 mm ammunition SAPPIE-T (Semi-Armor Piercing Pyrotechnically Induced Effect - Tracer, semi-light with pyrotechnic initiation, tracer).

According to Mike Gerber, head of ship cannons at Rheinmetall Air Defense, the target markets for the Searanger 20 are much the same as for the GAM-BO1: as the main armament for small vessels deployed fleets, coast guard, police and other maritime security agencies; or as auxiliary melee weapons for larger vessels. “These weapons are for four tasks,” he said at a briefing in Zurich in October 2015. “Show the presence, make an accurate warning shot, make an accurate shot at the target and, if necessary, deliver maximum firepower.”

Cannon's successor

The main component of the Searanger 20 gun mount is the Oerlikon KAE 20-mm gun, recently introduced as a successor to the KAA. “The KAE gun in essence is the previous version of the KAA only with the addition of an electric trigger and an electric gun control unit,” Gerber explained. - Electric release allows you to get a remote control system, in addition, the operator can now choose the exact number of shots in the queue. It also increases safety, since we now have a remote-controlled safety-actuating mechanism. ”

The KAE cannon can operate in one of three selectable modes: single shot, fast single shooting and turn. “Fast single shooting is a programmed sequence that gives the same low level of dispersion as a single shot,” Gerber explained, “but it allows you to fire a target with a single“ continuous ”queue [100-300 shots / min rate of fire] with just one click on trigger. This is the main mode we offer for fleets and coast guards. ”

In the Searanger 20 system, Rheinmetall integrates a KAE cannon and its cradle assembly with an installation having electric drives and independent stabilization, supplied by South African company Reutech Solutions. This is essentially the same installation that is part of the Reutech Super Sea Rogue remotely controlled gun system. The Super Sea Rogue version with the KAE cannon (the basic version with the Denel GI-2 20xXNNUMX mm cannon was adopted by Reutech) has already been ordered for the coast guard of one of the Middle East countries.

