That.154. Wooden "Anti-Mosquito" Luftwaffe

Among the reasons that led to the emergence of the German twin-engined fighter Ta-154, two should be considered, of course, the main ones. The first is the absence of Germany’s specialized night interceptors by the beginning of World War II. And the second is the appearance in the English of the famous high-speed "Moskito", which had a wooden structure. The British plane literally spawned an inferiority complex from the ambitious leadership of the Luftwaffe, which it decided to eliminate by creating a similar machine in Germany, which has even higher flight characteristics.

In fairness, it is worth noting that before World War II, not only in Germany, but also in all countries of the world, fighters for night combat were not specifically designed, but represented a version of conventional combat vehicles. Everything changed with the advent of the first radar, still imperfect and cumbersome. In the mid-thirties, the British tested a night interceptor based on the Blenheim two-engined bomber with the A1 Mk.II radar. An awkward bomber was not very suitable for the role of a high-speed fighter, although it became clear that the future was precisely such aircraft. Subsequently, the Royal Air Force entered the successful version of the interceptor with a locator based on "Moskito", which was originally created as a light bomber. And the first plane, from birth itself intended for night operations with the radar, can be considered the American P-61 "Black Widow", work on which began at the end of 1940 of the year.

Naturally, to have a modern night fighter would not hurt Germany. But such a plane did not fit into Hitler's concept of blitzkrieg. The Führer was about to smash his opponents very quickly, and no bombing of Germany by enemy aircraft was simply intended. So with the creation of a special night interceptor did not rush. Goering promised his Fuhrer that not a single enemy bomb would fall on German soil. And the first months of the war seemed to confirm the Fuhrer’s statements that no one in the world could resist the powerful blows of the German tanks and dive bombers. The British retaliatory strategic raids launched in 1940 by the British at first resembled pinplugs and, first of all, demonstrated Churchill’s determination to continue the war, and not the power of the British Air Force. At this time, no one in the leadership of the Luftwaffe had ever thought about changing the defense system and creating a specialized night fighter. To equip the German night aviation, created in 1940 by order of Goering, Colonel Kammhuber, the material part was recruited from what was available. Nevertheless, the number of fighter jets grew rapidly, and the crews gained experience, which made it possible to effectively resist the limited night raids of the British.

However, the British night raids became increasingly large-scale and reached their first peak during the Millennium (Millennium) operation on the night of May 31, 1942. What was called the "Kammhuber line" (a strip of spotlight fields, anti-aircraft artillery batteries and night fighter interception sectors controlled by ground-based radar detection and guidance along the Reich borders from Switzerland to Norway) was simply disorganized by a huge armada of 1047 bombers going to Cologne.

In the end, something happened that was going to happen. The German air defense system was able to knock down the entire 41 enemy machine or 3,9% of the forces making the raid. The fact of the powerlessness of the crews of the German night fighters, which became obvious to all, demanded that urgent measures be taken. It would be an exaggeration to say that absolutely nothing has been done. The Luftwaffe was armed with Bf.110F, Bf.110G and Do-217J, which had special equipment to carry out night interception in the form of infrared sensors that notice the hot exhaust of British engines (Q-tubes), in addition, soon German fighters planned to equip the airborne radar. The basis of the night fighters was to make Ju-88C, designed to replace all the diversity of the previous types. But this did not solve all the problems; an interceptor was needed with good speed and maneuverability, powerful armament and equipped with radar.

Technical management issued an urgent task for the development of specialized night fighters firms "Junkers", "Heinkel" and "Focke-Wulf." The specialists were the first to take the Ju-188 bomber, which was based on which they proposed the Ju-188R night fighter, a prototype of the future Ju-388J. Ernst Heinkel resurrected a two-year-old Kampfzerstorer P.1060 project, which was eventually embodied in the famous Non-219.

The most difficult task in this program fell to the company "Focke-Wulf". The Technical Department of the Ministry of Aviation has developed requirements for such an aircraft, which was to become an analogue of the multi-purpose English Mosquito, and also have an all-wood construction. This made it possible to save scarce duralumin and quickly establish the production of much-needed aircraft. Of the weapons planned to install four guns caliber 20 mm and 30 mm, and the first machine was to take off in mid-July 1943 year.

