Gun GSH-18 - the brainchild of Tula gunsmiths

At the beginning of the 21st century, the Russian army and law enforcement agencies faced an acute problem of equipping personnel with effective short-barreled weapons.

A new complex of service small arms was supposed to include two main elements - ammunition and weapons. For short-barreled weapons (pistols) due to the small distances of fire contact, the main role in the complex was assigned to ammunition (cartridge). It was assumed that the design of the cartridge should provide a high level of service safety. The choice of the cartridge was carried out from the conditions of the maximum stopping effect of the bullet given the restrictions on the size and weight of the weapon, based on the specific use of the weapon. These restrictions are caused by the necessity of secretive carrying of weapons, the speed of reaction (extraction and pointing of weapons), etc. Compared with the military, such short-barreled weapons should have provided a greater stopping effect with a smaller distance of effective shooting and minimal possibility of a ricochet of a bullet (to reduce the risk of injury to surrounding citizens). Except in special cases - the need to shoot at a car, through an obstacle (doors, partitions, etc.), a criminal protected by individual armor protection - bullets for a new weapon should quickly lose energy in the obstacle, ensuring a minimal likelihood of a secondary defeat when it breaks through.

Given that pistols are the main weapon of self-defense for law enforcement officers, a new structure of these weapons was developed at the Russian Ministry of the Interior. Depending on the tactics of use, it is divided into three categories: service, compact and tactical. At the same time in the modern "police" short-barreled weapons used a number of cartridges with a wide range of designs of bullets.

Service pistols are the main weapon of the internal affairs bodies, units and subdivisions of the internal troops that perform their duties, as a rule, in uniform. With a sufficient level of efficiency, they must ensure high security of official treatment and unpretentiousness to climatic conditions with long-term duty. It is believed that a double-action firing mechanism is optimal for service pistols (only a self-resetter without fixing the trigger in the cocked position after the shot), which ensures maximum safety and quickness of reaction with acceptable firing accuracy. The frame of the gun, as a rule, is made of steel, as the polymer reduces the weight of the weapon, which leads to discomfort when shooting. Simple sights should have anti-glare protection and fluorescent inserts for shooting in low light conditions. The handle should be comfortable for a hand of any size. Typical dimensions of the service gun: length - 180 - 200 mm, height - 150-160 mm, weight without cartridges - 0,7 - 1,0 kg, caliber 9,0 - 11,43 mm.

Compact pistols are designed for operational services of law enforcement agencies in need of covertly carrying the main weapon or as a second (spare) pistol for those with service weapons. As a rule, compact pistols use less powerful cartridges than service ones, although it is preferable to have a single cartridge for both types. Compact pistols differ from service ones with smaller dimensions, weight, magazine capacity and a minimum number of protruding parts, including sights, which can make it difficult to quickly remove the weapon. Smaller handle sizes, shorter barrel and sighting line make shooting from compact pistols less comfortable and accurate, which significantly limits their effective range. When using a single cartridge, a compact pistol was required to allow shooting with both a shortened magazine and a magazine from a service pistol. A compact pistol for a single cartridge should be no more: length - 160 - 180 mm, height - 100 - 120 mm, weight - 0,5 - 0,8 kg, caliber 9,0 - 11,43 mm. Typical dimensions of a compact gun chambered for reduced power: length - 120 - 150 mm, height 80 - 110 mm, weight 0,4 - 0,6 kg, caliber 5,45 - 9,0 (9х17) mm.

Tactical pistols are designed to arm only special units of internal affairs bodies, units and subunits of internal troops. As a rule, they use a more powerful cartridge and can install more attachments, such as a silencer, laser designators, tactical lights, collimator sights, etc.

One of the most prominent representatives of modern domestic service weapons was the 9-mm self-loading pistol, created at the end of 1990-s in the Tula Instrument Design Bureau under the guidance of renowned armament designers V.Gryazev and A.Shipunov "GSH-18" (Gryazev -Shipunov, 18 - the capacity of the store).

