Self-propelled mortars: what is offered on the market

120-mm mortar complex 2R2M installed on the French machine VAB 6x6

The transition from towed mortars to self-propelled in most armies of the world opens up new opportunities for manufacturers around the world. Look at some current industry proposals.

Mortars are very effective weapons, which can be used both in open areas and in the city, in addition, small-caliber systems are easy to use and can be carried by one person. Due to this “usefulness”, the armies continue to use them extensively and until they are really replaced by a new technology, they will remain a key part of military property in the future.

However, in the sector of heavier mortars, there is a tendency to move from towed systems to more mobile self-propelled mortars.

If the mortar is self-propelled, it means that it is mounted on a large tracked or wheeled vehicle and also shoots from the same platform, whereas a towed mortar involves installing weapons on a trailer and shooting from a trailer after taking a firing position.

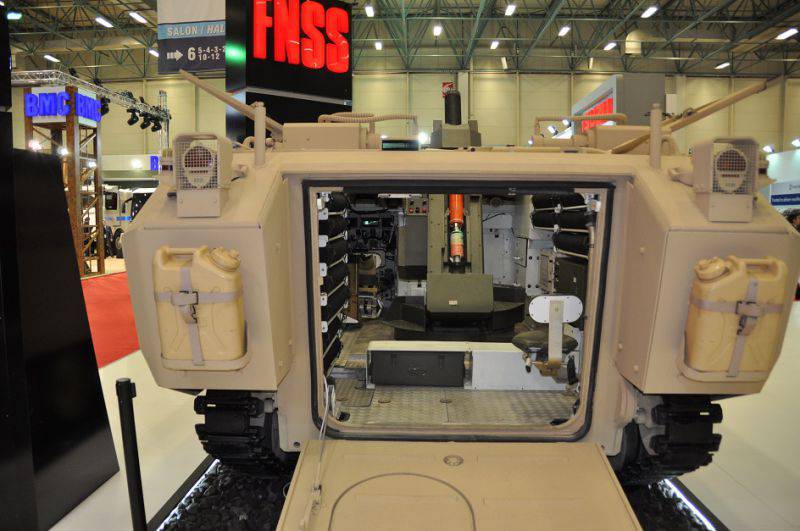

Khaldun Olgun, director of business development at the Turkish company FNSS, said that the reason for the transition to self-propelled mortars is that the crew is protected in an armored vehicle of the type BTR or BMP. There are many threats, especially in urban space, and soldiers can become a target if they leave the car and work with a towed mortar.

Continuing his thought, he said that since the machines are maneuverable and mobile, this makes mortars more effective. “It is very easy to drive to a position by a car, open a hatch, get coordinates, shoot off a few minutes, immediately close the hatch and change position before the enemy can determine your position. Mobility provides a huge advantage in a combat situation. ”

“The newest technologies allow the enemy to easily determine your position as soon as you take the first shot. Therefore, mobility gives you the opportunity to leave the position immediately. ”

The French mortar 2R2M is mounted in the rear of the M113 BTR. IDEF 2015 Exhibition in Turkey

Middle support

Mortars, in general, are designed or used at a significantly shorter distance from combat units compared with artillery and are used primarily as a means of fire suppression. This is due to the fact that mortar ammunition has much more explosive per shot, and they themselves are for the most part much less accurate than artillery.

For example, a typical US Army brigade has just 18 artillery guns, which are controlled at the brigade level, but more than 50 mortars of various types are controlled at company and battalion levels.

Self-propelled mortars allow you to have a greater degree of mobility and more ammunition. A light infantry unit with a mortar, as a rule, has very limited reserves, since all this must be carried on the shoulders of the calculation. Installing the same mortar on the machine can significantly increase the amount of ammunition.

BAE Systems has in its portfolio the mortar transporter M1064A3, which was first deployed in 1996 year. A 120-mm mortar is installed on the machine and 69 shots and a crew of six people are placed in it: the driver, the commander, the squad leader and three mortar gunners. The turntable inside the habitable compartment can turn the mortar by 90 °.

The mortar can be removed from the shooting machine from the base plate, which is placed outside the machine. Mortar can be installed back into the car by the forces of calculation. This is very important, because if you take a system with a sliding mortar, then there is a need for maintenance work at a higher level when installing it back on the machine.

Egypt, Israel, Thailand and the USA are the main operators of this system; currently, 468 of M1064A3 systems is deployed in various versions. BAE Systems offers an improved version of the previous model M1064A2, which was modified for transportation and firing from a larger 120-mm mortar and has a modernized transmission and engine, new places for laying ammunition, a modified layout for combat laying and external fuel tanks.

