Armored recovery vehicle BREM-1

By order of the Main Armored Directorate of the Ministry of Defense, the industry had to create a protected special vehicle with high maneuverability and mobility, as well as with a set of special equipment. The main objectives of this technology were identified evacuation of damaged equipment from the battlefield, followed by delivery to the collection points, assistance in carrying out repair work, as well as the implementation of various lifting work in the field. The development of such a multi-functional vehicle made it possible to reduce the fleet of auxiliary equipment and thereby simplify the system for repairing damaged armored vehicles.

The creation of a promising repair and recovery vehicle was entrusted to OKB-174 of the Omsk Transport Engineering Plant. The development of the project was led by the chief designer A.A. Morov and lead designer V.A. Stepanov. The project received the factory designation "Object 608". The task of the engineers was to create a special machine with a set of various equipment built on an existing chassis. In order to accelerate the development and simplify operation, the chassis of the serial main chassis was taken as the basis for the “Object 608” tank T-72. Similar equipment was already in service, which made it possible to simplify the construction of repair and recovery vehicles, as well as facilitating their future operation due to unification of a large number of units.

The use of the finished chassis and the enthusiasm of the design bureau staff made it possible to create a new project in a relatively short time. Already at the end of 1972, a set of documents was prepared, which is necessary for the construction of an experimental armored vehicle. The construction of the “608 Facility” was entrusted to Plant No.183 (Nizhny Tagil), which produced T-72 tanks. The prototype didn’t take much time to build - it was ready for testing in March of the 73. Soon after its construction was completed, the first inspections began at the nearest test sites.

During 1973, the experienced "608 Object" passed the entire complex of factory tests, after which it went out to the ground-field. Military experts tested the proposed machine in 1974-75. According to the results of military tests, a new special armored vehicle was recommended for adoption. 13 June 1975, the Minister of Defense of the USSR signed an order, according to which the armored repair and recovery vehicle "Object 608" was put into service under the designation BREM-1. After that, preparations began for the mass production of new equipment.

BREM-1 was assigned a wide range of auxiliary tasks, for which it had to be equipped with a variety of special equipment. With it, an armored vehicle can tow various vehicles, including those stuck on different surfaces, carry different loads, provide repairs, carry out some earthworks, etc. In accordance with a similar technical assignment, the main aspects of the appearance of a promising machine were identified.

The basis for the "Object 608" became the tank T-72B, which influenced some features of its appearance. Repair-evacuation machine retained the power plant and the chassis of the base machine, but some of its units have noticeable differences. Noticeable processing, directly related to the tasks performed, has undergone the layout of the hull. Inhabited compartment with jobs for all three crew members is located in front of the hull. The workplace of the driver is located in the central part of the compartment, the commander is on the right and shifted back. The place of the hitchman with a set of necessary controls was placed at the left side and moved back relative to the commander.

All crew members received their own hatches in the roof of the car. In addition, there was one escape hatch in the bottom, located behind the driver's seat. The main crew hatches are equipped with optical instruments to monitor the situation. The driver can use prism instruments during the daytime, and at night the average device should be replaced with a TVNE-4PA night vision device. The commander has a small rotating turret, in which there are two prism devices and one combined (day and night) TKN-3. The coupler, like the commander, has a small turret, but it is not equipped with rotation mechanisms. The ripper has four prism appliances TNP-160, the same as on other roof hatches. Means for observation at night at the workplace of the coupler are absent

Behind the back of the crew provides so-called. machine partition separating the habitable compartment and the engine room. In the last part of the special equipment is located, designed to solve basic problems. Behind the engine is the engine compartment with power plant units. Serial BREM-1 equipped with diesel engines B-84MS power 840 hp, which allows you to keep the main characteristics at the level of the base of the main tank.

The hull of the “Object 608” was built on the basis of the main tank T-72B and has similar protection. In the frontal projection, the crew and internal units of the vehicle are protected by a combined obstacle located at an angle 60 ° to the vertical. Board sheets and the roof, in turn, provide protection against small weapons and small-caliber artillery. Part of the external units of special equipment are also made of high strength materials, which allows them to withstand firing from small arms without damage.

BREM-1 is not a combat vehicle, but has some weapons for self-defense. As the main means of protection is proposed large-caliber machine gun NSVT, located on the turret above the hatch commander. Ammunition machine gun is 400 cartridges. If necessary, the crew can use three AKS-74U automatic rifles with a common 360 ammunition ammunition and 18 hand grenades. Also in the layouts of the habitable compartment a signal pistol and a supply of ammunition to it are placed. An additional means of protection is thermal smoke equipment. With its help, the “608 Object” can protect itself and the evacuated car from observation and, as a result, attacks.