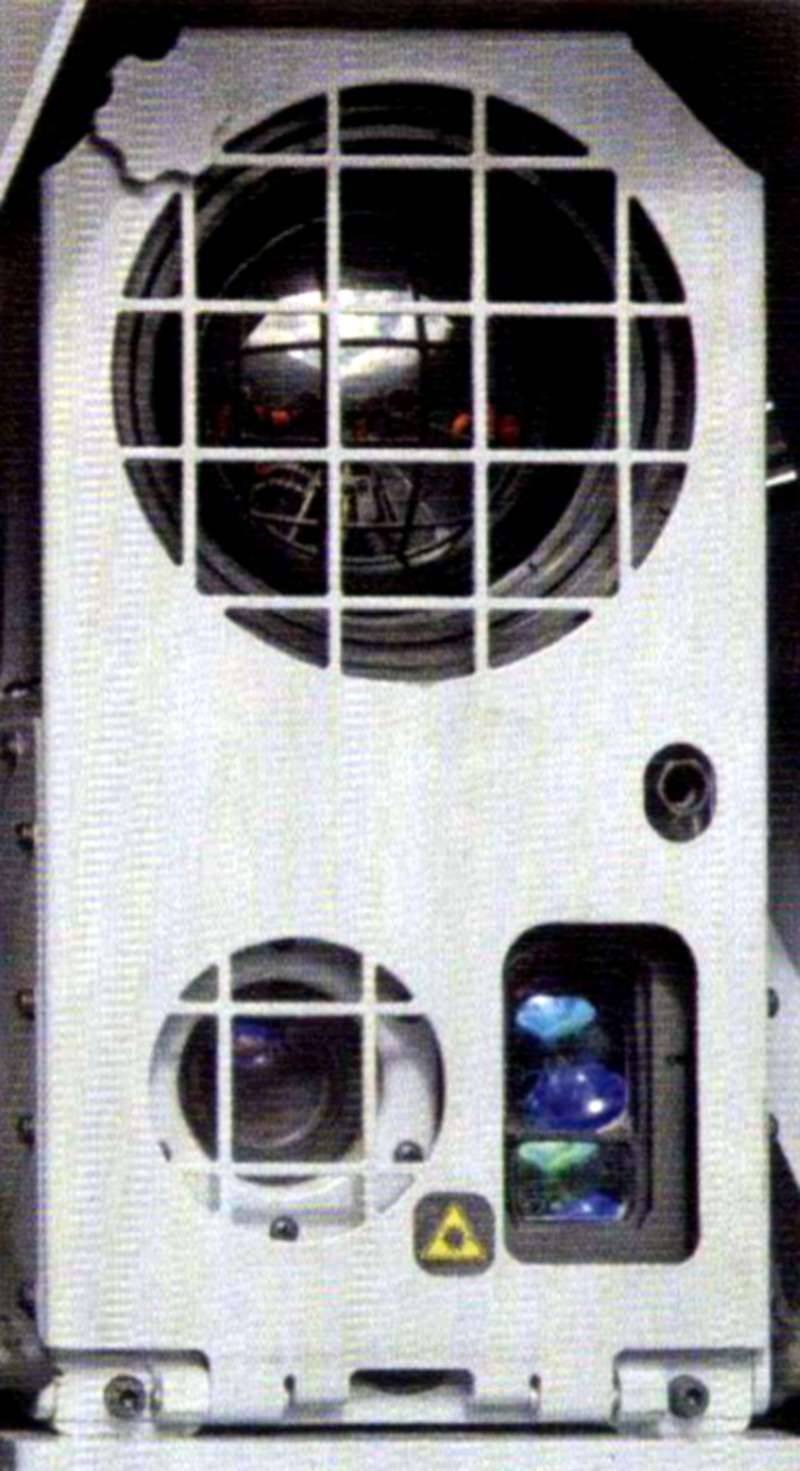

To provide round-the-clock surveillance, target tracking and fire control, the Searanger 20 system is equipped with an optical-electronic sensor kit. It includes a HVK-S color camera, an uncooled thermal imager (8-12 µm) with two fields of view (4,6 ° and 14,3 °), an optional laser range finder and an integrated video tracking device.

The system is monitored from a compact operator console, which can be installed on the bridge or in the operational cabin. The console consists of a central display unit (the actual display plus function keys for mode selection and display) and control handles on the sides. According to Gerber, from the very beginning the console was developed taking into account the fact that relatively inexperienced operators can work on it. “Four steps are needed. Point the gun. Move the fuse to the "fire" position. Press the "ready to fire" button. Press "fire".

In a lightweight version, the Searanger 20 installation weighs 490 kg, its weight increases to 570 kg with an installed shell shell on the 200 ready shots. For installation on the vessel, a total of eight M20 bolts are required for attachment to the deck plus installation of the corresponding electrical system and control unit.

The Searanger 20 unit is equipped with a coaxial optical-electronic sensor set consisting of a HVK-5 color camera, 8-12 micron thermal imager, laser rangefinder and video tracking device

Rheinmetall manufactured two prototypes of the Searanger 20. “We completed the firing and environmental tests,” said Gerber. “All that remains to be done is qualification for shock vibration loads and testing for electromagnetic compatibility.”

The goal of developing a SAPPIE-T 20x128 mm ammunition, which is also scheduled to be completed by the end of the 2015 year, was to increase the armor penetration of the 20 mm projectile and at the same time reduce the cost of training, transport and storage. “SAPPIE-T has the same characteristics as a high-explosive fragmentation projectile (OFZ), but is inert as a practical tracer with a tracer,” said Gerber.

The SAPPIE-T ammunition developed by Rheinmetall Weapons and Munitions over the past two years has been designed to combine the advantages of an armor-piercing projectile with an increased over-obstacle effect of PELE (Penetrator with Enhanced Lateral Effect) and a pyrotechnic charge to create the so-called pyrotechnic induced effect PIE (Pyrotechnically Induced) . At the same time, it uses ready-made and already qualified components: a liner, a propellant charge and an obturator belt.