The designers of the company Focke-Wulf began work on the project in September 1942. By this time, the head of the company, Kurt Tank, had great prestige among the leadership of the Ministry of Aviation and was the vice-president of the Academy of Aviation Research. In recognition of his services to German aviation, the company's aircraft began to be denoted in a new way - “Ta” instead of “Fw”. New fighter received index Ta. 211, however Kurt Tank was displeased with this number. Perhaps he did not want his interceptor to go in order after the unsuccessful twin-engined Me 210. Therefore, soon the German "Moskito" was assigned a new designation - Ta.154, and the previous numbers Ta.152 and Ta.153 were given to high-altitude modifications of the Fw-190 fighter.

The deadlines for the designers led by Ernst Nipp were tough, and the work was carried out practically without days off. Quite quickly, drawing of the new aircraft, made according to the scheme of the twin-engine upper plan with the forward nose landing gear, began to appear on the drawing boards. The choice of an advanced chassis design was also influenced by the fact that even before the war, tests of such a landing gear were carried out on the Fw 58 training aircraft. For testing wooden parts of the structure, an unusual method was used, testing them for strength while moving in a channel with water, thus simulating the loads in flight. The tested parts were then delivered to Hannover, where the aircraft was assembled.

The 154 had an all-wood fuselage of oval cross-section, sheathed with plywood, with the exception of the front part, which had a duralumin trim. Plywood was also used to cover a two-spar upper wing made of wood, with a straight leading edge. All steering surfaces, including flaps, had a metal pipe construction and were sheathed in canvas. Two crew members sat behind each other in the cockpit with a common lantern, which was reclined to the right, and in front there was a fixed bulletproof glass 50 mm thick. In addition, the cockpit protection consisted of an 12 mm front armored plate and side protection panels 8 mm thick. The fuel, with a total volume of 1500 liters, was housed in two tanks behind the cab, and the oil tanks were each in their own engine nacelle. In front of the fuselage, there were four guns, two on each side - their barrels went out at the level of the front edge of the wing. Lighter MG 151 of caliber 20 mm were placed on the top, and millimeter MK 30 MN was mounted on the bottom of 108. As the power plant, we chose 12-cylinder engines of liquid cooling Junkers Jumo 211М, take-off power 1460 hp, in the future they were going to be replaced with more powerful Jumo 213. The engine nacelles had dural lining, and the main landing gear with one wheel were removed. The first two prototypes were Yumo 211F motors (hp 1340 take-off power) with three-blade wooden screws VS 11.

