Cunningham Factory Tanks

As Andrei aka MooH, a companion correctly noted, the American system for the development of military equipment was completely different and different from the Soviet one. In the Soviet Union, specialized design bureaus and factories were engaged in the development and production of weapons, that is, this process was singled out in a separate branch of industry - the defense industry, which is exclusively controlled by the state.

In the USA, from the very beginning of mechanization at the front, this interesting and profitable business was given into private hands, if not in everything, but in many respects. So, on the one hand, it seems to be good in that many firms, apart from military orders, also have civilians, and this significantly reduces financial risks. In this case, even among such “enthusiastic” people like Walter Christie, there is a chance not to disappear right away in the debt trap, but to stay afloat for some time, giving a lot of sensible ideas to the mountain. But, on the other hand, such a state "tender" procedure for the production of military products makes it much more expensive. No, of course, state acceptance commissions always choose what is better and cheaper (if they are not bought in advance), but any “private trader” will never work at a loss and, naturally, will try to cash in as much as possible. In tsarist Russia, by the way, such a scheme was also practiced, but there the “cut-and-roll” was wildest, but in the USSR collectivization and the absence of private entrepreneurship simply would not allow such a phenomenon to appear.

So, let me introduce you to one of the "pioneers" of American tank building - James Cunningham, Son & Company. And then all the fans of World of Tanks happily threw up their hands. Well, of course, you know at least one of their cars, but you don’t know how fun it is to look for grains of sensible information among the endless "reviews and guides", and yes, even in English-speaking Google.

James Cunningham

Founder James Cunningham himself and his son Joseph before production tanks did not survive (1815-1886 and 1842-1914, respectively). James was an immigrant from Ireland, somehow a son, and preferred a career as a producer of a split farming life. In 1834, together with a company of associates, he organized an office (and later an entire factory) for the production of horse-drawn carriages. And the wagons are very different, for every taste: from mail stagecoaches to hearse.

On the last journey ...

Going through the hardships of business to commercial success (and there was anything, up to a completely burned plant) in 1908, the company started to produce cars in step with progress. True, not to a wide market, but mainly for its regular customers. And how they made it ... They made the hulls themselves and completed them with spare parts from subcontractors. In 1916, by the way, this “small” family business produced the first American car with a V-8 engine. Then there were more planes, but there were no tractors. Russian-speaking sources insist that they were, but English-speaking people mention agricultural products only in the period after the end of World War II. But we, of course, are interested in tanks ... At once I will make a reservation that some models of Cunningham were developed simultaneously, therefore there will not be a clear time sequence of the model range.

Handsome from 1919

Cunningham T1E1 / T1EX3 Light Tank

Immediately after the end of the First World War, the American military leadership began a search for the best way to develop armored vehicles. The only light tank in service with the United States at that time was the French six-ton Renault, which was produced under license, but I wanted something of my own. So far, back and forth, by 1922, the technical task for the production of a light American tank was ready. Naturally, everyone could participate. According to the task, the two-seater had to be armed with an 37-mm cannon and a machine gun of the 0.30 caliber, anti-bullet armor and speed at the level of 20 km / h. The hardships began in search of the best layout solution, initially only on paper, but Cunningham's 15 March 1927 received a government order to produce a prototype lightweight Cunningham T1 tank. Please note that it is not the adventurous approach of Christie, when it is first done, then it is shown, but a long, thoughtful work with the drawings, and work in coordination with the army team from Rock Island Arsenal. So, what was this prototype? In the process of working on “bugs”, they decided that the layout of “renochek” does not correspond to fashion trends. T1 made with a front engine, in fact - armored vehicle. Yes, and the chassis took the tractor with a large number of small road wheels (8 on board) and the lack of suspension as such. The driver with the commander-shooter had to sit behind the engine in the armored jacket. One thing is good - the tower was.