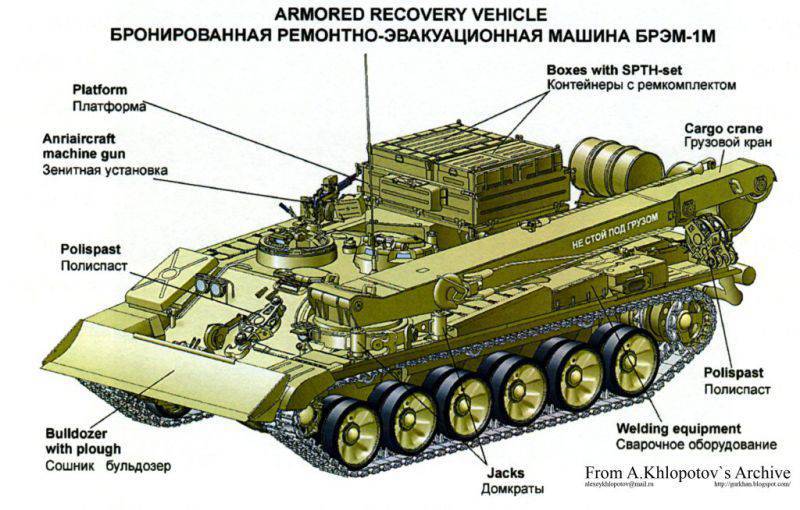

One of the most noticeable elements of the special equipment of the BREM-1 machine is a coulter-bulldozer 3,1 m wide, located in the front of the case. This unit is installed on the levers and is equipped with hydraulic actuators that ensure its raising and lowering. Dredging into the ground up to 0,45 m is provided. The main task of the coulter-bulldozer is to keep the recovery and recovery vehicle in place when using the traction winch. Due to the use of powerful winch available tracks are not always able to provide the desired adhesion to the bearing surface. In some situations, the coulter can be used for earthworks. The coulter-bulldozer hydraulic drives are controlled from the driver’s workplace with a pair of buttons.

A window with a roller device for issuing a pull winch cable is provided in the front hull sheet. The cable passes through the front sections of the hull and enters the engine room, where the traction winch is located. This cable is intended for pulling stuck equipment or, if necessary, for towing damaged machines, in the absence of the possibility of using the hitch. The cable has a length of 200 m and a diameter of 28,5 mm. For greater strength, the cable consists of several strands of spiral lay. The basis of the cable is galvanized steel wire.

The cable is wound on a mechanical winch drum with planetary and distributing gearboxes. The winch design provides for the issuance of a cable with a speed of the order of 0,3 m / s. Winding is performed at a rate of up to 0,217 m / s. A characteristic feature of the traction winch BREM-1 is a large traction. Without additional devices, it is able to generate traction (on the cable end) up to 25 tf. The special equipment of the repair and recovery vehicle includes a separate chain hoist, with the help of which the tractive effort can be brought to the 100 vehicle.

The engine room also houses an auxiliary winch driven by a hydraulic motor. It is equipped with a 400-meter cable and is capable of developing tractive effort up to 530 kgf. Auxiliary winch is designed to ensure the work of the main. So, it should be used to supply a sufficiently heavy cable of the traction winch to the towed car. In addition, with its help, it is proposed to move the blocks of the chain hoist, for which a special skid is transported by car.

A pulled out car can be towed away. For this, the BREM-1 on the hull stern sheet transports a semi-rigid towing device with two-sided internal damping. In the working position, this device is attached to the towing unit of the machine, and its ends are attached to the hooks of the evacuated vehicle. Towing vehicles weighing up to 50 t is provided.

In the left front of the engine room, support mechanisms for a crane are provided. For lifting various loads, the BREM-1 is equipped with a rotary jib crane with a lifting capacity of up to 12 t. The crane design provides lifting and moving of various loads, however the width of the service sectors and carrying capacity are limited by the weight of the load. For example, with a maximum load in 12 t, operation within a sector of width 45 ° is possible, and at maximum boom reach (4,4 m), the lifting height of the load does not exceed 1,9 m above the ground. The crane is operated using a separate remote control, so that the operator can stay outside the machine and without any difficulty monitor the operation of the systems. In the stowed position, the crane boom is placed along the body by turning back. The hook is attached to the bottom of the boom.

On the roof of the engine and engine compartment is a special cargo platform, equipped with rollers to move around the body. Part of the equipment is proposed to transport spare parts, as well as the tools necessary for the repair of various equipment. The loading platform is a movable design with a length of 1320 mm and a width of 1630 mm. There are flaps 410 mm high.

The BREM-1 machine transports various equipment for carrying out repairs in field conditions. In particular, it is equipped with an electric welding machine ESA-1. An interesting way to power this equipment: to supply energy using a regular starter-generator of the power plant SG-10-1С. When using welding equipment, this device switches to generator mode and ensures that the necessary work is performed.

On the fencing shelves are provided boxes and fasteners for the transport of various equipment used for certain operations. So, on the left shelf, under the crane boom, a two-horned crane hook, a spare parts box, a drawer rack with electric welding and accessories, two polyspast blocks, and two 30 ton-jacks are stored. On the right fender, a box is placed for the remaining blocks of the chain hoist and the transport sled. In addition, another SPTA box is transported there. In the stern of the starboard, there are fastenings for the pipe-hole, which is included in the set of equipment for underwater driving.

