The first Soviet anti-tank mine T-4

Project T-4 was developed by N.N. Simonov at the very beginning of the thirties. The project was presented to the specialists of the People's Commissariat of Armaments, who studied it and gave the go-ahead to the deployment of mass production. It should be noted that Simonov created a new mine from scratch, without having the necessary information. Moreover, the creation of all early anti-tank weapons faced similar problems. Full tactics of armored vehicles have not yet been formed and tested in practice, which had a specific impact on the development of tools to combat such machines. Nevertheless, the Soviet engineer managed to develop a curious project, which reached mass production.

At the very beginning of the 1930s, there was no developed industry in the Soviet Union, and this fact imposed serious restrictions on the design of weapons. Simonov had to build a new mine on the basis of the most simple and cheap materials. In addition, as part of the ammunition required to use only existing components, the production of which has already been mastered. One can imagine how difficult the work of the designer was in the conditions of a shortage of materials and the lack of experience in creating anti-tank weapons.

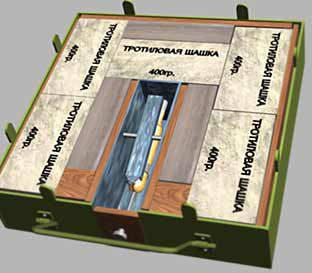

General view of the mine

The main element of the T-4 mines was the hull with dimensions of 21,5 x21,5 cm and height of 6 cm. The total weight, depending on the material of the hull, reached 4-4,5 kg. In addition, due to the target sensor carried upward, the overall height of the product increased to 10, see. The body could be assembled from boards or assembled from stamped metal parts. In the case of a wooden case, all the parts were connected using nails, and the metal case of the mine was assembled with the help of teeth in the upper part of the main box, which were inserted into the slots of the lid and then bent. In the side wall and the bottom of the mine provided a removable cover designed to install the fuse.

As a target sensor, the mine T-4 used a board with dimensions 20x20 cm. A stem was attached to its central part, which was responsible for interacting with the fuse and entering the round hole in the center of the housing cover. When assembling the mines, the sensor cap was installed at a certain height above the body cap and was fixed in this position with metal rods or nails. In the middle part of the target sensor stem there was a through hole into which a wooden rod was inserted, which served as safety checks and was responsible for breaking the mines when pressing the desired force.

In the central part of the body, with a shift to the front wall, a small tray was provided, which contained a fuse and associated mechanisms. Explosives were stacked around the tray. The dimensions of the case, as well as the free space between the tray and the walls, allowed five pieces of 400 g and three 200-gram charges to be placed in a mine. Mina T-4, depending on the capabilities of the manufacturer, could be filled with explosives of various types. It was proposed to use TNT, Melinite, French mixtures of different types. In addition, it was allowed to use not only checkers, but also powdered explosives. In such a case, when assembling the mines, oiled paper should be used in which the explosive was placed.

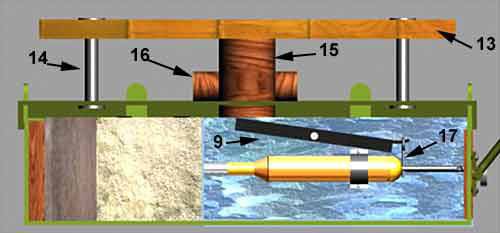

T-4 mine layout

Metal-cased mines usually contained various auxiliary materials. The fact is that the project T-4 meant the manufacture of metal and wooden cases with the same external dimensions. Due to the smaller thickness of the metal, the internal volume of the “iron” mines was slightly larger than in the case of the “wooden” ones. To hold the checkers in their places, they had to use small plank pads or fill the free space with other materials, even paper or resin.

An explosive charge weighing up to 2,6 kg should have been placed inside the case at the factory. After that, the case cover and the target sensor were installed in its place. To install the fuse in the front wall and the bottom of the case, a notch covered with a sliding cover was provided. With it, the miner accessed the central chassis tray.

To explode the main charge in the composition of the T-4 mine, a hydrocarbon fuze was used. He had a tubular body, inside which there was a spring-loaded drummer. In the cocked position, the drummer moved out and was fixed with the help of checks with a loop at the end. When extracting the checks, the firing pin was released and, under the influence of the mainspring, hit the primer. For direct ignition of the main charge was used primer-detonator №8.

The central tray of the case contained in itself all the details necessary to detonate the mine when you press the target sensor. A hole for the tail part of the blasting cap (the nearest piece was placed in the socket to this hole) was provided in the rear wall of the tray, in the middle - a ring to hold the fuse body. In addition, there was a special lever suspended on the axis for the central part. A cylindrical pin was provided on its front shoulder.

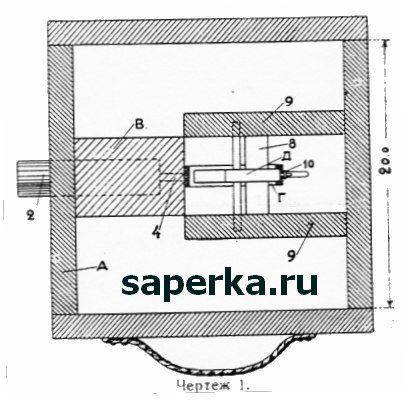

Body section, rod, lever and fuse visible

Upon arrival at the site of the mine, the sapper had to remove the sliding cover of the case and install the fuse with the primer-detonator in its place. In this case, the detonator cap passed through the opening of the tray, and the fuse body was fixed with a metal ring. During the installation of the fuse, the loop of the checks was put on the thin ledge of the lever's shoulder, after which the mine was ready for laying and disguise.

