Guerrilla ammunition. 2 part

So, in this article we are talking about the alteration by partisans of captured German rifle and pistol cartridges for firing from the local rifle weapons. On the picture already familiar to the readers (from the first part) the "heroes" of this stories. In our narrative, we dwelt on the extremely unsuccessful results of tests of converted cartridges at the Shchurovsky test site in early May 1943. The contents of the archival documents referred to in this article can be found at the following links:

* Test Commission Act of April 1943;

* Report NITSVO K about tests from 18 May 1943 of the year.

Let's continue.

First, let's figure it out - what is the reason for such unsuccessful results?

If you carefully read the previous Test Act, and also proceed from the logic of the cartridge-weapon system, you get the following:

- During the first tests, the pressure and initial velocities of the bullets of pistol cartridges were much closer to the requirements of domestic technical specifications. When firing from the TT "Reliability is fully provided". But the commission indicated that "It is desirable to reduce the rate of fire [of the PPSh and PPD] by reducing the charge". That is, by “correcting” one remark, we received a bunch of other, more serious problems.

- The data on the initial velocities and the pressure of the powder gases given in the Report of the landfill for converted rifle cartridges also differ significantly from the data of the previous Act, and for the worse. It seems that here the developers also “insured” both from the tight and “problematic” extraction of the sleeves after the shot (especially for CW and PD). As can be seen from the results, this path turned out to be wrong.

- The problems with the tight closing of the bolt on the Mosin rifle, obviously, are related to the size and tolerance for the size of the over-pressed German cartridge in the skate area. Fearing excessive sagging of the cartridge deeper into the chamber, which is fraught with misfires when the capsule is broken, they again insured and overdid it.

- The unacceptable manufacturing quality of the converted cartridges and ejectors, as well as weak bullet attachment is unacceptable and is most likely the result of haste and insufficient process performance - NIPSWO tests took place in early May, 1943, and the previous Act was dated 18 of April of that year.

- The main cause of delays when firing a SVT rifle arr. 1940 G. and the machine gun DP became improper operation of the extractors. Which were developed by OKB-44 and were intended to replace the staff. Obviously, their design, or rather the size of the main "functional places" was unsuccessful. Why we didn’t check it ourselves by shooting before delivery to the landfill is not completely clear. Again because of the rush?

- All other aspects and results of alterations were normal, it was necessary to be careful and not to miss the achievements.

We cannot provide further developments with the involvement of the final test report on converted cartridges after the improvement and refinement of the rework method, due to the lack of archival finds on this subject (at the moment).

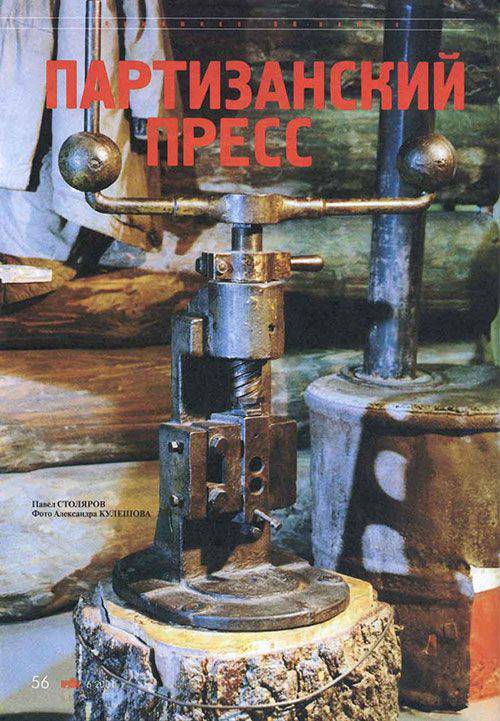

Therefore, we can evaluate the “measures taken by the developers” only on the basis of the analysis of the content of the “Manual to the rifle press ...” published in the Book-1 “From the invention of gunpowder to the middle of the twentieth century” of the monograph “Small arms fighting cartridges” by V.N. Nobleman; evidence from Pavel Stolyarov’s article “Partisan Press ...” published in the magazine “Arms”, No. 6 for 2001 a year, as well as the content of archival documents first published in November 2012 of the year in his Livejournal blog by user Christopher Reed (kris_reid ) above.

