Day of Aviation and Cosmonautics in the German Center for Aviation and Cosmonautics of the city of Cologne

Antoine de Saint-Exupery

Perhaps this quote can be used to describe the general strategy and idea of the activities of the German Center aviation and astronautics, the framework of which is simply impossible to describe with specific goals, situational financial, scientific and technical capabilities for their implementation.

The German Center for Aviation and Aerospace (hereinafter –DLR) is the national center for aerospace, energy and transport research in Germany. The offices and research centers of the organization are located in several places throughout Germany, the headquarters is located in Cologne. The organization is responsible for the planning and implementation of programs initiated by various ministries and departments of the German federal government.

Including:

German Federal Ministry of Education and Research.

Federal Ministry of Economics and Energy of Germany.

Federal Ministry for the Environment, Nature Conservation, Construction and Nuclear Safety of Germany.

Federal Ministry of Health of Germany.

Federal Ministry for Family Affairs, Senior Citizens, Women and Youth.

Federal Ministry of Transport, Building and Urban Development

Federal Ministry of Defense of Germany.

DLR is engaged in a wide range of research projects, both national and international. DLR employs around 8000 employees (as of 2013) and has 37 in Germany with various institutes, test and production facilities, mainly concentrated in 16 locations. The DLR office in the suburb of Cologne (which is also the headquarters of the DLR) employs around 1500 employees.

From all of the above, it becomes clear that the topics of scientific research of DLR institutes are quite diverse and are not limited to research and development in the field of aviation and cosmonautics, as can be inferred from the name of the cluster.

Немного stories.

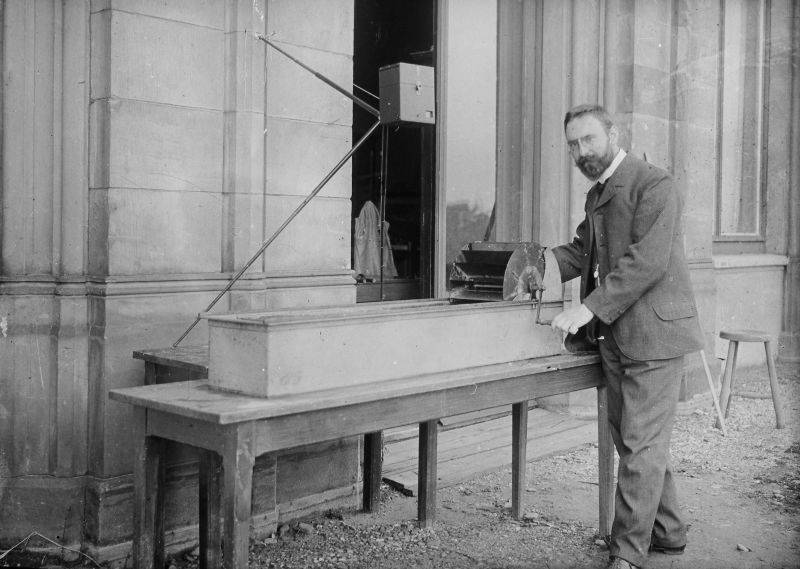

The oldest predecessor of the DLR is considered to be the Modellversuchsanstalt der Motorluftschiff-Studiengesellschaft in Göttingen, founded in 1907, by Prandtl. It is believed that the first closed wind tunnel was built in 1908 in Gottingen under the direction of Ludwig Prandtl. The idea of creating this closed air channel was pushed by a demo hydro channel created by him in 1904. At that time, he had already defended his doctoral thesis at the Technical University of Munich (in 1900 year). He was a professor in Hanover and from September 1 1904 - in Göttingen.

So with the works of the member of the Council of the Royal Aviation Society of Great Britain, Francis Herbert Wenham, Russian military engineer V.A. Pashkevich, Konstantin Eduardovich Tsiolkovsky, Corresponding Member of the Imperial Academy of Sciences in the category of Mathematical Sciences Nikolai Egorovich Zhukovsky, I think, was familiar. ...

From this research society of motorized aircraft (yes, this is not a typo - it is aircraft, since they were previously engaged in aeronautics) later created the Research Institute for Aerodynamic Research (AVA). In 1969, the German Aerospace Research and Testing Institute (DFVLR) was established by merging several institutions. After numerous renaming and incorporation into the cluster of new and new institutions, which by the nature of their research were already quite far from aviation and astronautics, this formation from October 1 1997 of the year is called Deutsches Zentrum für Luft- und Raumfahrt (DLR).

20 this September, an open day was held at the main branch of this research cluster, which is located near Cologne - Tag der Luft- und Raumfahrt des DLR.

