Tractors Tankprom

The enterprises of the Uralvagonzavod research and production corporation are known in the world primarily for their military developments. Working in the field of creating the most modern special equipment, they produced not less unique products, for example, for the national economy of the country. Tractors, bulldozers, excavators, two-link tracked carriers - they will be discussed in this article in the section of the exhibition “Unknown Tankprom”, which is organized by the UVZ corporation and will be held in Moscow in the autumn of this year.

One of the leading enterprises of the integrated structure is ChTZ-Uraltrak LLC. It is the main manufacturer of tractors and engines for them.

The fate of the Chelyabinsk Tractor Plant is inextricably linked with the history of the country. The course for industrialization, taken by the Soviet Union in December 1925 of the year at the XIV Congress of the CPSU (b), responded to both historical and practical tasks. Both in the city and in the countryside, the absolute majority of the working people were engaged in heavy manual labor. There was a need for widespread use of agricultural machinery. Industrialization gave Russia the opportunity to reach the level of industrialized countries.

The choice fell on the Urals

Of great importance was the creation of domestic tractor construction, the flagship of which was CTZ. May 29 The 1929 of the Year of the Council of People's Commissars of the USSR adopted a resolution “On the attack to build a tractor plant in the Urals”. Several factors played a crucial role in the selection of the site for the plant. This is, firstly, the location of the coal mines of Kopeysk to provide the future plant with cheap fuel. Secondly, the fact that Chelyabinsk GRES, which came into operation in 1930, was to provide energy, and the uninterrupted supply of iron and coke was carried out by the Magnitogorsk Metallurgical Combine. The location of the city on the Trans-Siberian Railway made it possible to significantly reduce transport costs for the delivery of tractors to the eastern regions of the country. Plus, the oldest industrial area - the Urals - is a skilled workforce.

In November, 1929, by order of the USSR Supreme Economic Council, approved that the future ChTZ should become one of the first factories in the country for the large-scale production of tracked tractors and produce 40 thousand cars a year.

The initial project of the CTZ and the technological process of assembling tractors were developed in the United States, taking into account the use of only American equipment. But already during construction, when it turned out that it was impossible to purchase the required units in the US, part of the orders were transferred to Europe. More than 120 factories manufactured machines and mechanisms for CTZ. The share of domestic equipment as a whole was more than 40 percent.

The development of a master plan for the Chelyabinsk Tractor Plant began in June 1929. By the spring of 1930 in the design bureau specially organized in Leningrad, a design draft of the enterprise was drawn up. The high rates of construction work allowed the transition to full-scale installation of production equipment in 1932. At ChTZ, a special conveyor was built for the production of tracked tractors "Stalinets-60" (C-60), its prototype was the American tractor "Caterpillar-60".

The first experienced C-60 tractor with a naphtha engine was assembled at the 15 pilot plant in February 1931 of the year, and the first serial tractor was manufactured on the main conveyor of the main 15 production in May of 1933. It was produced until March 31 1937. Since that time, ChTZ has been continuously working on improving the tractors produced and creating new, more promising models.

In 1935, a group of designers from Moscow NAMI, under the leadership of P. V. Mitsyna, brought to the CTZ the drawings of the M-17 diesel engine. The M-17 engine had horsepower 75, was made up to the 1941 year, it was a “descendant” of the M-13 and M-75 engines, worked on a mixture of autola and kerosene, and was easily turned into 30-degree frosts. In January, the 1937 of the M-17 was submitted for approval by the NKTP, and on June 20 the first C-65 diesel tractor rolled off the conveyor. In February, 1938, the first batch of the machine "Stalinet-65" (C-65) in the amount of 60 pieces was exported. With the C-65 began dizelizatsii tractor fleet of the country. The success that came to the Soviet designers in the 1937 year allowed the Soviet Union, after 20 years, the first in the world to convert the entire tractor industry to diesel.

At the international exhibition “Art and Technics of Modern Life” in Paris in May 1937, among the exhibits of the Soviet pavilion were two ChTZ tractors - C-60 and diesel C-65. The international jury awarded the Ural tractors Grand Prix - the highest award of the exhibition, which was a kind of international recognition of Chelyabinsk tractors.

At the international exhibition “Art and Technics of Modern Life” in Paris in May 1937, among the exhibits of the Soviet pavilion were two ChTZ tractors - C-60 and diesel C-65. The international jury awarded the Ural tractors Grand Prix - the highest award of the exhibition, which was a kind of international recognition of Chelyabinsk tractors.From the end of 20 to 1941, 490 thousand wheeled and 195,7 thousands of tracked tractors were manufactured in the country, of which CTZ produced more than 100 thousands of heavy tracked C-60 and C-65.

With the beginning of World War II, the Kharkov Special Design Bureau SKB-75 for engines was evacuated to Chelyabinsk. Ivan Yakovlevich Trashutin was the chief designer for tank engine building at ChTZ from 1941 to 1981. But tank The design bureau was also engaged in the development of engines for civilian products.