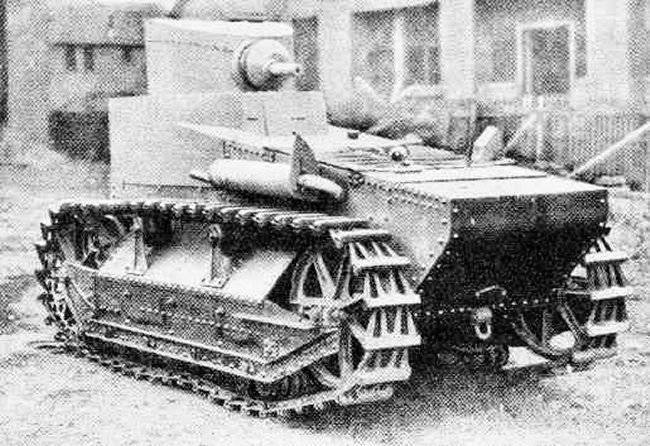

The first prototype T1

The car was demonstrated on September 1, however, due to haste, wooden mock-ups were installed instead of an armored tank and a tower. Naturally, the running gear, not very adapted to overcome trenches and funnels, immediately made itself felt. Oddly enough, for all thehistorical"The erroneous placement of the modules, the new tank in the tests showed superiority over the" six-ton ". Perhaps the blame for the successful V-8 engine with 110hp and reliable box 3/1. The maximum thickness of the reservation of vertical surfaces reached 10 mm. The body was made partly by welding, partly by riveting. In the process of testing, the machine was slightly disassembled, removing the wooden case and the tower, and the result was an armored personnel carrier, which, in principle, was called - Light Cargo Carrier T1. So if you please love and favor - the first American armored personnel carrier.

The military, without much thought, ordered Cunningham's as many as six cars: four Light Tank Т1Е1 and two Light Cargo Carrier, also Т1Е1. The new tanks differed from the prototype in the first place by the hull, which now did not go beyond the dimensions of the tracks and the fuel tanks placed on the sides of the cabin above the tracks. Also, several modernized air circulation system in the engine compartment. Well, of course, now instead of the model of the turret, there was a full-fledged one with a pair of 37-mm cannons and Browning 0.30 machine guns.

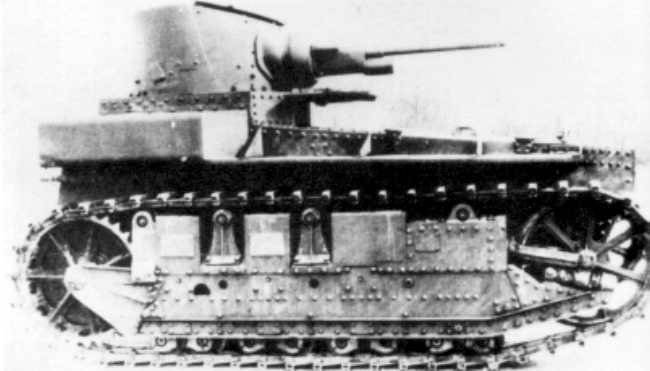

T1EX1

24 January 1928, the tank was adopted under the designation Light Tank M1 (generally a wild confusion they have with these indices). The machine weighed 7 tons, had a power supply in 16 hp / ton, a maximum speed of almost 30 km / h and a power reserve of 120 km. On June 20 of the same year, all the 4 T1EXNNXXs ordered were ready and went to Fort Meade, Maryland. There, in the first Experimental Mechanized Brigade, they continued to test them in every way. Of the interesting things: one of the tanks for 1 days passed more than 57 thousands of kilometers without a single serious damage, which is quite impressive compared to the old six-ton trucks that ran an average 3 km from repair to repair.

The tests were quite good, the result was a number of comments, one of which concerned the thickness of the reservation. The maximum for T1EX1 was only 10mm, while for М1917 it was 15mm. 8 December 1928, the company Cunningham received an order for the upgraded machine - Т1Е2, which was already ready for 3 June 1929, and delivered to Aberdeen for testing. The new tank, of course, was different from its predecessor. Primarily boosted to 132 l / s engine. The thickness of the reservation was increased and now reached 16 mm in frontal projection. The outdated 37-mm M1916 fluff was replaced by a long-barreled semi-automatic from Browning with an initial velocity of the projectile 600 m / s. Slightly simplified the design of the tower, paying tribute to the manufacturability of production. Naturally, the weight of the equipment increased to 8 tons, and the linear dimensions increased, so we had to upgrade the suspension.

One of the 1EX2 is preserved and is now stored in Aberdeen.

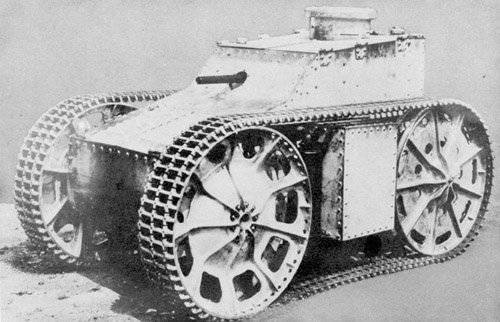

Again, the unsatisfactory permeability of the new tank insisted on doing something about it. As an experiment, we took the second T1EX1 car and significantly altered the chassis by installing spring springs with hydraulic shock absorbers. Engine and gun taken from the new T1-2. Also replaced the 6-volt electrical system on the 12-volt. New technology received the designation T1EX3 and in April, 1931 went to the test site. The test results showed significantly improved patency compared to its predecessors. At the same time, multiple technical flaws and difficulties in production prevented the T1 from being “on stream”, but Cunningham did not fold its hands and continued the research.

