Series submachine gun Evelyn Owen (Australia)

Having been refused by the military, E. Owen soon lost interest in small arms and went to serve in the army. On this, his career as a gunsmith could have ended, but the situation soon changed. The first prototype submachine gun accidentally caught the eye of Owen's neighbor, Vincent Wardell, who at that time worked for Lysaghts Newcastle Works. Wardell and Owen again discussed the prospects of the project and decided to once again present it to the military, this time as a new development of an industrial enterprise, and not a lone designer. In a new capacity, an experimental weapon in 1940 was presented to the newly created Central Council of Army Inventions.

Council specialists, led by Captain Cecil Dyer, showed interest in the Lysaghts Newcastle Works proposal. This interest was not least connected with the events in Europe. By the time the experimental weapons were demonstrated to the Council, Nazi Germany had captured France and was preparing to attack Great Britain. Thus, in the near future, Australia could lose the opportunity to purchase British weapons and equipment, which is why it needed to develop its own systems. Owen and Wardell's proposal could then become an "alternate airfield" in case of supply problems.

Owen Mk 1 serial submachine gun. Photo by Awm.gov.au

However, further work on Owen's submachine gun was associated with some problems. By the time the prototype was demonstrated, Australia received assurances from the UK that STEN submachine guns would be delivered soon. There were reasons to believe that British weapons were superior in their characteristics to domestic ones, but Australian experts decided not to rely on assumptions and conducted comparative tests of two samples. Lysaghts Newcastle Works ordered several prototype weapons chambered in .38 S&W.

Since E. Owen at that time served in the army, most of the work on the development and improvement of his weapons was carried out by Lysaghts Newcastle Works. The main work involved the brothers Vinsend and Gerard Wardela, in addition, they helped master gunsmith Freddie Künzler. In the later stages of the project, Owen himself joined Wardell and Künzler.

Probably, the military did not want to contact the domestic manufacturer and wait until he completed all the design work, testing, improvements, etc. Because of this, Lysaghts Newcastle Works received an order, but was left without the necessary raw materials. The military department refused to provide ready-made barrels and ammunition for testing. Not wanting to lose the order, Wardell and his colleagues managed to convince the military of the need to change the requirements. After a series of disputes and consultations, it was decided to make a new submachine gun chambered for .32ACP. Such a change in the project made it possible to provide acceptable firing characteristics, but the main advantage was the possibility of using ready-made barrels from Short Magazine Lee-Enfield Mk I rifles. To do this, the rifle barrel had to be cut into several parts and chambers of the required dimensions should be drilled into them.

Evelyn Owen with her submachine guns. Photo Forgottenweapons.com

The creation of a submachine gun chambered for .32ACP took only three weeks, after which it was presented to the army. It should be noted that some sources indicate the date of delivery of this prototype, which can raise certain questions. According to some reports, it was presented to the army on January 30, 1940, however, such information may contradict other data about the project. One way or another, all work on the project of weapons chambered for .32ACP using a barrel from a serial rifle was completed during the 1940 of the year.

The prototype submachine gun was sent for testing and proved its performance. After that, the military demanded to conduct resource tests, during which the weapon was supposed to fire 10 shots. At the same time, they refused to provide the necessary ammunition, and the chances of the development company to get them on their own tended to zero. Thus, the military department again transparently hinted that it did not want to deal with domestic enterprises and wanted to purchase British-made weapons.

In response, Wardell and his comrades proposed a new version of the weapon, this time chambered for .45ACP. Gunsmiths rightly believed that the Australian army definitely had no shortage of such ammunition, since Thompson submachine guns and some other systems chambered for this cartridge were in service. An order was placed for the supply of cartridges, but by mistake (or malicious intent) a batch of .455 Webley cartridges arrived at the Lysaghts Newcastle Works. However, these events did not affect the course of the project. The already finished prototype received a new barrel made from the units of an old rifle of the appropriate caliber.

At the beginning of 1941, the team of developers of a promising submachine gun was replenished with Evelyn Owen. He was recalled from the army and sent to participate in the development of new weapons. What kind of design innovations were proposed by Owen is unknown. Working as a team, Australian gunsmiths did not try to perpetuate their names to the detriment of the common cause. At the same time, however, in the end, the weapon received the name of E. Owen, who joined its development only at one of the last stages.

