Anti-tank mine TM-39

As the name implies, the TM-39 mine was developed and put into service in the 1939 year. Its development took into account the experience of creating and using mines TM-35, which were in large quantities in warehouses. In addition, it was supposed to use some ready-made parts and mastered ideas, which made it possible to simplify the design and manufacture of new weapons. It was proposed to increase the power of the ammunition due to a significant increase in the explosive charge. Arrange a larger number of checkers proposed in the so-called. elongated body.

Available mines had a hull diameter of no more than 20-22 cm, which reduced the likelihood of a run over them. To increase the likelihood of a collision with the subsequent defeat of the target, it was proposed to increase the length of the hull. On the way, the enemy’s armored vehicles should have laid down relatively long mines that were easier to hit. In addition, the larger size of the hull made it possible to increase the weight of the charge and, as a result, the damage caused to the undercarriage or the bottom of the target.

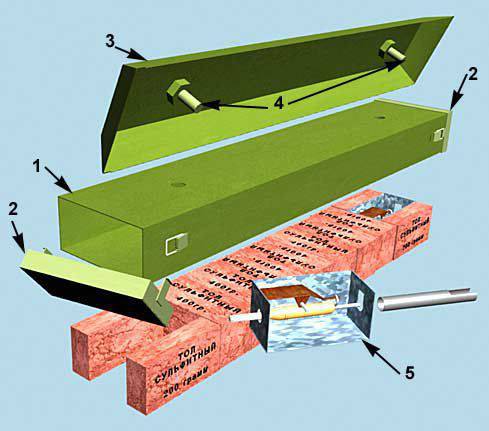

The main element of the TM-39 mine was an elongated body, made in the form of a parallelepiped without end caps. In the upper surface of this part, two holes were provided for the details of the target sensor, on the sides there were latches for installing the side covers. A cap in the shape of a truncated pyramid was placed on top of the rectangular case. The assembly of such ammunition had a length of about 60 cm, width of the order of 13 cm and a height of no more than 12-12,5 cm. The weight of the product with an explosive charge was 6,7 kg.

The TM-39 mine should have been made by stamping from roofing iron. To protect against external influences, metal parts were painted. In most cases, mines of this type had a dark green color. In addition, the necessary marking was applied on the side wall of the case with black paint. Some mine bodies did not have removable end caps. In this case, the lid was welded to the body, and a hole was made in it, closed by a sliding lid.

Inside the case was placed a charge of explosive. In the middle part there were seven pieces weighing 400 g, along the edges - four 200-gram. The latter fit the largest surface to the side wall, so that between them left free space for the mechanism of the fuse. The total charge weight was 3,6 kg of explosive. For equipment mines TM-39 could use any existing pieces made of TNT, ammotol, French mixture or other explosives.

