World market and production of armored vehicles (part 2 of 3)

OCELOT from Force Protection Europe - the preferred applicant in the UK LPPV program

VALANX JLTV is the response of the BAE Systems-Navistar team to the 27-month JLTV technology demo.

With the off-road WARTHOG 16 tracked carrier, ST Kinetics successfully entered the European terrestrial market

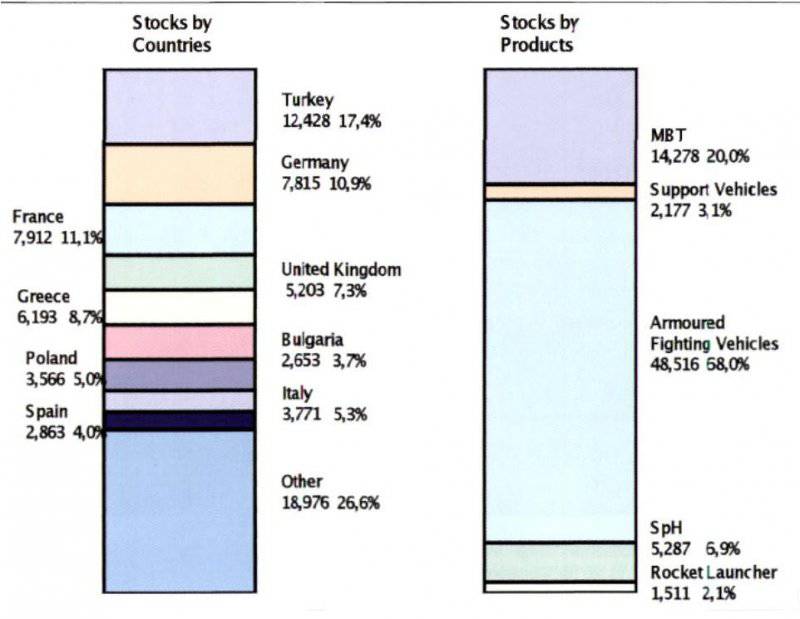

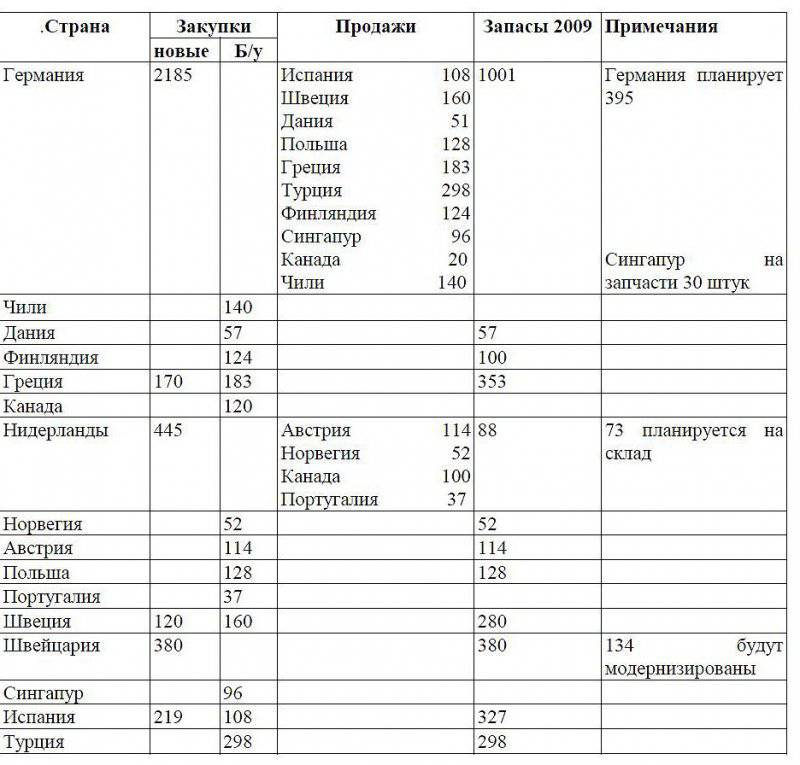

Fig. 6: Armored vehicles in Europe

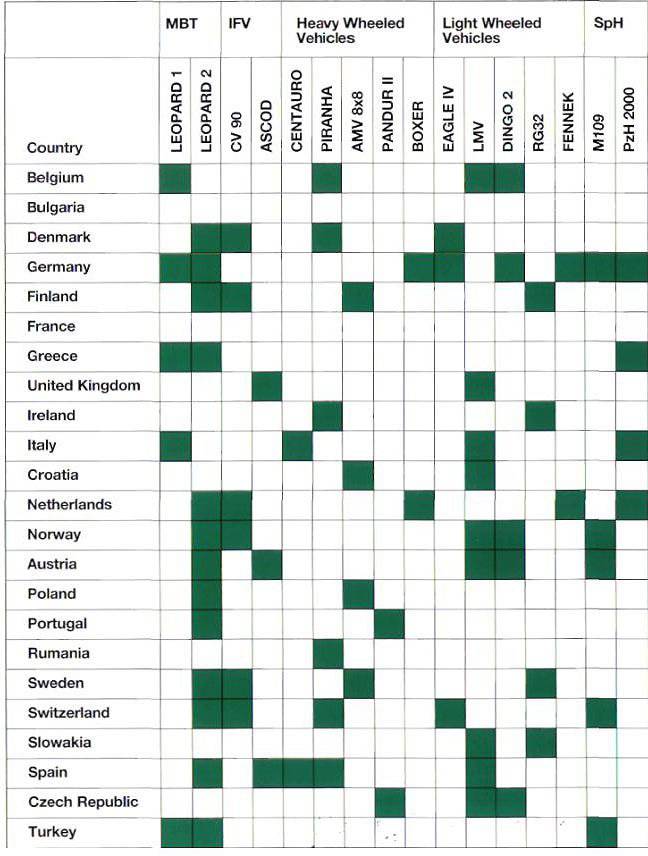

Fig. 7: European patchwork of armored vehicles (sample)

8x8 configuration machines

In order to manage international crises, many armed forces have purchased or plan to purchase armored wheeled vehicles of configurations 6x6 or 8x8 in various versions. In Europe, from 1998 to 2007, the stocks of these machines without the Russian versions increased from 2272 to 3438 machines, showing the military and industrial importance of this rapidly growing market segment.

23 September 2009, the KMW and Rheinmetall Defense companies handed over the first serial BOXER machine. The serial order included all 272 machines for the Bundeswehr and 200 for the Dutch army. The Netherlands Army will also accept BOXER shipments from 2011 to 2016 end of the year. Thanks to its modular design, the wheel-horned BOXER 8 x 8 off-road can be quickly modified for a wide range of tasks, for example, up to the medical-evacuation option and to the command post (all that needs to be done for this is to change the combat mission module on the vehicle chassis) . The BOXER has a maximum combat weight of 33 tons and an MTU engine with an 530 kW with a ZF transmission.

