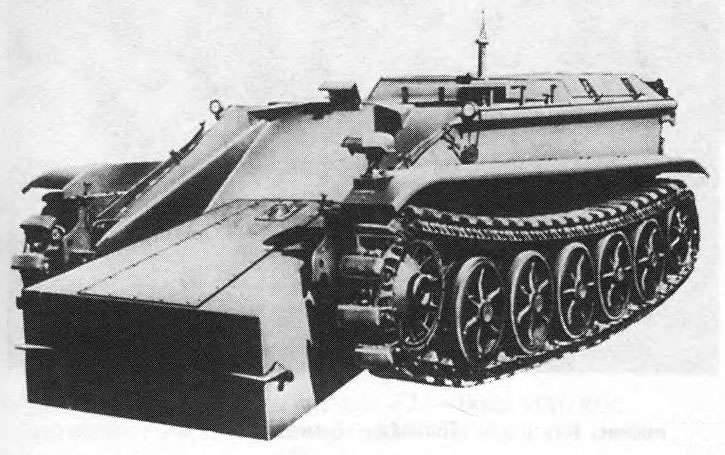

Transporter of ammunition Borgward VK 302 and vehicles based on it (Germany)

An order for the development of a promising ammunition transporter was issued to Borgward as early as 1937. The development of the required project did not take much time, but in the future the promising machine faced some problems of various kinds. For some reasons - first of all, the creation of alternative models of equipment of similar purpose - the start of the production of the conveyor was postponed. However, over time, the project was still brought to the stage of mass production.

In accordance with the technical specifications, the new machine was supposed to serve the artillery units. It was necessary to ensure acceptable protection of the crew and cargo from small weapons and splinters, and also to give the machine the opportunity to act in the same order with towed and self-propelled artillery. The project of the new ammunition carrier has received the symbol Gepanzerte MunitionsschlepperVK 302. In addition, the developer has assigned him an alternative working designation B III.

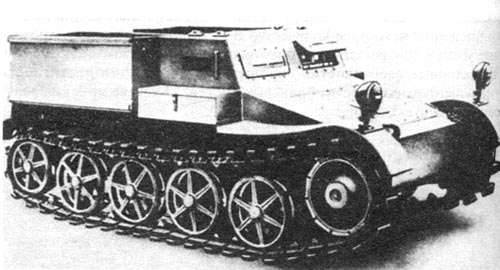

One of the prototypes of the VK 302 machine. Photo Aviarmor.net

The main requirements for the new machine and the intended role determined the main features of the project. In particular, the layout of the hull was chosen precisely in connection with the need to transport various types of ammunition. It should be noted that, in the future, such a layout made it possible to develop on the basis of the carrier VK 302 several variants of a self-propelled artillery installation with different weapons.

The main element of the new machine was to be the armored body of the welded structure. The front part of the body was proposed to be made from parts with a thickness of 14,5 mm (lower) and 15,5 mm (upper). The sides and the feeds were 10 mm thick, the bottom and the roof were 8 mm thick. It was assumed that such protection would be able to withstand shelling from small arms, as well as provide reliable protection for the ammunition being transported.

The frontal part of the hull consisted of several armor plates of different thickness, mounted at different angles to the vertical. There was a small vertical bottom sheet, above which a large-sized part was located under a large slope. The last front plate was equipped with two inspection hatches and protected the crew from shelling from the front hemisphere. The body was equipped with vertical sides. The front part of the hull, in the area of the department of management, had a smaller width in comparison with the aft one. To use the internal space more efficiently, it was decided to equip the stern of the hull with developed fender shelves with boxes for ammunition.

In terms of housing layout, the VK 302 machine did not differ from some similar types of German-designed equipment. In front of the case, directly under the frontal sheets, there were transmission units. Behind them was placed the office of management with the jobs of the crew. The engine was located in the central casing in the rear of the hull. The space on the sides of the engine, including in the fenders, was given for the placement of the payload.

