Aviation industry comes to life

The revival of such a knowledge-intensive and costly industry as the aviation engine-building, besides being in a state of stagnation for 20 years, is impossible without the support of the state. And she appeared recently. For example, in 2007, the decision was made to collect the remnants of enterprises under the roof of the United Engine Corporation. The task of this integrated structure is to produce engines for military, civil aviation and space programs, installations of various capacities for generating electrical and thermal energy, gas pumping and ship gas turbine units. JDC unites more than 85 percent of the industry’s assets and is a subsidiary of the United Industrial Corporation Oboronprom. According to the Deputy Director of the Aviation Industry Department of the Ministry of Industry and Trade Alexey Lyashenko, within the framework of the state program “Development of the aviation industry for 2013 – 2025 years”, production of aircraft engines is planned to increase from 690 to 3000 units. According to the program, a threefold increase in the revenue of aircraft manufacturing is expected - from 504 billion to 1,776 trillion rubles. From 2011 to 2025, there has been an increase in the number of aircraft supplied - from 102 to 298 units, helicopters - from 262 to 465. In addition, an almost tenfold increase in labor productivity is planned - from 1,5 million to 14,5 million rubles per person. Financing of the state program is 991 billion rubles, although more recently, before the entry of the Crimea into Russia, it was estimated at 1,7 trillion rubles. The conference participants asked how, with a reduction in funding of almost a trillion, to maintain quantitative and nomenclature indicators, given that only 21 billion rubles are needed for the production of MC-360 aircraft.

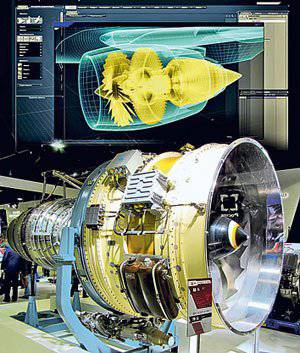

PD-14 - our common success

UDC General Director Vladislav Masalov said that the corporation had completed the formation period and is now in the process of developing a development strategy for the period up to 2025. “We decided to create a reliable, sane action plan that will allow us to achieve the performance indicators voiced by Alexey Lyashenko. All the executive bodies, primarily the Ministry of Industry and Trade and the Ministry of Finance, participate in the development. I will not hide the fact that the task to achieve a confident financial condition has not yet been solved. The main reason is the debt burden of the enterprises that we received in 2009 during the formation of the corporation. This circumstance hinders the possibility of dynamic development of the UEC, ”complained Masalov.

Simultaneously with the development of a strategy, the corporation is increasing its engine production. “On average, production at enterprises from 2009 to 2013 year increased from 950 thousand to two million. The sales volume increased significantly - from 98 billions in 2009 to 168 billions of rubles in 2013. In 2014, it is planned to increase this figure by another 18 percent. An increase in the state defense order affects the improvement of the structure of commodity output. In 2013, the state defense order was 25 percent, and in 2014-m it reached 32 percent. The improvement is on the basic indicators, but, unfortunately, the debts that we received together with the plants make it impossible for us to conduct proper technical re-equipment, ”added the General Director of the UEC.

He believes that corporations are required to match the time. “Given the smaller production volume compared to the 80's period, industry enterprises cannot be effective in the current configuration. It is necessary to create a new industrial model for the development of inter-plant cooperation. It is used in almost all segments of promising programs. First of all, we are talking about the power plants “117 product” and “30 product” for the fifth generation fighter T-50 (PAK FA). This year, the first pilot units will be manufactured in metal, and by the beginning of 2015, the engine-demonstrator will be assembled, ”Masalov stressed.

Another important segment of the program is civilian engine-building. “We are at the stage of manufacturing engine demonstrators for testing. Five PD-14 should be collected this year, after which they will begin their bench and flight tests. The civil engineering program involves co-financing from the state in the amount of 35 billion rubles, as well as the placement of a bond loan for the purpose of technical re-equipment of the enterprise - 12 billion rubles. In principle, the entire program budget amounts to about 75 billion rubles, ”he said.