Since 1993, the French-German collaboration has stalled, the French Defense Procurement Agency has ordered a total of 630 VBCI machines from Nexter in four batches with a total value of 2,86 billion euros in BMP options and a command post. The first three cars were handed over to the French army in June 2008.

From February 2009 onwards and on 2014, the Italian army received the 249 BMP FRECCIA 8x8 from the IVECO / OTO Melara consortium with the HITFIST tower from Melara with the 25-mm SPIKE anti-tank missiles.

Also, the largest program in Europe is the program of the Spanish army, which plans to transform its eight brigades into multi-tasking brigades (Brigada Polivalente) based on the 8 × 8 platform in combat, reconnaissance and command versions, followed by a mortar, anti-tank, evacuation, sanitary and engineering options. However, the current financial situation in the country has strongly postponed for the distant future all these plans for modernization, the replacement of existing weapons has been postponed to 2020 - 2040 years.

The Belgian army purchased 138 Mowag PIRANHA IIIC for 500 millions of euros in seven different versions with deliveries in 2007 - 2015, with an option for 104 additional machines. 32 vehicles will be equipped with an Elbit combat module with an 30-mm cannon and 40 vehicles will be supplied in the version of self-propelled artillery systems with a CMI tower with an 90-mm cannon.

New NATO members have a significant need to modernize their armed forces in order to meet the requirements for managing international crises. The Polish army bought 690 armored vehicles AMV 8x8 from Patria, named ROSOMAK, and the Polish company WZM Siemianowice became the main contractor. With 1,25 worth a billion euros, it is one of the largest armored vehicles projects in Europe. Machines were delivered in 2005 - 2014's.