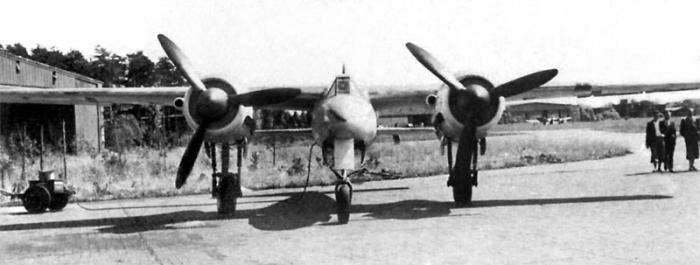

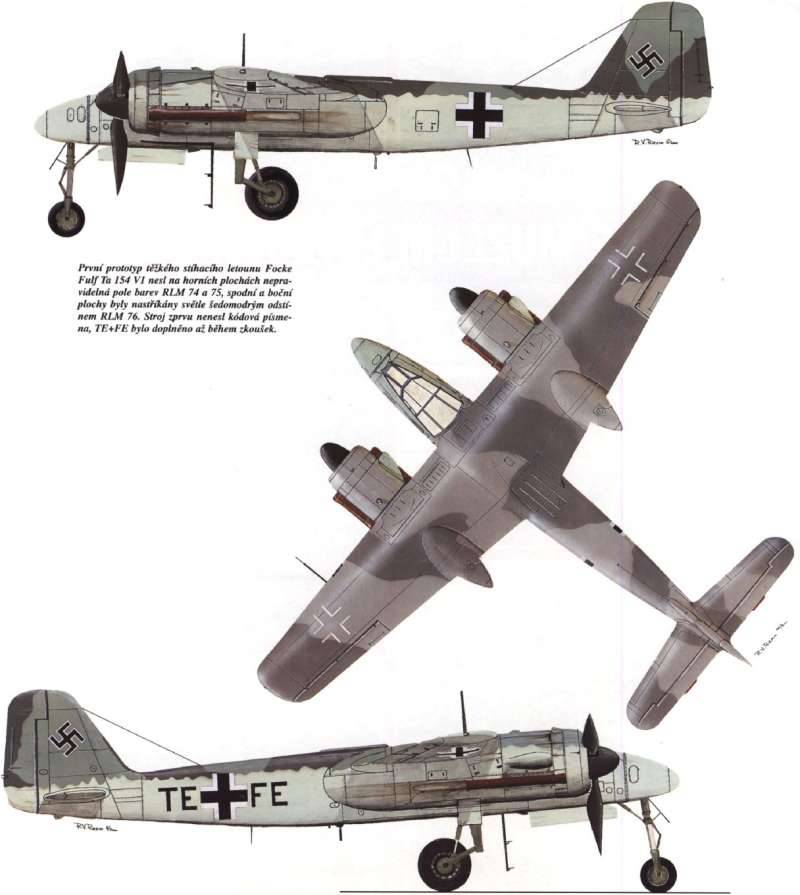

The first aircraft, the Ta.154V1, began to run and test the engines at Langenhagen airfield in June 1943, not yet equipped with radar, guns and flame arresters at the exhaust pipes. 1 July 1943 of the year, two weeks before the deadline set by the Ministry of Aviation, finally took place the first flight. At the helm was the chief pilot of the company, Hans Zander, and the back seat was Test Engineer Walter Schorn. The flight, which Kurt Tank himself watched, lasted about an hour and did not go as smoothly as the designers wanted. First, the pilot immediately noted that Ta.154 was leading to the left, and only after working out the rudder with a trimmer, he managed to cope with this problem. Secondly, the nose gear of the chassis is not completely removed. Seeing that the pressure in the hydraulic system is below normal, Zander did not re-issue and clean up and continued the flight. In the end, the pressure dropped to zero, and on landing for the landing gear and flaps, the emergency system had to be used.

All shortcomings were quickly eliminated on the ground, and Kurt Tank himself set off as a pilot on the tenth July 7 flight. Pilot reviews about the management of the new aircraft were encouraging. Hans Zander commented on the behavior of Ta.154 in the following words: “The efforts on the control levers and the maneuverability of Ta.154 are identical to Fw-190. The effectiveness of the rudder is quite sufficient for flying on one engine. And, in general, a very pleasant car in flight. ” Were indicated and shortcomings, because the new aircraft without them does not happen. So, with some fighter maneuvers, exhaust gases from the engines got into the cockpit. Radiator vibration and cooling fluid leakage was noted. And problems with the hydraulic system forced the use of a working fluid with a different viscosity.

23 July Zander and Shorn overtook the Ta.154V1 at the Luftwaffe test airfield at Rechlin, where military testers joined the flights. Three days later, Zander demonstrated a new fighter to the commander of the 1 th squadron of night fighters, Major Helmut Lenta and his pilots. The combat pilots doubted that the plane with the nose-rack could have a small landing run. Therefore, Tank asked Zander to perform landing with a minimum mileage, but the spectacular show failed. Zander, at too high speed, priter the car to the concrete, so that the load on the main landing gear turned out to be excessive. One of the racks broke, and Ta.154V1 spun on the runway at the front wheel and tail end. Fortunately, the damage was small, and after repairing the plane again began flying. Major Lente personally raised Ta.154V1 into the air on October 2, and his reviews were enthusiastic.

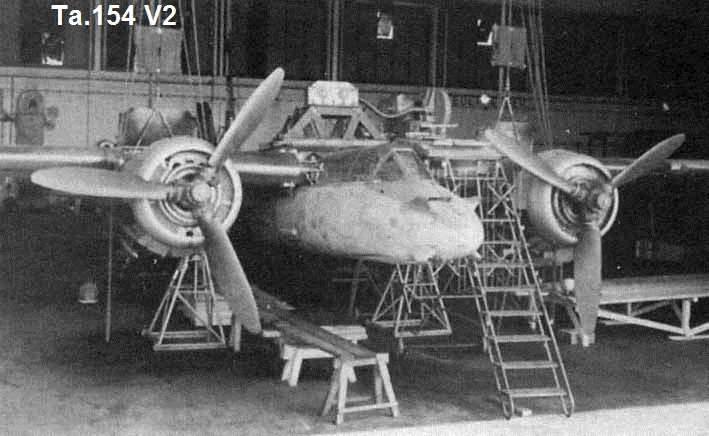

On the second copy of the Ta.154V2 fighter, which had the same engines as the V1, installed flame arresters on the exhaust pipes and FuG 212 “Liechtenstein” radar. Placed in the nose on four racks of the antenna locator reduced the maximum speed of about 20km / h. This aircraft has passed a series of ground tests on the stands. In order to provoke vibration of the fuselage and assess the strength of the structure, instead of screws, special flywheels in the form of wheels were installed. Changing the engine speed, respectively, changed the frequency of vibrations.