PELE ammunition is available in three calibers: 20 x 102, 25 x 137 and 30 x 173

The PELE 30x173 mm ammunition (20 and 25 mm options are available) is currently manufactured in the UK and the Netherlands. It has excellent fragmentation (fragmentation) and armor penetration compared to traditional ammunition, but it does not have a detonator or a high-explosive charge. The principle of operation of PELE is based on a significant difference in the densities of the outer steel pipe and the inner plastic core, which increases the dynamics of armor piercing. A blow to the target creates a large overpressure in the inner core, causing fragmentation of the projectile body upon exiting it. However, the fragmentation effect depends on the speed of the meeting with the target; low impact energy results in a relatively limited over-graded action.

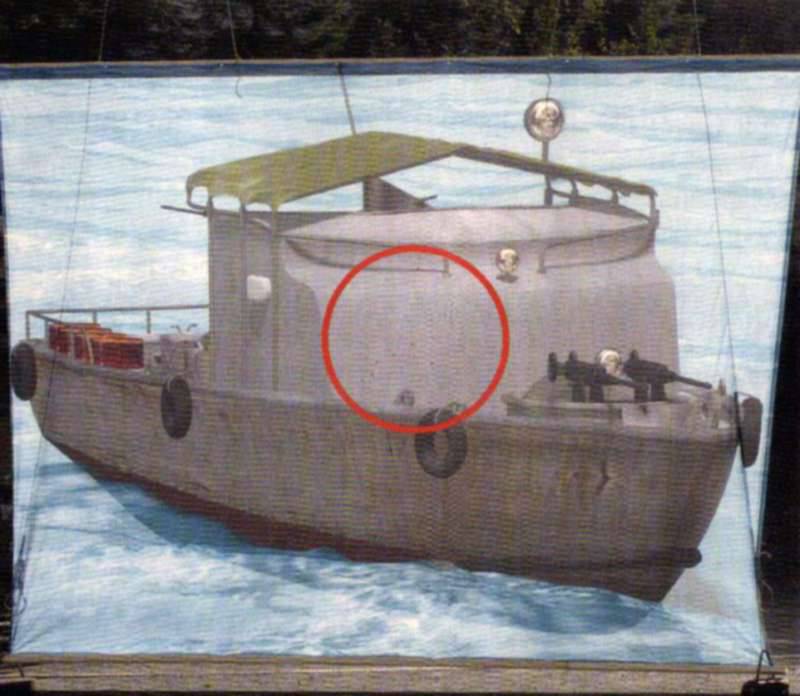

Take off the queue from 10 single shots on a poster of a speedboat from a distance of 1000 meters

All 10 shells from the line hit the deckhouse / bridge area of the drawn boat (photo below)

PIE also uses the difference in density of materials, but this time between a high-density body made of hardened steel and a pyrotechnic charge as a filler. In this case, when meeting with a target, the shock wave creates a mechanical “overpressure”, which causes fragmentation of the projectile body and at the same time instantaneous burnout of the pyrotechnic charge. This process accelerates the forward expansion of the fragments, resulting in an increased armor effect (the angle of separation of the fragments is almost constant throughout the distance and does not depend on the speed of the impact). In addition, the pyrotechnic charge has an additional “frightening” effect in the form of flash, noise and a blast wave.

The company states that by combining these two technological solutions, the SAPPIE-T projectile has penetration characteristics and a fragmentation effect (quantity and mass or size), at least not worse than PELE-T projectiles. The mass of the projectile, which received the internal designation PMA408, corresponds to the mass of the existing high-explosive fragmentation projectile, so that the ballistic characteristics will be identical from the user's point of view.

“SAPPIE-T is a projectile that not only creates an explosion and shrapnel, but also the so-called deep fragmentation penetration,” Gerber said. - Getting deep penetration in the ship is very important. We want to pierce the hull and due to this we can cause great damage to the engine room. Explosive and fragmentation effects are also important for damage to fuel lines, electrical cables and power supplies. "

Rheinmetall Air Defense in October 2015 invited potential customers to its Ochsenboden test site, located southeast of Zurich, where a demonstration of firing from the Searanger 20 unit was carried out, as well as the striking impact of SAPPIE-T ammunition.