In 2012, Patria, the Ministry of Defense of Slovenia and Rotis Plus signed a final agreement regarding the Slovenian AMV contract. The local AMV fleet consisting of Svarun 30 machines has already been delivered, the remaining supplies will bring the total number of machines to 135. AMV will be equipped with a PROTECTOR remotely-controlled combat module (UAB) with a 30-mm cannon and SPIKE ATGM. October 11 2007, the Croatian Defense Ministry signed a contract with Dure Dakovic Special Vehicles and Patria for the supply of 84 AMV 8 x 8 Patria by the end of 2012, and 22 on January 2009 of the year 42XNNXX AMV was signed.

In February, 2013 in South Africa, the Minister of Defense signed a contract for the Hoefyster machine (Badger), but the Agency for Technology and Procurement transferred this contract to Denel only in September of this year. Its cost is 680 million euros, it provides for the production of 238 machines in five different configurations. Mainly based on the Patria AMV car, however, Badger will feature numerous design changes to meet local needs. Among them, mine protection with a flat bottom based on Flat Floor technology from Land Mobility Technologies (by the way, the same company is responsible for the new interior). Other locally produced equipment will also help increase the national component of the project; the car is assembled in South Africa by Denel Land Systems, which will also provide a two-seat tower for the fire support option.

13 April 2009, the Czech Ministry of Defense signed a contract with GDELS on the 107 machines PANDUR II 8x8, which were delivered in 2009 - 2013. 17 machines were manufactured by GDELS - Steyr in Austria, the rest by Czech main contractor VOP 025 Novy Jicin.

LMV (Light Multirole Vehicle) 4 x 4 universal protected vehicle with a combat weight of 7,11 tons and an 140 kW engine from IVECO Defense Vehicles

KODIAK is an advanced multifunctional armored engineering system installed on the LEOPARD 2 mini-protected chassis and equipped with an articulated excavator and a sliding dozer blade, which can be replaced with a full-width mine plow if necessary

4x4 configuration machines

In the last decade, especially for reconnaissance and patrol missions, numerous lightly armored universal vehicles, most of which have a 4 x4 wheel formula weighing up to 12 tons, have entered the market, they are intended for the transport of personnel and various types of equipment.

As part of the armored command post program (Geschutzte Fuhrungs - und Funktions-fahrzeuge - GFF), the German army intends to purchase more protected, more mobile and more combat-oriented vehicles in four classes.

- GFF 1 machines for command, reconnaissance and surveillance tasks have a total weight of 5300 kg and a payload capacity of 1000 kg.

- GFF 2 machines have a higher level of protection and a full weight of 5000 - 7500 kg and a useful load capacity of 2000 kg. In this class, Mowag has supplied 198 EAGLE IV worth 105,7 million euros to 2011, plus 20 additional EAGLE IV ambulances in 2010. In 2010, additional 60 machines were ordered. GDELS-Germany has a significant share in the production of these machines. The machines have a total mass of 8,8 tons and a load capacity of 2,2 tons, they are equipped with a Cummins engine with a power of 184 kW.

- GFF 3 machines have more reliable protection and 7500 – 13000 kg full weight and minimum 2000 kg payload. In this class, DINGO 2 from KMW and YAK from Rheinmetall Landsysteme are selected. DINGO 2 has a total mass of 12,5 tons, outstanding off-road maneuverability on the UNIMOG chassis, has a maximum speed of 100 km / h and a cruising range of about 1000 km with an 163 kW engine. The German army purchased the Dingo 593 vehicles. Belgium ordered 220 DINGO 2, named MPPV, Austria 20, Luxembourg 48, Czech 21, and Norway 20 machines.

- GFF 4 machines have a total weight of more than 13000 kg and a payload capacity of 2000 – 4000 kg.

22 September 2010 was announced by the British Defense Department that Force Protection Europe was selected as the preferred bidder for a new generation of light protected patrol vehicles (LPPV). The Force Protection OCELOT machines were ordered through an urgent operational need process. The final number of 200 machines originally planned is negotiable. OCELOT, with a total weight of 7500 kg and 2000 kg maximum permissible load, has a V-shaped body design, a Steyr 3.21 diesel engine and a six-speed ZF transmission. The patrol option accommodates two crew members and four infantrymen.

