Bulletproof glass. Compromise of mass, value and characteristics

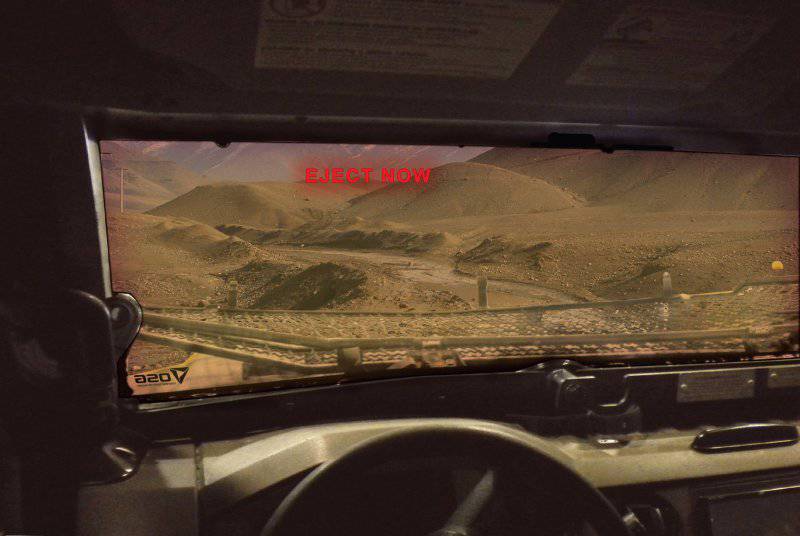

In order to increase the service life of armor glass users should use special measures in difficult environmental conditions. Pictured is M-ATV armored cars in Afghanistan.

The need for better situational awareness, which appeared along with the combat missions of asymmetrical combat operations, in which military units must move in civilian surroundings and avoid indirect losses, led to a sharp increase in the number of military vehicles with large armor glasses, allowing the driver to have a much better view. surrounding area, and soldiers sitting in the aft compartment, a better understanding of the local situation.

Although protection was the number one priority, all Mrap machines (Mine Resistant Ambush Protected, i.e. “protected from mines and ambush attacks”) were equipped with wide glass surfaces. But, despite the fact that some new cars that fall into the combat category, the windshields also began to be installed, they were still limited in size. With increasing levels of protection, mass, transparency and distortion have become a problem. With the same level of protection, standard armor glass has a surface density of four times that of armor steel - a problem that must be taken into account at the design stage. The size of transparent armor is also increasing, which creates certain problems, especially where new technologies are applied. In some armies, it is believed that in a light patrol car a two-pane windshield with a central pillar gives it an aggressive look and therefore they prefer a one-piece windshield. In addition, since many machines are currently manufactured with a basic level of protection, they must then be upgraded by installing additional booking kits. This means that they must also include an appropriate upgrade of the transparent protection, which of course creates a huge problem with the prevailing method of screwing glass panels onto the bolts.

The mass of more durable windshields and side windows is not only a negative factor, compared with opaque armor, the thickness also increases significantly, not to mention the deterioration of optical properties, since with increasing thickness the light transmission tends to decrease and distortion to increase. Given the growing market and demand over the past few years, manufacturers of armored glass have worked hard to solve the mass-defense puzzle. This was achieved by increasing the efficiency of standard laminates (laminated materials) and the study of alternative materials, such as transparent ceramics. In addition to the fact that some manufacturers are quite successful in finding the optimal density-protection-visual quality ratio, they see transparent protection as an ideal medium that can present large amounts of information to the driver and possibly even other passengers of the car. Projection displays from aviation - An interesting solution that could help improve ergonomics and reduce workload.

Recent missions in areas with large temperature variations (as a result, there is a big difference between the temperature outside and the temperature of the air-conditioned cabin), with sandstorms, etc. have a significant impact on transparent armor with sad consequences for its service life. Given that ground vehicles cannot be compared with aircraft in terms of maintenance costs, this cost should be reduced as much as possible, and it should be part of the equation along with weight and performance. Vehicle operators, of course, must also take measures to protect parked cars, as well as follow special techniques for cleaning armored glass. An important role in reducing the cost is also maintainability.

In order to improve the performance and reduce the weight of its transparent armor, the German company Schott uses the patented Borofilat borosilicate glass, which has very good optical characteristics.