By the end of the 1980-ies, with the advent of modern personal protective equipment, the clear backlog of domestic 9-mm Makarov pistols (PM), which were in service with the Soviet army and law enforcement agencies, clearly appeared from similar modern Western models. The army and law enforcement agencies needed a new pistol that would be able to incapacitate the enemy, protected by personal protective equipment, while maintaining a sufficient damaging effect at a distance of up to 25 m, and a stopping effect - up to 50 m. At the same time, the bullet should not yield the bullet with the steel core of the NATO Parabellum pistol cartridge 9x19 and the lead core bullet with the .45 ACP cartridge. Makarov pistol was successful for its time, but in fact it turned out to be much weaker, compared with foreign weapons of this class, designed for a more powerful cartridge. This situation was primarily due to the low stopping and penetrating effects of relatively low-power PM cartridges 9x18.

This was due to the fact that weapons were created by some designers, and their cartridges were created by others. Such a so narrow specialization to some extent stalled scientific and technological progress in the weapons business. Much was lost on this: both time, and strength, and nerves. It is much more effective when the same organization does everything in a complex - both weapons and ammunition.

Tula gunsmiths at their own risk and projected a service pistol and offered it to the competition to replace the PM.

First of all, designers Zelenko, Korolev and Volkov, led by Shipunov and Gryazev, started working on a new PBP cartridge (pistol armor-piercing cartridge). At the same time, the standard pistol PM cartridge 9x18 was taken as the base pistol, and the design of the bullet was based on the SP-5 automatic bullet scheme. It was decided to raise the power of the cartridge not by increasing the ballistic impulse, but by increasing the muzzle energy of the bullet with an armor-piercing core. For this, a special armor-piercing bullet with a heat-treated steel core in a polyethylene jacket was developed. A lighter bullet had a bimetallic shell with a bare nose section of the core. With the same ballistic momentum of the cartridge, as in the PM (0,22 kg per second), the initial speed increased from 315 m per second to 500. This cartridge could be used without any improvements in the standard PM pistols. But the external impact of the bullet has changed quite a lot. Previously, a standard PM bullet with 10 meters punched only one and a half millimeters of steel 10-mm sheet, but now from this distance the PM pistol punched a five-millimeter sheet, which even the standard US military 0,5-mm Beretta pistol could not get from the 9 distance. M 9.

The effect of the use of new pistol cartridges, in essence, was equivalent to rearmament, only without significant financial costs and retraining of personnel. However, the PM cartridge itself still lagged behind its main rival - the Parabellum NATO pistol cartridge 9x19, which is one and a half times higher than the domestic one. The gun of Yarygin "Grach" under the 9-mm cartridge "Parabellum" has already been developed in Izhevsk. However, both its design, 9x19.000 (manufactured by the Ulyanovsk Mechanical Plant) and 9x19 PSO (produced by the Tula Cartridge Plant) did not suit the design and production technology of its ammunition. In addition, the Tula designers considered these cartridges too heavy (the weight of the cartridge 11,5 and 11,2 g - respectively).

Therefore, in the KBP, it was decided to take the pistol cartridge as the basis for the 9х19 and upgrade it accordingly, using a bullet in it that is structurally similar to the PBP. The armor-piercing bullet also has a heat-strengthened steel core in a lead shirt and a bimetallic shell that is bare in the front part. The bullet of the 7Н31 cartridge weighs 4,1 g against 6 - 7,5 g in foreign 9x19 “Parabellum” cartridges, but it has a significantly higher speed - 600 m / s. A new very powerful 9x19 pistol cartridge 7H31 with a bullet of increased penetration ability now provided penetration of third-class bullet-proof vests or 8-mm steel plate at a distance to 15 m.

When designing a pistol, Gryazev took the line to create a model that was radically new in a constructive and technological plan that was as light and cheap as possible.

Before drawing the first lines of the drawing on his drawing board, Vasily Petrovich analyzed the latest designs of modern foreign pistols. He was attracted by the Austrian pistol "Glok-17", the main features of which included: plastic frame; firing-trigger firing mechanism, which is set on the half-platoon before the shot; and the lack of external, hand-operated fuses. The semi-drummer in this pistol was carried out in the process of rolling the housing-bolt: when not reaching the extreme front position, the hammer placed in the housing-bolt joined the sear, then the return spring, overcoming the resistance of the gun, brought the bolt to the stump. The spring remained at the same time compressed by about half. When the trigger was pressed, it was docked, after which the drummer broke off from the whisper and a shot occurred.