Still, upgrading

In the majority of modern programs on armored vehicles, the development of a mortar conveyor variant is envisaged. Here you can call VBM Freccia, the French Griffon VBMR and the Piranha 5 vehicle from General Dynamics European Land Systems, selected to meet Denmark’s need for an armored personnel carrier.

FNSS is expected to supply a self-propelled mortar variant to Malaysia as part of the country's purchases of AV-8 machines; she has already installed eight 2010-mm ACV-120 systems with a TDA 19R2M mortar in 2.

Olgun explained that although there are machines specifically designed for the installation of mortars, but their number is small. According to him, the main market for self-propelled mortars is a modification of existing vehicles, for example, an armored troop-carrier, for the transportation of mortars, since this is a cheaper alternative for most armies than buying new platforms.

“Army prefer to get into self-propelled mortars from converted machines, because they have enough on the balance of armored personnel carriers and infantry fighting vehicles. The mortar complex has always been considered as a towed system, and therefore not many cars were made specifically as mortar conveyors. That is why in the last ten years, several programs have been launched for alteration, especially with regard to the M113 BTR, because their 80000 units are in the whole world. ”

Over the past seven years, FNSS has participated in a similar modernization program for M113 vehicles for Saudi Arabia and has supplied 12 BTRs that have been modified to install a TDA 2R2M mortar; Some more such machines are expected to be delivered. FNSS delivered seven M113 vehicles converted into self-propelled 81-mm mortars to Bahrain in the 2007 year and the Philippines in the 2008 year. In other words, the company has sufficient experience in this field with different calibers and mortar systems.

“The main work is to install a base plate for the mortar itself and hatchways on the roof,” explained Olgun. The machine is equipped with electric and hydraulic actuators for the turntable and the opening system of the hatches. In case of problems there is a backup manual control system.

Another area of work - the transfer of fuel tanks. Olgun said that on M113 fuel tanks are located inside, and placing them outside allows you to get more space for ammunition and, moreover, it is safer for the crew.

“We also increased the suspension. You need a different suspension for mortars of different size and caliber, from 81-mm to 120-mm, because they have a different power rollback. Another change is to move ammunition racks to another location. ”

This is important because the more ammunition you carry in the car, the longer the crew will be protected. If the crew has to go out to gain access to a vehicle with ammunition to replenish their ammunition, then it again becomes the target and this negates the advantages of self-propelled mortars.

Olgun said the 120-mm mortar can fire up to ten rounds per minute. “If you use a semi-automatic mortar, you need a sufficient number of shots inside the car. That is why, compared to other platforms, the ACV-19 tracked and AV-8 8xNNXX wheeled platforms from FNSS are much better suited because they have a greater width and length. For example, you can stack up to 8 shots in an M113 machine, and you can put up to 16 shots in an ACV-19 machine, ”he continued.

Olgun said that there were disputes about the use of 120-mm mortars, as in urban areas they can cause significantly more indirect damage. The counter argument is that the fire control systems of modern 120-mm systems are very accurate, that is, using 81-mm mortars without a fire control system (FCS) is likely to cause greater non-combat losses than a larger caliber system.

Rifled barrel

The company TDA (part of Thales), producing systems 2R2M, said that although the system is not new, but it is a mortar with a rifled barrel, having higher accuracy and increased range and, consequently, a higher level of mortality. The complex is compact and has automatic guidance and loading systems to reduce the load on the calculation.

2R2M has been shipped to four countries and it is now also expected that Italy and France will buy this system. According to Thales, compared with the MO-120-RT (towed version, which is in service with these countries), the 2R2M complex has “better crew protection (during firing, the calculation remains inside the car); better mobility (no towed mortar); the best response (reduced time to take and remove from the position, reduced workload); and reduced time for combat training (easier to work). "

Thales is developing new 120mm ammunition to improve combat capabilities. These include: insensitive ammunition (IM); smoke gases without phosphorus (neither white nor red); extended range projectile (> 16 km); and a guided mortar shell Mortar Guided Munition.

However, the company believes that, nevertheless, the market for towed mortars remains; It also requires the replacement of “obsolete 4,2-inch mortars or 120-mm smooth-bore mortars in order to obtain compatibility with future new ammunition (IM, guided, extended range, etc.)”.

Singapore Technologies Kinetics 120-mm SRAMS mortar mounted on a rear Bronco ATV module

The MO-120-RT towed mortar of the French company is rifled and therefore more accurate, more long-range and more lethal, but they claim that it is also very durable and reliable because it has been in service with Belgium and France for several decades (purchased at the end of the 70-s) ) and the Netherlands. More than 1600 systems MO-120-RT were manufactured and delivered to the armies of 24 countries, including five NATO countries.