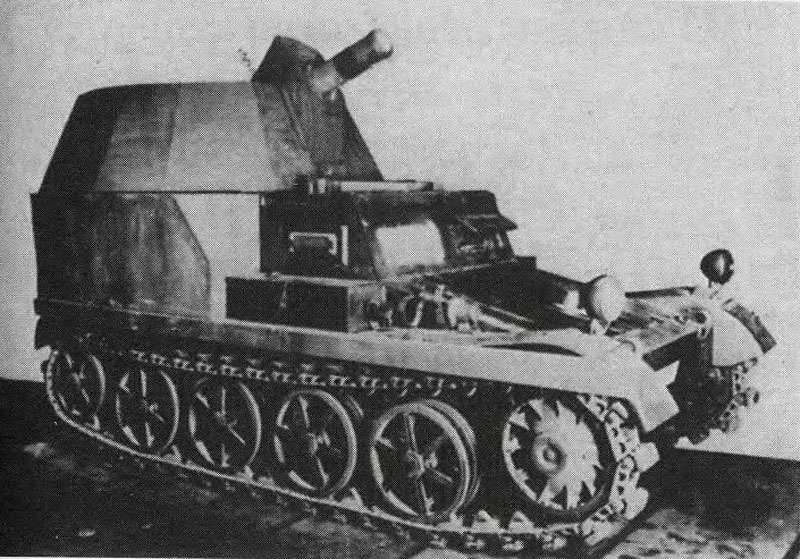

ACS based on VK 302 with 50-mm gun. Photo by Achtungpanzer.com

It was proposed to equip the car with the Borgward 6M RTBV carburetor engine with the 49 hp fashionability. With the help of a mechanical transmission located in front of the engine and in the front of the case (separate transmission units were connected using a cardan shaft), torque was transmitted to the front drive wheels. For service units of the power plant in the armored parts of the hull provided hatches. One of them was in the inclined front sheet, the second - in the roof of the engine compartment.

The chassis of the VK 302 conveyor received four support rollers with an individual suspension on board. In order to facilitate the construction, the rollers had a spoke structure. In front of the car were placed the driving wheels, in the stern - guides. As with many other German-made tracked vehicles, the drive wheels were placed with a large excess over the road wheels, and the guide wheels rose slightly above the track surface. A small-track caterpillar with steel tracks was used.

The crew of the carrier of ammunition was to consist of only two people: the driver and the commander. Seats of both crew members were located in the control room, protected by their own wheelhouse. For access to their seats, the commander and driver had to use hatches in the roof of the cabin. Observation of the environment was provided with the help of two hatches in the front sheet, equipped with covers with viewing slits, as well as two small hatches in the sides of the deckhouse.

The car turned out quite compact and easy. Its length was 3,57 m, width - 1,83 m, height - less than 1,5 m. The combat weight with full payload was 3,5 t. At the same time, the machine could reach speeds of up to 30 km / h and travel at a single station to 150 kilometers.

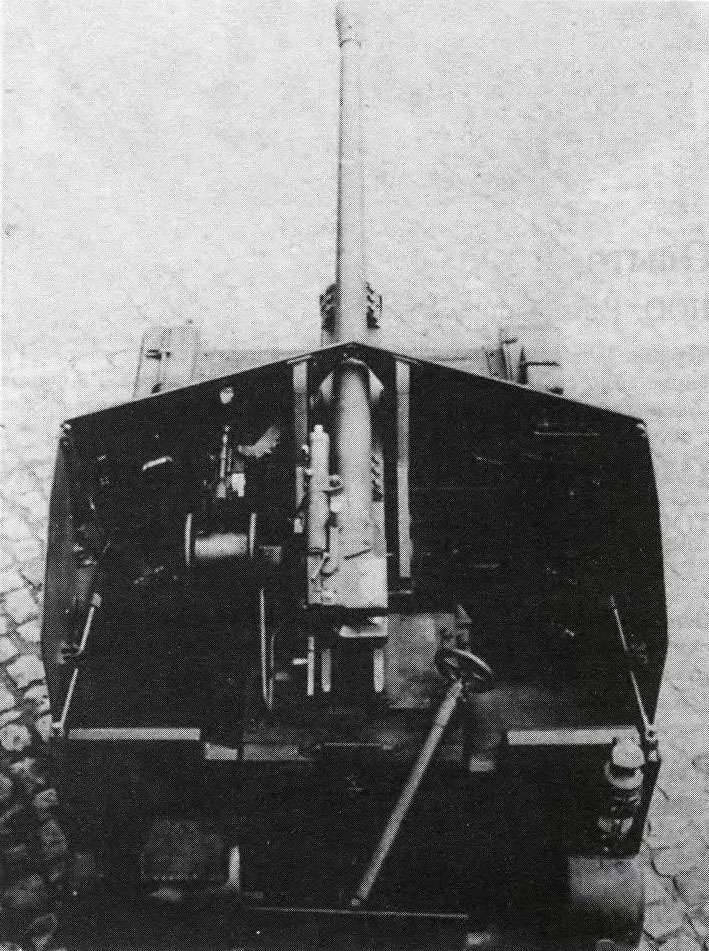

Self-propelled gun with PaK 38, view of the wheelhouse. Photo by Chamberlain P., Doyle H. "Complete German Reference tanks and self-propelled guns of World War II "