For easy carrying, the T-4 mine was equipped with a wire handle attached to the front wall of the case. Some mines for this had a piece of rope attached to nails. In most cases, a small handle was provided on the front wall of the sliding cover, making it easier to remove. Transport mines should be separate from the fuses. The number of simultaneously carried mines was determined by the task and the physical capabilities of the miners. Mine could be installed in the ground, on the ground and in the snow. At the same time, however, in some cases, problems could arise with soils that impeded the work of mine mechanisms.

The principle of the anti-tank mines T-4 was quite simple, but ensured a reliable defeat of targets. When you press the target sensor cover with sufficient force, its rod broke off the safety check, after which the cover together with the rod could move down. During the movement, the lid stem pressed on the free shoulder of the lever, after which the second shoulder rose and pulled out the fuse pin. After that an explosion occurred.

According to reports, the T-4 anti-tank mine was put into service in 1932, but did not become a mass weapon of the Red Army. Due to the weakness of the Soviet industry and some other problems, the production of new mines was limited to a relatively small batch. In the future, these mines were used for personnel training and in various tests. Full-fledged mass production with delivery and use in the troops was not conducted.

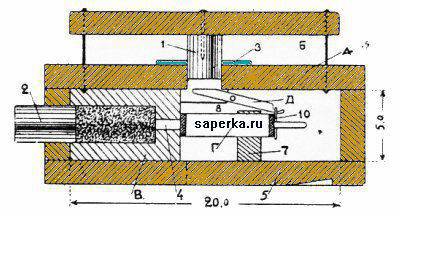

The body of the educational version of the mine

Despite the small number of mines released, they managed to establish their strengths and weaknesses. Thus, a relatively small (2,4 kg) explosive charge allowed to guarantee to disable vehicles or damage of varying severity to armored vehicles. Given the relatively weak booking of mass technology of the time, the T-4 mine could become one of the most effective types of weapons in its class.

However, lack of flaws. The main drawback was associated with the complexity of the production and the high cost of the products offered: the Soviet Union in the early thirties could not afford the mass production of such mines. The same mines that managed to get off the assembly line and enter the troops received a number of serious complaints. The military was not satisfied with several features of the proposed weapon.

It was quickly established that the T-4 mine in its original form could not be effectively used in areas with soft or loose soils. In addition, there may be problems with the use of such weapons in the autumn. The cause of these problems was the gap between the case cover and the target sensor. Soil and sand could get into it, blocking the movement of the target sensor. When mines were used in the fall and winter, the freezing of wet soil under the target sensor cap was not ruled out, which made the ammunition unusable. To correct this deficiency, the mines were wrapped in cloth or defended by other methods. However, the troops needed a weapon that did not need such additional means of protection.

Training mine with HC fuze

The reason for the claims was the design of the target sensor, namely a wooden rod and a wooden safety check. The project implied that the latter would increase the force of mine activation and thereby eliminate the detonation under a person, and not under the technique. However, due to the lack of experience in designing such systems and a low production culture, the real sensitivity of serial mines could fluctuate within fairly wide limits. Because of this, the mine could have been blown up by a relatively light man, or could not work even under a relatively heavy tank.

Like many mines of that time, the T-4 product did not have any devices for self-destruction after a certain period of time. Such a mine could remain in the ground and remain operational for several weeks or even months, until under the influence of moisture and other factors the wooden or metal hull would become unusable. The lack of sealing of the hull also led to the destruction of the internal parts of the mine, after which it could not operate properly. However, a certain risk of the spontaneous triggering of the fuse persisted.

Mina designs N.N. Simonov was not equipped with additional means that made it difficult to remove or neutralize. Despite this, attempts to clear the mine were associated with a very high risk. To eliminate the explosion, it was necessary to pull the ammunition out of the ground, remove the lid of the inner tray and remove the fuse. Due to the high sensitivity of the HC fuze, such operations posed a great danger. Mine should be destroyed by overhead. Thus, in fact, the T-4 mine was non-detectable.

Training mine with HC fuze

The T-4 anti-tank mine was put into service in 1932. At the same time, a relatively small batch of mines was made, sent to the troops for development. Full-fledged mass production did not start. Manufactured ammunition was used for training purposes and, apparently, was never used in the course of hostilities.

Nevertheless, there is information about the resumption of the production of T-4 mines or similar-design munitions at the very beginning of World War II. Remnants of mines similar to T-4 are occasionally found during prospecting at the 1941 battle site of the year. In addition, the existence and use of such weapons is mentioned in some German documents.

In addition to the military option mines N.N. Simonov offered to make and training. From anti-tank such a product was different internal parts. Thus, a training mine should not be equipped with an explosive. Instead, it was proposed to place a smoke bomb at the rear of the hull (behind the fuse). Thus, when the target mine sensor was pressed, the training mine should have signaled that the smoke had triggered. Simonov offered two options for a mine. One of them had a standard HC fuze with a lever borrowed from the T-4 combat. The second one was planned to be equipped with an electric ignition system of the smoke grenade and contacts under the stem of the target sensor, replacing the lever and the fuse.

The anti-tank mine T-4 was used for training purposes for several years, but it never became a full-fledged tool for creating mine-explosive barriers. Nevertheless, it was on its basis that the TM-35 anti-tank mine, which was actively used by the Red Army during the first years of World War II, was later developed. In addition, we should not forget that it was the T-4 that was the first domestic anti-tank mine produced commercially.

On the materials of the sites:

http://saper.etel.ru/

http://eragun.org/

http://saperka.ru/

Information