Bell Rocket Belt jetpack project

Project start

The initiator of the work at Bell was Wendell F. Moore, the namesake of Thomas Moore. Apparently, he had some data on the first project and also decided to participate in the development of a promising direction. Moore formed the overall look of his jet pack, but until a certain time the project did not leave the stage of preliminary discussions. Just at this time, the Pentagon refused to T. Muru to continue financing its development, because of which the prospects for other similar projects were dubious. As a result, no one wanted to support U. Moore in his works.

Until the end of the fifties, U. Moore completed an analysis of the available information about the work of his namesake and identified the minuses of his project. In addition, the available developments allowed us to form the optimal look of a promising jetpack. Initially, Moore proposed to use the engine on hydrogen peroxide. Such systems, for all their simplicity, could provide the required traction, and also did not differ in great complexity of design. It was required to create a simple, reliable and easy to use control system. For example, the existing T. Moore remote with three flywheels at that time did not provide the pilot with the necessary comfort and made it difficult to control the flight, because he didn’t have the most convenient design.

Thinking about the project and preliminary design work went on its own initiative until the very end of the fifties. In addition, by 1958, specialists led by U. Moore were able to build a simplified experimental jet pack that could demonstrate the correctness of the chosen ideas and decisions made. With the help of a simplified apparatus, it was planned to test existing ideas, and also to confirm or deny their viability.

First experiments

The experimental prototype had only to demonstrate the fundamental possibility of solving the assigned tasks, because of which its design was seriously different from the one originally proposed for a full-fledged jetpack. On the frame of a simple design mounted a system of hoses and a pair of nozzles. In addition, the system was attached to the frame seat belts. Two maneuvering nozzles were provided for maneuvering, located on one beam connected with control levers. The prototype did not have its own fuel tanks or other similar units and should have received compressed gas from third-party equipment.

The hoses of the experimental apparatus were connected to an external source of compressed gas. Nitrogen was proposed as a means of generating jet thrust, which was fed with a pressure of 35 atmospheres using a compressor. The tester who is on the ground was engaged in supplying gas and adjusting the thrust of such an “engine”.

The first tests of the prototype knapsack design by U. Moore looked as follows. One of the testers wore the device, in addition, he was tied to a test bench with safety cables that did not allow him to rise to a considerable height or lose a stable position in the air. The second tester controlled the compressed gas supply valve. Upon reaching the desired thrust, the first tester, together with the apparatus, rose into the air, after which his task was to keep the entire system in a stable position.

At the disposal of the pilot were two levers associated with the nozzles of the apparatus. By moving them, the pilot tilted the nozzles and thereby changed the direction of the thrust vectors. Due to the simultaneous deflection of nozzles forward or backward, the pilot could change the direction of the forward flight. For more complex maneuvers, the beam and nozzles should have been tilted by other means. A similar control system was proposed to be used on a full-fledged jetpack. In theory, it allowed for a rather high maneuverability.

Pilots of the experimental apparatus were various Bell engineers, including Wendell Moore himself. The first test flights were similar to jumps using jet thrust. The testers did not immediately learn how to keep the apparatus in a stable position, which is why uncontrolled maneuvers in roll and height began. Therefore, it was necessary to reduce the pressure of compressed gas and lower the pilot to the ground in order to avoid abnormal situations, injuries and equipment damage.

Despite some setbacks, the experimental prototype made it possible to solve several important problems. Experts were able to confirm the capabilities of the used control system. In addition, the optimal nozzle configuration was chosen. Finally, according to the results of these tests, we chose the most convenient design of pipelines and engines, in which the thrust vector passed through the center of gravity of the pilot + unit system and ensured its most stable behavior. The main load in the form of cylinders for fuel and the pilot was located between the two nozzles.

The absence of restrictions in the amount of compressed gas supplied by the compressor, made it possible to determine the potential capabilities of the apparatus. At the final stage of testing, the pilots managed to climb to a height of up to 5 m and stay in the air for up to 3 minutes. At the same time, they completely controlled the flight and did not encounter any serious problems. Thus, after several modifications, the experimental prototype has completely fulfilled the tasks assigned to it.

The tests of the experimental prototype, as well as its demonstration to specialists from other departments, had a positive impact on the further fate of the project. In 1959, Bell specialists were able to convince a potential customer in the face of the military department in the prospects of a new development. The result was a contract for a technical and economic assessment of such equipment, as well as the development and construction of a prototype jetpack.

