Production of aircraft engines in Russia

The main activities of the company are the development, production, service and repair of turbojet aircraft engines, the production and repair of helicopter units, the production of equipment for the oil and gas industry.

UMPO serially manufactures AL-41F-1С turbojet engines for Su-35С aircraft, AL-31F and AL-31FP engines for Su-27 and Su-30 families, separate units for Ka and Mi helicopters, gas turbine drive AELs 31ST for gas pumping stations of OAO Gazprom.

Under the leadership of the association, a promising engine is being developed for the fifth-generation fighter PAK FA (a promising front-line aviation complex, T-50). UMPO participates in the cooperation on the production of the PD-14 engine for the newest Russian passenger aircraft MC-21, in the production program of the VK-2500 helicopter engines, in the reconfiguration of the production of RD engines for MiG aircraft.

1. Welding in the Atmosphere-24 habitable chamber. The most interesting stage in the production of the engine is argon-arc welding of the most critical components in the habitable chamber, ensuring complete tightness and accuracy of the weld. Specially for UMPO, the Leningrad institute Prometheus in 1981 created one of the largest welding sections in Russia, consisting of two Atmosphere-24 installations.

2. According to sanitary standards, a worker can spend no more than 4,5 hours per day in the cell. In the morning - check costumes, medical control, and only after that you can start welding.

Welders travel to Atmosphere-24 in light space suits. Through the first airlock doors they pass into the chamber, air hoses are attached to them, the doors are closed and argon is fed into the chamber. After he expels the air, the welders open the second door, enter the chamber and start working.

3. In the non-oxidizing environment of pure argon, the welding of titanium structures begins.

4. The controlled composition of impurities in argon makes it possible to obtain high-quality welds and increase the fatigue strength of welded structures, provides the possibility of welding in the most inaccessible places due to the use of welding torches without using a protective nozzle.

5. In full vestments, the welder really looks like an astronaut. In order to get access to work in a habitable cell, workers undergo a course of study, first they are fully equipped in the equipment and trained on the air. Usually two weeks is enough to understand whether a person is suitable for such work or not - not everyone can withstand the load.

6. Always in touch with the welders - a specialist, watching what is happening from the control panel. The operator controls the welding current, monitors the gas analysis system and the general condition of the chamber and the worker.

7. No other method of manual welding gives such a result as welding in a habitable chamber. The quality of the seam speaks for itself.

8. Electron beam welding. Electron-beam welding in a vacuum is a fully automated process. In UMPO it is carried out on Ebokam installations. At the same time, two or three welds are welded, moreover, with a minimum level of deformation and a change in the geometry of the part.

9. One specialist works simultaneously on several installations of electron-beam welding.

10. The parts of the combustion chamber, the rotary nozzle and the blocks of nozzle vanes require the application of heat-shielding coatings by the plasma method. For these purposes, the TSZP-MF-P-1000 robotic complex is used.

11. Tool production. The UMP 5 tool shops total number of about 2 500 people. They are engaged in the manufacture of technological equipment. Here they create machine tools, dies for hot and cold processing of metals, cutting tools, measuring tools, molds for casting non-ferrous and ferrous alloys.