Using this approach, the following are the improvements and changes themselves, as well as the key points of the refined reworking method for captured German 9x19-mm pistol Parabellum and 7,92x57-mm rifle cartridges for firing from domestic small arms.

The first thing that attracts attention is the weight of the hand press. The Act of April 1943 gives a fairly detailed description of it, in which it is called a “typewriter”. Indicated that the machine weighs 10 kg. But the “Screw Hand Press VP-1”, presented in the exposition of the Central Museum of the Armed Forces, is slightly different "With a three-way worm, developing force 300-350 kg, weighing only 23 kg".

That is, in the process of refinement, this device has undergone serious changes, most likely associated with an increase in pressing force and an increase in the way (stroke) of pressing to ensure a softer re-compression of bullets and cartridge cases. Because the detected cracks on them are unacceptable in any case.

In the "Manual" there is a requirement: “Bullets for all calibrations must be lubricated with soapy water (emulsion) or oil. Calibration of non-lubricated bullets or clogged with sand and mud can immediately spoil the tool. ”. Perhaps the first version of the device was a lever rather than a screw press, in order to reduce its size and weight. The lever, of course, needed to be picked up and fitted already in place. Therefore, the original version was more like a “typewriter” and received just such a name.

The second and most significant change is the list of tools and devices attached to the press, which already included 20 names and differed from the list given in the April Act. The reason for this was both the introduction of new, additional operations, and some changes in the technology of calibrating bullets.

In the final process technology for both types of cartridges was introduced "Calming calibration"Manufactured cartridges, which are described in the Manual as “... control operation. The cartridges are alternately inserted into the chamber and the bolt of the chamber is turned with a finger. If the bolt turns - the cartridge fits, if it does not turn - the cartridge is long ... It is forbidden to use cartridges that have not been checked by the barrel or the barrel, since there may be cases of delay in the operation of the weapon’s automatics ”. The reason for the emergence of such an operation is obvious - to eliminate the tight shut-off of the shutter.

To guarantee a more accurate attachment of gunpowder, measurements were made for each type of cartridges and funnels to fill it in the liner. Mixing powders from pistol and rifle cartridges (sticks and plates) was prohibited. Including because "With mixed powder will be poor accuracy of the fight".

Reloading pistol cartridges now consisted of 10 basic process operations.

A significant change was the increase in bullet calibration operations from three to four, not counting the clearance of the belt on the pool. What was necessary to eliminate the appearance of cracks in the pool during the calibration process.

The ninth was the modified operation “Crimping the cartridge", which “It is necessary for reliable fixing of a bullet in a sleeve (to prevent cases of possible loss). It is produced on a special device (crimp head), the latter is fixed to the wall or table with nails. The left hand cartridge is inserted into the device with a bullet forward, the right hand turns the handle to the right side so that the sleeve of the cartridge cuts into the bullet (pressed into the bullet). Crimping is done at the very end of the barrel, for which the fixture has a regulating screw. ”. That is, the process is similar to the well-known crimping of tin lids on cans with the help of a machine for home canning.

The final operations were storing and controlling external inspection of manufactured cartridges. Was required “To reject outwardly, curves, crumpled sleeves, horny bullets, spoiled bullets, etc., should be discarded. Well-tested cartridges on the camor or the trunk and the external appearance, work in a weapon without a failure. ”.

Reloading rifle cartridges consisted of 7 core process operations.

The same matrix was no longer used for the final calibration of pistol and rifle bullets, which was previously explicitly stated in the Act. Each of them was given its own matrix for obtaining different calibers: for a rifle bullet - "MKVP-7,78", for a pistol bullet - "MKPP-7,60".

Also in the Instruction was separately stated: “In captured rifle bullets, bullets with steel and ceramic (pobedit) cores are often caught, which are not recommended to be calibrated, you can quickly spoil the tool. It is strictly forbidden to calibrate explosive bullets - pyrotechnic. Such a bullet can explode (explode) and cause injury. It is easy to distinguish pyrotechnic from ordinary ones by external coloring of the nose of a bullet or a cap of a sleeve..