In 2014, the company from Bolzano will complete the production of VTLM (the acronym means light tactical general-purpose vehicle) Lince, ordered by the Italian army, its units have already received more than 1600 machines. The latest batches are delivered in a Lince 1A configuration with a solid roof, which is able to accept the new protected support ring and the Oto Melara Hitrole Light combat module. The new roof guarantees complete safety in the event of overturning and replaces the original protective arcs, which allows you to increase the available space in the car and reduce weight. Italy is reducing its contingent in Afghanistan, and after five years of deployment there, statistics show that, with the exception of the initial minor problems, the car showed itself in full accordance with expectations. Approximately 30 Casevac Lince machines were also supplied. Iveco DV is currently negotiating with the Italian army on the final configuration of the VTLM-2. In order to increase the available space, the next generation Lince will be a little longer; Dutch requirements have steadily increased, and now they provide for the total length of the 2,02 meter. The new machine will have better protection, mobility and greater carrying capacity and will be distinguished by a consistent increase in carrying capacity. The total weight is kept at less than 9 tons, and Iveco does not intend to transform the LMV into a mini-Mrap. This target mass should be achieved by working on the design and materials of the crew safety capsule. It is planned that the machine is fully integrated into all network-centric systems, since the new Lince machine will become part of the Italian Forza NEC digital army.

By the end of 2014, Iveco DV will complete the fourth-generation LMV 62 machines ordered by Norway in January 2013; the adopted configuration is already a development of the aforementioned Lince 2. The car features a new crew capsule with improved protection, new seats and improved ergonomics, a new power drive with improved performance due to increased gross weight. Electromagnetic compatibility is greatly improved because Norway has requested the ability to accommodate various equipment, such as radio stations, intercom systems, combat control systems and electronic countermeasures, as well as the installation of the Kongsberg Protector Nordic module.

Turkey is constantly increasing its presence in the field of light armored vehicles. At IDEF 2013, in addition to Otokar, at least three more companies showed their offers in this market sector.

Since the end of the 90-s, when the production of the Cobra 4x4 tactical armored car, which used some of the components of the Humvee AM General, was used, Otokar has been constantly developing it along with other models to meet local and export requirements. Over time, in addition to Turkey, the Cobra armored car was commissioned by Algeria, Bahrain, Georgia, the Maldives, Nigeria, Pakistan, Slovenia and the United Arab Emirates, as well as a number of unnamed countries. The latest order issued by Turkey in September 2013 of the year demonstrates that the ratio size-performance-protection-cost for this armored car is still very much appreciated.

Rough Terrain Machines

In December, 2008 of the year Singapore Technologies Kinetics was awarded a contract worth over 150 million pounds on 115 WARTHOG all-terrain tracked transporters ordered by the British Department of Defense according to the emergency needs process. The first car was released 28 September 2009 of the year. Compared to BRONCO, the WARTHOG has a large tonnage capacity of 6,0 tons, improved engine cooling and air intake filtration and a new Caterpillar C7 engine. France, on the other hand, decided to purchase the Swedish XVUMX all-terrain vehicle Bv53S.

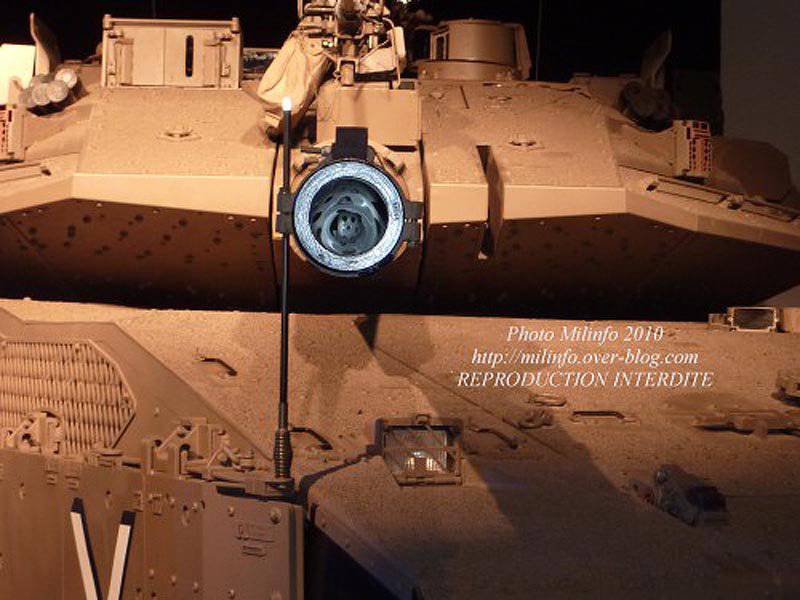

The tank MERKAVA IV was first shown outside of Israel at the Eurosatory 2010 exhibition.

