Baltic Plant - construction of the country's nuclear fleet

Today the Baltic Shipyard is a brand associated with the nuclear icebreaker fleet countries. It is on the slipways of the St. Petersburg enterprise that the world's largest and unique orders are being built.

Now the Baltic Shipyard specializes in the construction of icebreakers and ice-class vessels, as well as large-tonnage vessels for the transportation of various cargoes. The world's only floating power unit in the world is being built as part of the FNPP and in 2017 will arrive at the base in the northern city of Pevek. For 159-year-old history The Baltic plant here is built around 600 ships and ships.

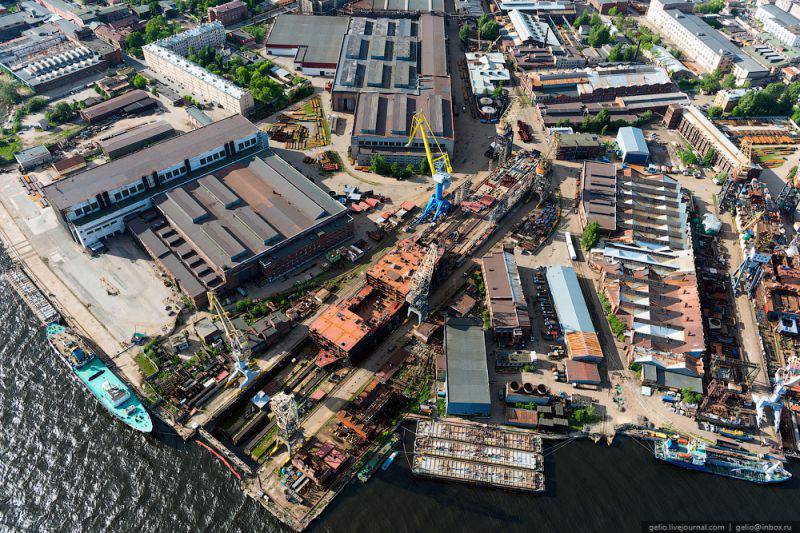

The shipbuilding enterprise has three construction sites - two stocks and a slipway. The A-berth of the Baltiysky Zavod is the largest in Russia and has a length of 350 meters. Currently, the construction of the 22220 60 MW, an atomic icebreaker of the project with the name “Arctic”, is under construction.

1. The Baltic Shipyard was founded in the middle of the 19 century, and in nearly 16 decades it has survived several wars, economic recessions and upsurges, and reorganization.

Today, the company remains one of the largest shipyards in Russia. At various times, the first metal ship in the country was built here - the armored gun “Experience”, the first combat submarine “Dolphin”, unique floating research and development complexes designed to support manned space flights, diesel-electric icebreakers, and heavy nuclear-powered cruisers. type "Kirov".

The plant is located in the western part of St. Petersburg, on Vasilyevsky Island, at the mouth of the Neva River. The company covers an area of more than 650 thousand square meters and now about 4000 specialists work in workshops, departments and divisions. The plant continues active search and recruitment of qualified workers - after all, now the Balts will have to build a serial nuclear-powered icebreaker, and later a second serial icebreaker, the contract for which was concluded in May of last year.

2. The cycle of production of the order begins with the housing department, where the processing of metal and the manufacture of parts. At the moment, the shop is able to process up to 30 thousand tons of metal per year.

3. From the steel warehouse, the metal is transferred to the line, which makes it clean and primer.

4. Then, the processed metal is moved to the cutting site, where two Messer machines using plasma cutting process further metal processing.

5. Cutting and marking of parts from the rolled products is carried out on the robotized cutting line of the IMG company profile.

6. It also performs cutting holes, cutting edges of the profile parts, as well as drawing inverse (rectifiable curves) lines to perform bending parts without templates.

7. Transportation of sheets, profiles and parts outside the transport system is carried out with the help of bridge and semi-gantry cranes. Cranes are capable of turning metal sheets up to 180 tons by 12,5 degrees.

8. Manufacturing of units, flat sections of ship hulls and their assembly into volume is carried out in the assembly and welding shop.

9. Crane equipment of the workshop allows producing sections weighing up to 80 t.

10. The workshop is divided into 4 span, which are intended for the manufacture of a set, planar sections, the manufacture of foundations, bottom-side sections, etc. In addition, the workshop is equipped with an automated line of flat sections produced by Pema (Finland).