The sixth, obligatory operation for rifle cartridges was to check the cartridge length, for which the control bracket of the rifle cartridge length “SDP-77,16 - 75,91” appeared in the tool. After stinking (the seventh operation), the cartridges were prescribed “Inspect outwardly and discard wrinkled sleeves, horned dults, curves, etc. To discard cartridges that have wrinkles (metal influx) around the slope when crimping dults, do not, as this does not have any effect when fired”.

Separately, it is necessary to dwell on those “narrow” points on which there were major and serious complaints following the results of the May tests in Shurovo.

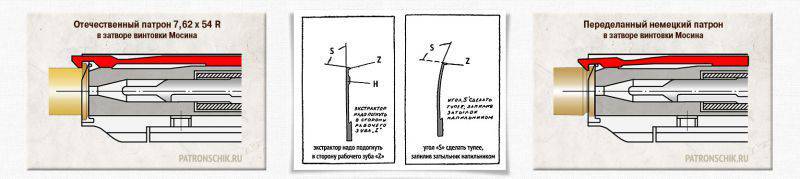

In addition to problems with the length of cartridges and the caliber of the re-bullet, which were corrected and “stabilized” by the dimensions of the matrix and the introduction of additional control operations in the technology of reworking rifle cartridges, the question remained of the extraction of spent cartridges. The following figure conventionally shows the location of the sleeves of the domestic staff and trophy cartridges (after rework) in the Mosin rifle shutter larvae, as well as the revision of the rifle ejector proposed by OKB-44. The ejector is shown in red.

The Manual says on this occasion:

Ҥ 6. Due to the fact that the combat larvae and extractors in domestic weapons (rifles of the 1891 / 30 model, rifles "SVT" and machine guns "DP") are designed for a sleeve with a rim (cap), and trophy sleeves have no caps, the existing extractor (ejector) does not extract the spent cartridge from the chamber, so the extractors (ejectors) in rifles mod. 1891 / 30 g., "SVT", machine gun "DP" must be replaced with new ones with the inscription "DTP" (for captured ammunition), made according to a special drawing and delivered as spare parts.

Note: In some machine guns “DP”, after rearranging the ejector (extractor), in order to ensure trouble-free removal of the sleeves after the shot, it is necessary to gash the barrel of the barrel a little, so that the new extractor does not rest against the neck of the barrel and freely hook the sleeve (you can only fit disassembled) .

In rifles arr. 1891 / 30 of the year can be used and the existing extractor, for which the latter must be removed with a hammer and screwdriver from a combat larva and bend to 15 - 20 ° in the direction of the working tooth "z", cut the file "H" with a file (see the figure on the left ), and cut the “S” angle, making it somewhat dumber (fig. on the right), so that it does not rest on the stump of the trunk.

The extractor (ejector) thus converted completely ensures trouble-free removal of a spent cartridge case and is reliable in operation. In the “SVT” rifles and the “DP” machine gun, the extractors (ejectors) are not amenable to correction, but are replaced by the new “DTP-43”. ”

Also in the admonition was indicated

Ҥ 10. When firing a pistol "TT", a submachine gun "PPSH" and "PPD" in the weapon no changes are required. Single and automatic firing of correctly reloaded cartridges, according to this instruction, works smoothly, as well as firing domestic gross cartridges. Ballistic data verified by official firing and fully comply with the requirements for pistol cartridges: a) Starting speed; b) Barrel pressure; c) the accuracy of the fight; d) Destructive power; e) Flight range - Fully meet the technical conditions, as well as in some indicators, the accuracy of the fight and the destructive power are better than gross cartridges.

§ 11. ... Rifle cartridges correctly reloaded according to this manual, reliable in operation. Ballistic data meets the technical requirements for these cartridges. ”.

We have no reason to distrust the data set out in the Manual for the manual press today. Since the level of responsibility of the performers and the whole system of “work” in those years practically excluded the possibility of fraud or artificial improvement, fitting the results. And also considering that the developed method of alteration implied its practical use in partisan detachments and verification in real combat conditions.