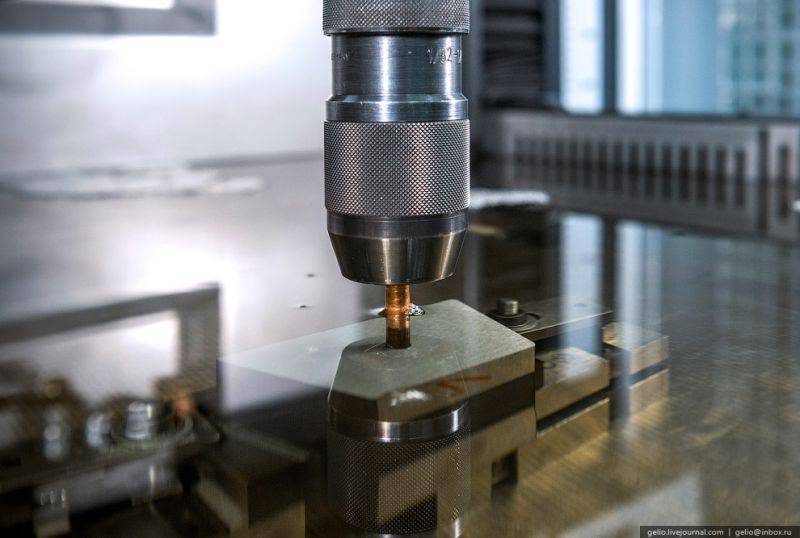

12. The production of molds for blade casting is carried out on CNC machines.

13. Now it takes only two to three months to create molds, but earlier this process took six months or longer.

14. An automated measurement tool catches the smallest abnormalities. Details of the modern engine and tool must be made with extremely precise observance of all sizes.

15. Vacuum grouting. Automation of processes always involves reducing costs and improving the quality of work performed. This also applies to vacuum cementation. For cementation - saturating the surface of parts with carbon and increasing their strength - Ipsen vacuum furnaces are used.

For maintenance of the furnace is enough one employee. Parts undergo chemical and heat treatment for several hours, after which they become ideally durable. UMPO specialists have created their own program, which allows cementing with increased accuracy.

16. Foundry. Production in the foundry begins with the production of models. From a special mass, models are pressed for parts of different sizes and configurations, followed by hand finishing.

17. At the site of the production of the melted models, mostly women work.

18. Facing the model blocks and obtaining ceramic forms is an important part of the technological process of the foundry.

19. Before pouring, ceramic molds are roasted in furnaces.

20. The ceramic form is calcined - then it is waiting for you to fill the alloy.

21. This is the ceramic form poured in with alloy.

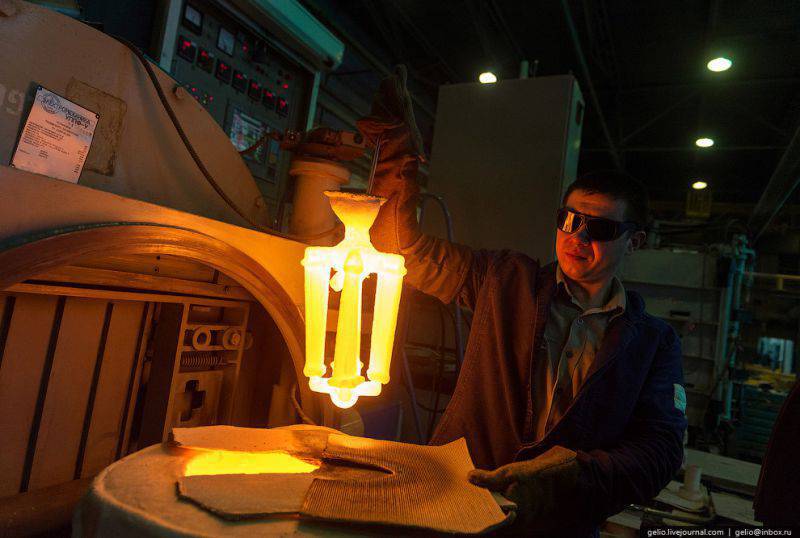

22. “Worth its weight in gold” is about a blade with a single-crystal structure. The production technology of such a blade is complicated, but this expensive item in all respects works much longer. Each blade is “grown” using a special seed from a nickel-tungsten alloy.