In the helicopter segment, in accordance with the technical tasks of the holding company "Helicopters of Russia", there is a phased work at the St. Petersburg plant of OAO "Klimov". The company is upgrading the engines VK-2500, which are supposed to be used to create a promising high-speed helicopter. Masalov says: “It is extremely important that UEC cooperates with the United Aircraft Construction Corporation. We finally have a mutual understanding, it is implemented in long contracts, unlike in past times. The previous planning system for a period of one year led to the fact that many difficulties arose for the construction of the production program. Now, at least, a plan has been agreed on for the delivery of engines for military transport aviation for the period up to 2020, which makes it possible to formulate a program for the scientific and technical re-equipment of industry enterprises.

The production of gas turbine units based on aircraft engines saved the industry from complete degradation in the 90s. ODK and now does not refuse the production of these products. “This is an important segment of our program, to which we are neat, we build long-term relationships with the main consumers, Gazprom and oil companies. Now we have begun negotiations on the transfer of repair plants to the competence of the JDC to improve the after-sales service system, ”said Vladislav Masalov.

VIAM General Director Academician Yevgeny Kablov recalled that funding for the creation of the PD-14 program began thanks to the fact that scientists convinced Vladimir Putin of the ability of domestic manufacturers to create a competitive engine for MS-21: “If there had not been a conversation with the President during his visit to the exhibition in VIAM, it would hardly have been possible to get 12,8 a billion rubles of budget funds in order to start the implementation of the PD-2008 program in 14 ”.

The academician called the great merit of Alexander Inozemtsev, Managing Director and General Designer of Aviadvigatel OJSC (part of UEC), the main developer of PD-14, Alexander, who entrusted VIAM with the creation of new materials for this power unit. “Foreigners understood that the West would not give them to us and that we can develop only in our country. For PD-14, VIAM specialists presented 20 new materials, including composites, as well as more 50 semi-finished products from mass-produced materials, Kablov shared. - This engine is an outstanding achievement of our scientists and designers. What has been done today is really our common success, because in the conditions in which we had to work, it was difficult to create such an engine. ”

The UEC created cooperation ties to which the metallurgists were also connected. They set the condition - the order must be at least 100 engines. The UEC accepted it, and all business leaders agreed that they would keep prices down. “The second achievement of Alexander Inozemtsev is that he showed the will and entrusted us with the development of his nacelle from polymer composite materials. The UEC supported the general designer not to buy it for big money, but to make the domestic version, ”Kablov said. As a result, VIAM has developed a number of polymeric and composite materials, built cooperation and started the delivery of units for the engine nacelle.

Speaking about the application of additive technologies, the academician noted that “the mastering of these technologies will make it possible to manufacture complex-shaped parts with selective laser synthesis from domestic powders”. Using these technologies, you can create blades with any complexity of channels and cavities, which is determined not by the capabilities of the casting technology, but by design necessity. In addition, there will be the prospect of applying alloys-coatings directly in the process of "growing" blades and other parts, as well as the possibility of combining the properties of two or more alloys in one part.

Fighting Pratt & Whitney

Alexander Inozemtsev spoke about the implementation of the PD-14 project. According to him, aircraft manufacturers have been living with the idea of creating the MS-21 family for 12 years, but full-scale investments began after a key meeting with Vladimir Putin at VIAM. To maintain Russian competence, it is necessary to create an engine with a thrust of 12,5-14 tons, which is designed for several types of MS-21, which can accommodate up to 212 people. The most popular will be the model with a capacity of 150-175 passengers. It is important that Russian engine builders are tasked with certifying PD-14 not only in Russian, but also in a number of international registers. MS-21 is planned to be sold on the global market, therefore, for the first time in the practice of domestic aircraft construction, two engines are used at once on the same type of aircraft. In international practice, this is a normal phenomenon, due to the fact that airlines are very reluctant to change power plants, rather they are ready to change the aircraft itself, because such replacements entail changes in the entire service system. Therefore, the MS-21 will be offered with two engines - the American PW1400G from Pratt & Whitney and the Russian PD-14.