Provisioning machines

Support vehicles, such as armored evacuation vehicles, combat engineering vehicles, armored bridge laying machines and demining machines, facilitate the movement of Allied forces and impede the movement of enemy forces. Rheinmetall Landsysteme, together with RUAG Defense, developed the KODIAK armored engineering vehicle based on the LEOPARD 2 chassis. As part of the Swiss Army 2006 armament program, both companies were awarded a contract to supply 12 KODIAK worth 95 million Swiss francs from 2010 to 2011. In January, 2008, Sweden and the Netherlands placed orders with Rheinmetall on 10 systems for the Dutch army and six KODIAK for the Swedish army. The total value of these orders is approximately 100 million euros.

The Dutch-German Panzerschnellbrucke 2 will be presented on the LEOPARD 2 chassis. Germany has a need for 11 units, the Netherlands for 14 systems. Beginning with 2003, KMW has supplied two prototypes for testing at the customer. The bridge laying system is based on three bridge modules that can be laid as one, two or three bridges.

TERRIER is a light armored engineering vehicle with two crew members and a combat weight of 31,5 tons, it is transported on the A400M cargo plane. In 2005, the first prototype was made by BAE Systems and after three years of delay, the delivery of the first production vehicle to the British army is scheduled for the 2011 year. In the framework of the British FRES program, it is planned that up to 35 maneuverable support vehicles as armored bridge laying systems: according to the SDSR 2010 document, the number of TITAN AVLBs will be reduced from 33 to 23 machines.

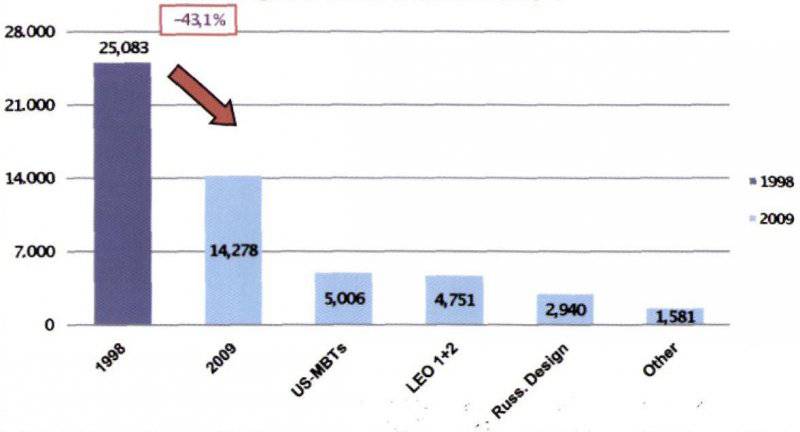

Fig. 8: MBT Stocks in Europe

Canada

Following LEOPARD, the Canadian military also identified the TAPV tactical armored patrol vehicle program as a general universal combat vehicle that would be needed to perform various tasks on the battlefield, such as reconnaissance and surveillance, operational management, cargo transportation, and personnel transportation. TAPV will provide a very high degree of crew protection while maintaining high mobility. TAPV is designed to overcome rough terrain, providing troops with the ability to cross rough terrain in order to give them greater flexibility on their chosen routes. In March 2010, the Canadian government released a SOIQ (Solicitation of Interest and Qualification - Requirement of Interests and Qualifications) for an “exemplary initial” purchase of 500 pieces and an option for up to 100 additional TAPV machines. The ministry also has a need for logistical support for the TAPV life expectancy estimated in 25 years. The Canadian Army will acquire up to 200 reconnaissance options and up to 300 universal options. Deliveries will begin in 2012, and initial combat readiness is expected a year later.

Соединенные Штаты Америки

The 2010 defense review, which comes out every four years, has set itself the goal of “once again balancing the capabilities of the American armed forces with the aim of dominating modern wars, while creating the capabilities necessary to deal with future threats and ... buy weapons that are suitable, affordable and truly necessary.” The US Army is the strongest and most efficient army in the world with a budget of 2010 billion dollars in 215,6 year.