Т1Е3 with long barrels

Cunningham T1E4 / T1E6

It is quite obvious that the front location of the engine in a tank at least complicates the work of the mechanic drive, limiting its visibility. To the heap was added increased gas content of the fighting compartment. This was one of the reasons why Cunningham decided to radically alter their tank, namely, turning the engine back, with all the associated alterations. The question of the suspension remained open, but just at that time in the USA they tested the new Vickers 6-ton with which they licked safely. Well, as they licked, what was there to steal it? Took ordinary semi-elliptical springs and installed on the support rollers. In principle, it turned out quite a good machine. The engine was put all the same V-8, only now on the 140 hp There were still some problems with the transmission, but they were successfully solved. Armament and booking remained the same. By the way, the tower was still being installed as on T1-1, and not modified from T1-2. The new tank received the designation T1EX4.

T1EX4

With the next version came curiosity. This machine falls out of the line several. As part of testing the transmission system, namely, the differential, they took the fourth T1EX1 manufactured in a row, installed a new engine (which is hp on 140) and transmission elements, respectively. This is the tanchik and received the designation T1EX5. That is, formally, it belongs to the previous family. This is all American confusion to blame.

Meanwhile, work on improving his brainchild of the engineer continued. And in the arena appears T1EX6. The tank was different from its predecessor, the new 12-cylinder engine with an 245 horsepower. Naturally, the dynamic characteristics improved. Now the maximum speed was 32 km / h, but the weight also increased, which did not have the best effect on controllability and terrain. And besides, the maintenance procedures have become more complicated.

T1EX6

The army refused further work to improve this family of tanks.

Cunningham T2 Medium Tank

The first unsuccessful attempts to create an adequate medium tank naturally led to the appearance of an 11 March 1926 order from the military authorities to continue working on this issue. Began long painstaking searches for layout solutions. The maximum mass of the machine should not exceed 15 tons. Finally, by 1929, the design of the tank was finally worked out in the Rock Island arsenal. The basis taken T1X1 factory Cunningham. In addition, quite a significant impact on the concept of the prototype had a "fresh" at the time the British Vickers Medium Tank.

New T2 Cunningham already by 1930 year entered the state tests. His crew consisted of 4-x people, full weight reached 14 tons, and the power of the Liberty engine - 338 hp The maximum speed of the car reached 40 km / h, despite the fact that a bit later the maximum speed was reduced to 32 km / h to increase the service life of the transmission and gearbox. It would be very curious to know exactly how the speed was reduced? Not electronically, maybe the box was installed new with other gear ratios, but I could not find any data about it.

T2 medium surrounded by gentlemen

The T2 gun turret was equipped with an 47-mm semi-automatic cannon and a Browning 0.50 heavy machine gun. This already impressive enough arsenal was supplemented by the installation of an 37-mm gun in the front hull sheet, next to the driver, or the commander didn’t get bored, or the loader ... A weight was installed on the main cannon for balancing the breech, much like on the gun mask. In the process of testing in October, 1931 of the year 37-mm refused and replaced it with a conventional machine gun caliber 0.30. The booking thickness of the T2 tank ranged from 22 to 6, which is actually quite good for the 1930 of the year.

On the test machine showed itself very worthy. The amortized suspension protected by an armor plate worked well, and the powerful engine gave confident traction. However, in January 1932, the tests completed. And, although T2 was called the best tank, which passed state tests, the car was not accepted for service. Guilty was the notorious savings on the financing of the army, which in 30-s reached a significant scale.

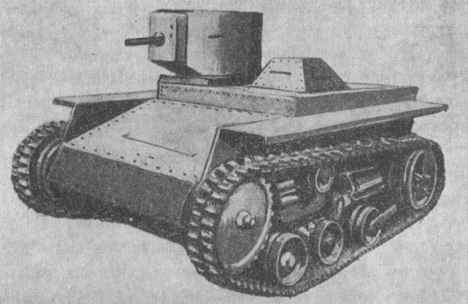

Experimental tank chassis Т1 / Т2

In addition to working on a clear design assignment from the army team, Cunningham did not disdain an experiment. For example, in 1926, the T-1, an experimental tank chassis, was developed and built by the Tank Development Chassis. Single armored box with weapons from one Browning 0.30 machine gun and booking only 3 mm. The most interesting thing was the chassis with four large-diameter road wheels. The machine was positioned as a light reconnaissance wedge. The engine was installed four-cylinder from Ford A, hp power 42. Despite the fact that the wedge was not interested in the military as weapon, it nevertheless served for a long time as a test bench for new types of caterpillars, including those with rubber tracks.