Thales also claims that the advantage of towed systems is that they can be “easily deployed by light vehicles and / or helicopter”.

This is what is considered in the framework of the operational concept of the US Marine Corps STOM (Ship-to-Objective Maneuver) according to which the MV-22 Osprey convertiplane is used to transport the Expeditionary Fire Support System (EFFS) expeditionary fire support system.

The US Department of Defense issued a request for proposals for the M2015 EFSS mortar in May 120, and at the end of the year a five-year supply contract is expected with an unspecified time and quantity. The complex will be able to shoot high-precision precision range 120-mm ammunition Precision Extended Range Munitions (PERM) at a distance of 17 km.

In order to develop a new ammunition for this program, Raytheon teamed up with Israel Military Industries, and Orbital ATK teamed up with General Dynamics Ordnance & Tactical Systems (GD OTS). Work is in full swing and both tandems are nearing the end of their development stages. At first, it was intended to entrust this task only to GD OTS, but then the case was put on a competitive basis.

Alternative platforms

In smaller armies, there is also a tendency to install lighter mortars not on armored vehicles, but on alternative platforms, such as trucks. In this case, the weapon is considered as a cargo carried in the rear part of the truck and is removed from it for firing and mounted on the ground. Alternatively, you can install the mortar on an ongoing basis, but with the mandatory installation of a system to reduce the forces of recoil. This increases the cost and complexity, but allows the use of a wider selection of fire platforms.

Instead of trucks, EXPAL installs its EIMOS 81-mm mortar set on lighter armored vehicles. This combination of long-range mortar and light car 4x4 has an automatic guidance system and a fire control system, and also includes its own racks for projectiles. The company argues that the recoil system allows you to install a mortar on a car without any additional stabilization in the form of support racks.

The unnamed overseas customer purchases EIMOS in accordance with the 2014 contract of the year, which provides for the delivery of EXPAL's Techfire fire support system and Shepherd-Mil micro UAVs for advanced observers. The first complexes entered service at the beginning of 2015 of the year.

In March, 2015, at HOMSEC in Madrid, EXPAL showed a new version of the 81-mm mortar EIMOS, installed on the car URO VAMTAC 4x4. The design of the platform was modified to reduce the preparation time for the calculation. The integration of sensors has been improved (including a meteorological station for ballistic calculations), a new Techfire software version has been introduced with additional functionality and a simplified user interface. The system retains the soft rollback system and automatic guidance with circular firing.

Reduced rollback

Singapore Technologies Kinetics (STK) is also going to go this route. Its advanced rapid-fire 120-mm mortar complex SRAMS (Super Rapid Advanced Mortar System) was mounted on the Bronco tracked armored personnel carrier, as well as the RG-31 4x4, HMMWV and Spider Light Strike Vehicle self-developed.

The chief engineer of the weapons systems center at STK said that the SRAMS complex consists of a 120-mm smooth barrel, two retractable cylinders, power drives, a baseplate and some other systems.

He said that SRAMS used several technologies developed for mortar systems, which can significantly increase its capabilities compared with the previous versions. “It is equipped with an inertial navigation system and an onboard ballistic computer associated with the SLA, which allows the SRAMS 120-mm complex to perform automatic guidance and autonomous fire missions.

"In order to connect the mortar crew to the general communications system of the upper echelon, the combat control system can be integrated into the complex, which improves situational awareness and makes it possible to exchange information with other units."

SRAMS has a semi-automatic loading system. The 120-mm shot is manually placed on the loading tray, at the command of the SLA it moves along the barrel axis until it reaches the muzzle, and then released into the barrel. This reduces the fatigue of the calculation and increases the rate of fire. With this level of automation, SRAMS can serve the calculation of only three people.

“Another key feature is the innovative construction of the recoil mechanism, which does not allow the recoil force to exceed 24 tons,” the chief engineer continued. This is especially important when the 120-mm complex SRAMS is installed on light machines. The low spans of the SRAMS complex help to reduce the overturning moment during a shot, and in combination with its relatively small recoil forces, this means that the stability of the machine during firing has been significantly improved. ”

Blast diffuser is another technology used in SRAMS. It reduces the pressure near the output of the wave, increases the safety of the mortar calculation and allows you to increase the rate of fire. The maximum range of the complex when shooting with standard 120-mm mines is 8,5 km.

Since the complex is installed on light platforms, the entire system can be transported by helicopter, thus combining the good deployability of the towed system with the mobility of the self-propelled system.