Trends

The purpose of this article is not to review products of all manufacturers of transparent armor around the world (and their number is growing every day. For example, in October 2013, the Mexican National Defense Secretariat announced the creation of another armor glass manufacturing plant), but a desire to identify the latest trends. in this region. Most manufacturers look at both civilian and military markets. The largest of these are American Glass Products (plants in Colombia, Brazil and Peru) and the French Saint-Gobain Sully. In the US, there are also many companies in this area, for example, PPG Aerospace, which manufactures transparent armor that meets Stanag standards (typically, levels from 1 to 3) and US ATPD 2325P (levels from 1 to 3).

Another major player in the arena of transparent armor for the military is the German company Schott. In addition to manufacturing in Germany, which produces armored glass in accordance with Stanag, the company also has a branch in America that produces glass in accordance with US standards, but independent of the International Trade Rules weapons. The current European product for military use is Resistan, which varies from 1 level to 4 level of Stanag 4569 standard and in which the identification number indicates the thickness in millimeters. In its production of transparent protection products, Schott uses Borofloat 33 high-quality borosilicate glass with outstanding properties, which allows you to reduce weight by 12-15% compared to silica glass while maintaining optimal optical performance.

In the 2013 year, three new types of glass were introduced, corresponding to the Stanag 2 and 3 levels. For 2 level applications, NY 52 BF armor glass was developed by optimizing the design and lamination, it is designed for machines operating under normal temperature conditions from –32 ° C to + 49 ° C; the material has a surface density of 112 kg / m2 and ensures 86% light transmission. The glass was fired at 20-mm with a single FSP fragmentation projectile at speed 630 m / s and universal armor-piercing incendiary bullets (API) 7,62x39 mm. NY 58 BF glass density is 124 kg / m2, which is approximately 10% more than NY 52 BF density (respectively, increased weight and thickness), but it has a larger operating range (up to + 75 ° C) and is tested against fragmentation ammunition with a higher initial speed (700 m / s) and more powerful armor piercing incendiary bullets 7,62x51 mm.

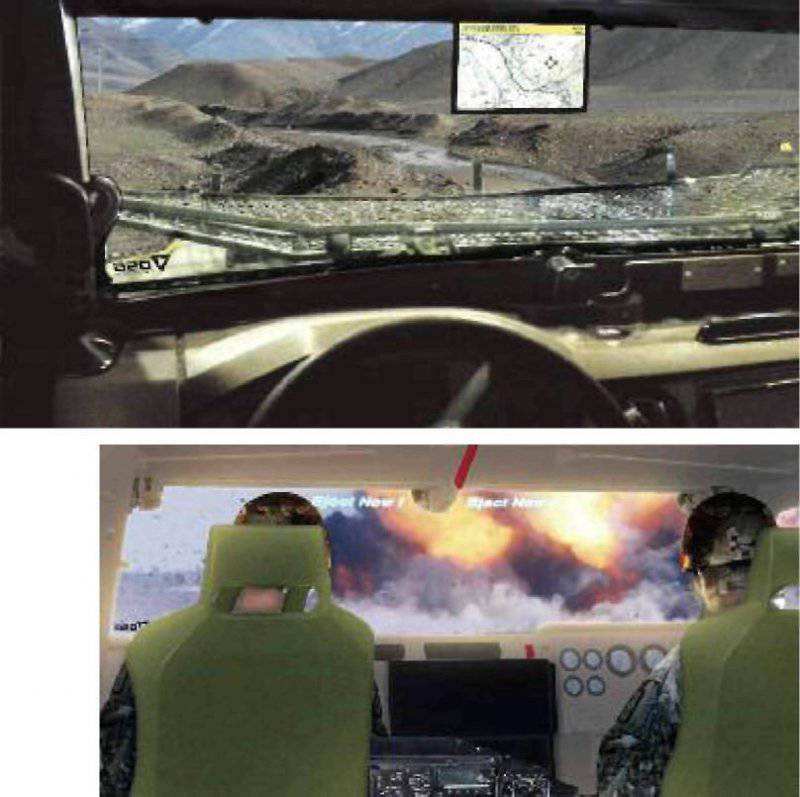

OSG's Digital Visual Window technology (top) can integrate a digital display into armor glass without reducing the level of protection, while the Silk-light technology (two pictures below) allows short warning messages to be inserted into the windshield.

