F. Charlton automatic rifle (New Zealand)

At the beginning of the forties of the leaders of New Zealand and Australia anxiously looked to the north. Japan continues to capture more and more territory, which ultimately could lead to an attack on the southern states of the Commonwealth of Nations. To protect against a possible attack, they needed weapons and equipment, but the capabilities of their own industry did not allow them to count on the beginning of a full-fledged mass production of the necessary products. Nor could one rely on the UK, which was in charge of replenishing the losses after the evacuation from Dunkirk. The way out of this situation could be a relatively simple projects rework existing systems in order to improve their performance.

Approximately in the second half of 1940, Philip Charlton and Maurice Field joined the development of new weapons for the New Zealand armed forces - amateur arrows and weapon collectors. Charlton and Field had extensive experience with small arms, and in addition, Charlton had the opportunity to expand the production of the necessary systems in his own company. All this allowed the two enthusiasts in a short time to create a promising system for "turning" outdated rifles into automatic weapons.

The project, later called Charlton Automatic Rifle (“Charlton Automatic Rifle”), was launched with a proposal to refine the Winchester Model 1910 self-loading rifle. It was proposed to create a set of additional equipment, with the help of semi-automatic weapons which might lead fire in automatic mode. After such a revision, relatively old rifles could be of interest to the army.

Learning about the idea of F. Charlton, M. Field, in general, approved it, but criticized the chosen basic weapon. The Winchester Model 1910 rifle used an .40 WSL cartridge that would hardly suit the military. The search for alternatives did not last long. In the warehouses of the New Zealand army was a large number of old rifles with manual reloading Lee-Metford and Long Lee chambered for .303, released in the late XIX century. They were decided to use them as the basis for a promising rifle system. In addition, in future the automatic rifle was created based on the Lee-Enfield.

After selecting a new base rifle, some plans had to be adjusted, with the result that the final appearance of the device providing automatic firing was formed. Now the Charlton Automatic Rifle project implied the use of the barrel, part of the receiver and bolt group, as well as some other units of the Lee-Metford rifle, which should be equipped with a number of new parts. The main innovation of the project was to be the gas engine, which provides for the reloading of weapons after each shot without the need for the direct participation of the shooter.

Working with existing weapons, Charlton and Field came to the conclusion that significant changes in the basic design of the rifle. It was necessary to recycle the receiver, as well as make some changes in the design of the trunk. All these improvements were aimed at ensuring the correct operation of automation and improving the combat qualities of weapons. As a result, the Charlton Automatic Rifle rifle looks much different than the base Lee-Metford rifle.

The barrel, muzzle brake, and bipod. Photo Forgottenweapons.com

For use in the existing weapons, the existing barrel received a developed muzzle brake and fins in bureaucratic honor. The first was designed to reduce recoil and improve shooting performance, and the use of the second was associated with an expected change in the process of heating the barrel when firing. Doing automatic fire should have led to intense heating of the barrel, to which the base weapon was not adapted.

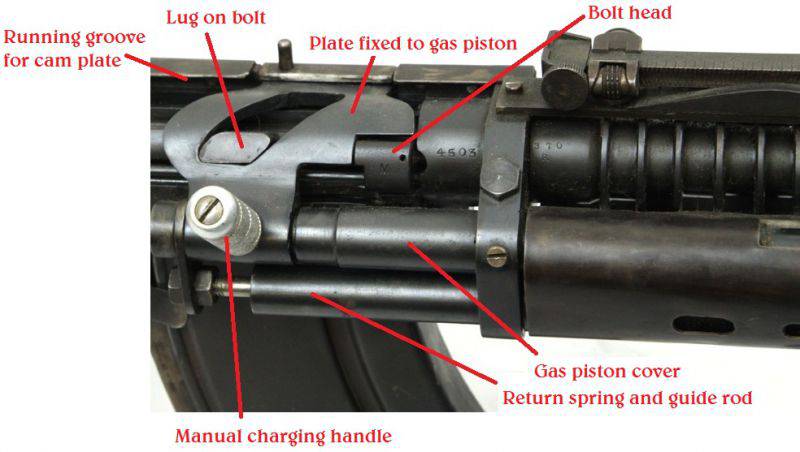

Was redesigned receiver. Its lower part almost did not change, whereas a relatively high and long port side appeared at the top. In the back of the box, special restraints for the shutter were provided. The right side of the weapon, in turn, placed the gas engine units of the original design.