The center’s chief engineer also reported that the SRAMS complexes were sold in 2008 to a customer from the Middle East in the amount of 31,6 million dollars and delivered in 2011 year, and nowadays the company is focused on exporting its system to other countries. “Latin America is an important market for the ST Kinetics SRAMS complexes, which allow to give outdated armored platforms new fire capabilities.

"We see a tendency to install such systems on an existing fleet of light and medium platforms, since the mortar complex is usually a means of combat support in combat units."

High precision fire

STK is also exploring the use of high-precision ammunition to minimize indirect damage, as well as the integration of the SRAMS sensors into the firing process in order to shorten the firing sequence.

A spokesperson for STK said that as more and more armies are moving into rapid deployment of their motorized forces, the towed mortars cannot provide the necessary fire support.

He added that self-propelled mortars equipped with on-board sensors are “autonomous and do not need the support of additional reconnaissance groups. Equipped with ballistic solvers and mechanical actuators of the barrel, self-propelled mortars can answer the call of fire in seconds. The firing of precision-fired mortar shells also makes it possible to precisely regulate the lethal effect. ”

However, it is rather difficult to achieve the desired result due to the use of self-propelled mortars, mainly due to the lack of a complete doctrine on the integration of sensors, communications and weapons systems.

“The military should consider the mortar as a single integrated system uniting the platform, ammunition, communication system, weapons and sensors. Self-propelled mortars can deliver the necessary fire strike with the right impact and at the right time for the most part through the use of an integrated systems approach. "

Tower options

Kari Reunamaki, vice president of weapons systems at Patria Land Systems, said tower mortars offer even greater advantages compared to towed systems and modernized hatches. He said that the armored personnel carriers and infantry fighting vehicles equipped with hatches on the roof, or towed systems mounted on the ground do not provide ballistic protection from debris and bullets and are vulnerable to the threat of hand grenades and IEDs.

In addition, with open hatches, survivability and masking deteriorates. These systems also do not provide protection against weapons of mass destruction and, therefore, gas masks and separate kits are necessary for survival when working in contaminated areas — the crew will be exposed to infection when the hatches are opened.

In open areas, a muzzle wave will affect the crew and ammunition handling, and there is always the risk of double loading. Reunamaki said that "residues from firing [poisonous gases] pollute the air around the habitable compartment, there is no possibility for direct fire and there is no possibility for indirect fire below 40 °."

He pointed to other restrictions: the length of the trunk is reduced due to the size of the hatches, as a consequence, a smaller range; there is a risk of fire hazard from residues of burnt powder; the space inside the chassis is limited, especially when transporting weapons; and limited space for ammunition that is not stored securely enough.

He suggested that the simple integration of mortar complexes with armored personnel carriers "is only a theory," since a "serious modification of the chassis" is necessary. There is only room for a short pullback, which creates an unnecessary burden. Reunamaki also said that the impact of mechanical shocks causes "cracks in the hull, deformation, damage to the suspension, problems in the electrical system, has a negative effect on ammunition."

Patria manufactures a Nemo 120-mm tower mortar. According to Reunamaki, this system offers significant advantages: better crew protection and a higher level of ballistic protection (up to STANAG 4569 4 Level); good level of vitality due to the management of signs of visibility; low effective area of dispersion; the shape of the tower with subtle signs and effective camouflage; protection against weapons of mass destruction; loading from the breech, therefore, the error of double loading is excluded; high rate of fire with automatic loading; and finished ammunition in safe packing.

Tower mortars allow you to increase the length of the barrel and the range of angles of vertical guidance. The crew is protected from blasting of gases, gases and combustion residues do not fall inside the hull and therefore the crew is not exposed to their harmful effects.

Patria's Nemo system, in addition to these features, offers a circular rotation of 360 ° over the entire range of vertical angles; the possibility of direct fire; MRSI mode (simultaneous impact of several projectiles; the angle of inclination of the barrel changes and all projectiles fired at a certain time interval arrive at the target simultaneously); more space for ammunition and accessories; high long-term rate of fire with cooling weapons; automatic guidance and semi-automatic loading; and a quick change of target from the same firing position.

Reunamaki said that this turret system easily and simply integrates with the existing chassis without a radical change in the layout scheme, and a large rollback length reduces the load on the chassis and increases crew comfort.

Patria believes that tower systems offer more advantages than towed mortars and self-propelled mortars with open hatches.

Materials used:

www.shephardmedia.com

www.fnss.com.tr

www.baesystems.com

www.patria.fi

www.thalesgroup.com

www.stengg.com

www.wikipedia.org

Information