Inozemtsev explained Russia's adherence to medium-haul narrow-body airliners in the following way: “This is the most dynamic and rapidly developing niche in aircraft construction. Forecasts up to the 50s and 60s of the XNUMXst century indicate a XNUMX% increase in demand for this type. Two participants - the firms Pratt & Whitney and Snecma - usurped the market, but, according to our information, already today this leads to long delays in the supply of engines. Therefore, there is a real opportunity to compete with these companies ”.

When the creators of PD-14 began work, the airlines set a number of conditions: to achieve reliability of the power unit, fuel efficiency, low maintenance costs and environmental safety. According to Alexander Inozemtsev, now it is possible to work out all the required parametric characteristics. For the first time in the domestic practice, aircraft builders set the task to create an integrated power plant, that is, not only the engine, but also the engine nacelle. In the West, these two industries have long been interrelated. Inozemtsev believes: “In recent years, designers have been chasing the maximum“ licking ”of efficiency, including in terms of the interaction of a power plant with a wing. Therefore, the requirements of Irkut Corporation and UAC for the supply of engines for MS-21 together with engine nacelles are in line with the global trend, and we took up this work. ”

The main developers of PD-14 from Aviadvigatel OJSC hope that their offspring will be competitive in the market. The characteristics of the new unit should exceed the parameters of existing world analogues by 12 – 18 percent. First of all, CFM56 and V2500 are meant. “If we do not achieve this, then after 2017, the competitiveness of our engine will be very difficult to ensure among medium-range narrow-body aircraft,” warned foreigners.

The reliability of aircraft on 200 thousands of flying hours should be determined by one shutdown. “Such a shutdown frequency is a pass to the elite engine builder unit. In addition, we need to reduce airline operating costs by at least 15 percent. Airlines do not require that we make huge reserves from current environmental regulations, because they do not receive any bonuses for this. Considering the fact that the requirements are tightening all the time and every time it is insanely expensive to rework the engine to meet prospective standards, we set ourselves the task of creating a product with noise margin of 10 – 15 percent and emissions of harmful substances by 30 – 45 percent of today's ICAO standards “- said the general designer of Aviadvigatel OJSC.

Alexander Inozemtsev did not at one time pull the blanket over himself in order to receive budgetary funds, but managed to unite the engine factories for the PD-14 project. “For Western colleagues, the creation of cooperation in modern super-expensive developments is a common practice, but we did not have this. Each design bureau and its serial plant had their own cooperation for the supply of components. For 20 years Russian engine builders did not build anything, but only devoured what was in the USSR. In Perm we had to descend from heaven to earth and create industrial gas turbines for the energy complex. This allowed us to survive. These are the conditions under which the country's leadership set us the task of building an engine that would be competitive with the products of General Electric and Pratt & Whitney within a tight timeframe (six to seven years). Initially, we understood that if we did not create the most powerful cooperation, then nothing would come of it within the specified time frame. Everyone understood that the industry was so weak that it could not compete with the whole world, ”Inozemtsev said.

According to him, the UEC helped to solve the problem of consolidation. All key enterprises were invited to work on the engine, in accordance with their competence, they determined the scope of work. All had the experience of independent creation of both individual units and power units as a whole. OJSC Saturn and OJSC Aviadvigatel cooperated with Western firms - the first one certified the turbofan SaM-146 in Europe, the second one worked for some time with Pratt & Whitney on the PS-90A project and gained useful experience, especially in the field of billet quality assurance.