When firing along the valley from a distance of 1000 meters, all three of their operating modes of the Searanger 20 system were demonstrated. In the single-shot mode, five practical shells with a tracer were shot at a small stationary target, standing slightly ahead of a larger shield with a drawn speedboat. The first shell hit the target, breaking a barrel of water mounted behind the shield. Thereby, the capabilities of the system “to conduct high-precision fire on the nose” were demonstrated.

The following 10 shots were shot on the shield with the boat in fast single-shot mode, they all fell into the bridge / deck zone. In a real-life scenario, this could lead to significant damage inside the vessel.

Finally, 18 shells were shot in the queue mode with a rate of 1000 shots / min. “The queue creates maximum power for the most difficult purposes,” Gerber noted.

Comparative demonstration firing of SAPPIE-T ammunition was carried out in an underground dash in another part of the Ochsenboden test site. The shells of the SAPPIE-T and OFZ fired on a set of metal sheets from a distance of 100 meters and at an angle of meeting 0 °. A sheet of 4-mm mild steel was installed up front (typical of the engine room). Behind it, at intervals of 300 mm from each other, eight 2-mm sheets of aluminum alloy were installed; another 4-mm steel sheet was installed one meter behind this set.

The result of the shelling by a SAPPIE-T shell of a set of metal sheets from a distance of 100 meters (below). The shell pierced a small inlet in the first 4-mm sheet. The shards are directed forward at an almost constant angle of expansion, the effect of deflagration is felt by each aluminum sheet and the last steel sheet.

Comparative tests

Comparison of the impact of projectiles of two different types showed a significant difference. SAPPIE-T punched a small inlet in the 4-mm sheet, but then created a wide distribution of fragments with a deflagration effect (fast combustion without detonation), which was visible on each aluminum sheet, and at the end pierced the last sheet. In turn, the high-explosive fragmentation projectile punched a large hole in the first sheet and had a good explosive effect on the first three aluminum sheets. However, he could not break through the last five sheets.

The second comparative test included the shooting of SAPPIE-T and OFZ shells at a monoblock target from a simulated 1000 distance of meters. In this test, projectiles were fired at a sheet of armor steel 10 mm thick at an angle of encounter 45 °. Behind it was installed an aluminum witness sheet (for assessing the prohibitive effect of the ammunition) 0,5 mm thick also at an angle 45 °, followed by three 2 mm sheets of aluminum alloy witness with a nominal meeting angle 0 °.

In this case, the SAPPIE-T projectile pierced the armor plate with the formation of large fragments, then pierced four aluminum sheets. The OFZ shell, as expected, could not break through the first 10-mm sheet.

Rheinmetall believes that the Searanger 20 naval artillery and SAPPIE-T ammunition will attract particular attention from maritime security agencies, such as the coast guard and border forces. “Searanger 20 is very easy to install, operate and maintain,” said Craig McLaughlin, vice president of offshore systems at Rheinmetall Air Defense. - SAPPIE-T ammunition is cheaper than high-explosive fragmentation, it is much easier to store and transport because there is no explosive or detonator in it. A low hazard class means that it can be loaded directly from a conventional pier, which does not have a special pier.

“KAA cannons have a great basis for installation, so we have the opportunity to refine and upgrade these guns to the KAE standard. At the same time, this means that existing customers can reuse logistics and support infrastructure for KAA cannons. ”

The development and qualification of the Searanger 20 artillery and 20x128 mm SAPPIE-T ammunition reflect the desire of Rheinmetall Air Defense to increase its market through small fleets and maritime security forces.

The company believes that the installation area and volume, accuracy of target tracking and fire control, as well as the low cost of operating the Searanger 20 unit, combined with the characteristics of armor penetration and fragmentation of SAPPIE-T ammunition, will allow small armed forces to deal with surface targets only armament caliber 30 mm.

Materials used:

www.rheinmetall.com

www.oerlikon.com

www.diehl.com

www.janes.com

www.wikipedia.org

en.wikipedia.org

Information