The US military has 54265 armored vehicles, 52204 for the army and 2061 for the Marine Corps. They are divided into 6253 MBT, 2892 machine support, 42696 BBM, 1594 SG and 830 MLRS.

In the United States, two major players participated in the restructuring of the defense industry of ground systems: General Dynamics Land Systems (GDLS) and BAE Systems, but very successful companies appeared, such as Force Protection and Navistar.

Major tightened programs, such as the Future Scout Cavalry System (Advanced Intelligence System), CRUSADER, and FCS were closed, but new programs, MRAP, JLTV, GCV (Ground Combat Vehicle) and HMMWV Recap were initiated to meet military requirements.

Machines with enhanced mine protection MRAP (Mine Resistant Ambush Protected Vehicles)

With the program on minestop (MRAP) machines - a new category of armored vehicles - urgent military requirements for better survivability, transportation, combat performance and operational management were met. The fleet of heavy, medium and light vehicles covers weight from 14 t to 32 t. However, these machines have limited off-road performance.

The Navistar Defense MAXXPRO MRAP family consists of various 11 options. Combining a proven cargo platform with proven solutions to increase survivability, Navistar was awarded a contract for the production of 7589 MAXXPRO pieces, 2272 of them in the DASH version. In 2009, Navistar Defense made a profit of US2885 million in its defense sector.

30 June 2009, the US Department of Defense chose Oshkosh to supply the 2244 1,06 MRN M-ATV (All Terrain Vehicles Program) program for high-pass vehicles for the XNUMX.

In 2009, the Force Protection company made a profit in the defense sector 977,1 million dollars and is a leading company in the field of minesteam machines, releasing CHEETAH, COUGAR 4х4, COUGAR 6X6, and BUFFALO.

JLTV (Joint Light Tactical Vehicle - light tactical vehicle)

The JLTV family is intended to replace part of the outdated American light tactical wheeled vehicle fleet (TWV), including the HMMWV, and is an initiative for all branches of troops in the family of promising light tactical vehicles and the corresponding trailers for the US army and marines. Military expect to take an order for 65000 machines JLTV. The JNTV 10-year contract with the estimated value of a billion-dollar 40 represents one of the most significant purchasing decisions for the US ground forces in recent years. JLTV balances protection, performance and payload and will be integrated into the Brigade Combat (Tactical) Groups (BCT). The JLTV program covers three categories:

- Category A is a versatile mobile vehicle designed for towing an 1590 kg payload,

- Category B - a mobile command post and personnel transporter with a payload of 1745 - 2040 kg, and

- Category C is a model that can serve as a universal car, a shelter van and a tractor with a load capacity of 2310 kg.

As part of the JLTV 66 machines and 18 trailers (each of AM General, Lockheed Martin and Oshkosh in August 2013 were supplied on 22 machines and 6 trailers), semi-annual tests in the army and marines will be conducted. Against the background of pessimistic remarks about most of the programs of the American army, the press conference at AUSA 2013 on the JLTV project sounded a bit different, since all three speakers persistently described this new machine as one of the highest priorities for the new structure of the armed forces. Kevin Fahey of the Office of Combat Support and Logistics Support for the Combat emphasized that the government crisis of October 2013 had a negative effect on the testing program, as several test sites were closed; "We are now outside the current ideal plan," he said, "but we are not lagging behind on schedule." The reduction of the armed forces should not affect the number of JLTV armored cars. Although it is envisaged to reduce the fleet of light vehicles by 25%, “and so we will reduce the number of our Humvee,” said JLTV’s program manager at the Joint Program Development Office, Colonel John Cavedo and his deputy, Lieutenant Colonel Mike Burks, who also confirmed that the Marine Corps need 5500 machines. At the end of the 2013 of the year, field tests were carried out and a readiness assessment for production was carried out, while the readiness analysis itself was conducted at the beginning of the 2014 year. Success, however, has not yet been definitively fixed, since difficult decisions on the programs of the Ministry of Defense will be made in the second half of 2014, and the choice of the winning participant will occur only in 2015.