There are two new products on the market that match the 3 level. They can significantly reduce the mass compared to the previous type of glass NY 92 BF, which is qualified for high temperatures and is definitely stronger, since with a surface density of 195 kg / m2 XB can sustain 20-mm projectile FSP at speeds above 1250 m / s, as well as 7,62X54R API, 7,62x51 API and regular 12,7xXNNUMX bullet. The new NY 109 BF is notable for 80 kg / m174 density (2% reduction), although the tests did not include 10 mm bullets, while the NY 12,7 BF comes with 69 kg / m153 density (2% less than the NY 22) and it was tested only against the 92x7,62R API. As for the level of 54, here the company Schott offers two types of glass from its family Resistant. These are NY4 with a density of 135 kg / m284 and NY 2 with a density of 194 kg / m398. Both withstand an 2-mm FSP projectile at speeds above 20 m / s and an 1550x14,5 API cartridge, although thinner glass is tested for only one hit, while thicker glass has multiple impact characteristics. According to Schott, the NY 114 glass is the only approved and certified glass a solution that meets the 194 level, since it was certified by the BAAINBw (former BWB) German Armaments Office. The Resistant catalog includes many other products, the VPAM family conforms to EN 4 and VPAM BRV 1063 standards, and the DV family ATPD Revision T standards. In order to better respond to market needs and increase production, not only for the military, but also for civilian needs, Schott recently redeveloped its flat laminated glass manufacturing plant into a fully integrated line, which also includes bending with bending radii 2009-500 mm and edge processing.

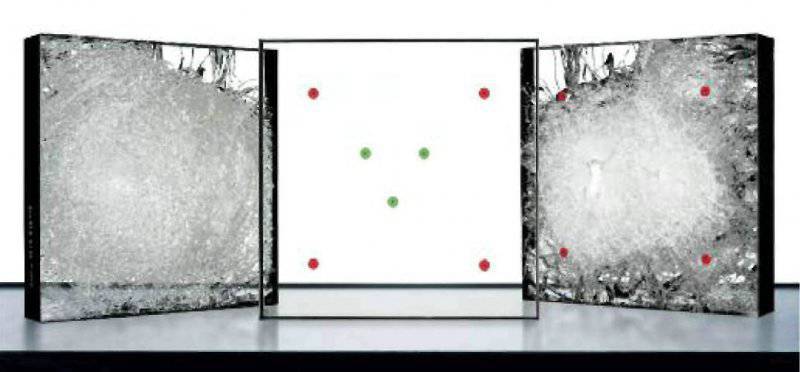

The Israeli company Oran Safety Glass has developed Adi technology, which eliminates the internal anti-splinter polycarbonate layer, which according to OSG doubles the service life of glass

Looking into the future, Schott is closely studying new materials, such as transparent ceramics and spinels (a group of natural and artificial minerals of a class of complex oxides that have high hardness). Considering the strict rules of the road in Germany, the company believes that the optical characteristics offered by such alternative materials cannot be accepted for windshields, but due to their light weight they could be well suited for side windows. However, the cost of such innovative materials has yet to be determined. As for the classic laminated glass, Schott experts believe that currently available technology will not allow any improvements in the coming years. Such glasses approached their limit corresponding to the 3 level, which corresponds to a thickness of approximately 75 mm and a surface density of 160 kg / m2. Schott North America specializes in glass ceramics, polycrystalline materials, manufactured by controlled crystallization of glass base, mainly due to heat treatment. During processing, a crystallized surface layer is created with a thickness of 35 nanometers, while the rest of the ceramics has a crystal structure on 80%. This material does not give weight savings, but complies with the American ATPD-235 standards (although the results obtained remain classified).

Another key player in the field of armor glass is Oran Safety Glass (OSG) from Israel, the only supplier of the Israeli army. The company supplies flat and curved armored glass to the first-tier states, such as the USA, France, Germany, Italy, etc. OSG, in particular, is focused on the US market, although its armor glasses are built on two out of three JLTV vehicles. To achieve this goal, a company with two factories in Israel established its OSG Inc branch in Virginia. OSG certainly seeks to reduce weight for this level of protection, but it also aims at further development, at combining various technologies in its products in order to add such “lotions”, such as defrosting to improve visibility within 30 seconds at –42 ° C.