During 1941, the Lysaghts Newcastle Works team of engineers continued to work on their new project and "fought" with the military. In addition, several prototypes were tested, the results of which were used to refine new samples. Tests have allowed to establish the strengths and weaknesses of the project in its current form, as well as improve ergonomics and make some other adjustments.

In early September, the 41st military department again changed its requirements for a promising submachine gun. Now the military has demanded that the weapon be converted to use the 9x19mm Para cartridge. Such cartridges were used by a large number of systems, including the STEN submachine gun. By the end of the month, work on the modernization of the submachine gun was over, and another prototype was submitted for testing.

For comparative tests, Owen, Wardell and Künzler presented submachine guns of their own design chambered for 9x19 mm Para and .45ACP. Their rivals were the British STEN and the American Thompson using similar ammunition. These tests, during which all possible parameters and characteristics were tested, allowed Lysaghts Newcastle Works to prove their case and demonstrate the superiority of their development over the designs of competitors.

At the beginning of the tests, all four types of weapons showed their best side, but as the conditions became more difficult, the characteristics of the submachine guns changed noticeably. Differences in the perfection of designs manifested themselves especially clearly during tests with pollution. The American Thompson, after being in the mud, continued to shoot, although it was not without delays and other problems. The British STEN failed the mud test. At the same time, both samples of Owen's submachine guns coped with all the tests.

Comparison of four samples in conditions close to real, helped the Australian military figure out which weapons should go into battle and which ones should be abandoned. In this regard, Lysaghts Newcastle Works received an order for the production of a batch of 2000 submachine guns, which were planned to be sent to the army for military testing. Moreover, several samples and documentation for the new weapons were sent to the UK with a proposal to test them and start mass production. According to reports, in 1943, British specialists conducted their comparative tests, during which Australian weapons again bypassed STEN and other samples.

A characteristic feature of E. Owen's first submachine gun, assembled in his own workshop, was the extreme simplicity of design. In the course of further development of weapons, simplicity of design was put at the forefront, which ultimately affected its final appearance. At the same time, the Wardell brothers and F. Kunzler did not exclusively develop Owen's first design. They proposed a number of significant innovations that were supposed to provide high performance without the use of compromise and questionable solutions.

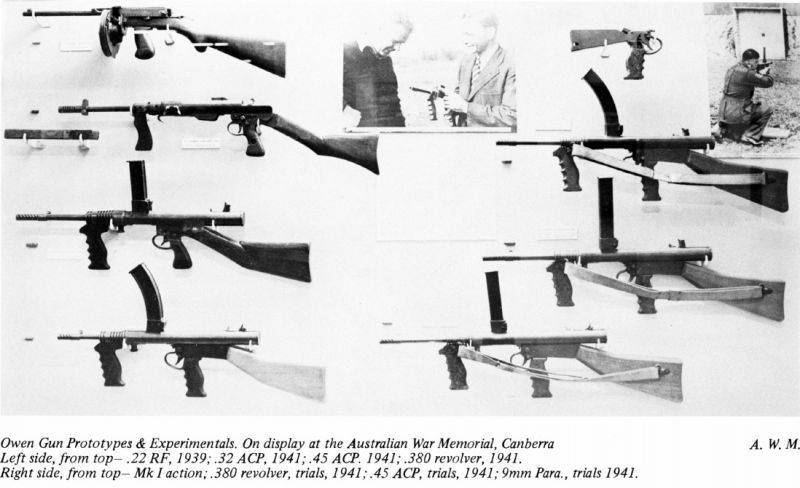

During the tests, the authors of the project constantly identified various deficiencies and corrected them. In addition, new original ideas were introduced to improve performance. Because of this, the 1940-41 prototypes differed markedly from each other in both the appearance and the structure of the internal units. Consider the design of a serial submachine gun, designated Mk 1.

