In the defense industry developed a new radio-electronic equipment for aviation and space technology

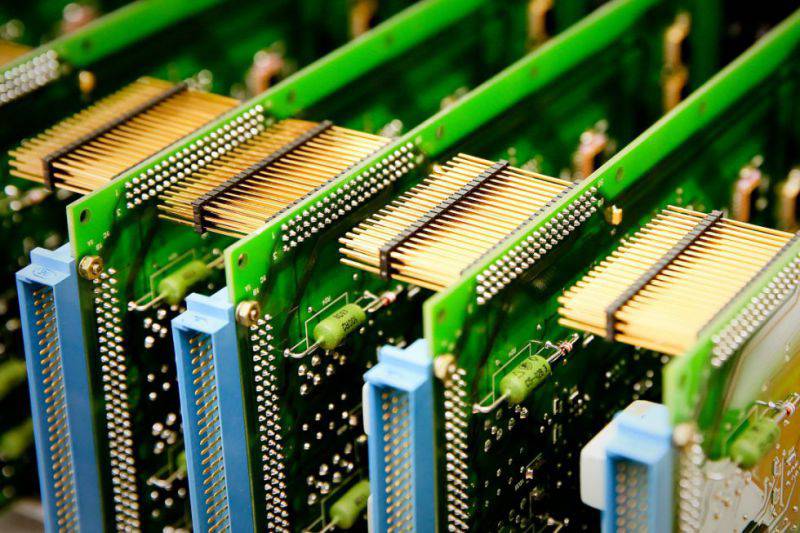

“OPK has created and successfully tested the first samples of high-density radio electronics of a new generation, including digital, power and microwave modules. Products built on 3-DMS technology of volumetric assembly have no analogues in Russia and surpass foreign samples in a number of technical characteristics. Modules are manufactured using unpackaged components. This greatly reduces the weight and dimensions of the products, allowing you to significantly expand the capabilities of the equipment. The novelty of technical solutions is confirmed by patents of the Russian Federation ", - stated in the release.

It is reported that "3-DMS technology is planned to be used in the production of new communication equipment, automated control systems, computing systems, robotics, unmanned aerial vehicles."

“Due to the unique design and improved characteristics, the modules can be used in various types of electronic equipment, in fault-tolerant on-board systems of airplanes and spacecraft. In particular, they can be equipped with Doppler meters for speed, angle of demolition and height (DISS-MLK) used in civilian and military aviation and rocket technology, ”the release notes.

Information