Charlton-Field gas engine consisted of several parts assembled on the basis of two long tubes. The upper tube, at its front end, was connected to the gas outlet hole of the barrel and contained a piston. The piston rod was removed in the back of the tube and connected to the recharging mechanisms. The lower tube was a casing of the return spring, responsible for discharging the cartridge and locking the barrel.

A special curved plate with a figured hole was fixed on the rear stem of the gas engine, with which it was proposed to move and lock / unlock the bolt. Also, a small handle was attached to this plate for manual reloading of the weapon: the native handle was removed as unnecessary. To avoid displacement, the plate was rigidly fixed on the piston rod, and its second face slid along the groove in the wall of the receiver.

Relatively minor modifications undergone shutter. The recharging handle was removed from it, instead of which a small protrusion appeared on the outer surface in contact with the gas engine plate. Also had to modify some other details of the shutter. The principle of its action while remaining the same.

The standard Lee-Metford rifle was equipped with an integral box magazine on 8 or 10 cartridges, which was not enough for an automatic weapon. For this reason, the authors of the new project planned to abandon the existing ammunition system and replace it with a new one. At the bottom of the receiver, it was proposed to attach a slightly modified box magazine of a Bren light machine gun on 30 cartridges. However, some problems were associated with this device, which also used the original 10 magazine magazines.

Sights were borrowed from the base rifle, but their location has changed. The mechanical open sight was proposed to be mounted on special clamps above the breech, and the front sight was to be placed on the muzzle brake. The sight was not refined, which made it possible to count on the preservation of the previous indicators of range and accuracy of shooting. To further improve the accuracy of shooting rifle also equipped with a folding biped bipod.

F. Charlton and M. Field abandoned the existing wooden lodge and replaced it with several other details. A new automatic rifle got a wooden butt, connected with a pistol grip. A front vertical handle appeared in front of the store, making it easier to hold the weapon. To protect against the heated barrel, its breech was closed with a short curved metal forearm with openings for ventilation.

As conceived by the authors of the project, the advanced weapons automatics should have worked as follows. Having equipped the magazine, the shooter had to use the gas engine handle to move the bolt forward, thereby sending the cartridge into the chamber and locking the barrel. When moving the handle forward, the shaped-cut engine plate was supposed to provide the bolt rotation in the extreme forward position.

When fired, a part of the powder gases had to enter the gas engine chamber and displace its piston. At the same time, the plate with a hole was shifted, with the help of which the shutter was rotated with its subsequent shift to the rear position. After that, the spent cartridge case was thrown out, and the return spring was used to dismount the next cartridge with the bolt locked.

The trigger mechanism of the weapon allowed to fire only in automatic mode. This device was borrowed from the base rifle without significant changes, because of which there was no fire interpreter. However, this was not considered a minus, since the introduction of an additional mode of fire would require a serious refinement of the weapon design and thereby complicate its manufacture.