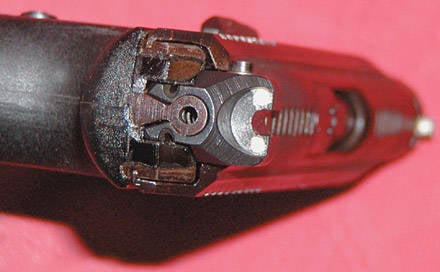

9-mm pistol GSH-18 (rear view). Well visible drummer and pillar

9-mm pistol GSH-18 (rear view). Well visible drummer and pillarIn the process of creating a pistol GSH-18 Gryazev decided to use the most successful elements of the Austrian pistol, including making the same plastic frame, half-armature of a drummer and abandon external fuses. In addition, Gryazev, like his Austrian counterpart Gaston Glock, abandoned the previously mandatory attribute of most service pistols - the trigger trigger with an open trigger, which promised considerable benefits: the projected pistol should have become simpler and cheaper. In addition, in this case, it was possible to bring the trunk to the hand. With a low position of the pistol barrel, the shooter’s unpleasant perception of recoil of the weapon during a shot was reduced, thus allowing a more speedy aimed pistol shooting.

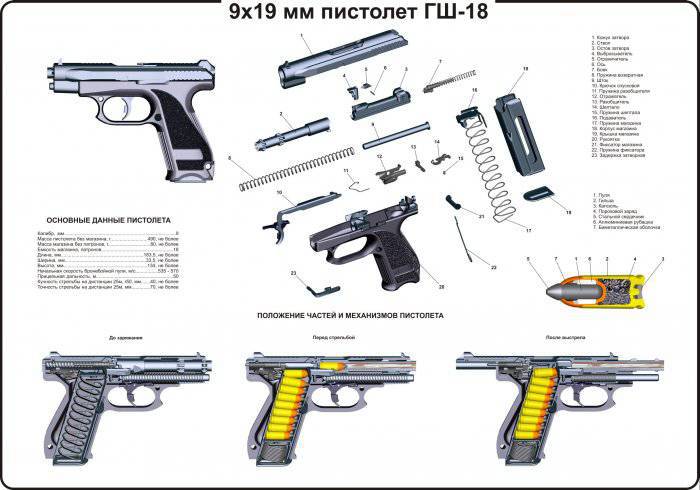

The main features of this weapon include the principle of operation of the automation using the recoil energy in the short course of the barrel, which ensured the minimization of the mass of the bolt.

When choosing the type of barrel bore locking, Gryazev resolutely rejected the locking with a separate part - a swinging arm of an 9-mm German Walter R.38 pistol used by the designers of the Italian Beretta 92 pistol and the Russian Serdyukov PS Gyurza PS. In the weapons business, there are other types of locking without the use of individual parts, for example, the barrel distortion invented by John Moses Browning. Or the turning lock of the barrel, first used by the talented Czech gunsmith Karel Krnka.

Attempt to implement in the GSH-18 the locking of the trunk by distortion from the interaction of its wedge projection with a frame like a Glock pistol was not successful. This method was attractive because the locking was done without auxiliary parts and the fact that when the trunk was bent, the breech reduced it to the store, which made it easier to send the cartridge to the chamber. Then, an earring was used in the construction of the mechanism for locking the barrel of the GSH-18, like in a TT pistol. The mechanism with an earring had a greater efficiency, but he could not stand the check in difficult conditions. Also, the attempt to apply the barrel rotation like an Austrian pistol "Steyer" М 1912 was not successful. When locking this type, the barrel turned on 60 degrees, and with such a large angle of rotation, a lot of energy was spent to overcome the friction forces. The task was solved only after a sharp decrease in the angle of rotation of the barrel - to 18 degrees, while locking was carried out by turning the barrel on the 10 lugs, which, in combination with the polymer frame, helps reduce the perceived recoil. Rotation of the barrel after a short stroke redirected some of the recoil energy to the rotation of the barrel, and the polymer frame made of polyamide gave the weapon optimum elasticity and rigidity.

The pistol GSH-18 received a double-action firing mechanism of a striking type with a preliminary partial hammering of the firing pin during the movement of the bolt and the addition of a firing pin when the trigger was pulled.

The idea of applying a trigger mechanism with a half-armature drummer in the new pistol turned out to be tempting. This idea, first used in the early twentieth century by Karel Krnka on the Roth pistol, was revived by Gaston Glock after many decades of oblivion, but now at the modern technological level. Glock pistols did not compress the mainspring when the housing-bolt rolled back; it did not shrink in the initial run-up stage, only with some shortfall to the extreme forward position, the mainspring through the drummer stopped in a sear. On the remaining path, the return spring, overcoming the force of the warfare, brought the cover-bolt to the extreme rear position, while compressing the battle spring by about half of its combat stroke.