In November 1943 of the year, the third machine started the flights - Ta.154V3. The Yumo 213E engines were still not ready, and on V3 they put the same Yume 211F as on the V1 and V2, and then replaced them with the Yumo 211N. It was the first copy of a fighter with weapons, however, all four guns were caliber 20 mm. In addition, since the V3, the keel had a slightly larger area for better road stability when flying with radar antennas. The first 15 minute flight of Ta.154V3 took place on November 24, and after a few days V3 together with V1 showed Hitler at a demonstration of new equipment in Insterburg (now the city of Chernyakhovsk, Kaliningrad region).

Ta.154V3 after the factory flight flew to Rechlin, where he became the first aircraft of a special 154-th test squad commanded by Helmut Bruning, created for a comprehensive test of the new fighter. The first departure Bruning made 3 February 1944 of the year and immediately made a number of claims to the designers. It was difficult for a medium-qualification pilot to land with flaps fully extended, especially if the flight took place at night. The lack of visibility from the cockpit has been criticized. After replacing the FuG 212 radar with a new FuG 220 with four large antennas in the nose, road stability deteriorated and, accordingly, there were problems with aiming. In addition, during the firing of all the guns in some places could not withstand fasteners, and there were cases of damage to the skin.

Despite the shortcomings, the overall impression of the aircraft was good. The participants in the test program on Ta.154V3, Major Wilhelm Herget and Hauptmann Ludwig Meister from the 4 squadron of night fighters, once again noted good maneuverability and control in general. True, at the end of February, the nose landing gear of the V3 crashed during landing, and the plane received serious damage.

The next fighter, the Ta.154V4, was the first to receive standard armament from two MG 151 guns of the 20 mm caliber and two 108 XM XM on the mm 30. The German "Mosquito" under the fourth serial number since birth was haunted by failure. During the first launch of 19 on January 1944, one of the hoods of the right engine flew off in the air. A month later, the landing gear damaged the main landing gear, and on May 26 the left engine caught fire in flight. The last in the list of misfortunes Ta.154V4 was the destruction of the front pillar fork during takeoff in early June, after which the plane could not be restored due to heavy damage.

At the end of 1943, the Ministry of Aviation finally decided to conclude a contract with Focke-Wulf for the serial production of Ta.154. The fighter was very necessary, and they were going to build it simultaneously on four factories, and during the 1944 year they planned to bring the number of monthly aircraft to 250. For flight tests connected new machines, considered pre-production Ta.154-0. This designation began with the third aircraft, which, in addition to the Ta.154V3 index, had the second - Ta.154-03. The double name has been preserved for subsequent pre-production fighters.

In February, the 1944 of the year, the Ta.154V5 and V6 flew out for the first time, on which there was no weapon, but only FuG 212 radar, and in March they were joined by V7. The assembly work was carried out very hastily, and the praised German pedantry was not always respected. On airplanes already ready for flights, sometimes they found very serious defects, starting with poor-quality fastening of power elements, rusty control cables and ending with improper installation of equipment. The assembly technology was not always respected, for example, on the Ta.154V5 after the rain into the fuselage through the slots and gun holes a considerable amount of water was collected.

All the planes built so far had Yumo 211 engines, and on April 8 flew into the air Ta.154V8, on which stood Yumo 213А engines (takeoff 1776 hp power) with three-blade propellers VS 111. Since the Yumo 213 was heavier than the Yumo 211 on the 270kg, the weapons and radar were not installed, and in the back there was a ballast to maintain balance. In the future, with such engines flew Ta.154V10, V20, V21. V22 and V23. Pre-production fighters, as a rule, equipped with radars FuG 212 and FuG 220. The designers proposed to strengthen the arming with an additional pair of 20 millimeter cannons mounted behind the cab at an angle 70 ° upwards. Shooting from them could lead, being below enemy aircraft. However, for the time being they did not do this, since the characteristics of the fighter deteriorated due to the increased weight.