During the day, more than 60 thousands of people visited the institutes, including the author of these lines. In places that were open to the public, it was also allowed to take photographs. Although I knowingly and constantly asked again about this possibility in each particular case. Not everywhere, where the opportunity was provided, I managed to visit due to long queues and a banal lack of time. Also, I was not quite prepared (both informatively and technically, as well as in time) for this event, since for this day it was an option "B" in my personal plans. So do not blame the harmoniously non-integral publication material. There will be at least two parts.

So:

As for the logistics of delivering such a number of people to the western entrance (it was the only one open for the public on this day), the DLR was organized at the highest level (my subjective opinion). People were collected by charter buses from five points - three huge parking lots, mainly for those who arrived on their own and two stops of electric trains. Charter buses went every minute.

The link to this file is more obvious:

http://www.dlr.de/dlr/de/Portaldata/1/Resources/documents/2015/tdlr15_Anfahrtsbeschreibung.pdf

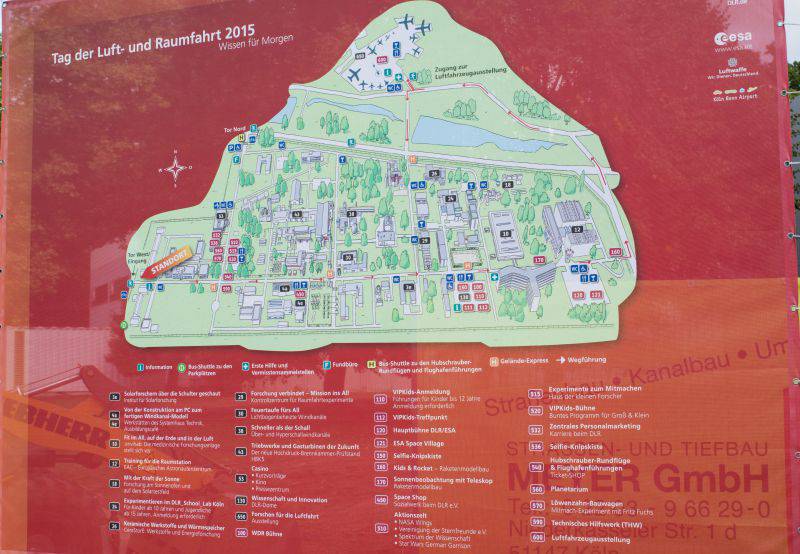

Plan-map where DLR territory is visually represented:

file: /// C: /Users/lex/Desktop/tdlr15_Gelaendeplan.pdf

Or in the photo below:

Further relevant comments to the photos will be located under them.

The first on the right is the Institute of Materials Science (№51. It is not numbered on the map).

We will come back to it.

Between the buildings of the institutes were chalets. Photo by NASA Wings and Vereinigung der Sternefreunde ev

In the distance is the European Transonic Windtunnel, the European transonic aerodynamic channel, a pleasure so expensive and complicated that four European countries — Germany, France, the United Kingdom and the Netherlands — built it and used it together. (At the moment, France has withdrawn from the project.) Construction began in the 1990 year, and was completed in the 1993 year. In 1995, the facility was commissioned.

The peculiarity of this complex is that the experiments take place at temperatures up to -160 Degrees Celsius. Moreover, the tested models are blown with a stream of pure nitrogen. There is a need for this: Aircraft models that are tested in wind tunnels are much smaller than the originals, then testing at room temperature with ordinary air gives the unpleasant effect of the discrepancy between the derived parameters when testing on the model to the flight original. Easier said - it is necessary to maintain the similarity of the size of the molecules of aerodynamic environments when scaling models.

Read more here: www.etw.de/cms/

Photos can be viewed here: www.etw.de/cms/index.php?site=gallery#MS

For public visits this complex was closed.