Summarizing brief results and evaluating this interesting story, one can say:

- The work was carried out in an extremely short time. The first Act is dated April 1943 of the year, and the article by Pavel Stolyarov in the magazine "Weapon" states (based on a copy of the memorandum of the deputy chief of the Central Headquarters of the partisan movement Colonel Naumov): “After a comprehensive test of the specified device, a batch of 175 devices was sent to the rear of the enemy in partisan detachments and according to information received from the commanders of partisan detachments, the Central Headquarters knows that these devices have found their practical application ... Of the detachments com. KOZLOVA has a telegram from which it is clear that his units in the June-August months of 1943 reworked German 9 mm. ammunition TT under the caliber 7,62 mm. PPSh submachine gun - 300.000 pcs., rifle 7,92 mm. under the caliber 7,62 mm. rifle arr. 1891 / 30 - 120.000 Pieces. ".

- The rework method developed by OKB-44 is surprising in its originality, especially considering such a large difference in the size of the cartridges and the design of the weapon for them. There are no analogs in world practice. It is the ingenuity of our software engineers who have shown them in this work that causes our greatest admiration today.

- There is no doubt that any artisanal manufacture of cartridges cannot reach the level of standard ammunition manufactured in industrial conditions. Moreover, much depends on the skill, accuracy and strict observance of the technology of remaking by the partisan craftsmen. There might have been some problems or delays when shooting with converted cartridges. But the important thing is that the developers have reduced such possible troubles to an acceptable minimum.

- Today, assessing the practical need for such a method, any “expert” will immediately say that “there is no faith in amateur labor, I will not go into battle with such cartridges” or “you give a captured weapon”. And, in principle, will be right. But it is today, theoretically. And what was the partisans to do then, in 1943-44, when there really was no other way out? Therefore, even such an “exotic” way out was very helpful.

- Considering, for example, that the city of Minsk was liberated only on July 3 of the year 1944, and all the occupied territories in which guerrilla formations fought - even later, it is safe to say that the developed method of remaking trophy cartridges was not in vain and contributed to the overall Victory .

By the Decree of the State Defense Committee (GKO) of 16.01.1946 of 11, XNUMX developers, among them - A.I. Zabegin, N.M. Elizarov, B.V. Semin, were awarded medals to "Partisan of the Patriotic War."

The OKB-1943 created in 44 was later transferred to Klimovsk, a town near Moscow, in 1946, and transformed into a research institute-44, the first head of which was appointed to A.I. Zabegin, and the head of the cartridge department - B.V. Semin. It is worth noting that, having completed the work on the alteration of captured cartridges, from July 1943, OKB-44 began to create an intermediate-power cartridge. The very same - the legendary and known today as the 7,62x39-mm cartridge for AK, AKM. But that's another story.

With the passage of time, OKB-44 turned into a scientific research institute-61, and then into the Order of the October Revolution, the Central Research Institute of Precision Engineering (TsNIITOCHMASH), known today worldwide and leading in the USSR and in modern Russia, the center for developing small arms ammunition . Within the walls of which practically all modern state-owned domestic small arms cartridges were developed, fundamentally new approaches and design schemes of small arms were developed, and in-depth research and studies were conducted.

The history of these developments, achieved and not achieved by our engineers, the results are described in detail in the four-volume monograph "Small arms combat cartridges" V.N. Noblemanova. Which, from 1982 onwards, for the years 29 has headed the “cartridge” department at TsNIITOCHMASH. Many data on the history of domestic developments are unique and published in this monograph for the first time.

In preparing this article the following materials were used:

* V.N. Noblemen. Book-1 "From the invention of gunpowder to the middle of the twentieth century" (ISBN 978-5-9906267-1-3) of the monograph "Small arms combat cartridges" (ISBN 978-5-9906267-0-6). D'Solo Publishing House, Klimovsk, 2015;

* The magazine "Weapon", №6, 2001 year;

* Archival materials provided by kris_reid;

* Own photographs and drawings of the authors;

* Materials free encyclopedia "Wikipedia";

* N.G. Menshikov. Album designs of small-bore and large-caliber automatic weapons. Publisher Artillery Academy. F.E. Dzerzhinsky, M., 1946.

Information