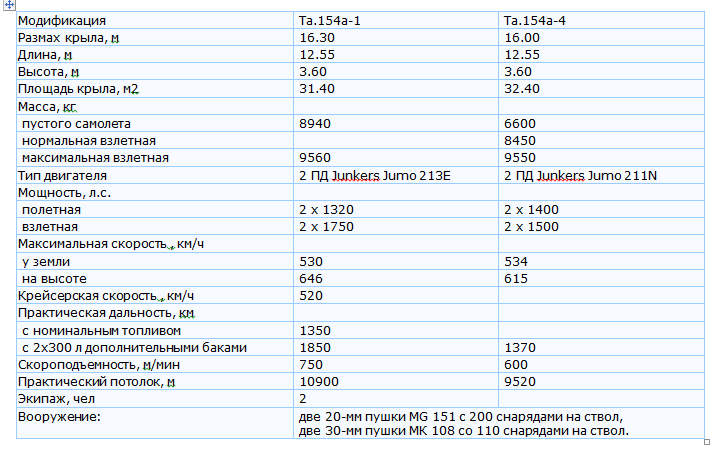

The first production aircraft were modifications of the Ta.154А-1 and Ta.154А-4, released in May 1944. A-1 had a FuG 212 radar, and on the A-4 was FuG 220 or FuG 218 "Neptune" (with wing antennas). In addition, they created the Ta.154А-2 single-seater day fighter equipped with the GМ1 system for injecting nitrous oxide into the engines, and the Ta.154А-2 / R-2 with a pair of 300 overhead tanks of liters. But these two modifications were not commercially released. For training, the pilots were going to build X.UMNXX-20 X.UM training based on Ta.154.A. 3.

For several reasons, the planned mass release of the German "Moskito" did not take place. Many small firms were involved in the production as subcontractors, and not always finished parts arrived on time. This was hampered by the constant bombardment of Allied aviation, delivery difficulties and problems with raw materials. In addition, the wooden structure turned out to be low-tech for the Germans, and this also took precious time. So, on the wing assembly took about 400 hours instead of the planned 200.

In addition to the difficulties with serial construction, the Kurt Tank fighter was in trouble at the Ministry of Aviation. By the end of the war, the leadership of the Ministry and the Luftwaffe sometimes did not know which aircraft to prefer, exchanging from one machine to another. Erhard Milch, head of the technical department of the Ministry of Aviation, who initially advocated the early introduction of the Ta.154, unexpectedly changed his mind and suggested choosing Junkers Ju-388J from the main night fighter.

Not losing hope to save his plane, Kurt Tank turned for help to high-ranking friends. He wanted Ta.154 to be personally flown by Lt. Gen. Adolph Galland and the night fighter pilot-inspector Colonel Werner Shtreis, hoping for their positive feedback. 2 June 1944 of the year near Berlin, both pilots took to the air on the Ta.154 V14, but the Tank didn’t get much support from them. And although Galland was pleased with the management of the fighter, he said that Ta.154 would not be able to effectively fight at night with the English "Mosquito".

In June, two more events occurred that also did not add credibility to Kurt Tank’s aircraft. June 20 is broken Ta.154А-1 with the serial number 0004, and after eight days the second serial Ta.154А-1 crashed. And if the first accident occurred due to the failure of the left engine, the second one was much more serious - a wooden wing collapsed in flight.

To investigate the last incident, a special emergency commission chaired by Hermann Goering himself was created. It turned out that the power elements of the wing for prototypes and pre-production aircraft were made by Tego-Film. But after the plant was destroyed by the Royal Air Force bombers, the order was transferred to the small enterprise Kaurit. Failure to manufacture wooden parts in this factory led to a catastrophe. In addition, in the conclusions of the commission, a lot of criticism was voiced against the outdated all-wooden aircraft structure, and one of the proposals was the closure of the Ta.154 production program. This decision 14 August 1944 was made, although Kurt Tank still hoped to push his brainchild into the series. Work on the fine-tuning at the company did not stop, but the fate of Ta.154 finally decided at the end of the year. In November, they approved a program for the construction of combat aircraft, in which they relied only on fighters, but the German Mosquito was not even mentioned in it.

Before the official closing of the serial production of the Ta.154, the designers of Focke-Wulf developed and created a number of modifications of their aircraft. Ta.154V4 served as the basis for the two-seater fighter Ta.154А-1 / R-1. There was no radar on the plane, the cabin had a convex lantern having a better view, and a large-caliber MG 131 machine gun (13 mm) was mounted behind the glazing to protect the rear hemisphere.