The layout of the mines TM-39. Figure Saper.etel.ru

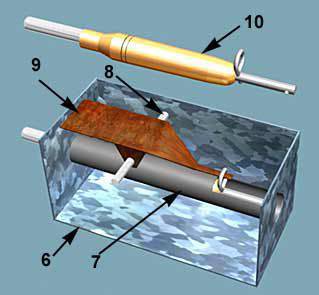

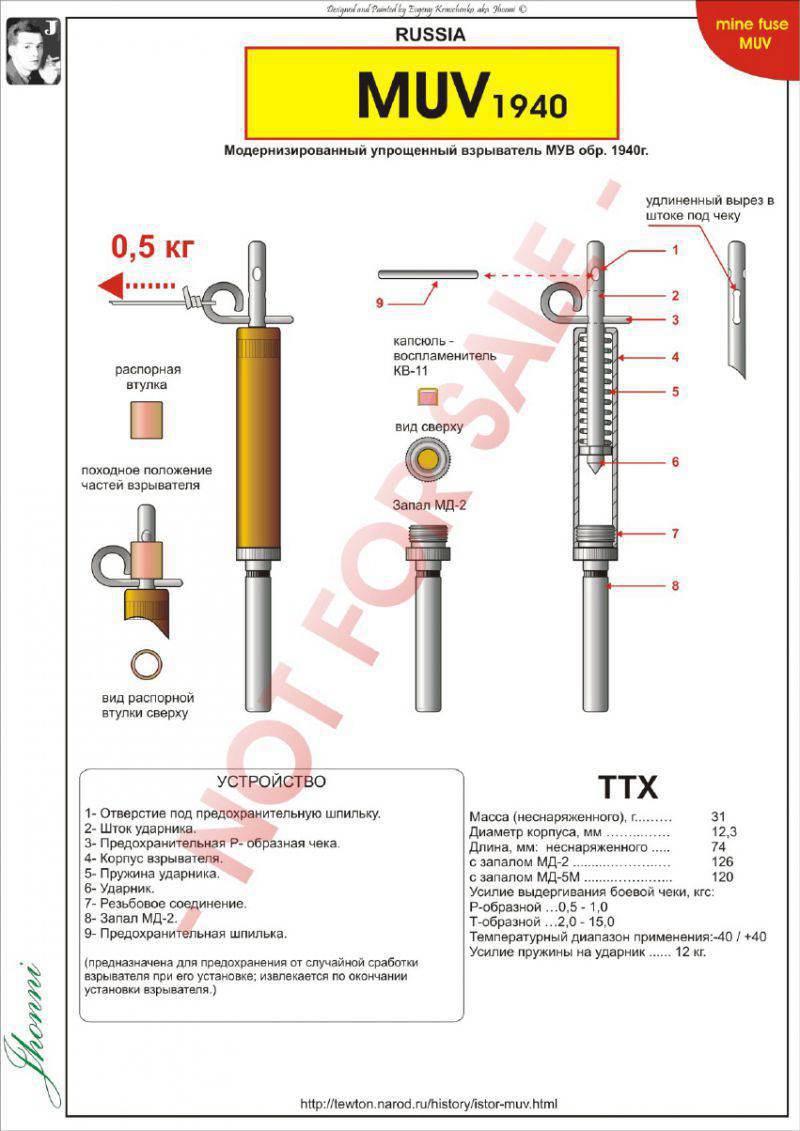

To undermine the main charge, it was proposed to use a mechanism borrowed from previous mines. In this case, the lever system for extracting checks from the fuse was placed in a separate case. All the main elements of the explosive mechanism were placed in a metal box without a lid with dimensions 10x5x5 cm with holes on the side ends. At the factory the tube with a notch in the upper part, which was intended to hold the fuse, was soldered to these holes. In the middle of the box there was an axis for a curved lever. A fuse of an HC or MUV with a detonator cap No. 8 or an MD-2 fuse was placed in the tube. In the working position, the detonator or the fuse protruded from one of the holes in the case, and the P-shaped check with its ring was put on the lever.

Mina TM-39 standard was completed with two such explosive mechanisms. They were placed at the side ends of the hull, with the upper arm of their levers located under the hole in the hull. In its place, the mechanisms were held by end casing covers and 200-gram checkers, which were located on either side of them.

The cover of the mine, which served as the sensors of the target, was stamped from an iron sheet and had the shape of a truncated pyramid with an elongated base. The side edges of the cover had no welds or other fastening for easier deformation under the weight of the target. On the sides of the upper surface of the cover were fixed two bolts. When mines were fitted, they entered the holes in the upper surface of the hull and were directly above the levers of the explosive mechanisms.

By the principle of operation, the TM-39 product was similar to the older TM-35. Driving on a mine, the enemy’s armored car had to press down on the cover and deform it. The operation of mines was provided with an effort of at least 90 kg. Under the weight of a caterpillar or wheel of an enemy vehicle, the cover was tinned, as a result of which the side bolts were lowered and pressed on the levers. Those, in turn, swinging on the axle, pulled out checks fuses. After that, the striker was released, who hit the primer and provoked the undermining of the main charge.

It was assumed that the relatively large size of the target sensor (58х10 cm) would significantly increase the probability of hitting the target in comparison with existing mines. For greater reliability, mine equipped with two fuses. Nevertheless, it is known about the existence of mines with one explosive mechanism. In this case, additional explosive checkers with a total weight of up to 400 were put in place of the second fuse box.

Mines TM-39 were delivered to the troops disassembled. It was necessary to equip corps with TNT or other swords, and also install fuses in explosive mechanisms in the army. Thus, before leaving for the mines, the sappers had to place the necessary number of pieces inside the mine body, then close the end caps. In this form, the ammunition was transported to the installation site. Explosive mechanisms were assembled and installed only at the mining site.