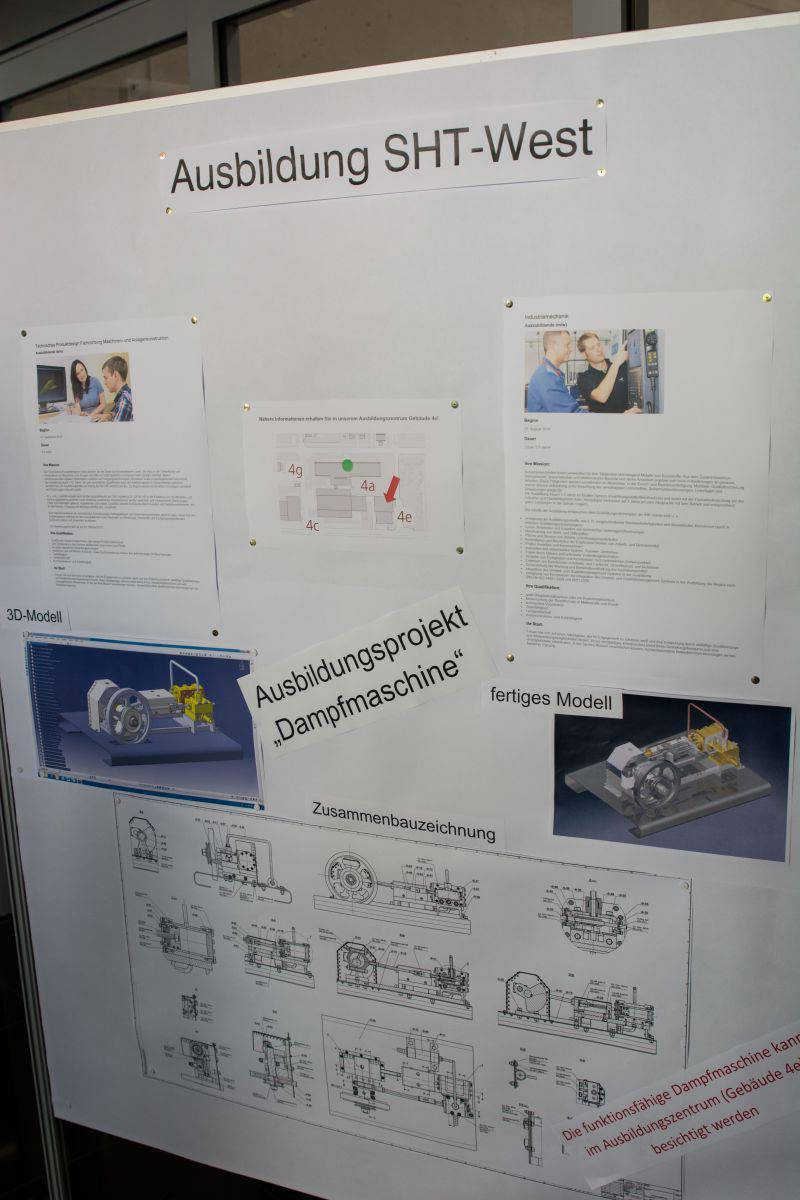

4 Systemhaus Technik - Bureau for analysis, design, selection of materials and construction of test technical systems for a variety of projects for both the DLR, and for development partners.

Read more here: http://www.dlr.de/sht/DesktopDefault.aspx/tabid-10542/7213_page-1/

Through the lobby on the first floor of this office one could get into the workshop of this office. By the way, informative flyers hung in places open to the public.

Here are a couple of them in the foyer of the 4 building:

As you can see from this flyer, Systemhaus offers the opportunity to also get an education.

A couple of examples: technical product designer (computer designer) - works side by side with designers in the design and construction of various products.

This training lasts 3,5 year. They study this specialty in the dual system (by the way - the most common system of prof. Education in Germany) - three to four days a week are trained in practice and one or two days of theory at Berufsschule (simply - vocational schools). Moreover, to get prof. study, you must first conclude a contract for prof. studying with an employer who, in addition to everything else, offers the opportunity to study (in this case, DLR) and only then go to Berufsschule with this contract, moreover, you can choose the latter only by the place (in some cases, by region) of the enterprise with which the training was concluded contract ...

Industriemechaniker - (general definition) is qualified to handle (their production, repair, control, adjustment, commissioning) with the units and systems in production.

In the flyer from DLR we are talking about obtaining qualifications in prototyping, single and small-scale production, installation, quality assurance and service of products. This training lasts 3,5 year. They study this specialty also in the dual system.

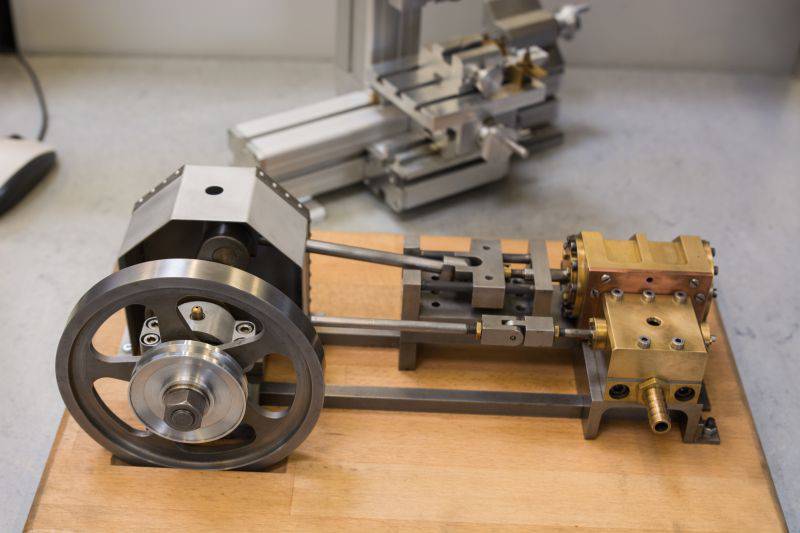

At the bottom of the photo you can see the “Steam Machine” training project (by the way, the model is fully functional).