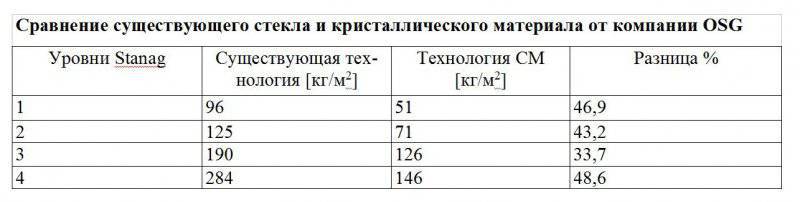

Using semi-exotic materials, OSG recently developed a solution with a density of 170 kg / m2 and a thickness of 83 mm, corresponding to the level of 3. In order to maximize the service life of its laminated glass, the company has developed a special sealant to combat the effects of heat, humidity, sand and the effects of air conditioning. OSG also offers its own Crystallized Material (CM) technology, which makes it possible to reduce weight by 30 - 50% (see the table) with a decrease in thickness from 40 to 60%. Of course, the weight reduction in this case is more significant, since it is necessary to take into account the weight reduction of the glass frame itself. Here the problem is not only technical, but also economic, since ceramic-type glass is significantly more expensive than standard bulletproof glass.

The technology of crystallized material allows OSG to produce transparent armor three times cheaper than the cost of analogues of laminated glass. The Israeli company has also developed two new technologies in order to improve the characteristics of laminated glass. The first was designated the Rock Strike Glass (RSG) and is intended to prevent splitting of the inner glass layers in the event of low-velocity fragments, like gravel and stones. This not only allows the driver to continue driving with a minimally impaired view, but in most cases the glass will not require immediate replacement, which saves time and ensures greater readiness of the fleet. Since there are no standards related to this problem in the military sphere, OSG has taken French railway standards as a basis, according to which a conical object with a diameter of 90,5 mm and a weight of 20 gram after impact at speed of 40 m / s should not cause any damage. These figures for military use have been increased to 140 m / s; as a result, the OSG RSG glass showed resistance to multiple impacts at speeds of 160 m / s.

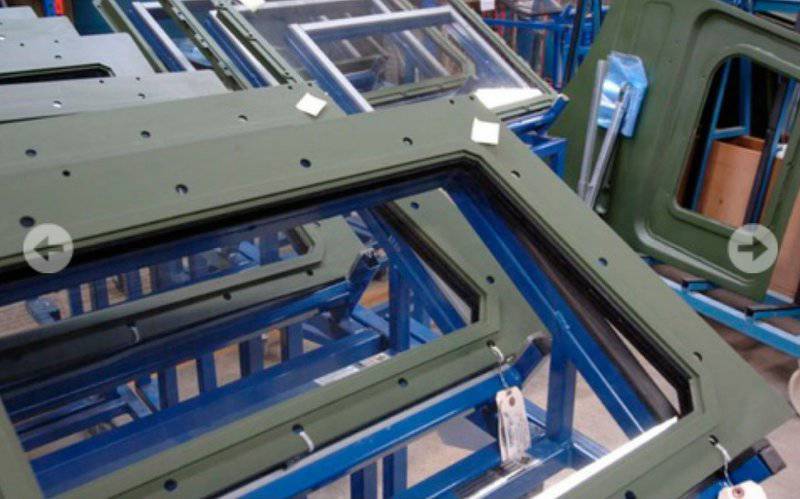

Transparent armor from the German company GuS. The company has supplied transparent surfaces for German Dingo machines in Afghanistan and is currently considering switching to ceramics

Another technology under the designation “Adi” (a Hebrew jewel) was shown at DSEI 2013. Today, typical laminated glass has a polycarbonate inner layer, which prevents fragments from spreading inside the machine when it enters the glass. According to OSG, a bundle of glass and polycarbonate accelerates delamination, polycarbonate can also be damaged by improper operation or cleaning. The statistics provided by the company show the expected service life of three to five years for ordinary clear glass in the field. Adi technology will provide fragmentation without polycarbonate plus doubling the life. OSG has been working on this technology for more than two years. The latest ballistic tests were carried out in the fall of the 2013 of the year, and Adi glass production began in the 2014 of the year.