The aircraft of the “A” series had Yumo 211F engines, and the more powerful Yumo 211N planned to deliver on the “B” modification. The variants B-1, B-2 and B-3 are A-1, A-2 and A-3. Since the series "A" and "B" almost did not differ, in the end all the aircraft with Yumo 211 engines of all modifications began to be designated as the series "A".

A more serious variant of Ta.154С with Yumo 213 should have been. Six prototypes have already flown with these engines - Ta.154V8, V10, V20, V21, V22 and V23. At Ta.154C, they planned to install a new convex cockpit lamp ejected by the crew seat using compressed air and change the design of the bow to a metal one. They were going to reinforce the armament with two additional 30 mm caliber guns mounted behind the cab and shooting upwards, and also to replace the radar with the FuG 240 "Berlin". One of the modifications of the C series was the Ta.154С-2 single-seat day fighter, equipped with a GM 1 system of nitrous oxide injection into engines. Ta.154С-3 was conceived as a high-speed reconnaissance aircraft, and Ta.154С-4 as a two-seat fighter-bomber.

At the beginning of 1944, the designers presented the next modifications of the German Mosquito - Ta.154D-1 and D-2. These options were to receive the Yumo 213E engines (hp 1750 take-off power) and be used as high-altitude fighters: the D-1 as a double-night fighter, and the D-2 as a single for daylight hours. Since the changes in the basic design were significant (increased by 30% of the wing area, new four-bladed propellers were installed and a number of improvements were introduced), the “D” series was renamed Ta.254.

On the double night fighter Ta.254А-1 with the same weaponry as on the Ta.154А-1, they planned to get the maximum speed of 680 km / h on 10000 meters. Approximately the same data should have been a day fighter Ta.254А-2 with a crew of two people. According to the designers, the Ta.254А-3 single, equipped with the MH 50 water-methanol injection system, seemed to be the fastest - its maximum speed when switching on the MW 50 was about 740 km / h. The next step in the evolution of the German "Moskito" was planned by Ta.254В with powerful liquid cooling motors Daimler-Benz DВ 6031. However, due to the closure of the Ta.154 production program, none of the above options have risen to the sky.

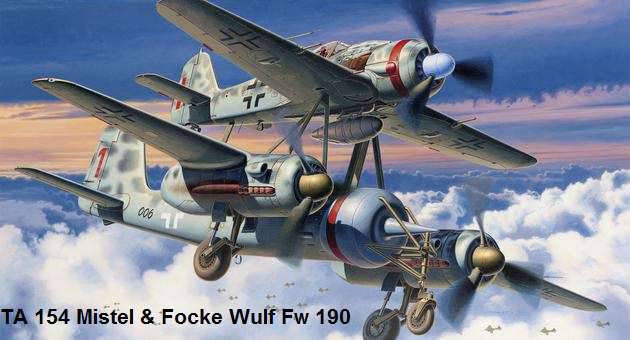

By the end of the war, German aircraft designers were carried away with the development of aircraft winged bombs or "Mysteles". Ta.154 did not stay away from this idea. The Ta.154А-0 / U-3 variant consisted of the unmanned Ta.154А, on which all the excess equipment was replaced with two tons of explosives. On top of the metal truss, the Fw-190А-4 fighter was attached, the pilot of which controlled the entire hitch. This option was designed to combat enemy bomber units, and the tactic was quite simple. Approaching the enemy's aircraft at a sufficient distance, the Fw-190-4 pilot directed his Ta.154 to them and unhooked it. And when the German "Moskito" reached the goal, it was necessary only to detonate a flying bomb on the radio. In the summer of 1944, the test pilot of Juncker, Horst Lux (who had previously tested Misteli with Ju-88), flew around the Ta.154А-0 / U-3 version, but refused to launch the serial production of such a coupling.

The next development was a modification called “interceptor connection” (“Рulk Zerstorer”). Here the coupling consisted of two Ta.154, taking off in tow one after the other, and the rear aircraft was unmanned. Approaching the compound of the bombers, the pilot of the first fighter picked up speed in the canopy dive and unhooked the towing cable, continuing to drive the second plane through the wires connecting the wings of both machines. After making sure that the flying bomb was on the right course, he finally disconnected from the unmanned Ta.154 and undermined the explosive charge on the radio. The flight tests here did not come to an end, and such an exotic option remained only in the project.