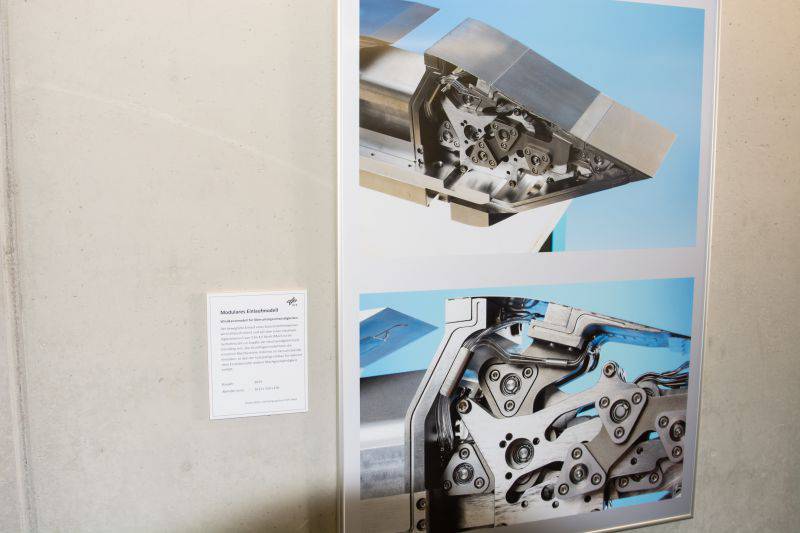

This photo shows a modular model for research in the Mach 3-4,5 speed range in an aerodynamic channel. The peculiarity of the idea embodied in this design lies in the possibility of permanently changing the geometry of the leading edge of the air intake of a ramjet jet engine when conducting experiments. (I repeat once again - the objects presented by me were allowed for photographing).

In the gallery between Systemhaus and their workshop.

Some photos from the workshop.

The last photo shows the processing of the demo model on one of the machines.

This photograph shows parts of the combustion chambers of rockets, made by the process of selective laser alloying. It takes up to ten hours to make one of them.

The material - the so-called “Iconel” - is a nickel-chromium heat-resistant alloy, which is rather difficult to machine. In a car, a layer of approximately one grain of powder is placed on a special pad: 0,05 of a millimeter. Then a laser beam of the required power is sent to the powder, which produces fusion exactly in those places where we need it. The process is carried out in an inert medium - in argon, in order to exclude metal oxidation reactions. After the fusion is performed in the first layer, the platform is lowered, a new layer of material is applied, and the process is repeated.

Another pair of parts created in this way.

In aerodynamic channels not only models of rockets and airplanes are blown through.

Modular model for research in the speed range of Mach 3-4,5 in an aerodynamic channel.

Leave the workshops behind and go on.

So to say the gates of a professional technical institution.

This unit, I think, does not need explanations.

Look to the right.

Look to the left.

Joint work of students.

Overall plan (Photo: DLR).

View of the building (Photo: DLR)

This building was commissioned 20 August 2008 of the year. It is taught by profession industrial mechanic and mechanic of exact mechanisms. In 2008, in the DLR department of the city of Cologne, the 54 person received vocational education in the professions of an information technologist, office worker, industrial mechanic, technical draftsman, photographer, and cook. During the summer holidays, people attending vocational education in the DLR department of Cologne have the opportunity to get practice in workshops and laboratories. DLR also offers a wide range of both higher education and career growth opportunities. http://www.dlr.de/dlr/jobs/desktopdefault.aspx#S:326

Starting with a bachelor's degree and further to the degree of doctor of science. Here they defend their dissertations, doctoral and dissertations.

One of the main tasks of the DLR is to stimulate interest in natural science among the younger generation, i.e. DLR works with students in schools and gymnasiums. With eight DLR research centers (Berlin, Bremen, Braunschweig, Göttingen, Cologne, Neustrelitz, Oberpfaffenhofen, Stuttgart), as well as with four partner universities (Aachen Technical University of Dortmund, Dortmund, Dresden, Universities, Hamburg, in-place, in a number of partners, in a non-profit, Hamburg, Dortmund, Technical University of Aachen; laboratories at the Technical University of Darmstadt) work the so-called

“School_Lab”, which enable students of junior and senior classes to discover the fascinating world of research. In total, school laboratories at DLR institutes and their partners are engaged with 20.000 students in schools and gymnasiums per year.

To be continued ...

Information