Full sample

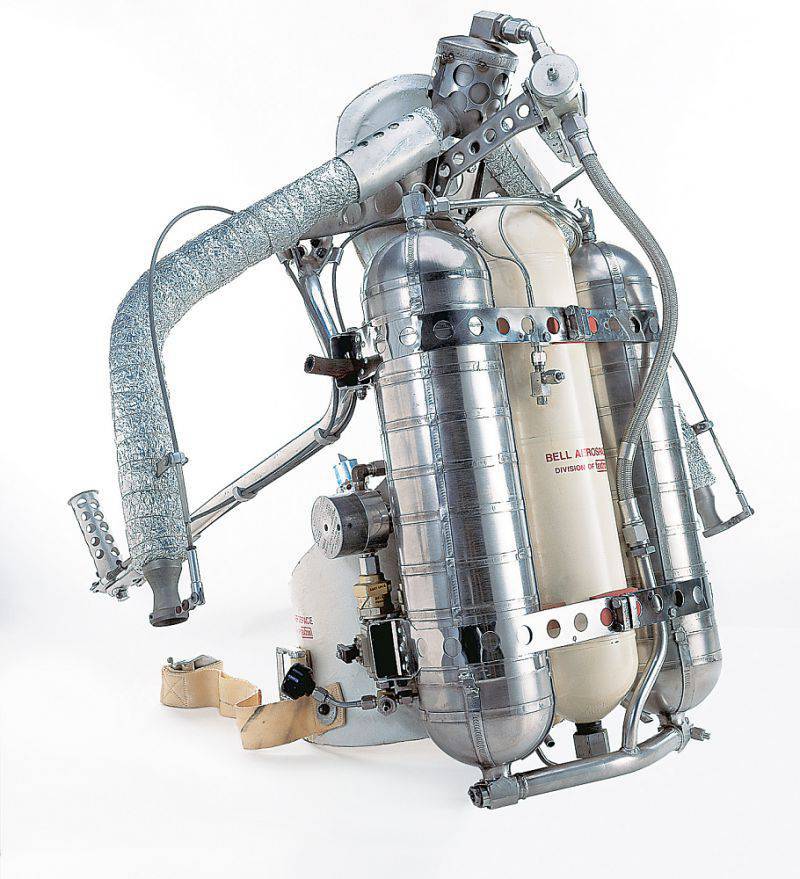

The jetpack development program received the official designation SRLD (Small Rocket Lift Device - “Small Rocket Lift Device”). The developer company used its own designation - Bell Rocket Belt ("Bell Rocket Belt"). It is worth noting that the internal corporate designation of the project did not fully correspond to the design of the device. Externally, the “Small Rocket Lifting Device” looked more like a satchel with a mass of unusual and even strange aggregates. Due to the weight of complex units, the device was not at all like a belt.

Having received an order from the defense ministry, Moore and his colleagues continued to work on the project and, as a result, created its final version, according to which several rocket vehicles were built. Ready-made “Rocket belts” were noticeably different from the products of the preliminary project. In the course of the design, the specialists took into account the test results of the experimental product, which had a noticeable effect on the design of the finished knapsack.

The main element of the SRLD / Bell Rocket Belt device was a metal frame, mounted on the pilot's back. For ease of use, the frame is equipped with a rigid fiberglass corset, adjacent to the pilot's back. Also attached to the frame straps harness system. The design of the frame, corset and tether system was made so as to evenly redistribute the weight of the jet pack on his back when on the ground or to transfer the weight of the pilot to the structure in flight. Due to the presence of an order by military engineers of Bell, they took into account the convenience of future users of promising technology.

Three metal cylinders were vertically fixed on the main frame. Central intended for compressed gas, the side - for hydrogen peroxide. To save weight and simplify the design, it was decided to abandon any pumps and use displacing fuel to the engine. Above the cylinders was installed pipeline in the form of an inverted V with a gas generator in the center that served as the engine for hydrogen peroxide. The central part of the engine was pivotally connected to the frame. At the ends of the pipes located nozzles. Due to the bending of the support tubes of the jet engine nozzles were at the level of the pilot’s elbows. In addition, they were moved forward and were located on the plane of the center of gravity of the “pilot + unit” system. To reduce heat losses, it was proposed to equip the pipes with thermal insulation.

