The rear should be ours

The experience of Russian companies that have been working for the development of domestic production for several years now will help implement import substitution. Dependence on foreign manufacturers, both in the military-industrial complex and in other areas that are closely related to the national security of Russia, has already been partially overcome on the initiative from below. For the final transition to import substitution, Russian Deputy Prime Minister Dmitry Rogozin and the country's Minister of Industry and Trade, Denis Manturov, have only been given two or three years. Is it possible to have time to reorient the national economy in such a short time and what steps have already been taken in this direction, Alexey Kayfajyan, general director of the Tethys group of companies, tells the Military Industrial Courier correspondent.

- Alexey Alexandrovich, the refusal of Ukraine from military-technical cooperation with Russia, the current situation in the world became a signal that the time has come "to significantly reduce imports in many positions and to return our own market to national producers," as President Vladimir Putin said about this in May . Do you think the Russian economy will be able to meet the deadlines announced by the ministers?

- I think that behind the designated deadlines are serious preliminary calculations. I don’t dare to judge them, but for my part I can say that the transition of the military industry to domestic rails began long ago. He has his background and his pioneers. For example, back in the 2011 year, long before the current foreign policy crisis, the Russian NPO Saturn launched the 36MT rocket engines, designed to replace the Ukrainian РХNUMX engines manufactured by Motor Sich. There are such pioneers in other areas that are not directly related to the production of military equipment, but which are no less important, including for ensuring the country's defense capability. One of such areas is the production of specialized equipment and hardware for the forces of search and rescue support of the Navy and emergency response forces, such as the Emergencies Ministry, the MVD, the FSB. And one of these companies is the Tetis group of companies.

Tethys specialization is relevant for Russia both in peacetime and in wartime. In addition to the obvious practical sense (provision of underwater work, rescue of submarine and surface ship crews, safety of work in a fire, provision of emergency medical care, etc.), the products produced and supplied by the company also have great psychological significance. She as if speaks to those to whom it is addressed: your life is dear, they remember you and in an extreme situation they will try to save you. In fact, for people in extreme situations, this is the rear, and in order to be reliable, there can be no “foreign production”. The rear should be ours.

Bet on Russia

- As far as we know, the company you are heading depends to a great extent on foreign components. Or is it not?

- History Tethys group of companies is to some extent symbolic. It began at the turning point of 1991, the year the company was founded. In the first period of its existence, the company was a supplier specializing in the import to Russia of professional diving equipment and equipment for the production of underwater work. However, rather quickly, this situation ceased to satisfy the company's management.

- History Tethys group of companies is to some extent symbolic. It began at the turning point of 1991, the year the company was founded. In the first period of its existence, the company was a supplier specializing in the import to Russia of professional diving equipment and equipment for the production of underwater work. However, rather quickly, this situation ceased to satisfy the company's management.In addition to economic calculation, there was also an “insult for the state.” Among the executives of the company were people who perfectly remembered the military and industrial might of the USSR. The role of an intermediary between the so-called advanced West and the “backward East” reasonably seemed to them to be humiliating and unsafe for the future. Thus, the top management initially relied on its own production.

As a consequence of this decision, the first in-house production facilities appeared in the Tethys group of companies by the end of 90's. From year to year the volume of self-produced products increased, and by now the share of equipment and equipment of own production is more than 50 percent of the product portfolio.

- Due to what has this been achieved?

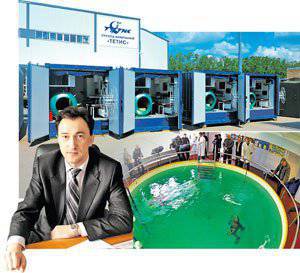

- First of all, thanks to the accelerated development of the corresponding production and testing base. The first assembly shop, as well as the office itself, with an area of not more than 100 square meters was rented at the Central Research Institute "Dolphin" back in 1995. Then, on the lessor’s machines, the workers did only some of the necessary details, however, it was precisely at that time that the development of their own production was laid on the basis of the knowledge and skills of professional workers of the Soviet “mailbox”. Later, the former Orekhovo-Zuevsky oxygen equipment design bureau was corporatized and rebuilt from the ashes - now the modern high-tech enterprise KAMPO OJSC is a leader in the production of breathing equipment for aviation, astronautics, emergency medicine, diving and firefighting. In the early 2000s, the company included the engineering center for the production of underwater equipment "Depth", a little later - the scientific and production enterprise "Reef" - a developer of sonar systems.

Growing ambitions and plans, an increase in production against the background of the country's general economic upturn in the middle of 2000, pushed shareholders to take the most important strategic decision for the company - building their own building that would meet the growing needs of the company. In 2009, the office and production complex was built. The new building housed machining, electrical and electronic areas, assembly shop. A specialized test base was created in the main production building, including, among other things, a test pool.

In connection with the increase in production in June 2014, in addition to the already existing, a new production site was opened, designed to assemble diving complexes, fire and compressor stations, training complexes, high-pressure compressors, uninhabited underwater vehicles and other equipment. As a result, Tethys production facilities increased to 2000 meters.