Three competing teams can not provide very much information, since the requirements are currently being determined and tested. At AM General, they consider it an advantage that the car has a modern, locally-made engine Optimizer 3200. This 3,2-liter engine from General Engine Products is developed on the basis of the Steyr M16 engine under a license agreement signed in 2009 with the Austrian company Steyr Motors; It is currently produced at a Ohio plant. The engine develops power 300 HP at 4300 rpm, torque 69 kgm at 2200 rpm. These engines with slightly better performance are also installed on AM General HMMW M998, Alvis Scorpion CVR (T), KMW-Rheinmetall AMPV and BAE Systems BVS10 machines. The mass of the Optimizer 3200 is just 250 kg, the specific power 1,2 hp / kg, and the power density 94 hp / l. At AM General, they also emphasize the unification of their JLTV and Humvee machines, the 40% component, which has a positive effect on cost, and also the fact that the company has a special assembly line for light tactical machines.

Fig. 9: International sales of LEOPARD 2 OBT

HMMWV Upgrade

Textron Marine & Land Systems, together with Granite Tactical Vehicles, offer SCTV (Survivable Combat Tactical Vehicle - a combat tactical armored vehicle with good survivability). It has a habitable V-bottom monocoque capsule that provides a level of protection similar to that of less protected MRAP vehicles. Textron offers to take the Humvee frame in good condition, remove the old cabins, replace the engines, upgrade or replace the suspension depending on the model, install improved wheels and a new cab. Undercarriage upgrades are relatively limited as the new capsule does not add much weight thanks to the adopted integral protection concept. Mine protection is provided by a V-shaped bottom, the materials of which the body is made, as well as greater ground clearance. A fifth door has also been added to the back of the capsule to facilitate entry and exit. The sides of the capsule, including the doors, are tilted, which increases protection against ballistic and RPG threats. According to Textron, the SCTV project should have a cost comparable to the cost of general-purpose vehicles of the same class.

Meritor Defense offers its own enhancement package for the Humvee in the form of a frame with an upgraded power unit and suspension. A Meritor MXL (Meritor Xtended Lube) transmission is installed on the chassis, in which improved hermetic seals prevent water from entering and guarantee the protection of lubricants from contamination. This makes it possible to increase the intervals between lubricants of universal joints and sealed parts to 160 000 km, which, therefore, significantly reduces maintenance costs. Mobility is improved mainly due to the installation of the ProTec High Mobility Independent Suspension (HMIS) 30 independent suspension. The lightest suspension from the ProTec 30 series has a permissible axle load of 8150 kg and independent wheel travel to 533 mm.

At AUSA 2013, Meritor Defense showed two new solutions that further increase the mobility of not only the Humvee, but also the mobility of the JLTV machine (the company goes to the group led by Lockheed Martin). The first of these is the SmartFlow system, which periodically checks the tire pressure of each wheel and adjusts it according to the type of movement chosen, be it a highway, dirt road, dirt / sand / snow, or emergency mode. The system is based on a control unit in which electronics and pneumatics are integrated and which is connected to the CAN bus (messaging bus of automotive systems without an onboard computer), with one channel for each wheel. A supplement to SmartFlow is the DriveCommand, a pneumatic transmission control system that actively monitors and controls the state of the differentials and transfer case, which are locked and engaged due to the appropriate algorithmic sequence. Electric and pneumatic channels connect the transmission control unit with the front and rear axles and the transfer case, the connection with the human-machine interface is again via CAN bus. Modes of operation are the same as those of SmartFlow. When installing both systems, a single human-machine interface can be used. Each system weighs only 1,9 kg and both are connected to a compressed air tank. Meritor Defense is preparing to begin production of the SmartFlow and DriveCommand systems, which have been thoroughly tested by the Marine Corps as part of the Humvee modernization program.

Navistar is still actively promoting its International MXT vehicle. The MVA armored version retains full weight up to 10 tons, but approaches the 15 tons in an armored (ISS) version and BTR version. The main operator of this vehicle remains the British army with the MXT-MVA machines ordered in April of the 2009 of the year 262 (in the British army known as Husky); then in September 2010, the order was followed by another order for 89 machines. The full axle load is 8,6 tons with a payload of about 1,6 tons, four people are accommodated in the car. The patrol version is equipped with a secure armament installation with an 12,7-mm machine gun or an 40-mm automatic grenade launcher, while the support version has an armament installation with an 7,62 mm machine gun.

Information