Device for giving the projectile (bullet) rotational motion

The invention relates to military technology and can be used in a smooth-bore small arms, airguns, artillery and other devices that require throwing a ballistic projectile under the pressure of gases.

A device for tightening a projectile or bullet, known as "rifling" in the gun barrel channel to give a projectile or bullet rotational movement, is known, which ensures its stability on the trajectory, flight range and accuracy of fire.

The disadvantage of the prototype is the difficulty of making rifling, as well as the fact that a bullet or projectile, passing rifling, experiences considerable resistance to the friction force, which negatively affects the durability of the barrel, the accuracy of the fight, and also requires an increase in the powder sample. In addition, the bullet, passing the bore, on the departure is deformed due to the interaction with rifling, which also adversely affects the ballistic characteristics.

The invention solves the following problems.

1. The possibility of giving the projectile or bullet rotational motion without the use of rifling.

2. 3 is a significant simplification of gun barrel production.

3. Increased accuracy and range.

4. Reducing the powder charge, which should have a positive effect on saving the production of cartridges, reducing the recoil of weapons during firing, increasing the life of parts and mechanisms of the weapon, and the resource of the barrel.

5. The possibility of using all-metal shells or brass, copper, steel bullets, which will positively affect penetration.

The technical result obtained from the invention, is to give the projectile or bullet rotational motion in a smooth-bore weapon.

This technical result is achieved by the fact that in order to give the projectile or bullet a rotary motion, the pressure of powder gases or other gases is used by means of special side slots in the device. Under the term “other gases”, the author assumes any other gases through which pressure the projectile or bullet is thrown.

The claimed invention can be applied in small arms, air guns, artillery and other devices that require throwing a ballistic projectile under the pressure of gases. In addition, this invention can be applied in an existing rifle to increase the speed of rotational movement of the projectile or bullet.

Technical solutions with features that distinguish the claimed solution from the prototype are unknown. This suggests that the proposed solution is new and involves an inventive step.

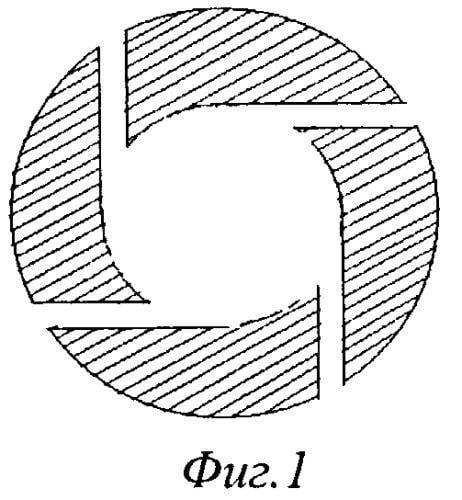

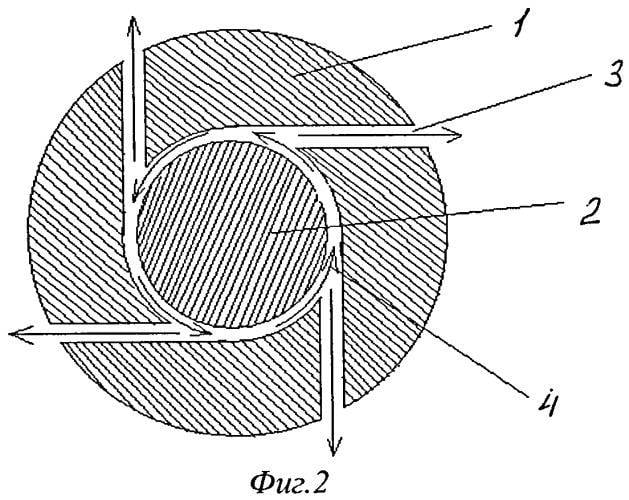

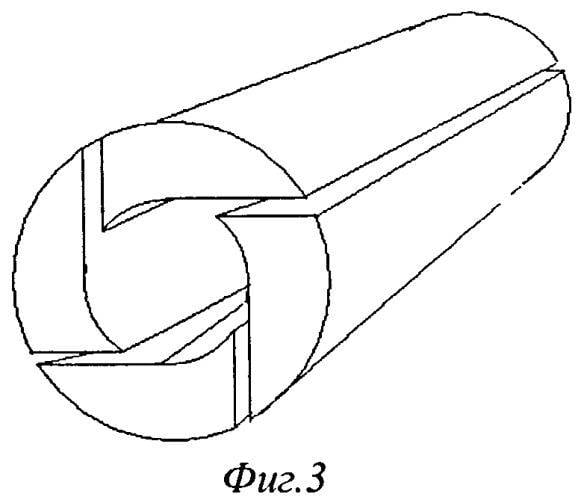

The appended invention is illustrated by drawings, where in fig.1 shows a cross section of the device. On fig.2 shows the cross section of the device and the direction of rotation of the projectile or bullet, as well as the direction of movement of the powder or other gases, where: 1 - the device itself; 2 - projectile or bullet; 3 - the direction of movement of the powder or other gases; 4 - the direction of the projectile or bullet rotation. FIG. 3 shows the device in perspective.

A device for giving a projectile or a bullet a rotational movement is a section of the barrel or a nozzle to the barrel, having side slots arranged at an angle to the bore of the barrel.

The device works as follows.

Powder or other gases, pushing a projectile or a bullet through the bore and reaching the device, due to the presence of side slots in the device, exit these slots, creating simultaneously a lateral rotational thrust for the projectile or bullet, the projectile or bullet performs axial rotational movement.

Using the term “slots”, the author was guided by a technical dictionary, namely: “Slots are holes that are usually oblong in shape”. Since the term “usually” is not exclusive, the author assumes that these holes may have another shape.

A device for imparting a projectile or bullet rotational motion, characterized in that the axial rotation of the projectile or bullet is achieved by the pressure of the powder gases using the side slots in the barrel or the nozzle, these slots are angled to the bore.

Information