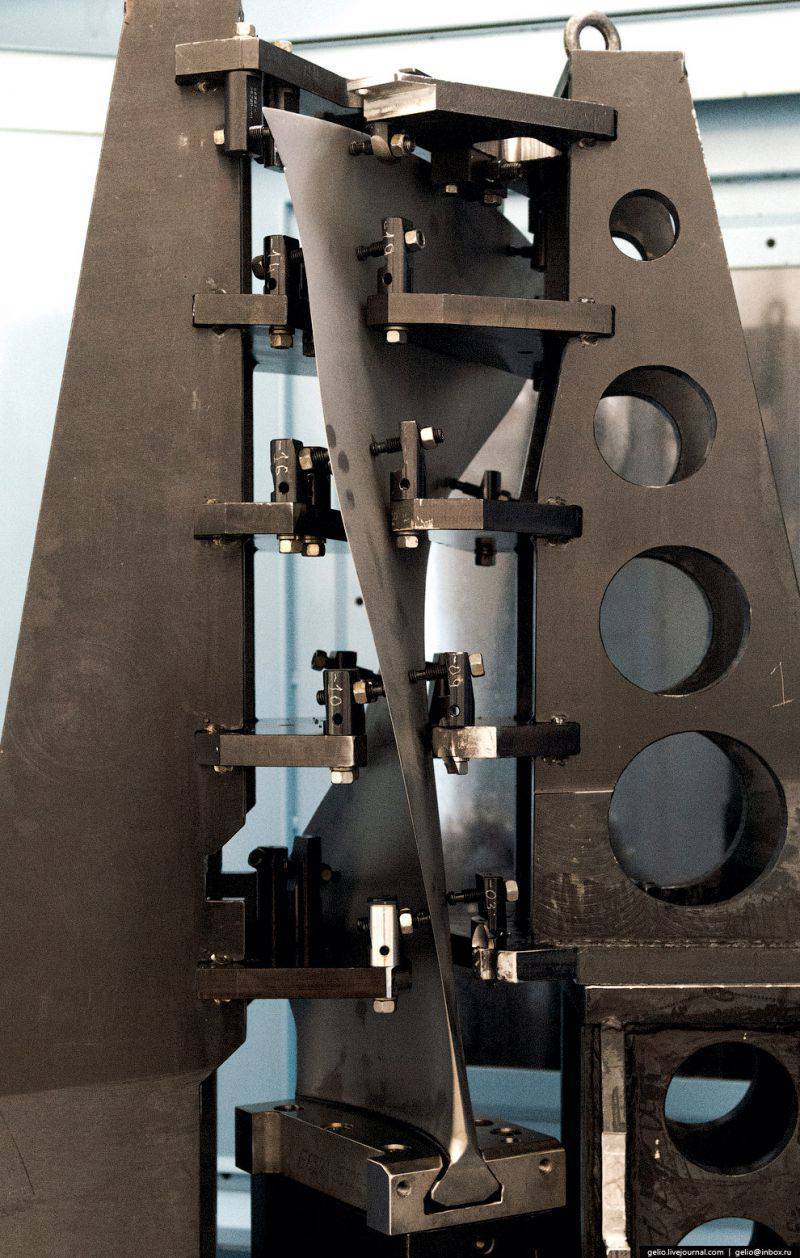

23. The processing area of the hollow wide chord fan blade. For the production of hollow wide-chord fan blades of the engine PD-14 - the driving unit of the promising civil aircraft MC-21 - a special section was created where cutting and mechanical processing of blanks from titanium plates, the final mechanical processing of the lock and the blade feather profile, including its mechanical grinding and polishing, are carried out .