During the work, the compressed nitrogen from the central cylinder under the pressure of 40 atmospheres was to displace liquid hydrogen peroxide from the side tanks. That, in turn, through the hoses entered the gas generator. Inside the latter there was a catalyst made in the form of silver plates coated with samarium nitrate. Under the action of the catalyst, the hydrogen peroxide decomposed, forming a vapor-gas mixture, the temperature of which reached 740 ° C. Then the mixture passed through the curved side tubes and pulled out through Laval nozzles, forming a jet thrust.

The controls of the “Rocket Belt” were made in the form of two levers rigidly connected with a rocking engine. At the ends of these levers there were small consoles. The latter were equipped with handles, buttons and other equipment. In particular, the project involved the use of a timer. According to calculations, the supply of hydrogen peroxide was enough only for 21 from the flight. For this reason, the device was equipped with a timer, which was supposed to warn the pilot about the development of fuel. When the engine was turned on, the timer started the countdown and gave a signal every second. After 15, after the engine was turned on, the signal went continuously, which meant the need for a speedy landing. The signal was given by a special buzzer mounted in the pilot's helmet.

The control was carried out using the rotary knob on the right panel. Turning this knob triggered the nozzle mechanisms, with the result that the thrust was changed. Management on the course and maneuvering was proposed to implement by tilting the V-shaped pipeline of the engine. In this case, the thrust vector of jet gases changed its direction and shifted the device in the right direction. Thus, to move forward, we had to press the levers, and to fly backward, to lift them. The sideways movement was planned to be done by tilting the engine in the desired direction. In addition, there were actuators of finer control by nozzles connected to the lever of the left console.

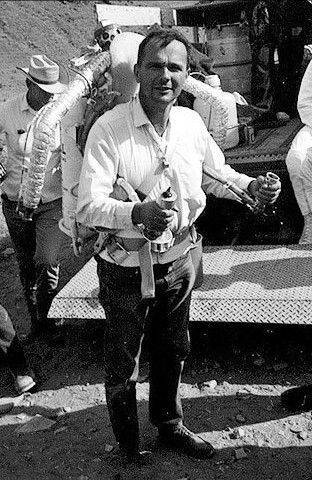

Astronomer Eugene Shoemaker “tries on” a jet pack. Photo of Wikimedia Commons

It was assumed that the pilot of the Bell Rocket Belt will fly in a standing position. However, by changing the posture, one could influence flight parameters. For example, by slightly lifting the legs forward, it was possible to provide an additional displacement of the thrust vector and increase the flight speed. However, the authors of the project considered that the management should be carried out only with the help of the staff of the device. Moreover, the new pilots were taught to control only levers, while maintaining a neutral body position.

Some of the design features of the new rocket pack forced the engineers to take special measures to ensure the safety of the pilot. So, the pilot had to use a suit of heat-resistant material, a special helmet and goggles. The overalls were supposed to protect the pilot from hot reactive gases, goggles protected his eyes from dust raised by jet jets, and the helmet was equipped with hearing protection. Due to the large engine noise, such precautions were not superfluous.

The total weight of the design with a full supply of fuel at the level of 19 l (5 gallons) reached 57 kg. The hydrogen peroxide jet engine gave thrust near 1250 H (127 kgf). Such characteristics allowed the “Rocket Belt” to lift itself and the pilot into the air. In addition, there remained a small stock of traction for transporting a small load. For obvious reasons, during the tests, the device transported only the pilot.

Test

The first sample of a full-fledged SRLD / Bell Rocket Belt machine was assembled in the second half of 1960. Soon his tests began. For greater safety, the first test flights were carried out on a special stand equipped with tethered cables. In addition, the stand was located in the hangar, which protected the pilot from the wind and other adverse factors. To determine the parameters of the device used some measuring devices mounted on the stand.

W. Moore himself became the first test pilot of the “Rocket Belt”. Within a few weeks, he made two dozen short-term flights, gradually increasing the height of the climb and mastering the control of the device in flight. Successful flights continued until mid-February 1961. The authors of the project were happy with the success and made plans for the near future.