The main task of the VK 302 was the transportation of ammunition. In the armored box-shaped aft hull compartments, located on the sides of the engine compartment, it was proposed to transport ammunition of various types. The new hauler was intended to serve artillery units armed with various systems, because of which it was supposed to transport ammunition of various types. Regardless of the types of shells, the machine could carry at least several dozen ammunition in boxes. Loading shells and feeding them to the guns was suggested manually. No additional funds to facilitate the work of the crew and gunners, were not provided.

The development of the VK 302 / B III project was completed in a relatively short time, but for several reasons, the construction of a new type of experienced vehicle was delayed. The first sample of the ammunition carrier was tested only in 1940 year. The prototype showed itself well and confirmed the main design characteristics. The new machine could actually accompany the units of the towed and self-propelled artillery, ensuring timely supply of ammunition. In addition, the perspective carrier chassis could be used as a basis for other armored vehicles. For example, at a certain point there appeared a proposal to build on the base of VK 302 new self-propelled artillery systems.

At the end of 1940 of the year (according to other data, at the beginning of 41), Borgward received the first order for the serial construction of ammunition transporters. The army demanded to build and supply 20 machines in the original version, and also to make some adjustments to the project and to assemble another hundred drivers from the updated project. By the fall of 1941, only the first pre-production batch of 20 machines in the original version was built.

Due to the presence of other orders and due to some other problems, the contractor was able to establish the assembly of a full-fledged serial batch only in October 1941. By this time, the project was faced with some difficulties, because of which until January of next year, only eight conveyors were assembled at the Borgward plant, and after their construction was frozen and in fact stopped. One of the reasons for stopping the construction was the controversy surrounding the prospects of several auxiliary equipment projects. The relatively old VK project 302, the development of which was launched back in 1937, did not fully suit the customer.

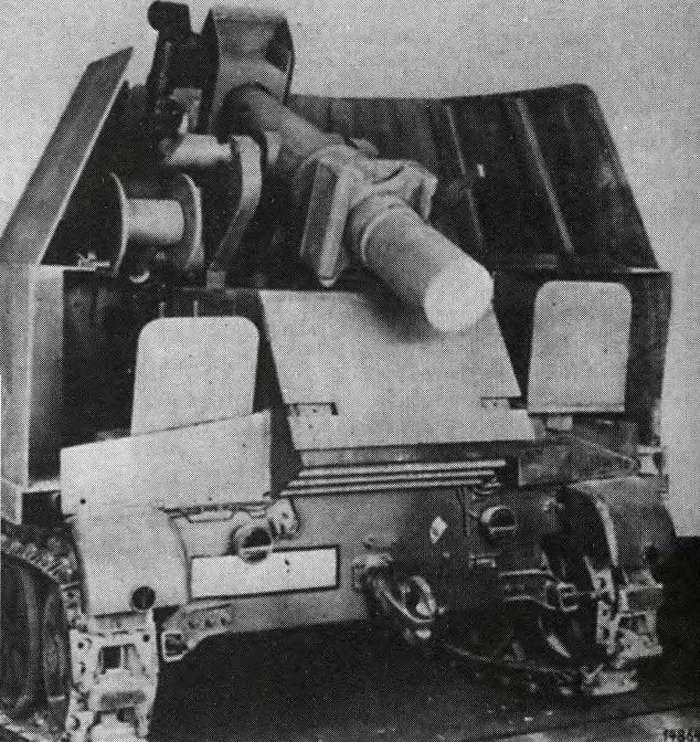

ACS with 150-mm tool. Photo of Chamberlain P., Doyle H. "Complete reference book of German tanks and self-propelled guns of the Second World War"

At the beginning of 1942, it was decided to abandon the further construction of ammunition carriers VK 302 in favor of other equipment of a similar purpose. As a result of this decision, the assembly of conveyors stopped. Before the cancellation of the order, Borgward managed to assemble only 28 armored vehicles of its development, of which only eight were built according to the finished serial project.

By the beginning of the summer of 1942, all the new cars built were distributed among the operators. The entire pre-production batch of two dozen cars was sent to the army. Five serial transporters remained at Borgward, while three others went to the management of Waffen Prüfungsamt, who was responsible for testing the new technology. It can be assumed that 20 transporters were used in the army for its intended purpose, however, there is no exact information about their operation. There is also no detailed information about the machines transferred to WaPrüf.