But the idea of a half-starter in its original form did not pass with the Tula. In difficult conditions, the return spring was not always able to overcome the force of the mainspring, and the bolt stopped before it reached the barrel. And here Gryazev again acted in his own way.

On the pistol of the GSH-18, when the housing-bolt moves to the rearmost position, a full compression of the combat spring located around the drummer occurs. At the beginning of the roll-on, the slide guard rushes forward under the action of two springs — return and combat — pushing the cartridge from its store into the barrel chamber in its path. The drummer stops at the sear, and the bolt from the force of only one return spring reaches the final position. Thus, the idea of stopping the striker at the half-platoon, but in a completely different version, much better, in terms of the energy balance of the sliding parts, was implemented.

In his gun, Gryazev used an 18-charging magazine with a double-row, staggered arrangement of cartridges and rearranging them at the exit in one row. With this, he greatly facilitated the layout of other mechanisms of the pistol, in particular, the pull of the trigger. At the same time, the conditions for sending the cartridge from the magazine to the barrel improved. Along with this, attention is drawn to the fact that the shop of the pistol GSH-18 received a relatively strong supply spring, which ensured the reliability of the supply of cartridges. The magazine latch is mounted behind the trigger guard and could easily be rearranged to either side of the gun. With a slight push with your thumb, the magazine drops out of a pistol under its weight.

One of the serious problems was that under extreme test conditions, the shutter-casing in the overrun sometimes completely lost its stored energy and stopped, resting on the bottom of the extended cartridge with a extractor. The failure to reach the extreme front position was only one and a half millimeters. However, to overcome the force of the spring extractor at the gate forces are not enough.

From this seemingly impasse, Gryazev found an elementary way out - he invented a springless extractor. The extractor tooth was forcedly inserted into the groove of the liner with the barrel visor, while rotating during locking. When fired, the drummer, passing through the hole in the extractor, rigidly fastens it with the sleeve and firmly holds it in rollback before meeting with the reflector.

The bolt and drummer with a pistol spring GSH-18 (top view)

The bolt and drummer with a pistol spring GSH-18 (top view)When pressing the trigger, the finger first presses the small protrusion of the automatic safety device into the trigger, and with further pressure on the trigger, a shot is fired. In addition, the drummer, located at the half-platoon, protrudes approximately 1 mm at the rear of the bolt, allowing the shooter to visually and to the touch determine the readiness of the pistol for a shot. The course of the descent is about 5 mm, which is quite acceptable for service weapons. Trigger pull - 2 kg.

The GSH-18 pistol received unregulated sights: a replaceable front sight and a rear sight, which was mounted not on the cover-casing, but on the shutter block. At the same time, the removable front sight can also be with luminous tritium inserts, and in the front part of the trigger guard there is a through hole designed for mounting a laser pointer (LCC).

The complexity of the production of the pistol GSH-18 was at least three times less than that of the American pistol Beretta M 9. On the one hand, this was achieved due to the fact that previously the most time-consuming part of the pistol - the frame - was now produced from durable molded plastic with steel inserts. On the injection molding machine, this process took only five minutes. At the same time, the strength of the plastic frame itself was confirmed by the most stringent tests, in particular, by multiple throws of the pistol on the concrete floor from a height of 1,5. Wide use of high-strength polymers in the design of the pistol made it possible to achieve an exceptionally low total weapon mass - 0,47 kg without a magazine.

The second most complicated part of the GSH-18 pistol was its shutter casing. The shutter casing and the actual shutter are different parts and can be separated with incomplete disassembly, which was done to reduce the cost of production. Previously, as a rule, the shutter-casing was made of steel forgings with further sequential machining on metal-cutting machines. In the gun Gryazev - Shipunova was widely used stamped-welding technology for the manufacture of parts, including the housing-bolt. The initial blank for its manufacture was the cutting of 3-mm steel sheet. Following this, it rolled up and welded. At the final stage of production, the shutter-casing was adjusted on metal-cutting machines. For greater strength, the shutter casing stamped from steel sheet received a rigidly fixed insert at the point of adhesion to the barrel and the shutter block removed during disassembly, in which the drummer and the ejector were mounted. Special plating was used as electroplating, which gave the casing-shutter a light gray color. In addition to the housing shutter and all other parts of the pistol GSH-18 developed to the minimum complexity of their manufacture.