11. In the zero span, there is a section for the manufacture of volumetric sections, and in the near future it is planned to commission an already installed line of micropanels of the IMG company (Germany). The site is equipped with two bridge cranes with a load capacity of 50 and 80 tons. In the span of the No. 1 there are production areas for the set, planar and volumetric sections. In the span №2, there are sections for assembling and welding panels, making foundations, bottom-side sections and bulk sections of extremities. In the span №3 there are assembly sections of the bulk and bottom, side sections.

12. The welding equipment of the workshop includes automatic and semi-automatic machines for welding in the environment CO2, as well as installations for argon-arc welding.

13. Bulk section of the serial icebreaker in the 4 span of the assembly and welding shop.

14. Transportation of manufactured bulk sections and large-sized equipment is carried out with the help of two auto-trailers with a load capacity of 150 and 200.

15. To form the hulls of ships and ships and launch them into the water, the Baltic Shipyard has two inclined slipways (slipway "A" and slipway "B") and a covered slipway, designed to assemble ships and ships of increased complexity.

16. Building berth "A" of the Baltic plant with a length of 350 meters is the largest in Russia. It allows the company to build and launch ships with a deadweight of up to 100000 tons.

At various times, such orders as the cruiser Kirov, the nuclear-powered icebreaker 50 years of Victory, the heavy nuclear-powered missile cruisers Admiral Ushakov, Admiral Lazarev, Admiral Nakhimov and Peter the Great, as well as research ship "Cosmonaut Yuri Gagarin", as well as two fodder parts "Mistral."