The main unit of the weapon was a tubular receiver, inside of which there was a bolt, a reciprocating mainspring and some elements of the firing mechanism. A 9 mm caliber barrel 247 mm long (27,5 calibers) was attached to it in front. To reduce the toss of the barrel during firing, a slotted muzzle compensator was provided, which removes part of the powder gases forward and upward. The design of the compensator during mass production has changed several times. In addition, initially the barrel had fins for better cooling, but then they abandoned it. The barrel was fixed in place with a special clamp. Behind the latter was a small vertical store shaft. A characteristic feature of the submachine gun was the upper location of the store, which simplified its design. Directly under the store shaft, on the lower surface of the receiver, there was a window for ejection of cartridge cases.

Behind the bottom of the receiver, a hole for a screw was provided for attaching the casing of the firing mechanism. The latter was a trapezoidal metal unit, in front of which there was a large trigger guard and a pistol grip. Inside were the details of the trigger mechanism. A butt was attached to the casing at the back. The weapon was not equipped with a forearm, instead of which an additional front handle was offered, fixed with a clamp on the barrel.

Owen submachine guns of different series (above and in the middle) and Austin SMG (below). Photo Forgottenweapons.com

The design of the USM casing and the butt depended on the model. Early serial submachine guns, the so-called. Owen Mk 1-42 were completed with a casing with solid walls and a frame metal butt. Subsequently, the design of these units has changed. The Mk 1-43 modification received a simpler and cheaper wooden stock to manufacture, and the weight increase was compensated for by windows in the walls of the metal casing. There were also some other differences, which consisted in production technologies, the design of the muzzle compensator, etc.

Owen's submachine gun had automatics based on a free shutter. The shutter itself was made in the form of a cylindrical unit with a hole in the rear part for installing a reciprocating mainspring and a front part of a complex shape formed by a cylinder and a rounded surface. Inside the bolt, a special rod was attached with a pin, on which a reciprocating mainspring was put on during assembly. When the shutter was placed inside the receiver, the rod passed into the hole of a special partition. Thus, the shutter and the spring remained in the front chamber of the box, and the rod fell into the rear, where a loading handle was attached to it, brought out through a slot in the right wall of the receiver.

The trigger mechanism was located in the casing, next to the trigger and the fire control handle. It consisted of only a few parts: a trigger, a sear that locks the bolt in the rear position, a fuse-translator of fire and several springs. The fuse-translator flag, displayed on the left side of the casing and located above the pistol grip, made it possible to block the sear, as well as to shoot single or burst.

Another option camouflage coloring. Photo World.guns.ru

Box-shaped detachable magazines for 32 rounds were placed in the receiving shaft of the receiver. The top location of the store simplified the supply of ammunition, and the spring ensured the movement of cartridges even in non-standard positions. It should be noted that the store shaft was located not along the longitudinal axis of the weapon, but shifted to the right. This provided the possibility of aiming with the help of the existing unregulated rear sight and front sight.

The Owen submachine gun had a length of the order of 810 mm and weighed (without a magazine) about 4,22 kg. Thus, this weapon could not boast of great ease of use, but comparative tests showed that the loss in weight and dimensions is fully compensated by reliability and firing characteristics.

The principle of operation of the weapon was quite simple. Before firing, the shooter had to insert the magazine into the receiving shaft and load the weapon by pulling back the bolt handle. In this case, the latter was retracted to the rearmost position, compressing the reciprocating mainspring and engaging with a sear. Shooting could only be carried out from an open shutter. When the trigger is pressed, the bolt moves forward under the action of the spring, catches the cartridge in the magazine and feeds it into the chamber. At the extreme forward point, the bolt striker hit the cartridge primer and a shot occurred.

Australian soldiers with Owen SMG. Photo of Wikimedia Commons

Under the force of recoil, the bolt began to move backward, stretching the cartridge case behind it. Having reached the rocking extractor, it was disconnected from the bolt and under its own weight fell through a window in the lower surface of the receiver. The shutter, in turn, went to the rear position and, depending on the fire mode, clung to the sear or went forward again.

Such mechanisms allowed the Owen submachine gun to fire at a rate of up to 700 shots per minute. The effective firing range provided by the 9x19 mm Para cartridge does not exceed the 150-200 m.

To disassemble and maintain the weapon, it was necessary to use the appropriate lock and remove the barrel. After that, the shutter and the reciprocating mainspring were removed from the receiver. By unscrewing the bottom screw, it was possible to remove the casing of the firing mechanism. The butt, regardless of the design and material, was also fixed on the screw and could be detached from the USM casing.