A guided "air torpedo" based on Ta.154 was brought to construction. On the serial Ta. 154А, they removed the unnecessary equipment and loaded two tons of explosives with three fuses - contact, time and acoustic. The pilot was in a simplified cockpit in front of the wing with the ejection-down seat (using compressed air). Taking off on an airplane weighing 9570 kg, the pilot had to direct him to the dense formation of bombers and to eject. The explosion occurred from the triggering of any of the fuses, or by radio command from the Fw-190 escort fighter. We managed to convert six Ta.154 into this version, but none of them went up in the air.

Until the shutdown of all works on Ta.154, the mass serial release of the German "Mosquito" could not be deployed. At first, the plant in Posen (now Poznan) was bombed, and only a few aircraft were assembled. 9 April 1944, Allied aviation completely destroyed the assembly plants in Messegeland, and in May, the plant in Kreisingen was the victim of an air raid. Therefore, only about 50 Ta.154А-1 and А-4 were released, although most of them were still handed over to the Luftwaffe.

The first information about the Ta.154 units that appeared in the combat units came in March 1945. It was then that the Royal Air Force reconnaissance aircraft photographed the Stade airfield near Hamburg, where the 3 squadron of night fighters was based. When the pictures were shown, then on the strip, along with heavy fighters Non-219 and Ju-88, they saw a pair of Ta.154.

Several Ta.154 entered the 10-th squadron of night fighters for operational tests, but these aircraft did not take part in the fighting. Also, not a single combat sortie was made by the German "Mosquito" from the 2-second reserve fighter squadron, based in southern Germany. The only part that managed to apply their Ta.154 for real missions was the 3 Squadron at the Stade airfield, whose British fighters photographed the March 1945 of the year. The first official sortie was completed by Feldwebel Gottfried Schneider on November 19, November, 1944, but he failed to knock down anyone. Naturally, only a few units of the night fighter Kurt Tank could not have any influence on the situation in the sky of Germany, and data on victories on Ta.154 are missing. But, for example, it is known that 16 March 1945, several Ta.154 III group 3 squadron unsuccessfully tried to intercept the Mosquito of the Royal Air Force.

After the war, the Allies got a few surviving Ta.154, but the evaluation tests were not conducted on them. One of the main trump cards of the German "Moskito" was supposed to be the speed under 700 km / h. But the maximum figure obtained on Ta.154V1 in September 1943 of the year was 626 km / h at an altitude of 6000 meters. And we must bear in mind that there was no radar on the car, the antennas of which reduced the speed by another 20-30 km / h. The not very high speed data was partially compensated by the excellent controllability and maneuverability of the fighter, clearly demonstrated in June 1944 of the year during the training battle of Ta.154V22 with Вf.109Н. Single-engine "Messerschmitt" lost the fight, failing to never go to the tail of his opponent.

Conceived as the main rival of the invulnerable English Mosquito, Ta.154 could not fight them on equal terms. And the reason is not only a very small series, but also the worst data of the German fighter. But it is impossible to call Ta.154 completely unsuccessful. The plane looked promising, and it was not the fault of the designers that the serial production of the Ta.154 did not take place with more powerful engines and reinforced armament, which most certainly would have caused a lot of trouble for the allied aviation.

Summarizing, we can say the following. The situation in Germany, where the German Mosquito was created, which was notable for the wooden technology that had already been forgotten in this country, was characterized by frequent breaks in the testing and production programs caused by regular Allied raids. This affected the fate of Ta.154 not less than intrigue among the highest ranks of the Luftwaffe. If the circumstances were more successful, this undoubtedly promising fighter would play a much more prominent role in the air battles over Germany. However, such was the fate of virtually all German combat aircraft, the creation and deployment of production of which began after the start of World War II.

Sources:

Volodin D. Ta.154 - "wooden idol" of the Luftwaffe. // Aviamaster. 1998. No.2-3. C.23-32.

Khvoschin A., Kanevsky A. Night fighter Ta.154. // Wings of the Motherland. 1998. No.1. C.17-21.

Kolov S. Ta.154 - German "Mosquito" // Wings of the Motherland. 2005. No.8. With 34-38.

Firsov A. Focke Wulf Ta.154. // Wings of the Luftwaffe. H.3. 1994. C.155-160

Information