Tank Development Chassis

The next experimental chassis was a model outwardly similar to the Light Cargo Carrier T1, the difference in the chassis design was that instead of the eight, only the 4 skating rinks were installed on board, and they were sprung using semi-elliptical springs. Later, in the framework of tests, an 75-mm howitzer was installed on this base. The engine there was a V-8 LaSalle, hp 87 power, and the reservation reached 10mm.

The Cunningham Scout, proposed in 1934, was probably inspired by light patrol Wickers. Little is known about this car. Only that it was a two-seater, with machine-gun armament located in the tower shifted to the right side. The running gear consisted of three basic skating rinks on board, one supporting well and the leading skating rink paired with a carrying sloth. It is not known whether the prototype was made and if so, what was its fate. At least, I did not find such data.

T4 Armored Car

The development of armored car firm Cunningham led in parallel with the tank business. As with the other branches of armored vehicles, the army at that time was in a creative search. Dense work with the customer led to the fact that the T4 became the first standardized armored vehicle of the American army. The infantry was not very interested in them, believing that they were only suitable for reconnaissance, but the cavalry wanted passionately. In 1931, two cars were made, which immediately went to the test. The layout was standard for the 30-ies, it was based on a heavy three-axle truck, driven by two rear axles, mounted on it an armored corps, and on top a turret equipped with twin Colt-Browning M1921 machine guns and Browning M1919. Also, an additional machine gun could be mounted in an onboard installation. The booking thickness reached 10 mm, and the total weight of the car was over 4,5 tons. All this mass was driven by a V-8 Cunningham engine with 133 horsepower.

Despite impressiveness, the armored car showed a slight decrease in driving performance compared to lighter brethren, and the maximum speed in 90 km / h did not leave a chance to competitors. The car was adopted under the symbol M1 and, before 1938, they riveted and welded 20 machines that cavalrymen used with pleasure until the very beginning of World War II.

Cunningham 4.2 "(107mm) Chemical Mortar

If you remember, one of the results of the work on the T1EX1 tanks was the 2 BTR without an open-hull tower. Here is one armored carrier decided to convert into a self-propelled mortar. Now such experiments with MT-LB are practicing. They hoisted the T1 into the body as much as a whole, and the whole 107-mm chemical (!) Mortar, which at that time was a regular American WMD. In addition to the possibility of infecting the territory of a potential enemy with poisonous filth at a distance of 4-x km into the distance, it was possible to shoot with ordinary ammunition. The experiment failed, because the return of large-caliber weapons was too large for a light tank chassis.

A little later, somewhere to 1935-mu tried to put a mortar on the chassis of the Cunningham mortar carrier - a specially designed tractor, but this attempt was not crowned with success. By the way, the information about this tractor is found in English-speaking sources, and is indicated exactly as Cunningham, but there is no detailed information about it.

Presumably Cunningham Prototype

Cunningham flamethrower

Well, for a snack interesting. In addition to self-propelled mortars on the chassis Cunningham mortar carrier in 1940 year built a flamethrower tank. It all started with the fact that the Kinkaid Company developed a large-size flamethrower for installation on a self-propelled chassis. Since the experimental development was carried out not for a specific machine, but in general, it was of little use for installation on the tanks that were in service. They took the first suitable technique, which turned out to be this “Motor Carrier”. An armor was put up, fire mixture cylinders were installed outside (the test bed), the product was designated E1, and let's experience it. The successful design of a benzo-kerosene-oil flamethrower allowed “splashing” more than 70 meters, and the total spraying time of the mixture exceeded half a minute. After conducting a series of tests during the year, the military smoothly switched to the E2 sample, and the experimental Cunningham Flamethrower safely sunk into oblivion.

Note that the flamethrower is made on the same chassis as the mortar from the previous photo

This is where the history of the Cunningham armored vehicles ends. In RuNet, there are still mentions that the T4 tank was also developed and produced by this company, but do not believe them. Т4 was developed by experts from Rock Island, while actively using the developments of Christie. This is how it is.

Sources used:

http://www.aviarmor.net

http://amhistory.si.edu/archives/AC1193.html

"US Army Flamethrower Vehicles" by Cpt. John ringquist

"A History of the American Light Tank" by RP Hunnicutt

"A History of the American Medium Tank" by RP Hunnicutt

"A History of the American Wheeled Combat Wehicles" by RP Hunnicutt

Information