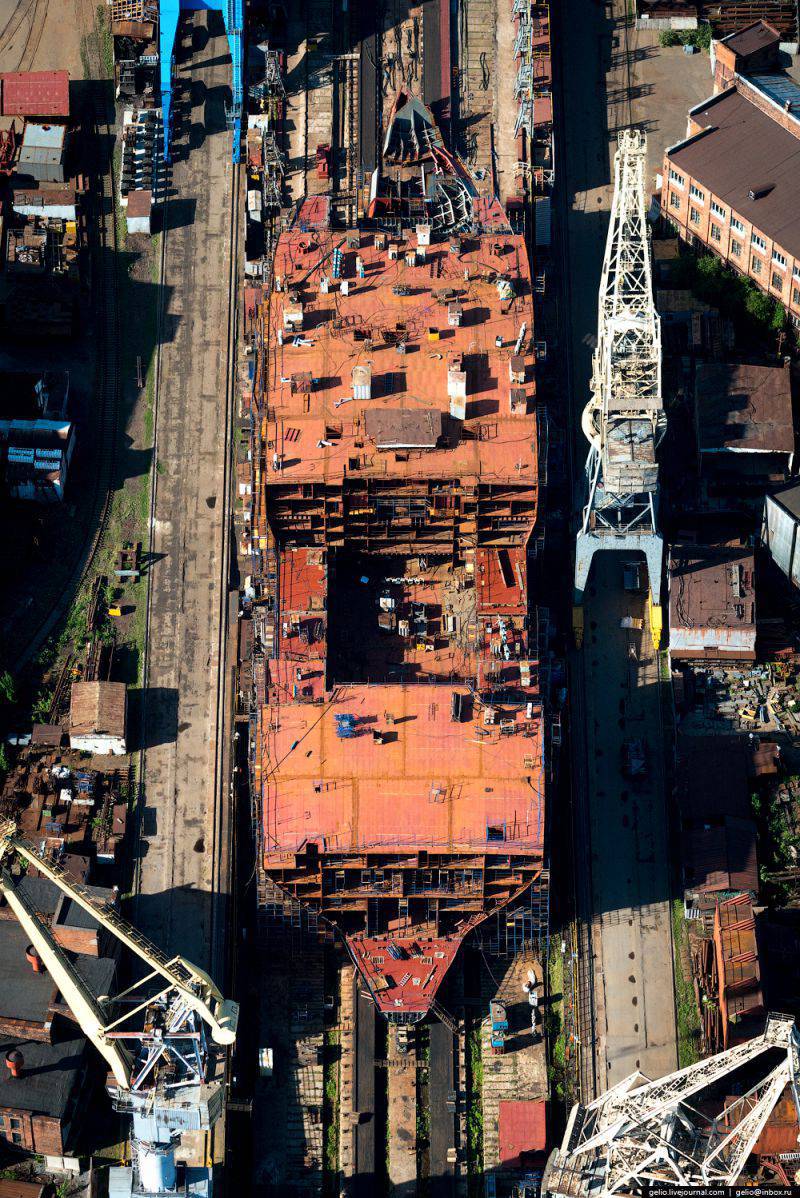

17. At present, the hull of the 22220 60 MW multi-purpose atomic icebreaker of the XNUMX project is being formed on the large A-berth.

The nuclear powered icebreaker named “Arctic” will be the largest and most powerful in the world!

18. The order for the construction of two production nuclear icebreakers of the 22220 project was received in May 2014.

Exceptional power supply allows them to overcome the ice thickness to 3 meters. As a result, the Northern Sea Route can be used almost all year round. However, the main task of the promising icebreaking flotilla is to ensure the delivery of hydrocarbons from the Yamal and Gydan fields. That is why the ship hull was made wider on the 4 meter than in the previous series.

19. The length of the vessel is 173 meters, the width is 34 meters, the draft on the constructive waterline is 10,5 meters, the minimum working draft is 8,5 meters, and the displacement is 33,5 thousand tons.

20. The two-draft design of the vessel allows using it both in the Arctic waters and in the estuaries of the polar rivers. The icebreaker will operate in the western region of the Arctic: in the Barents, Pechora and Kara seas, as well as in the shallower parts of the mouth of the Yenisei and in the Ob Bay area.

21. The main nuclear-powered icebreaker is to go on sea trials in the 2017 year.

22. Docking sections of the bow of the icebreaker head.

23. 26 May at the same slipway in a solemn atmosphere with the participation of Deputy Prime Minister Dmitry Rogozin, FSUE Rosatomflot CEO Sergey Kiriyenko, President of the United Shipbuilding Corporation (which includes BZS) Alexei Rakhmanov, guests and hundreds of Baltians made the first production icebreaker project called "Siberia".

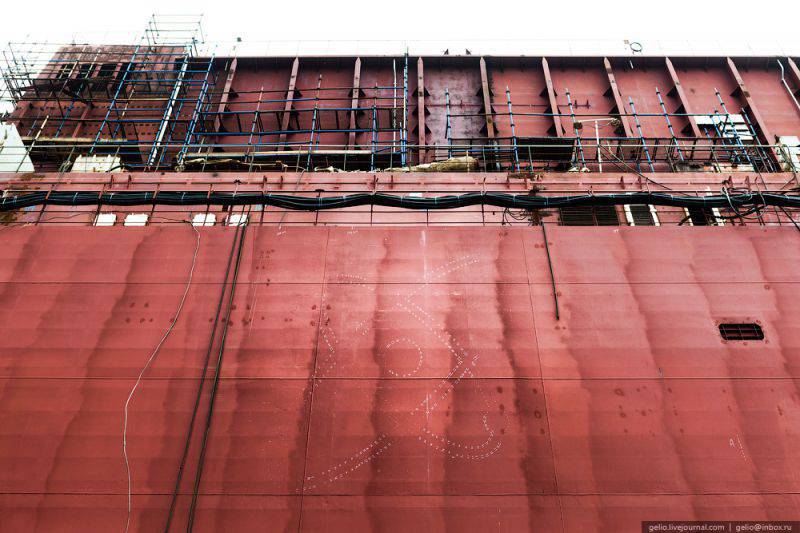

24. The nose of the head nuclear icebreaker "Arktika".

25. In addition, other unique vessels are being formed on the stocks of the Baltic Shipyard. For example, the world's largest diesel-electric icebreaker with a capacity of 25 MW of the 22600 project “Viktor Chernomyrdin” is under construction at the small building berth “B”.

26. . Metallurgical production includes: foundry, model, forge-thermal and production of finished propellers.

27. Foundry manufacture manufactures ship and general engineering products for its own needs, according to the orders of shipyards and shipyards in Russia, the CIS, the Near and Far Abroad.