OSG is also working on the use of glass surfaces as illustrative tools. The Silk-light technology (silk light) allows you to create an embedded light-controlled electronic system that allows you to demonstrate simple (mostly emergency) messages right on the armor glass. Also, the digital visual window technology (Digital Visual Window) allows you to integrate the LCD display in transparent armor without reducing the level of protection, allowing you to save space in the car. The display is connected to a separate electronic unit that can be easily repaired or replaced.

Glas und Optik GmbH, better known as GuS, is another major German manufacturer. In early September, 2013, the German management of BAAINBw qualified the new laminated glass for compliance with Level 3; its density was reduced from 215 to 170 kg / m2 (-20% mass) and thickness from 91 to 83 mm, while the operating temperature range was increased from –32 ° to + 49 °. In addition, its multi-impact characteristics were tested on a triangle with a base 120 mm instead of the usual 300 mm and the imprint was very small, thus the effect on the rear polycarbonate sheet was much reduced. As the only supplier of the German army, GuS showed its repair capabilities in Afghanistan, where stones were damaged around 3500 windshields (more Dingo 600 machines were deployed there), many of which were repaired by the company’s working group. In the field of transparent ceramics, GuS also runs many research programs with the German company CeramTec GmbH. While the level of protection does not seem to be a major problem, the company encounters obstacles in the German rules of the road, as glue bonding ceramic tiles causes visual effects that still need to be assessed regarding eye strain, headaches and disorientation. GuS is currently working closely with BAAINBw to analyze side effects before moving further in the direction of ceramics.

At the DSEI 2013 exhibition, Jenoptik introduced plastic transparent protection. It is heavier and thicker than laminates, but has the advantage of no bending distortion.

The German company ESW GmbH, a division of Jenoptik Defense & Civil Systems, showed at DSEI 2013 transparent plastic armor, which guarantees light transmission over 90%. One of the biggest advantages of the Jenoptik solution is that the windshield can be bent; this allows you to get away from the central pillar, typical of military vehicle windshields, consisting of two flat panels of bulletproof glass, and thereby provide maximum visibility. In addition, the plastic transparent Jenoptik protector does not create any distortion, even at the bending points. The company currently offers two types of surfaces, respectively with protection levels 2 and 3. The first has an approximate density of 144 kg / m2 and a thickness of 121 mm, and the second has a basis weight of 238 kg / m2 and a thickness of 201 mm. The Level 3 solution is also certified to withstand multiple bullet hits and projectile charges in the 0 ° to 45 ° sector and to resist RPG-7 hits at 45 °. Anti-icing and electromagnetic protection are available upon request. According to Jenoptik, its clear plastic bulletproof glass is capable of maintaining good visibility even after impact.

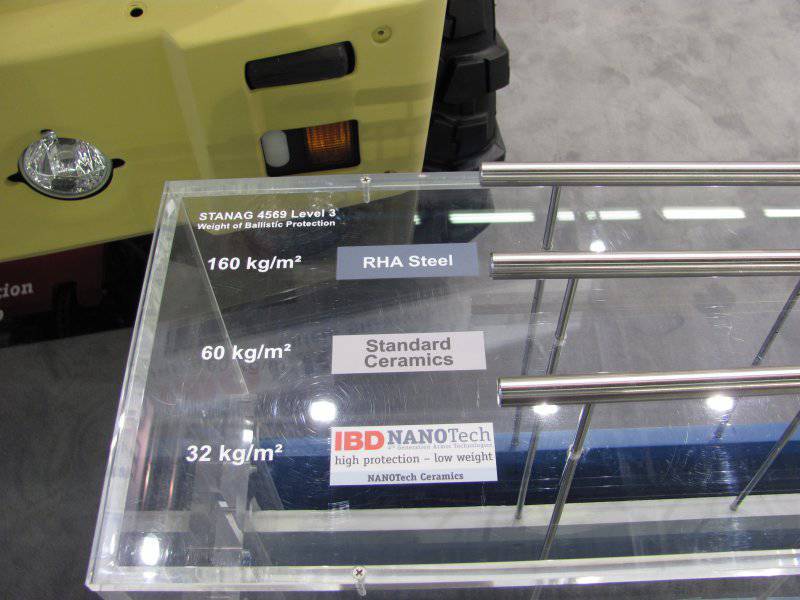

One of the authoritative European experts in the field of transparent armor is IBD. It was clear that a solution must be found in order to reduce the mass of transparent armor. Indeed, conventional armored glass for a truck with an area of 3 m2 not only weighs 600 kg, but also raises the center of gravity and catastrophically deteriorates stability. Using its NanoTech technology, IBD has developed protection from transparent ceramics, a key factor here is the development of special bonding processes for ceramic tiles (“mosaic transparent armor”) and lamination of these assemblies with strong supporting layers to form large transparent panels.