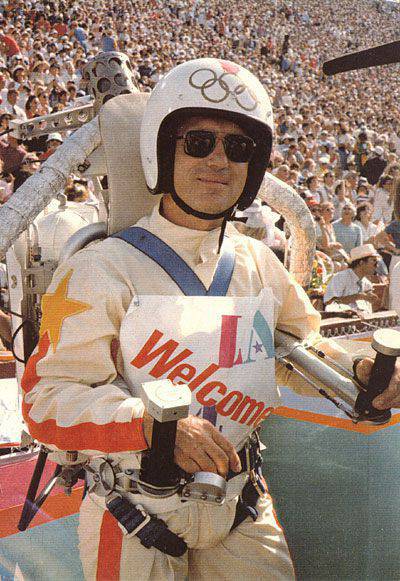

Pilot William P. "Bill" Sutor at the opening of the Olympics in Los Angeles. Photo Rocketbelts.americanrocketman.com

February 17 first accident occurred. During the next ascent, Moore lost control, as a result of which the device rose to the highest possible height, cut off the safety cable and fell to the ground. Having fallen from a height of about 2,5 m, the engineer broke the patella and could no longer participate in the trials as a pilot.

Repairing the damaged Rocket Belt and finding out the causes of the accident took several days. Flights resumed only on 1 March. This time Harold Graham, who also participated in the development of the project, became the test pilot. Over the next month and a half, Graham performed 36 flights, learned how to operate the device, and continued the test program.

20 April 1961, G. Graham performed the first free flight. The ground for this test phase was Niagara Falls Airport. Having started the engine, the pilot rose to a height of about 4 feet (1,2 m), then smoothly went into horizontal flight and covered the distance 108 feet (35 m) with a speed of about 10 km / h. After that, he made a soft landing. The first free flight of the Rocket Belt unit lasted only 13 seconds. At the same time, some fuel remained in the tanks.

From April to May 61, Mr. Graham performed 28 free flights, during which he improved his piloting technique and figured out the capabilities of the device. Were flying over a flat surface, over cars and trees. At this stage of the test, the maximum characteristics of the apparatus were established in the existing configuration. Bell Rocket Belt could climb to a height of 10 m, reach speeds of up to 55 km / h and cover distances to 120 m. The maximum flight duration reached 21 seconds.

Outside the landfill

Completion of design work and preliminary tests allowed to show the new development to the customer. The first public demonstration of the product Rocket Belt was held on 8 on June 1961, on the basis of Fort Eustis. Harold Graham demonstrated the flight of a promising apparatus to several hundreds of servicemen, which seriously surprised all those present.

In the future, the promising jetpack was repeatedly demonstrated to specialists, government officials and the general public. So, soon after the "premiere" at the military base, a show was held in the courtyard of the Pentagon. The staff of the Ministry of Defense appreciated the new development, which a few years ago was considered almost impossible.

In October of the same year, Graham took part in a demonstration maneuver at the Fort Bragg base, which was attended by President John F. Kennedy. The pilot started from the amphibious landing, located at a distance from the coast, flew over the water and successfully landed on the shore, next to the president and his delegation.

Later, a team of engineers and G. Graham visited several countries where demonstration flights of a promising aircraft were performed. New development each time attracted the attention of specialists and the public.