From serial production VK 302 refused soon after it began, because of what the first order was not executed even on 10%. Nevertheless, a promising project could lead to the emergence of new types of technology. Back in 1940, a proposal appeared to make a new ammunition transporter a base for self-propelled artillery. The result of this proposal and further work was the emergence of two projects of new ACS.

The order to create self-propelled guns appeared in July 1940. On the driver's chassis VK 302 should have installed anti-tank gun PaK 38 caliber 50 mm. In this regard, it was necessary to make some modifications to the design of the base machine, which allowed it to become a carrier of new weapons. As a result, the layout of the base machine was slightly modified, and it was supplemented with a new wheelhouse.

Felling self-propelled second version. Photo of Chamberlain P., Doyle H. "Complete reference book of German tanks and self-propelled guns of the Second World War"

To protect the calculation of weapons on the stern of the hull it was proposed to install a wheelhouse with open top and stern. This unit was made of four sheets: two frontal, installed at an angle to each other, as well as two sides. The installation for the 50-mm gun was placed in the central part of the cabin. The mounting systems made it possible to direct the instrument within the horizontal sector with a width of 40 °, as well as to establish elevation angles from -10 ° to + 20 °. The calculation of the instrument consisted of two people, the places of which were placed in the aft cabin, on both sides of the breech. To the left of the gun was the gunner, who had all the necessary tools and instruments, to the right - loader.

Calculations showed that the chassis has insufficient strength to use the PaK 38 gun. For this reason, a drop coulter with two support beams and a manual drive appeared in the rear of the car. Before shooting, it had to be laid on the ground, which made it possible to transmit a recoil impulse and reduce the negative impact on the undercarriage. In the stowed position, the vomer rose to the body.

Self-propelled gun had to be serviced by a crew of three people: the driver, the gunner and loader. At the same time, the department of management was reduced: only the driver’s workplace remained in it. In the old place of the commander in the cabin of the case placed most of the racks for ammunition.

In accordance with the order of the army, the company Borgward built two prototypes of the new self-propelled gun. By the summer of 1941, the cars were ready to participate in various trials. After testing at the landfills, in August, both self-propelled guns were sent to the front for testing in real fighting conditions. After all the checks, the potential customer considered the new equipment inadequate. The order for mass production of new cars did not follow.

Blasting machine Sd.Kfz.301. Photo of Chamberlain P., Doyle H. "Complete reference book of German tanks and self-propelled guns of the Second World War"

In September, 1941, the company Borgward began work on a new version of self-propelled guns based on VK 302. This time the ammunition transporter was supposed to be the carrier of the experimental IG2.540 recoilless caliber 150 mm, developed by Rheinmetall. Such weapons should have been mounted in a new wheelhouse. In terms of the overall layout of the ACS with the 150-mm gun, it differed little from the previous design. The gun mount was mounted directly on the roof of the engine compartment, and there were two gunners on either side of the latter. Due to less recoil, this self-propelled gun did not need a coulter.

By the beginning of 1942, Borgward built a model for a promising ACS. On one of the finished chassis VK 302 installed a wooden layout felling with weapons and gun crews. Such a product was shown to the customer’s representatives, after which the project stopped. The new version of self-propelled guns again considered unsuitable for serial construction and operation in the army.

Shortly after the order for the construction of the ACS with the 150-mm gun, in October 1941, Borgward began work on a new machine based on its ammunition transporter. This time, VK 302 / B III was supposed to be the base for a promising blasting machine with remote control Sd.Kfz.301. The hull and chassis of the base machine were finalized, as well as a radio control system and a special container with a disruptive charge. This special-purpose armored vehicle was launched into a series, and then itself became the basis for new developments.

The project of the ammunition carrier VK 302 did not lead to the full rearmament of the army. Attempts to make this car the basis for new SAUs also failed. Only a blasting vehicle on the basis of the carrier managed to reach mass production. However, in terms of strength, all the equipment of this family could not compete with other types of machines. As a result, the project, which was once promising and interesting, did not give tangible results and did not have a noticeable impact on the course of the battles.

Based on:

http://achtungpanzer.com/

http://aviarmor.net/

http://lexikon-der-wehrmacht.de/

Chamberlain P., Doyle H. Complete reference book of German tanks and self-propelled guns of the Second World War. - M .: AST: Astrel, 2008.

Information