At the same time, there was a deep modernization of the production of OJSC KAMPO, an update of the machine park, the introduction of modern technologies, the discovery of new directions.

In addition to the vast industrial sites, Tethys has its own design office, which allows a group of companies to combine in their activities the functions of a designer, a manufacturer and a supplier. Internal development work is ongoing on an ongoing basis.

At the same time, the company never demanded investments from the state. In the development of business money invested and invested by the shareholders themselves.

Today, it can be stated with confidence that, as a result of systematic efforts to develop the production base, the Tethys group of companies develops, manufactures and supplies a wide range of equipment and machinery, displacing a more and more wide range of imported products from the domestic market.

Step by step, from simple to complex

- It's amazing how small production turned into a developed enterprise that covered several areas of activity?

- We were led to this path by the overall strategy of the Tethys group of companies in the Russian market and in the market of the CIS countries. It consists in a gradual transition from the import of products to the manufacture of this equipment on its production base with a constant decrease in the share of imported components due to the organization of their production at its own facilities or other domestic enterprises.

So, today among diving equipment and equipment produced by Tethys there are diving equipment, underwater lights and tools, diving communication stations, underwater television complexes, diving descending control panels, compressors, container and mobile diving complexes and this list is constantly growing.

Of course, switching to our own production is instantly very difficult, one might even say, almost impossible. Especially when it comes to complex unprecedented projects. However, 20 years of focused hard work are not in vain.

- The current 2014 year, apparently, has become particularly fruitful for your company. The media report on a variety of original engineering developments, which from the offices and workshops have already entered the domestic market ...

- First, the Tetis designers have created a new domestic pressure chamber - BKD-120T. It is fully consistent with modern international standards and will soon replace imported counterparts. The first pressure chamber was collected in May of this year, it was certified by the supervisory authorities of Russia. Already prepared its mass production. Only this year it is planned to manufacture 10 sets of such new pressure chambers.

Another new development of Tetis Group this year was the remote-controlled uninhabited underwater vehicle Marlin. I must say that in Russia there are several organizations that have worked in this field and have already created quite successful samples of underwater uninhabited vehicles. However, from a single sample created as part of a research project to a serial product is a huge distance. Virtually no domestic developer company has managed to overcome this distance. Tethys was able to go this way, starting it, so to speak, from the other end. In the early stages, the company organized the delivery of imported underwater uninhabited vehicles to Russia, then a specialized customer service, an equipment warranty extension system and the creation of its own spare parts warehouse were organized. For several years, the service team of underwater uninhabited vehicles gained the necessary experience, studied the requirements of customers and the specifics of operating these technologically complex products in the Russian context. In 2010-ies, on the basis of accumulated experience, the development of our own uninhabited underwater vehicle was started, while we immediately set the goal not only to create, but also to mass production. As a result, an uninhabited remote-controlled underwater vehicle of the inspection class appeared, an analogue of the well-known and actively used in various organizations and departments of the English "Falcon". To date, our Marlin TNPA has undergone factory tests, its mass production has been prepared.

Another new development of Tetis Group this year was the remote-controlled uninhabited underwater vehicle Marlin. I must say that in Russia there are several organizations that have worked in this field and have already created quite successful samples of underwater uninhabited vehicles. However, from a single sample created as part of a research project to a serial product is a huge distance. Virtually no domestic developer company has managed to overcome this distance. Tethys was able to go this way, starting it, so to speak, from the other end. In the early stages, the company organized the delivery of imported underwater uninhabited vehicles to Russia, then a specialized customer service, an equipment warranty extension system and the creation of its own spare parts warehouse were organized. For several years, the service team of underwater uninhabited vehicles gained the necessary experience, studied the requirements of customers and the specifics of operating these technologically complex products in the Russian context. In 2010-ies, on the basis of accumulated experience, the development of our own uninhabited underwater vehicle was started, while we immediately set the goal not only to create, but also to mass production. As a result, an uninhabited remote-controlled underwater vehicle of the inspection class appeared, an analogue of the well-known and actively used in various organizations and departments of the English "Falcon". To date, our Marlin TNPA has undergone factory tests, its mass production has been prepared.In parallel with the underwater technology, the production of fire-fighting equipment developed - breathing apparatus, panoramic masks, complexes for examining and repairing high-pressure cylinders, air compressors of various types, fire-compressor stations. It should be noted that about half of the breathing apparatus used by firefighters in Russia was produced at the enterprise of GK Tethys - KAMPO OJSC.

However, the equipment supplied to the fire brigades of Russia is not limited to one breathing technique. In 2013, active work began on the production of training complexes for the practical training of firefighters and rescuers to work in an unfit environment for breathing and sight - the TD-1 heat sink and the TOK-1 fire complex. The heat and smoke chamber simulates conditions and a complex situation (smoke up to a complete lack of visibility, debris and labyrinths, noise-noise effects) that firefighters have to face daily at the fire site, while eliminating the consequences of accidents and in other emergency situations. CURRENT-1 is designed for testing methods and methods for extinguishing various modulated fires, controlling the flow of extinguishing agent. Also, practicing skills in the TOK-1 complex, firefighters can be trained in the use of respiratory protective equipment and special protective clothing.