During the war, in accordance with the order of the People's Commissariat of Industry on May 15 1944, 320, the plant was tasked to begin the design and production of diesel agricultural tractors for peacetime. The SKB-75 Chelyabinsk Constructor Plant (Chelyabinsky Kirovsky Plant, name of the factory during the war), under the leadership of I.F. Trotsky and A.A. Lazarev, is entrusted with the issuance of future diesel engine KDM-46 to equip the C-80 tractor. Eight months after the end of the war, in January, the first post-war C-1946 universal purpose tractor began to be assembled at ChTZ in January, its design made it easy to assemble with almost all machines. These tractors played a large role in the post-war restoration of the country's national economy and in the development of agriculture.

In 1948, the C-80 was presented at the International Exhibition in Prague. In 1952, each C-80 tractor used in agriculture accounted for 2830 hectares of conditional plowing. However, there were already farms, where this figure was four thousand hectares.

In 1954, the plenum of the Central Committee of the CPSU adopted a resolution "On the further increase in grain production in the country and on the development of virgin and fallow lands." The USSR State Planning Committee planned to plow in Kazakhstan, Siberia, the Volga region, the Urals and other regions of the country at least 43 million hectares of land. C-80 tractors have become indispensable workers in the development of virgin and fallow lands.

With C-80 began active supply of Chelyabinsk products abroad. In 1949, the first 194 tractors were shipped to Poland, Czechoslovakia and other countries. By the middle of 50, CTZ equipment was already sold to all countries of the socialist camp, as well as to Finland, Sweden, Austria, India, Burma, Syria, Egypt, Afghanistan, and Brazil. Approximately in 50 countries of the world worked tractors of the USSR production ChTZ. The geography of using C-80 covered the entire globe: from the Arctic to Antarctica, in total they were 200 296 units.

With C-80 began active supply of Chelyabinsk products abroad. In 1949, the first 194 tractors were shipped to Poland, Czechoslovakia and other countries. By the middle of 50, CTZ equipment was already sold to all countries of the socialist camp, as well as to Finland, Sweden, Austria, India, Burma, Syria, Egypt, Afghanistan, and Brazil. Approximately in 50 countries of the world worked tractors of the USSR production ChTZ. The geography of using C-80 covered the entire globe: from the Arctic to Antarctica, in total they were 200 296 units.In the future, based on the C-80, its gas generator version was created, the upgraded models: C-100, T-100М, T-100М3 and various modifications of these machines.

If C-60, C-65 and C-80 largely repeated the design of the American tractor company Caterpillar, in the future, their design is largely based on the original technical solutions of domestic designers. The plans of the country's government for the construction of hydroelectric power stations, irrigation canals, railways, highways, where giant earthworks had to be carried out, pushed Chelyabinsk designers to create a powerful industrial tractor in the second half of 50. The famous DET-250 has become the world's first diesel-electric industrial tractor with an 310 horsepower and electromechanical transmission, providing automatic control of traction and speeds. The big plus of DET-250 is the possibility of its use as a mobile power plant, which gives industrial current and has a power of more than 60 kilowatts. The design bureau of Trashutin resolved issues of ensuring the joint operation of electric transmission and diesel. He is recognized as the world's best car of this class. He has three gold medals at international exhibitions. Upgraded DET is produced in our days.

At the end of 60-x - the beginning of 80-ies, the Chelyabinsk Tractor Plant experienced a rebirth: it was fundamentally reconstructed in order to set up a new family of promising industrial T-130 tractors. High-performance automatic lines were installed in the workshops of the enterprise, which allowed to significantly increase the volume of production.

In 1984, the millionth tractor rolled off the assembly line of the Chelyabinsk Tractor Plant. The maximum production of industrial tractors was reached in 1988, when 31 700 machines rolled off the production line.

During the 80 years, the plant faced the most difficult tasks and Chelyabinsk tractor constructors successfully solved them. Today, ChTZ-Uraltrak is not only a tractor plant, but an industrial association for the production of a wide range of road-building equipment, engines, spare parts and other high-tech products.

Experience of tractor construction at Uralvagonzavod

To ensure the priority areas in the design of new products of agricultural and road-building equipment at Uralvagonzavod in 2002, the Design Bureau of Agricultural and Road-Building Equipment (KB DST) was established. Its main functions were the development of design documentation for agricultural and road-building machines at the level of world achievements, the author's support for the production of experimental and serial products.

In a uniquely short timeframe, KB developed the LTZ-155 tractor on the basis of the Lipetsk tractor and in 2004, introduced into production a family of agricultural universal wheel tractors of enhanced energy saturation with improved ergonomic qualities: PT-M-160 with controlled rear wheels and PT-M-160 with uncontrolled rear wheels.

These machines are successfully used in the 24 regions of the Russian Federation, as well as in Kazakhstan, Uzbekistan and Bulgaria.

The universal tilled tractor RT-M-160 is designed for general-purpose work, including the cultivation and harvesting of sugar beet, vegetables, potatoes and tall-stem row crops. It contains wide single-operation and combined units hung from the back and front, as well as containers for seeds, fertilizers and herbicides for carrying out plowed work, including reusable plows of various soils to a depth of 30 centimeters, continuous cultivation, sowing, harvesting grain and other crops, transportation of goods. Despite his young age, he has both gold and silver medals, he is a repeated winner of various exhibitions, and most importantly, he has already proven himself in the fields of the country.