The used ammunition system, despite the unusual appearance, provided the submachine gun not only with high performance, but also with good resistance to pollution. The lower location of the ejection window made it difficult for dirt to enter the receiver, and also made it easier to remove it: sand, earth or water fell out of the window when the shutter moved. The large protective guard of the trigger was also useful. When firing, the falling out shells fell on her and bounced to the side without burning the shooter's fingers.

Early prototype of Owen SMG Mk 2. Photo by Awm.gov.au

In 1942, after conducting military tests, the new weapon was adopted under the designation Owen SMG Mk 1 - "Owen's submachine gun, version 1." Later this designation was changed to Mk 1-42 (according to the year of manufacture) to distinguish it from later versions. During the years of the Second World War, the Australian industry produced about 45433 new submachine guns. About 12 thousand units belonged to the basic modification of the Mk 1-42 and were equipped with metal butts. In 1943, the production of the Mk 1-43 variant was launched, which featured a new trigger housing and a wooden stock. Such weapons were made in the amount of 33 thousand pieces.

A curious feature of Owen's serial submachine guns was the coloring. This weapon was intended for use by the Australian army, which fought mainly in the southern regions of Asia and the Pacific Ocean with its own landscape features. For this reason, the weapon received a camouflage coloring adapted for the jungle, mainly yellow and green. The vast majority of submachine guns that have survived to this day have just such a color, although there are black and unpainted samples.

There is information about the development of a modernized submachine gun with the designation Mk 2. Due to some design innovations, it was planned to increase the fire performance, as well as further reduce the weight. This version of the weapon reached mass production, but could not displace the base Mk 1. As a result, the release of the Owen submachine gun of the second model was limited to several hundred pieces.

Serial production of Owen SMG submachine guns continued until 1944. The simplicity of design and low cost of production made it possible to produce more than 45 thousand units of such weapons, which was sufficient to solve all the problems of the Australian army. This weapon was actively used by Australia during the Second World War and subsequent conflicts. With Owen submachine guns, Australian troops went into battle in Korea and Vietnam. At the end of the sixties, a mass write-off of submachine guns that had exhausted their resource began. Part of the remaining stocks were sold to third countries. The F1 assault rifles of our own Australian design became a replacement for the weapons of the Second World War.

Serial Owen SMG Mk 2. Photo by Awm.gov.au

While working at Lysaghts Newcastle Works, Evelyn Owen was listed as an employee and received wages on a par with his other colleagues. In addition, after the adoption of the new submachine gun, the payment of premiums and patent royalties began. In total, Owen earned about £10 from his project. He used the money he received to build his own sawmill. At the same time, Owen continued to work on promising weapons on his own initiative. After the war, the self-taught engineer became addicted to alcohol and died in 1949, never having seen the use of his weapons in new conflicts.

From the point of view of Lysaghts Newcastle Works, the submachine gun project was not particularly successful. Until mid-1941, she had to work on her own initiative, not counting on any compensation for expenses. In addition, Vincent Wardell had to literally fight for the project and, as they say, spend nerves on its promotion. Only after the start of mass production, the companies appointed a bonus for the creation of the project in the amount of 4% of the cost of orders. However, payments under this agreement were constantly delayed, which is why the full amount was transferred to the company only in 1947 - three years after the end of production. Due to delays in payments from the military department, the company could not pay loans on time, which led to an increase in already considerable debts. Payment of debts, fines, etc. led to the fact that the company's profit was reduced from the original 4% to 1,5% of the total cost of serial production.

Self-taught designer Evelyn Owen began creating his submachine gun in the late thirties, wanting to help the country defend against possible threats. In the future, specialists from Lysaghts Newcastle Works showed their enthusiasm on this basis, who brought the project to mass production. As a result of joint work, one of the most massive Australian types of weapons appeared, which, however, first led to big expenses, and then brought its creators only quickly faded fame. However, in stories small arms submachine gun Owen SMG remained as one of the most interesting developments, even if not received much distribution.

On the materials of the sites:

http://forgottenweapons.com/

http://world.guns.ru/

http://gunsite.narod.ru/

http://zonwar.ru/

Information