The logical continuation of the development of the production of systems and complexes for emergency services was a significant expansion in the production of emergency medicine equipment in 2012 for use by the Emergencies Ministry of Russia, the Ministry of Defense and ambulance services. Respiratory support equipment - oxygen inhalers, manual ventilators, laying respiratory support - this is the proven experience and daily work of the equipment used by medical teams throughout the country. Especially for military doctors created an apparatus for artificial ventilation of the lungs DP-11В. Also in the range of its own medical production is the trolley “Catet”, designed for transporting and immobilizing the patient. Thanks to the twin wheels and the special design, the Catet allows patients to be transported off-road, if necessary, by the forces of one person.

- Do you have a development that primarily meets the challenges of today's alarming time?

- These include the production of complexes for the protection of important state-owned facilities from the terrorist threat - from project design to commissioning. Today, Tethys enterprises have developed and manufactured hydroacoustic and seismic systems for detecting violations of the protected perimeter. Tetis Group has created unique engineering barriers to protect divers, saboteurs and small boats from penetrating, the intruder’s acoustic warning devices about intrusion into the restricted area and means of non-lethal impact on him by creating a shock wave in the water. All of these protection systems are part of the complex engineering security equipment (ITSO) objects from the waters. Since 2009, important state-owned facilities throughout Russia have been equipped with ITSO complexes.

With 2012, another new activity is developing that connects us with the Armed Forces - the production of multifunctional modular boats and modular pontoon systems - carriers of container complexes. The boat consists of block modules of full factory readiness, which are delivered to the construction site by freight transport, where they are assembled into the finished vessel and lowered into the water during 25 days. The economic effect achieved through this is enormous. Thanks to a variety of modifications, this boat can replace several specialized vessels, reduce the number of personnel, and also reduce the number of downtime inevitable for this category of crew.

In 2013, the first of 12 project 23370 multifunctional modular boats passed state tests and was accepted into the Russian Navy. In June 2014, launched the second boat in this series and begins state tests in Sevastopol. This is the first ship handed over to the Black Sea in the last 25 years. It opens a new milestone in the development of search and rescue forces of the Black Sea fleet as part of the Russian military shipbuilding program.

- In the past couple of years, the name "Tethys" was repeatedly mentioned by journalists in connection with the creation of the deep-sea diving complex GVK-450. You were even reproached for the fact that this complex was mainly foreign-made. Can you object to this?

- GVK-450 is an extremely important project for the Russian Navy and, of course, for us. He is able to provide multi-hour work of divers at depths up to 450 meters. The complex is intended for installation on board the rescue ship of the naval forces “Igor Belousov”, being built at the St. Petersburg Admiralty shipyards. Indeed, discussing the prospects for GVK-450, the media blamed Tethys that the complex was foreign. However, in this contract, Tethys maintains its position - the maximum possible localization of imported equipment. Already at the initial stage of work on the delivery of GVK, the company entered into an agreement with the supplier on the sequential replacement of the range of imported components with domestic ones: from 15 percent on the first sample to 75 percent on the fourth. The transfer of a significant part of the installation and commissioning works to its own production facilities is called upon to play its role in this. For this purpose, a special assembly shop is being built and equipped on the territory of the company.

- Still, cooperation with major foreign manufacturers has certainly enriched and taught Tethis Pro a lot ...

- Last but not least, it was this cooperation that helped us to establish our own production. We do not hide the fact that most of the developments of Tetis Group of Companies had their own foreign prototypes, which made it possible to introduce the latest world technologies into Russian practice and to at least partially overcome the lag of the Russian industry from the foreign one. For example, the basis of the standardized diving equipment SVU-5, produced by the company, is the equipment manufactured by Kirby Morgan (USA). At the same time, the French "rebreathers" (special breathing apparatus) "Aquawung" turned into a modification of "Tethys" sets of special-purpose diving equipment IDA 2000 and "Amfora", already accepted for supply by the Russian Armed Forces. Foreign diving complexes have practically been ousted from the market. The fire breathing apparatus is not inferior to the European and American counterparts. Import substitution gives impetus to the development of our company. The same will be true with respect to enterprises of the military-industrial complex of Russia.

"Armored train on the main road"

Thus, the continuous development and expansion of our own production turned into 20 years of fruitful work of Tetis Group. What seemed blind patriotism in the distant nineties turned out to be a sound economic calculation. And this is natural: in the modern domestic market, first of all those companies feel that, without any command, “from above” were engaged in “import substitution”. Now, in order to transfer industry to domestic rails, they do not need to create the entire “railway” from scratch. It is enough to pull the lever to bring the Russian economy to the main path.

Information