24. Final treatment of the end face of the blade blade.

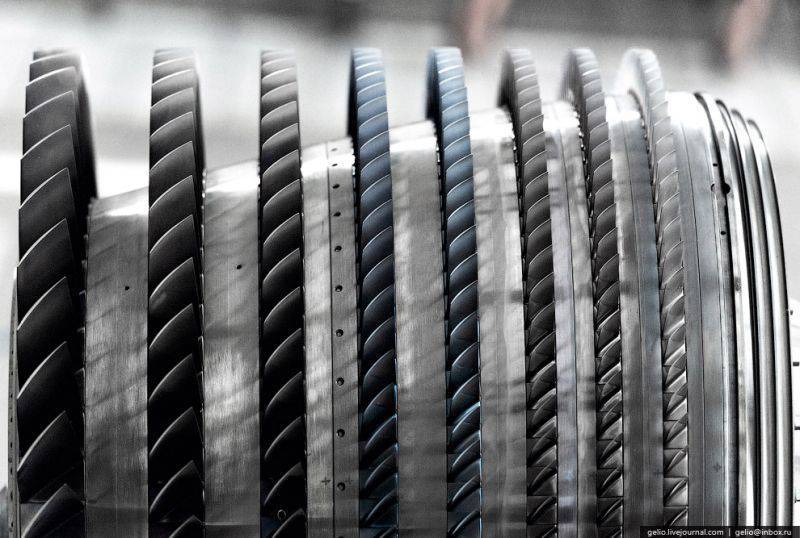

25. The complex for the production of turbine rotors and a compressor (KPRTK) is the localization of the available capacity to create the main components of the jet drive.

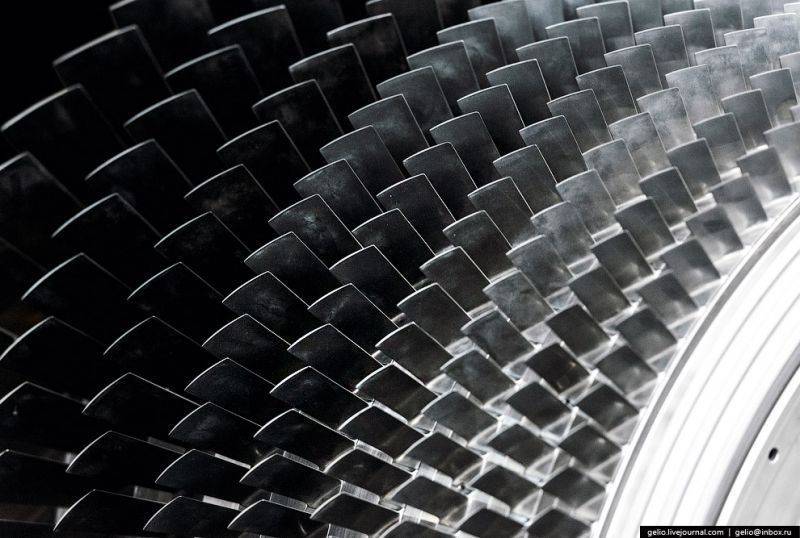

26. Assembling turbine rotors is a time consuming process that requires special qualifications of the performers. High precision machining of the shaft-disk-toe connection is a guarantee of long-term and reliable engine operation.

27. Multistage rotor is assembled into a single unit.

28. The rotor is balanced by representatives of a unique profession, which can be fully mastered only within the factory walls.

29. Production of pipelines and tubes. In order for all engine units to function smoothly - the compressor pumped, the turbine spun, the nozzle was covered or opened, you need to give them commands. The “blood vessels” of the aircraft’s heart are considered to be pipelines - it is through them that the most different information is transmitted. In UMPO there is a shop that specializes in the manufacture of these "vessels" - variegated pipelines and tubes.

30. At the mini-factory for the production of tubes requires jewelry handmade - some details are true man-made works of art.

31. Many operations on the pipe bender are performed by the machine with numerical programmed control of the Bend Master 42 MRV. It bends a tube of titanium and stainless steel. First, determine the geometry of the pipe by contactless technology using the standard. The received data is sent to the machine, which produces pre-bending, or in the factory language - beaten. After the adjustment is made and the final bending of the tube.