BREM-1 has a complete set of electronic equipment for internal and external communications. The crew must use TSH4 headsets associated with a P-174 intercom. Also in the car are installed VHF radio station P-173 and receiver P-173P. With the help of this equipment, the crew of the recovery vehicle can maintain voice communications with other equipment on the battlefield.

Being built on the basis of the main T-72B tank, the “608 Object” has similar dimensions and weight. The combat weight of this armored vehicle is 41 m. The maximum length is 7,98 m, width is 3,46 m, height is 2,42 m. the survivability of the machine in terms of solving the tasks under enemy fire.

The 840-strong B-84MS engine allows the BREM-1 to reach a highway speed of up to 60 km / h. When driving on a dirt road, the average speed does not exceed 40-45 km / h. When towing a T-72 or similar, the maximum speed on a dirt road does not exceed 10-15 km / h. On rough terrain, maximum speeds are further reduced.

Aft of the machine. The towing device and the loading platform are clearly visible. Photo Armor.kiev.ua

Several fuel tanks are installed inside the hull, in addition, it is possible to install additional barrels at the stern of the hull. With fuel in the 1730, the recovery and recovery vehicle can go along the highway to 700 km. On rough terrain, the power reserve is noticeably reduced. When driving on a dirt road with a tank on the hitch, the power reserve may drop to 150-200 km.

The armored repair-evacuation vehicle BREM-1 was put into service in the middle of 1975. Soon began preparations for the mass production of this technology, which was to be conducted in Nizhny Tagil. However, according to some data, due to various circumstances, the first installation batch of serial machines was built only in the 1985 year. By this time, the project has undergone some changes. In particular, the arrangement of the machine-gun installation changed and the design of the opener-bulldozer was modified.

The use of the existing serial tank as a basis made it possible to start mass production of new equipment and begin full-scale supplies to the troops. BREM-1 were delivered to evacuation platoons of the repair and restoration battalions of tank and motorized rifle divisions, as well as to other units of the corresponding purpose. The development of new equipment has allowed repair units to improve the efficiency of their work on the evacuation and restoration of damaged equipment.

Through the use of a number of original technical solutions, the authors of the 608 Object / BREM-1 project managed to create a very interesting special armored vehicle with high performance. In particular, the characteristics of the traction winch are of particular interest. This device is capable of developing an effort up to 100 tf when using a chain hoist. According to some reports, it is enough to pull out any modern domestic armored vehicles stuck in the mud or on other similar surfaces. It is reported that freezing of the soil is not a hindrance, and BREM-1 successfully pulls out the tanks along with a large lump of frozen ground. The only problem in this case is the correct emphasis on the ground with the help of the coulter-bulldozer.

With the help of an existing crane, some repair operations can be performed. Among other things, this unit can be used when replacing the power plant of a tank in field devices. The composition of the remaining elements of the special equipment is determined in such a way that the crew of the BREM-1 can provide comprehensive support to the affected equipment.

Application of BREM-1 during the evacuation of SU-100 after the parade in Moscow, May 2010. Photo Ifun.ru

For obvious reasons, the use of repair and recovery vehicles usually does not attract the attention of the general public. However, in May 2010, everyone could observe the work of BREM-1 right in the center of Moscow. After the Victory Parade, an abnormal situation occurred: one of the SU-100 self-propelled artillery mounts fell from a tank truck semi-trailer and overturned onto the roof. To return the armored car to the correct position, a BREM-1 traction winch was used. With its help, self-propelled gun was put on board, and then returned to the tracks, after which it became possible to send it for repair.

By the early nineties, the Soviet industry had time to build a sufficiently large number of armored repair and recovery vehicles based on the T-72B tank. After the collapse of the Soviet Union, this technique went to all the newly formed states. In addition, several contracts for the supply of similar machines to third countries were executed. Thanks to these agreements, the fleet of ground vehicles of the GDR, Iran, Iraq, Syria, etc. was added to BREM-1.

The development of a fairly successful project "Object 608" was continued after the collapse of the USSR. So, at the present time, potential customers are offered an upgraded version of the machine under the designation BREM-1M. Unlike the original, it is built on the basis of the T-90 tank and has the appropriate characteristics. In addition, during the modernization, the machine received a new crane with an increased boom length and a larger load carrying capacity brought to 20 tons. Due to this, the BREM-1М, unlike its predecessor, has the ability to lift towers of existing tanks without any special training. Also BREM-1M features an updated traction winch with a force of 35 tf, which with the help of a chain hoist can be increased to 140 tf.

A certain number of BREM-1 is still operated by the armed forces of Russia. The task of this technique is to help units equipped with T-72, T-80 and T-90 tanks. It can be assumed that this technique will retain its place in the troops for a long time, and will refuse from it no sooner than the full-scale decommissioning of existing tanks begins.

On the materials of the sites:

http://armor.kiev.ua/

http://dogswar.ru/

http://t-80b.ru/

http://rem-battalion.ru/

http://uvz.ru/

Information