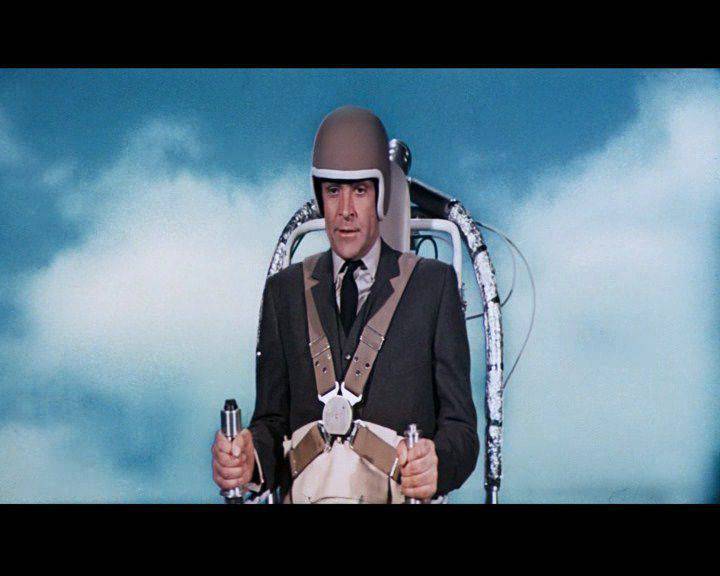

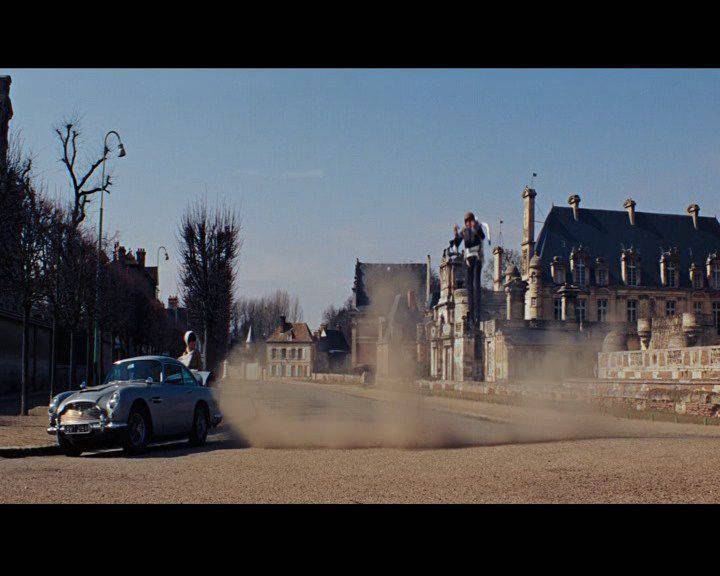

Sean Connery on the set of the movie "Fireball". Photo by Jamesbond.wikia.com

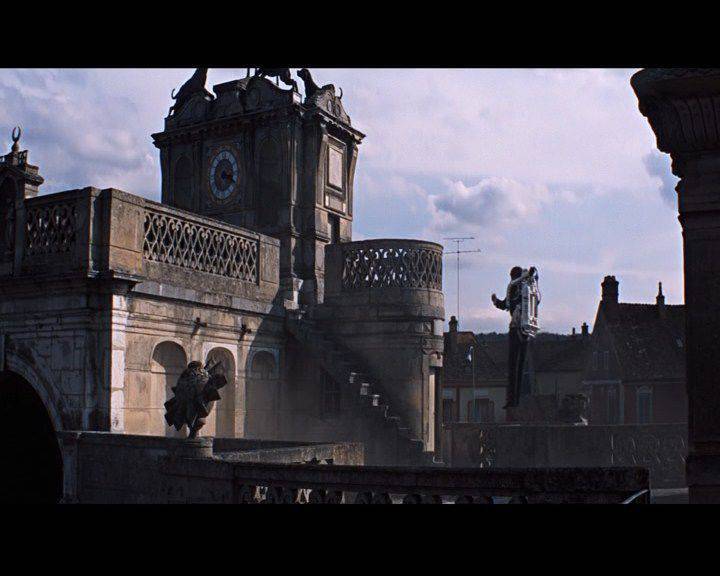

In the mid-sixties, Bell Aerosystems specialists had the opportunity to participate in filming for the first time. In 1965, another James Bond movie was released, in which the Missile Belt was included in the famous spy’s arsenal. At the beginning of the movie “Ball Lightning,” the main character moves away from the pursuit with the help of a jet pack designed by U. Moore and his colleagues. It is noteworthy that the entire flight of Bond lasts about 20-21 seconds - apparently, the filmmakers decided to make this scene as realistic as possible.

In the future, the development of the company Bell has been repeatedly used in other areas of entertainment. For example, it was used in the opening ceremonies of the Olympic Games in Los Angeles (1984) and Atlanta (1996). Also, the device several times participated in the Disneyland parks show. In addition, the “Rocket Belt” was repeatedly used when shooting new films, mostly of a fantastic genre.

Results of the project

The 1961 demonstrations of the year made a big impression on the military. However, they could not convince the Pentagon of the need to continue work. SRLD program cost the military department 150 thousand dollars, but its results left much to be desired. Despite all the developers' efforts, the Bell Rocket Belt was characterized by too high fuel consumption and “consumed” all 5 gallons of fuel in just 21 a second. During this time, it was possible to fly no more than 120 m.

The new rocket pack was too complicated and expensive to operate, but did not give the troops any clear advantage. Indeed, with the help of this technique, the fighters could overcome various obstacles, but its mass operation was associated with a large number of various problems. As a result, the military decided to stop financing and close the SRLD program in the absence of real prospects in the existing situation and with the existing level of technology.

Flight of James Bond. Shots from the movie "Fireball"

Despite the failure of the military department, Bell Aerosystems continued to try to modify its jetpack and create a modernized version with enhanced features for some time. Additional work lasted several years and cost the company about 50 thousand dollars. Due to the lack of noticeable progress over time, the project was closed. This time, the company’s management also lost interest in him.