Compared to foreign models, the GSH-18 pistol has received numerous advantages in many respects: it was very light, small in size, and at the same time it had high combat qualities. If the majority of foreign army pistols weighed about 1 kg, with a total length of about 200 mm, the GSH-18 pistol had a weight of 560 g, with cartridges 800 g. Its length was 183 mm; while he punched any body armor and steel sheet thickness 8 mm from a distance of 22 meter. When firing, the pistol of the GSH-18 takes up much less than the pistol of the PM. This is due to the expenditure of recoil energy on the rotational, that is, transverse, movement of the trunk. In addition, the good ergonomics of the weapon ensures the stability of the pistol during firing, allowing you to conduct aimed fire from it with a high practical rate of fire.

The GSH-18 pistol showed good performance when firing both high-performance 9х19 7H21 and 7H31 cartridges, as well as NATO’s Parabellum 9X19 and their domestic counterparts. Due to the reduced mass and increased initial speed in combination with the armor-piercing core, the bullet of the 7Н21 cartridge provided a high penetrating effect of the targets protected by 3-grade protection class armor (punching the standard 6BZ-1 armored vest with titanium armor plates + 30 layer, I had to use the X-ray access panel with the titanium armor plates + 50 layer, I was using the X-ray access panel with the titanium armor plates + 7 layer, and I had to use the X-ray access panel with the titanium armor plates + 31 layer, I was using the X-ray XJUMXBZ-XNUMX with the titanium armor plates + XNUMX of the X-ray protection vest XNUMXBZ-XNUMX with a titanium armor plates + XNUMX of the X-ray protection vest XNUMXBZ-XNUMX with the titanium armor plates + XNUMX of the X-ray protection vest while maintaining a sufficient over-graded action to defeat an opponent protected by a body armor. The performance of the cartridge XNUMXНXNUMX is even higher. In addition, the high initial velocity of the bullet significantly reduced the lead time when firing at moving targets.

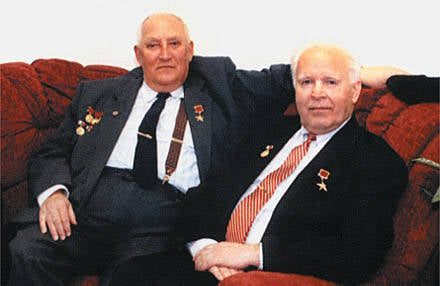

The creators of the pistol GSH-18 - A.G. Shipunov (left) and V.P. Gryazev

The creators of the pistol GSH-18 - A.G. Shipunov (left) and V.P. GryazevIn the end, the Tula designers created a new “pistol + cartridge” complex, much more effective than other similar models in combat use, because in penetration of solid obstacles when firing 7H31 cartridges to it, none of the existing army pistols can match to this day .

The reliability of the new pistol allowed him to go through the entire testing and government testing program that took place in the 2000 year. Virtually no serious complaints were made to the GSH-18 pistol or to its 7H31 cartridge, except for complaints about one of the characteristic features of this weapon - the shutter-casing open in front. Critics of the Gryazev-Shipunov pistol expressed fears that the cover-shutter would be easily accessible to the dirt, although Tula designers were able to prove that the dirt was thrown from the cover-shutter outside during a shot.

Already in the same year 2000, a powerful pistol complex GS-18 entered service with the Ministry of Justice. 21 March 2003, by decree of the Government of the Russian Federation No. 166, the GSH-18 pistol was adopted, along with the pistols of the Yarygin design and ATP Serdyukov designation, into service with the special forces of the Ministry of Internal Affairs and the Ministry of Defense of the Russian Federation.

Caliber................................................. ............... 9 mm

Chuck ....................... 9 × 19 Lugger, 7H31 and 7H21

Mass of weapons without ammunition ....................... 0,59 kg

Length................................................. ........... 183,5 mm

Barrel length ................................................ ..103 mm

Bullet speed

at a distance of 10 m ............................... 535-570 m / s

Combat rate of fire .......... 15-20 rds / min

Magazine capacity ................................ 18 cartridges

Information