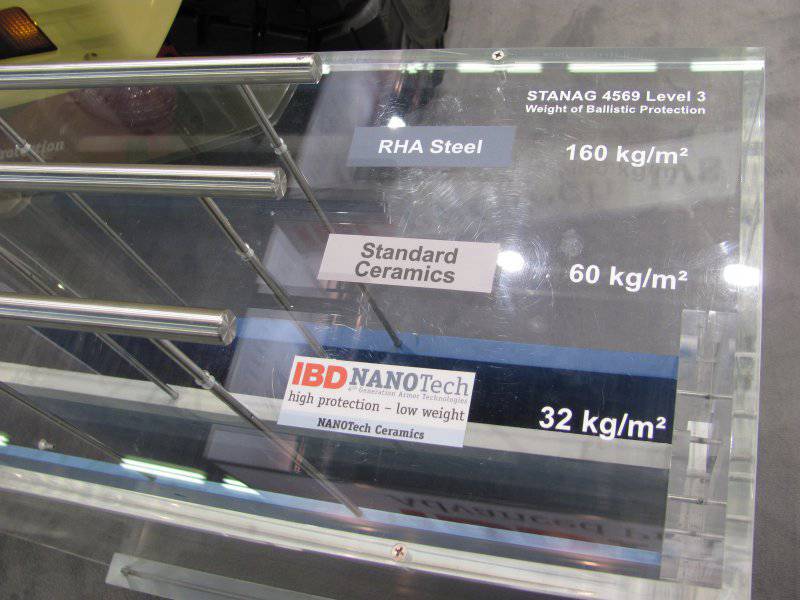

IBD Deisenroth developed tiles of transparent ceramics, as well as the technology of their gluing, which made it possible to create transparent armor that saves up to 70% mass compared to traditional laminated glass. The photo shows comparative samples of rolled homogeneous steel, conventional ceramics and new material IBD NANOTech, presented at Eurosatory 2014

The ArmorLine company makes spinel - the polycrystalline material allowing to reduce weight and thickness. It is used in multi-layered transparent armor.

Due to the outstanding ballistic characteristics of the ceramic material and the elastic absorption of residual kinetic energy, the company was able to obtain panels of transparent armor with a significantly reduced mass. Compared to the 200 density of kg / m2 of standard bulletproof glass, corresponding to the 3 Stanag 4569 level, the new technology reduces the mass of transparent ceramics for the same 3 level to 56 kg / m2. This represents a gain of 72%, which in absolute terms for truck windows, taken as an example, could mean 170 kg. According to IBD, the optical properties of new transparent ceramics are at least as good as the optical properties of traditional laminated armored glass, since it is less tinted and exhibits less diffraction, and also completely invisible edges of the glued tiles. These optical properties also extend to the infrared spectrum, meaning that night vision goggles can also be used. One of the NATO countries was faced with the problem of choosing reduced protection or adding another front axle for their trucks, but IBD’s solution allows you to either save the configuration with one bridge and save money, or double the number of bridges and increase the level of protection. According to IBD, its transparent ceramic protection is fully qualified and is currently at the implementation stage in which the optimization process focuses on cost reduction; The company's goal is to get a product of just 50% more expensive than standard glass. However, at the moment it is considered that it is possible to achieve a cost that is two times less than the cost of the current solution.