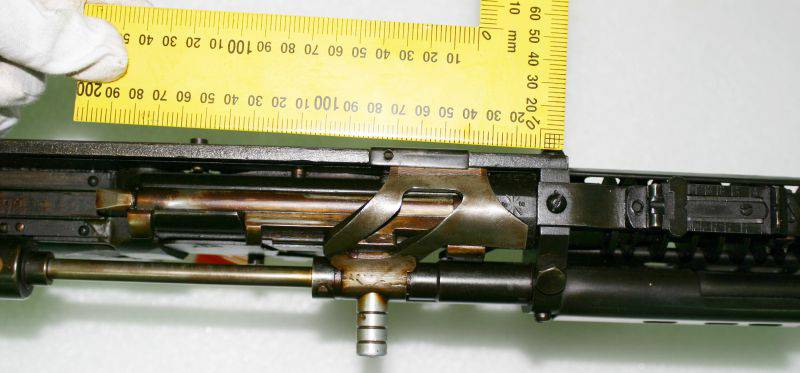

The first Charlton Automatic Rifle prototype was made in the spring of the 1941 of the year. This sample, built on the base of the finished Lee-Metford rifle, was equipped with all the necessary equipment and could be used in tests. The assembled weapon had a length of the order of 1,15 m and weighed (without cartridges) 7,3 kg. Due to the lack of other options, the prototype was equipped with a magazine for 10 cartridges. Soon after the end of the assembly, F. Charlton and M. Field began to test their design. As it turned out, the new automatic rifle can not stably fire bursts and needs to be improved. For some time, the inventors tried to find out the causes of delays in shooting, which were associated with jamming of the shells during the release.

The problem was solved by designers with the help of a familiar specialist. Radio engineer Guy Milne suggested filming test firing with a strobe camera of his own design. Only an analysis of the taken shots allowed to establish that the problems of the rifle are connected with a weak extractor that cannot correctly throw out the liner. This detail was finalized, after which the tests continued without significant problems. In the course of further tests, it was found that the technical rate of fire of the new weapon reaches 700-800 rounds per minute.

In June 1941, gunsmith enthusiasts presented their development to the military. A demonstration of the Charlton Automatic Rifle took place at the Trentham test site, during which a new weapon showed good results. Representatives of the command showed interest in this sample and instructed the inventors to conduct a refinement of their development. Charlton and Field have been assigned 10 thousand .303 cartridges to conduct new tests.

Further work continued until the end of autumn. In November of 41, another demonstration took place at the test site, which resulted in a contract. After seeing the results of the work, the military ordered an alteration of X-NUMX rifles from Lee-Metford and Long Lee from army arsenals. Production should have been completed within 1500 months. The contract was a confirmation of the success of the development, but its appearance did not make life easier for gunsmiths. They needed to find a company in which they could produce sets of new equipment and assemble promising automatic rifles.

This time, F. Charlton again helped the connection. He connected his friend Sid Morrison, who owned Morrison Motor Mower, to the project. This company was engaged in the assembly of lawn mowers with gasoline engines, but due to the war, production volumes fell sharply due to lack of fuel. Thus, a new non-standard order could provide the army with the necessary weapons, as well as save S. Morrison's company from ruin.

By the beginning of the 1942 of the year, the Morrison Motor Mower Company had prepared for the production of the parts necessary to "turn" rifles into automatic weapons. According to some information, the manufacture of new products was carried out even without drawings, because F. Charlton and S. Morrison considered the preparation of documentation unnecessary and negatively affecting the pace of contract fulfillment. Morrison’s company was to manufacture and supply the necessary spare parts, and Charlton and Field should have been responsible for reworking existing rifles.

Despite all the specific measures aimed at speeding up production, the estimated rate of release of "Charlton Automatic Rifles" did not suit the customer. In this regard, the military were forced to intervene in the process and involve new enterprises in it. Contract curators from the Department of Weapons John Carter and Gordon Connor distributed the production of various parts among several factories. So, the production of some of the main parts of the trigger mechanism and automation was entrusted to the Precision Engineering Ltd plant, the springs were to be supplied by NW Thomas & Co Ltd. Moreover, even Hastings Boy's High School, whose high school students were to produce gas engine pistons, was commissioned. Nevertheless, the students of the school managed to make only 30 pistons, after which the production of these parts was taken over by Morrison's company.