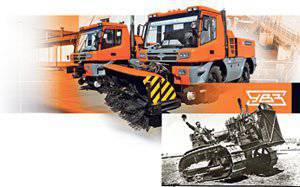

At the same time, a series of industrial tractors for the needs of the national economy were developed and produced in small series: a special welding tractor RT-M-160TS (designed for air-plasma cutting and welding in hard-to-reach areas), a communal tractor RT-M-160К, a tractor for snow removal work with rotors, snow plow SSHR-2,6, tow tractor towing.

The design bureau also conducted work on creating universal wheel tractors with a wide range of traction forces and various engines from Doutz, as well as the Yaroslavl Motor Plant, the Altai Motor Plant, and ChTZ-Uraltrak LLC. The design bureau developed design documentation and carried out work on serial production of the PT2-160 tractor with improved performance characteristics, on improving tractor units, in particular, on preparing gearbox production with gear shifting by hydro-compression couplings.

On the basis of the RT-M-160 tractor, a traction module of TMB-1 cars was created. In December 2008, three traction modules of the wagons were sent at the request of the Directorate for Repair of Freight Wagons of Russian Railways OJSC to the wagon depot of Yaroslavl, Magnitogorsk, Vikharevka. New items are designed to transport empty freight wagons from the station to the depot for repair, repaired wagons back, and also to clean the tracks from snow and debris. The car can work both on automobile, and on the railway course. The module is also equipped with a pneumatic system and is able to move 10 cars or tanks at one time.

Today, this development was abandoned. The new TMB-2 is an independent project with a frame structure, and not a product developed on the basis of any machines.

Where others will not pass

The idea of creating multi-link vehicles for unobstructed off-road movement arose long ago. Initially, their high maneuverability and maneuverability, high payload attracted the attention of various specialists, primarily those working in the interests of the military departments. The main purpose of creating articulated tracked vehicles (SGM) with the development of the rocket industry was the transportation of missiles to remote terrain. Today, as a result of the conversion of the main idea, articulated-tracked vehicles, two-link tracked conveyors (DT) are widely used to solve both military and civilian tasks. The absence of a special snow-plowing machinery in Russia hampered the development of the northern territories and turned into huge material costs.

A special place is occupied by two-link tracked transporters of the unified Vityaz family. Open Joint-Stock Company Vityaz Machine-Building Company since 2008, as part of a corporation.

The complex of works on the creation of a unified family of two-link tracked carriers "Vityaz" includes three main stages: the formation of prerequisites and prospecting for SGM (executor - SKB as part of the Altai Tractor Plant); research and development work to create the design of a unified family of DT "Vityaz" (performed by the SCB as part of the Rubtsovsky machine-building plant, Altai Krai); preparation and serial production of diesel fuel, putting them into operation were carried out as part of the Ishimbay transport engineering plant. Within six years - from 1977 to 1983, the first-class factory equipped with modern equipment and technology for the production of complex, unparalleled machines DT “Vityaz” was created in the city of Ishimbay BASSR.

All work on the creation of the DT family "Vityaz" was carried out in accordance with the decisions of the Council of Ministers of the USSR and the Central Committee of the CPSU under agreements with the Central Aeronautical University. The chief designer and technical manager of the work was the chief designer of the Rubtsovsk Machine-Building Plant.

As a co-executor, some branch research institutes, design teams and a number of leading plants in the country were involved in these works.

Work on the creation of DT "Vityaz" lasted about 30 years. During this period, developed several dozen variants of diesel fuel of various capacity. Of these, the 11 versions of the machines are taken to prototyping. For carrying out factory and state tests, 27 prototypes of diesel fuel with a carrying capacity of 10, 20, 30 tons in floating and non-floating versions were manufactured.

More than 2000 DT was serially manufactured and commissioned. The most intensively exploited diesel fuel in the Kola Peninsula, in the Tyumen and Tomsk regions, in Yakutia, in Kamchatka and Chukotka. As a rule, all cars (with rare exceptions) work out two or three warranty periods — this is for 12 – 16 thousands of kilometers. It is not uncommon for 24 – 30 to work thousands of kilometers with a warranty run of 6000 kilometers.

During production, a large number of various changes and improvements were made to the design of diesel fuel in order to improve the reliability, workmanship, manufacturability and performance of diesel fuel.

ATVs have proven themselves in geological exploration, oil pipelines, as the only reliable means of transportation in the conditions of continuous off-road, swamps, virgin snow, low and ultra-low temperatures in the Russian North, Siberia, the Arctic and Antarctic, as well as high and ultra-high temperatures in the sandy deserts of Central Asia and Arabia, ultrahigh humidity of the tropics and rarefied air of high mountains. Due to the versatility of the design, the Vityaz transporters can successfully be used as basic chassis for placing armaments, lifting, loading and unloading, earth-moving and other technological equipment for various purposes on them.

Information