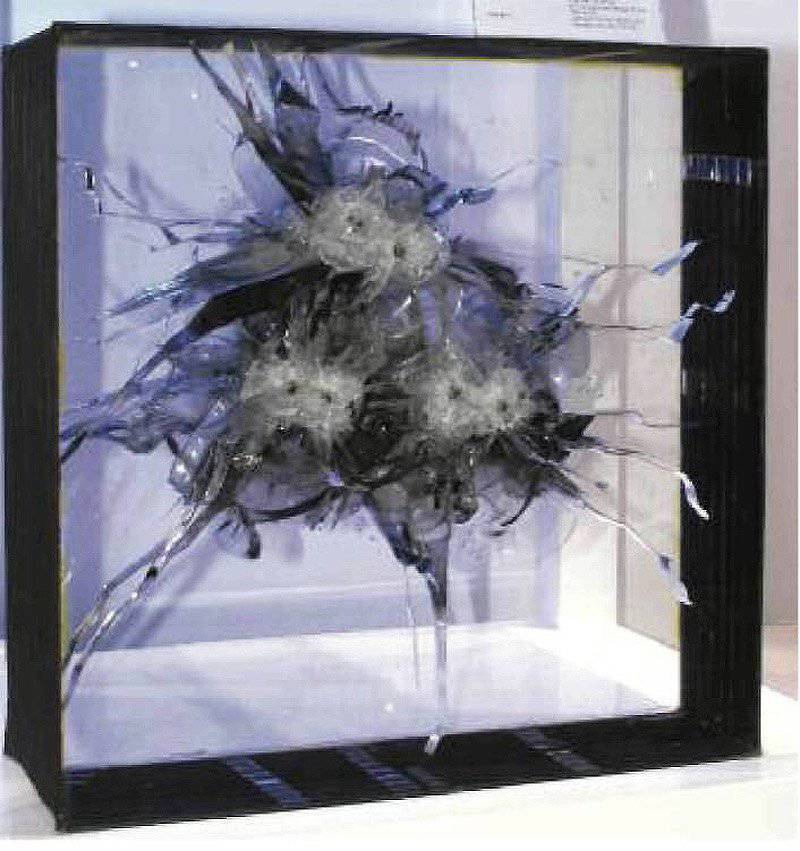

Multi-layer transparent protection 400x400 mm, made using spinel from ArmorLine, after six shots. The company hopes to start producing a half-size windshield by the end of 2014.

The American company ArmorLine, part of the Defense Venture Group, has developed optical spinel ceramics, which allows the manufacture of transparent armor with significant mass savings. ArmorLine's spinel is a polycrystalline material characterized by extremely hardness and strength; Featuring abrasive resistance, which is typical for ceramics, it guarantees translucency in the 0,2 - 5,5 micron range. This allows it to be used in the ultraviolet (0,2 - 0,4 micron), visible (0,4 - 0,7) ranges, the near-infrared region of the spectrum (0,7 - 3) and the middle infrared region of the spectrum (3 - 5). That is, it can be used in military applications not only as transparent armor, but also to protect sensors. The advantage of ArmorLine spinel is that it can be used to make panels of such dimensions that are definitely larger than the dimensions of transparent ceramic panels. The current large panels are approximately 70 x 50 cm in size, the company intends to begin production of 85 x 60 cm panels in the course of the year, both flat and curved (with a bend radius of 2500 mm) and, ultimately, the production of 100 flat panels x 75 cm, which is half the windshield.

The ability to supply curved transparent protection is seen as an advantage over other systems, allowing designers to implement more flexible solutions. Transparent spinel-based protection, which replaces several layers in laminated glass, has increased multi-impact characteristics and reduced weight and thickness by 50 – 60%. As an example, take a multi-layered armored glass that is able to withstand a hit of a single armor-piercing bullet 12,7x99 mm. It has a thickness of 103 mm and a surface density of 227 kg / m2, while the spinel from ArmorLine reduces these values to 49 mm and 100 kg / m2, in other words at 53% and 56%, respectively. These data are confirmed by looking at the transparent armor ATPD 2352 Class 3A, in which the thickness decreases from 112 to 52 mm, and the surface density from 249 to 109 kg / m2. However, ArmorLine does not deal with multilayered materials, that is, in these cases the masses are given for non-optimized test samples and can be further optimized. In terms of Stanag, the surface density achieved for transparent materials corresponding to the 2 level is about 69 kg / m2, whereas for the 3 level (armor-piercing incendiary bullet 7,62 x 54R B32) it rises to 84 kg / m2.