32. So the tubes already look like in the finished engine - they twist it like a web, and each performs its own task.

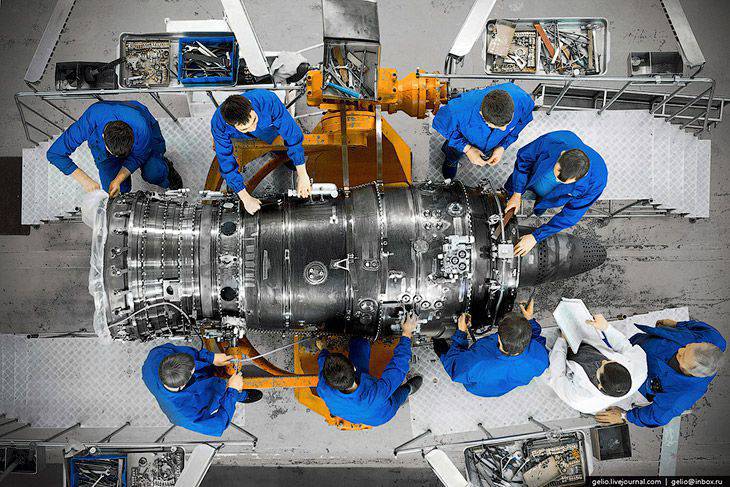

33. Final assembly. In the assembly shop, individual parts and components become a whole engine. Here work mechanics mechanic assembly works of the highest qualification.

34. The large modules assembled in different parts of the workshop are joined by assemblers into a single whole.

35. The final stage of assembly is the installation of gearboxes with fuel-regulating units, communications and electrical equipment. A mandatory check for alignment (to exclude possible vibration) and centering are performed, since all parts are supplied from different workshops.

36. After the bearer tests, the engine is returned to the assembly shop for disassembly, washing and fault detection. First, the product is disassembled and washed with gasoline. Then - an external inspection, measurements, special methods of control. Part of the parts and assembly units are sent for the same inspection in the workshops. Then the engine is collected again - for acceptance tests.

37. A fitter assembles a large module.

38. MSR locksmiths assemble the twentieth century’s greatest engineering, a turbojet engine, by hand, strictly checking technology.

39. The Technical Control Department is responsible for the impeccable quality of all products. Supervisors work at all sites, including - in the assembly shop.

40. In a separate section, a rotating jet nozzle (PRS) is assembled - an important structural element that distinguishes the AL-31FP engine from its predecessor, the AL-31F.

41. The service life of the ORS is 500 hours, and the engine is 1000, so nozzles need to be made twice as much.

42. On a special mini-stand, check the operation of the nozzle and its individual parts.

43. The engine equipped with ORS provides the aircraft with greater maneuverability. By itself, the nozzle looks pretty impressive.

44. The assembly shop has a site where reference samples of engines that have been manufactured and manufactured over the last 20-25 years are exhibited.

45. Tests of engines. The test of an aircraft engine is the final and very crucial stage in the technological chain. In a specialized workshop, bearer and acceptance tests are carried out on stands equipped with modern automated process control systems.

46. In the course of testing the engine, an automated information-measuring system is used, consisting of three computers combined into one local network. Testers monitor engine parameters and bench systems solely by computer readings. The test results are processed in real time. All information about the tests carried out is stored in a computer database.

47. Assembled engine is tested according to technology. The process can take several days, after which the engine is disassembled, washed, defect-proof. All information about the tests carried out is processed and issued in the form of protocols, graphs, tables, both in electronic form and on paper.

48. Appearance of the test shop: once the rumble of tests roused the whole district, now no sound penetrates.

49. Shop No. 40 is the place from where all the UMPO products are sent to the customer. But not only - here the final acceptance of products, units, input control, preservation, packaging is carried out.

The engine AL-31F is sent to the package.

50. The engine expects a neat wrap in layers of packaging paper and polyethylene, but that's not all.

51. The engines are placed in a special container designed for them, which is marked depending on the type of product. After packaging, the package is supplied with accompanying technical documentation: passports, forms, etc.

52. Engine in action!

Information