Viktor Chuiko, Director General of the Aviation Engine Building Union, spoke at MFD-2014 that the current state of the industry is far from modern requirements. In such a situation, all hopes for competitiveness are placed on scientists. His opinion is confirmed by the work on PD-14. “If it were not for the active participation of scientists from CIAM, VIAM in creating the engine, we would not have been able to make the gas generator and the engine-demonstrator so quickly. The fact that VIAM is a developer is familiar and understandable. But for the first time, CIAM acted not just as a scientific consultant, but as a component designer, for the first time signed a contract, which is responsible for designing the high-pressure compressor fan, ”said Alexander Inozemtsev Chuiko.

Black wing

The merit of the PD-14 developers, primarily from VIAM, was the creation of a wide-stroke fan blade technology. For its production, a whole plant had to be built in Ufa. “Technology patents are very vigilantly defended by Western colleagues. Pratt & Whitney and Rolls-Royce jealously guard their knowledge and are constantly suing, paying each other $ 1,5-3,5 billion in fines. We have created our own technology and protected the patent. Today, the wide-stroke fan blade is produced using serial technology. The products are 30 percent lighter than solid blades, which reduced engine weight by half a ton. This is a giant step forward, considering that the total mass of the engine is 3,8 tons, ”said Alexander Inozemtsev.

The MC-21 developers constantly compare their offspring with their main competitors, the Boeing 737 and the Airbus A320. “We provide superiority over them due to the parameters and maintain an approximate parity with the fact that, according to our information, will be released on the upgraded aircraft of these types. If we manage to withstand the specified characteristics and if Irkut and UAC are implementing their plans to install a black wing (composite, carbon-fiber alloys. - Ed.), Then in general MS-21 will have advantages. Our competitors do not yet have plans to install such a wing on aircraft, ”the general designer predicts.

The economic characteristics of industrial production of the engine give a certain superiority in comparison with what today flies in the world market. “For the first time, we are designing an engine for a given directive production consumption of materials and labor intensity. Having a market price, which we set ourselves as a competitive one, we “rewind” the task of the production cost of parts and components back, distributed everything in the factories and included these requirements on the level of parts that determine the production cost. Based on these requirements, the plants have developed a program of technical re-equipment, ”said Inozemtsev. The Ministry of Economy supported the idea, it is planned to allocate money on the basis of a bonded loan with interest rate subsidies. The issue of financing is key, it is much more important than other problems. AT stories Russian engine-building has not yet had any examples of technical re-equipment in view of the appearance of a new product. As a rule, the product was several times more expensive than the market price, and then over the course of 10 years, the real labor intensity and subsidy for the difference decreased - what is happening now with the Sa-M-146 engine. The creators of PD-14 plan to carry out technical re-equipment of factories by the second or third year of mass production and believe that this will provide an opportunity to enter the market with a competitive product. “PD-14 is a symbiosis of new, already proven and proven technologies and materials for all major nodes. This allows you to create not only a product, but also a powerful foundation for the future for the next generation of engines. Today, we are actively lobbying with the institutions and the Ministry of Industry and Trade to create a program from 22 key technologies of the sixth generation engine. This should be done in order to take into account the mistakes in creating PD-14, when additional risks arose related to the tight deadlines for implementing the program, ”said Alexander Inozemtsev.

Within the framework of the PD-14 program, two full-sized engines and several gas generators and model units were created. On the fourth engine, modernized gas generators are being tested. On the fifth unit, full-scale engineering and certification tests are deployed, the purpose of which is to confirm the planned calculations. Based on the IL-76, it is planned to create a flying laboratory, in which tests of the power plant will begin in February 2015.

“In total, an 22 prototype engine, including four for two aircraft and nine engine nacelles, should be created in order of certification. All these volumes are painted in the production schedules. The main thing now - to withstand them. All motor factories are undergoing tremendous growth in defense orders. Unemployment is over, and the plants are working at full capacity. But I am afraid that this will interfere with the implementation of the PD-14 program, ”the general designer concluded.

Information