The device is an explosive mechanism. Figure Saper.etel.ru

Arriving at the desired site, the miners had to screw the fuses / detonators into the fuses, remove the safety check (if any) and fit the explosive mechanism. After that, it was possible to open the end covers of the case and place the box with the fuse in its place. It should be noted that the explosive mechanism and fully equipped mine were a certain danger even for the sapper. The fuses HC and MUV had rather high sensitivity. Combat check was removed with an effort of no more than 2-3 kg, which required special care when working. Miners faced special difficulties when they had to work with the TM-39 mines, which were not equipped with end caps. In this case, the explosive mechanism was immediately placed in its place, and the fuses were installed through the holes in the ends of the case, covered with sliding covers.

The first domestic mines were not equipped with anti-handling systems. However, the neutralization of such weapons was associated with some problems. The high sensitivity of the fuses, despite the great strength of the cover, made it difficult to disarm the ammunition. For disposal it was necessary to remove the mine from the ground, remove the side covers, carefully remove the explosive mechanisms and defuse the fuses. In some cases, attempts to remove the fuses were useless, as a result of which the mine was destroyed by an overhead charge.

The service life of TM-39 mines was not limited, but in fact did not exceed several months. The metal case had the property to collapse under the influence of moisture and other climatic factors. As the hull lost its strength, the danger of mines increased. Rusty iron could not protect the fuse from external influences, due to which the old mine could explode even for no apparent reason. Such risks were somewhat reduced when using ammotol or other explosive substances that lose their properties when exposed to moisture.

The anti-tank mine TM-39 was put into service in 1939 year. Soon, several enterprises mastered the production of such weapons, after which mass shipments of mines began in the Red Army. With the appearance of the TM-39 product, the range of factory-made available anti-tank mines literally doubled, which to a certain extent improved the characteristics of the minefields.

However, during the operation of the TM-39 mines, quite serious problems were identified, including “inherited” from TM-35. The main reason for the claims was the need to assemble and equip mines in parts. Laying checkers and assembling explosive mechanisms took too much time and interfered with the normal work of the sappers. Also, in some cases, there could be problems with the supply of certain components, such as explosives or fuses. In addition, immediately before the installation of the mine it was required to perform several complex and lengthy operations for assembling an explosive mechanism. Because of this, the miners could not work at a small distance from the forward or in the dark.

There were problems in the design of the ammunition. So, through the slots on the side faces of the cover sand, soil or water could get into the space between it and the body. A large number of such pollutants blocked the movement of the cover, after which the mine could not work in normal mode. In winter conditions, the ingress of water into mines led to freezing of some parts, such as a lever or a fuse check.

With the outbreak of World War II, the Red Army began to actively use all available anti-tank mines, including TM-39. During the combat operation of these weapons, another shortcomings were identified. So, a charge weighing 3,6-4 kg was not enough to guarantee the defeat or destruction of enemy armored vehicles, first of all tanks. Damage was made to the undercarriage of the equipment, but its destruction did not occur in all cases. The reason for this was both the relatively low charge weight and the not-so-successful construction of the mine itself. Under the caterpillar or wheel of an enemy machine, most often only a small part of a relatively long body fell. As a result, some of the explosion energy went to the sides and did not harm the equipment.

In order to compensate for the small weight of the charge, sappers began to recommend laying mines TM-39 two each over time. However, in this case, ammunition consumption doubled, and preparation for the installation of a minefield was also complicated. To this must be added the other faults of the mines revealed before the start of the war.

The anti-tank mines TM-35 (including the upgraded TM-35M) and TM-39 were actively used in the initial period of the war. However, with the advent of newer and more sophisticated products of a similar purpose, miners began to abandon pre-war weapons. The latest use of the TM-39 mines is reportedly from the 1942 year. After that, TM-35 / 35М and TM-39 gave way to new mines with higher characteristics.

It is known that during the Great Patriotic War the Red Army spent far from the entire stock of the available mines TM-39. In the first post-war years, mines of this type remaining in warehouses as unnecessary were sent to the Chinese Communists who participated in the civil war. Such friendly assistance seems to have been helpful. There is reason to believe that all the anti-tank mines supplied by the National Liberation Army of China were used during the fighting. Any information about the use of such weapons after the Chinese conflicts of the forties is missing.

The TM-39 anti-tank mines were produced from 1939 onwards. Shortly after the start of full-scale production, some resource problems arose. Despite its simplicity, such mines used relatively expensive metal. In this regard, the project TMD-1940 appeared in 40. This mine was a revised version of the TM-39, made with the maximum use of wood. All the details of this mine, including an explosive mechanism, were made from cheap and massive lumber.

On the materials of the sites:

http://saper.etel.ru/

http://eragun.org/

http://lexpev.nl/

http://primeportal.net/

Information