28. And in 2003, the Baltic factory for the Holy Trinity Sergius Lavra produced a bell weighing tons in 72 - the largest of all existing bells ever made in Russia!

29. In the forging shop produce forgings and forgings from both ferrous and non-ferrous metals.

30. Baltiysky Zavod is the only Russian manufacturer of large bronze and brass rowing screws weighing up to 70 tons and with a diameter of up to 8 m.

31. At present, the plant has orders for the manufacture of propellers for shipbuilding enterprises of the entire North-West region.

32. The screws produced are used on large-tonnage tankers, container ships and passenger ships, all types of naval ships, nuclear-powered icebreakers, speedboats, including patrol vessels.

33. For the manufacture of propellers are used mainly colored or stainless alloys.

34. Shop for the manufacture of propeller shafts.

35. Shafts can be up to 33 meters long and up to 70 tons in weight. The big shaft in the foreground is for the atomic icebreaker "Arktika".

36. And this shop is notable for the fact that there is a beautiful spiral staircase-ladder installed in it, which leads to the ordinary crane operator's cabin. It is said that this ladder was removed from the cruiser "Rurik" (1906, built) during the cut in 1925 year.

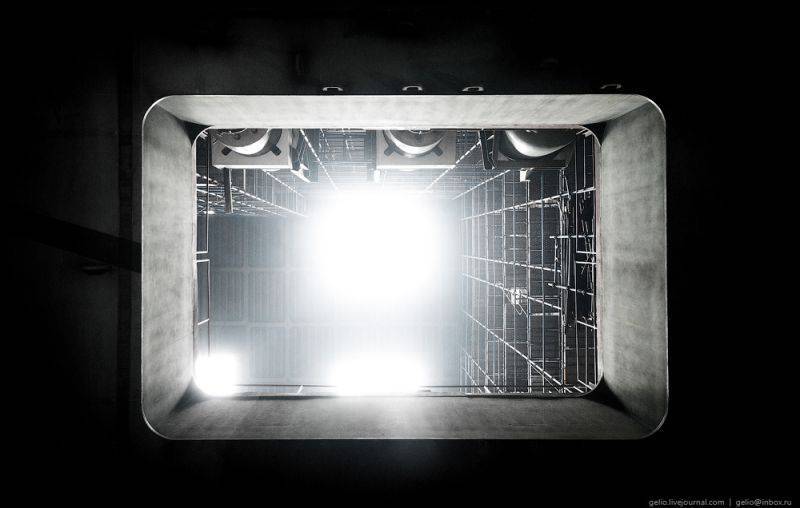

37. Out-of-embankment of the Baltic plant. Now the construction of the floating power unit (FBI) “Akademik Lomonosov” is being completed here.

PEB will be part of the world's first floating nuclear power plant of low power, consisting of a smooth-deck non-self-propelled vessel with two reactor installations.

38. PEB is intended for operation in the Far North and Far East. "Academician Lomonosov" in the future will be installed in the city of Pevek, Chukotka Autonomous Region.

39. A floating nuclear power plant can be used to generate electrical and thermal energy, as well as for the desalination of sea water. It can produce from 40 to 240 thousands of tons of fresh water per day.

40. The station is equipped with two KLT-40С modified reactor units, which are capable of generating up to 60 MW of electricity and up to 50 Gcal / h of thermal energy, which is enough to sustain the city with a population of 200 thousand people.

41. The lifetime of the plant will be at least 36 years: three cycles of 12 years, between which it is necessary to overload the reactor cores.

42. The length of the vessel - 144 meters, width - 30 meters. Displacement - 21,5 thousand tons.

43. The planned deadline for the completion of the construction and readiness of the safety and security policy for towing to the home site is September 2016. The planned commissioning of the main safety and security functions as part of the FNPP - 2017.

44. To install the add-on blocks afloat, the floating crane “Demag” of the 350 loading gauge is used, with a lifting height of up to 50 m. The height of the 76 crane itself is meters.

This crane was originally ordered in 1939 from the German company Demag. In 1940, it was pushed into Leningrad, but without a boom, which, according to German explanations, “due to the complexity of delivery”, was never delivered before the war. After the war, the Baltic plant manufactured and installed an arrow on its own.

45. Factory panorama

Information