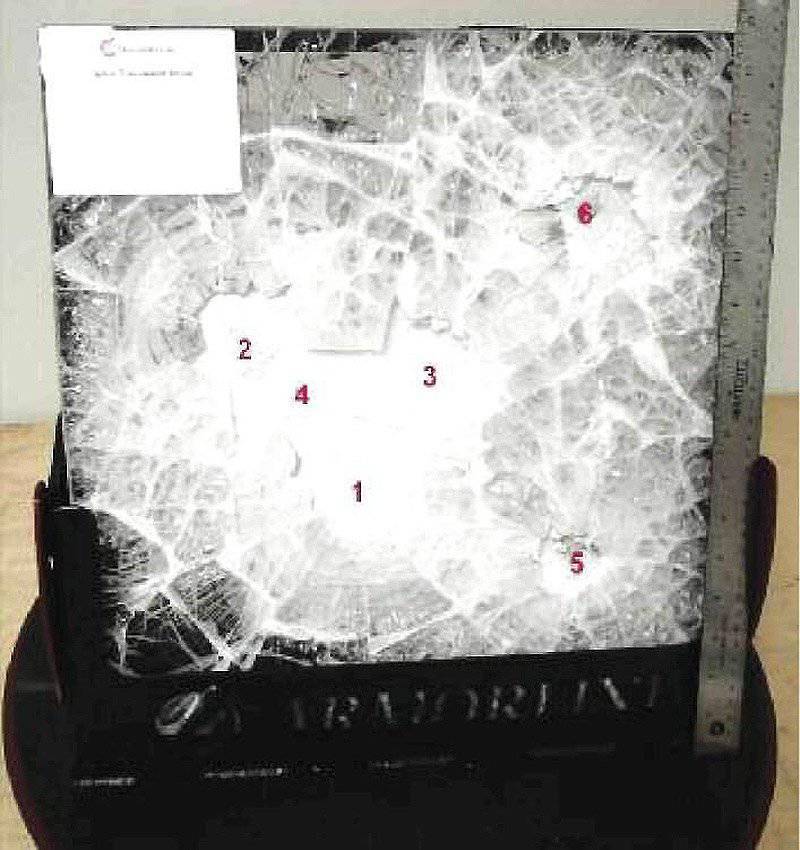

The Italian company Isoclima supplies Iveco most of the armored glass for the LMV Lince; in the picture is the glass after the shooting at the shooting range Nettuno

Among the technologies used to increase the strength of transparent armor, Isoclima has developed an encapsulation method that guarantees maximum service lines for its layered materials.

The Italian company Isoclima began working on transparent armor at the beginning of 80 for the civil and military markets and has since developed its own proprietary technologies for optimizing glass and polycarbonate lamination. She provided most of the transparent protection solutions for Iveco DV LMV, which were adapted to the requirements of different customers of this lightweight multi-purpose vehicle 4x4. For example, transparent armor, adopted for Russian LMV machines, is able to withstand temperatures from -45 ° C to + 70 ° C, the conjugation of different materials is a key element here, since the thermal expansion coefficient of polycarbonate is eight times more than the glass expansion coefficient. Among its products, we can find a solution that matches the 2 Stanag level, 58-59 mm thickness and 125-130 kg / m2 surface density, and a solution that corresponds to the 3 level, 79-80 mm thickness and 157-162 kg / m2 density; all values are given for operation in standard temperature limits.

The company is currently considering new solutions that improve performance while reducing weight. The company is testing new materials, such as spinel and others, although its leadership is convinced that improvements lie in comprehensive solutions, that is, improving the characteristics of glass and laminates, such as films, will allow Isoclima to improve its market position. The company also developed solutions to improve the service life of transparent protection, for example, anti-scratch treatment on a polycarbonate substrate, as well as a proprietary magnetic-fixed outer layer that protects the ballistic glass from stone damage known as Antistone Protection Solution (AspS). The removable protective layer is based on a double-layer magnetic gasket that holds the outer protective layer made of external glass and an internal technopolymer; an air gap is created between this layer and the transparent armor. All possible deficiencies, that is, condensation, optical distortion, etc., were taken into account and verified, tests showed a minimal effect of these factors on the characteristics of transparent protection. On the other hand, AspS technology contributes to a significant reduction in maintenance volumes and increases the service life of transparent armor. Many of the solutions developed by Isoclima are created thanks to the company's participation in the design of modern transparent protection systems for the aerospace industry.

Materials used:

www.armada.ch

www.baesystems.com

www.schott.com

www.osg.co.il

www.gus-visionsystems.com

www.jenoptik.com

www.finind.com

www.ibd-deisenroth-engineering.de

Information