All major parts were planned to be manufactured in New Zealand, but the 30 shop offered to order cartridges in Australia. One of the Australian companies already collected Bren machine guns, which was the reason for the appearance of the corresponding proposal.

The general assembly of automatic rifles was carried out at F. Charlton's own firm. Even before the war, he opened the car body shop, which by 1942 was experiencing not the best of times. By this time only Charlton himself and a certain Horace Timms worked at the enterprise. Soon they called for help engineer Stan Doherty, and the three of them began to turn the workshop into an armory. After starting the supply of rifles for rework, the company hired several new employees.

The New Zealand rifle (above) and one of the prototypes of weapons for Australia (below). Photo Militaryfactory.com

The first batch of Charlton Automatic Rifle was made without F. Charlton. By this time, the Australian command had learned about the development, wishing to get similar rifles. Charlton departed to Australia for negotiations on weapons refinement and the deployment of its production. The management of the workshop passed to G. Connor from the Department of Armaments. He recruited another gunsmith specialist, Stan Marshall, who took over some of the engineering work.

Having studied the situation on the spot, G. Connor came to sad conclusions. Charlton and Morrison’s refusal of the drawings, limited production capabilities and the specific design of the automatic rifle could seriously hit production rates. Because of this, S. Marshall and S. Doherty had to modify the design of the weapon and improve its manufacturability. The made improvements of technical and technological character allowed to begin full-fledged mass production of all necessary details and alteration of the available rifles.

Production of Charlton Automatic Rifle rifles began only in the middle of the 1942 year and took longer than originally planned. The last batch of weapons was handed over to the customer only two years later, although initially only six months were allocated for all work. Nevertheless, all delivered weapons were not only manufactured, but also passed the necessary checks.

The project of F. Charlton and M. Field implied the use of modified Bren machine gun shops with 30 ammo capacity. The production of these products was entrusted to an Australian company, which, as it turned out later, was not the right decision. Due to loading with other orders, the contractor was unable to deliver the stores on time. Moreover, when the stores were still delivered to New Zealand, it turned out that they were incompatible with the new rifles. Because of this, they had to be refined already in place and, in this form, attached to rifles.

"Charlton Automatic Rifles" based on Lee-Metford (top) and SMLE Mk III (bottom). Photo Guns.com

As a result of such problems, full-fledged 30 magazines received only about fifty rifles from the last batch. The rest of the weapon remained with the "short" magazines on 10 cartridges obtained from the base rifles. After completing the assembly of 1500 automatic rifles in warehouses, almost one and a half thousand large-capacity stores were unusable. In view of the completion of arms supplies, the stores were sent to warehouses.

F. Charlton's four-month trip to Australia led to the start of the production of a new modification of his weapon. Together with the specialists of Electrolux Vacuum Cleaner, which produced household appliances, the New Zealand gunsmith created a version of the retrofit kit for Lee-Enfield SMLE Mk III rifles. A contract was signed for the manufacture of 10 thousand such automatic rifles, but it was not fully implemented. According to various sources, no more than 4 thousand rifles were redone. The Charleton Automatic Rifle based on the SMLE Mk III had minimal differences from the base rifle based on the Lee-Metford.

Despite all the difficulties and the threat of attack, the army of New Zealand never considered Charlton Field as a rifle. However, this weapon was ordered to form a reserve in case of additional mobilizations. Manufactured automatic rifles were sent to three warehouses, where they were kept until the end of World War II. In connection with the end of hostilities and the complete elimination of the threat of attack, more unnecessary weapons were transported to Palmerston. There the rifles were stored for some time, but later a fire occurred in the warehouse, as a result of which the overwhelming majority of them were destroyed. Only a few samples of Charlton Automatic Rifle, which are stored in museums and private collections, have survived to our time.

On the materials of the sites:

http://popularmechanics.com/

http://militaryfactory.com/

http://forgottenweapons.com/

http://candrsenal.com/

Information