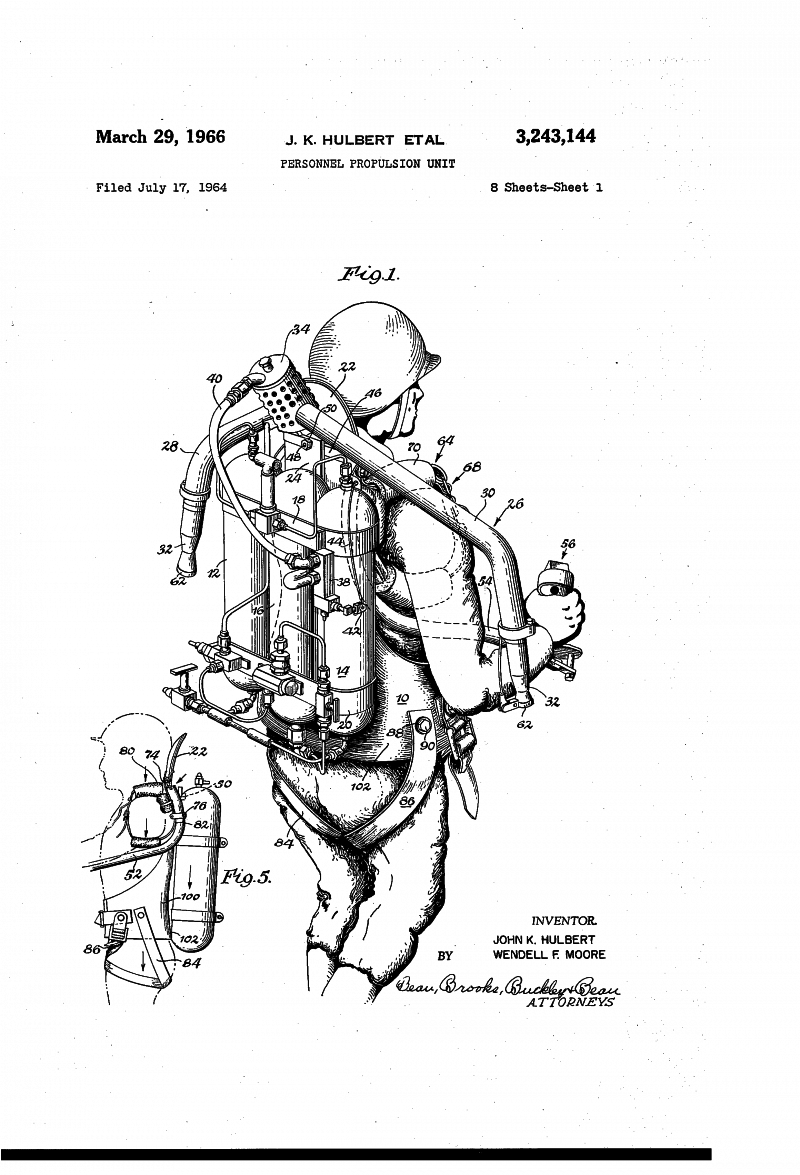

In 1964, Wendell Moore and John Hubert filed an application for a patent, soon receiving the document under number US3243144 A. The patent describes several variants of the jet pack, including the one used in the tests. In addition, this document contains a description of the various units of the complex, in particular, a helmet with a signal buzzer.

During the first half of the sixties, Bell's specialists collected several samples of promising technology, with some minor differences. All of them are currently museum exhibits and are available for inspection by everyone.

In 1970, all documentation for the Rocket Belt project, no longer needed by Bell, was sold to Williams Research Co. She continued to develop an interesting project and even achieved some success. The first development of this organization is the project NT-1 - in fact, a copy of the original "Rocket Belt" with minimal modifications. According to some information, this particular device was used in the opening ceremonies of two Olympiads and other festive events.

Through some improvements the new team of engineers was able to significantly improve the characteristics of the original jet pack. In particular, later versions of the device could be in the air for up to 30 seconds. Nevertheless, even such a significant increase in characteristics could not open the way for the device to practical use. The Bell rocket belt and further developments based on it have not yet reached mass production and full practical operation, which is why they remain an interesting, but ambiguous, example of modern technology.

On the materials of the sites:

http://rocketbelts.americanrocketman.com/

http://unmuseum.org/

http://thunderman.net/

http://airandspace.si.edu/

http://tecaeromex.com/

US3243144 A Patent:

http://www.google.com/patents/US3243144

Information