Universal fighter engineering troops. Part two

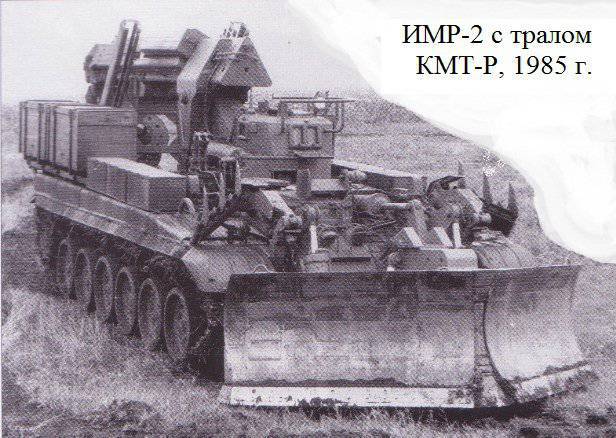

IMR-2 with KMT-R trawl

Note.In the first article about IMR-2, an inaccuracy was made. It says (including in the captions to the photo) that the vehicle used the KMT-4 mine sweep. The KMT-R trawl was developed for IMR-2, for which the knife sections of the KMT-4 trawl were taken. KMT-R was developed in 1978-85. as part of the Crossing research project, where they developed a built mine mine trawl for armored vehicles (Tanks, BMP, BML, BTR, BTS, BMR and IMR). The studies were not completed - the military leadership of the USSR considered that enough existing means of trawling and the creation of additional funds were inappropriate. As a result, only IMR-2 and later IMR-2M were armed with this type of trawl. But back to stories.

Part of 2. Application of IMR-2

Afghanistan. The first baptism of fire IMRY held in Afghanistan. But, as usual, application information is minimum. Even the officers of our former Kamenetz-Podolsk engineering school could not tell much. Mostly about BIS and trawls. IMRIs are seen mainly in the Salang Pass. But the reviews on the work of these machines are only good.

The overwhelming majority of them worked in Afghanistan on an NRM model 1969, created on the basis of the T-55 tank. Years since about 1985, the first IR-2 based on T-72 and with improved mine resistance appeared. In Afghanistan, WRI was mainly used in movement support units (OOD) and road groups. Their task was to analyze the debris on the roads, clearing the roads on passes from snow drifts and landslides, overturned cars, as well as restoring the roadway. Therefore, in the area of responsibility for the protection of each motorized rifle regiment, an OOD was created as part of the BAT, MTU-20 and WRI, which allowed them to constantly keep their way in a passable state.

During the movement of the columns of the combat units, the outposts were necessarily assigned, where the WRI could also enter. For example, the marching order of a motorized rifle battalion during the operation in the area of Bagram 12 in May 1987: hiking intelligence, a tank with a roller mine sweep, followed by an engineering detachment machine IMR-1 and a tank with a universal tank bulldozer. Next - the main column of the battalion.

In Afghanistan, in conditions of stony and hard soils, the knife trawl was almost never used. The same can be said about PU demining - there were practically no suitable targets for it either.

WRI is the first in Afghanistan. 45 Engineer Regiment

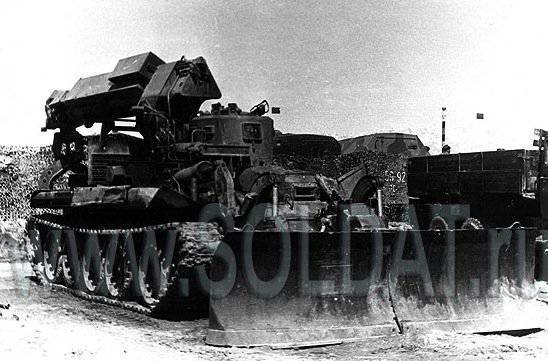

IMR-2 in Afghanistan. 45 Engineer Regiment

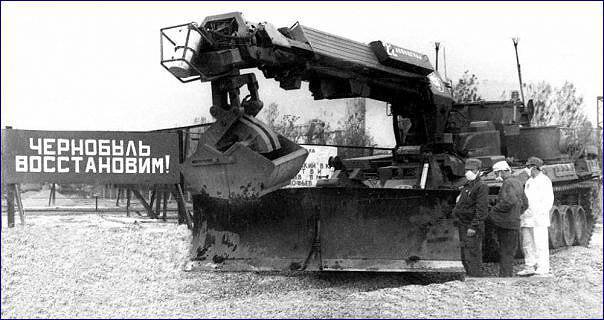

Chernobyl. But the real test for the IMR has become Chernobyl. When the accident at the Chernobyl nuclear power plant occurred, the equipment of the type WRI turned out to be very useful. In the course of eliminating the consequences of the catastrophe, engineering troops faced difficult tasks that require a creative approach to solving them, namely, improving the protective properties of engineering equipment to perform work in the immediate vicinity of the destroyed power unit. Already in the month of May, they performed tasks up to 12 WRI. The focus was on their improvement, improving the protective properties. It was in Chernobyl that these machines showed their best qualities and only WRI turned out to be the only machine capable of operating near a destroyed nuclear reactor. She began to build a sarcophagus around the reactor, delivered and installed crane equipment.

IMR-2 around 4 power unit

Certain deficiencies in the construction of IMR-2, which were described by Lieutenant Colonel E. Starostin, a former teacher of the Kamenetz-Podolsk Engineering Institute, have also affected Chernobyl. He and his subordinates were among the first liquidators of the accident. At the nuclear power plant E. Starostin arrived on April 30 on April 1986: Despite the fact that IMR-2 turned out to be the most suitable machine for those conditions, some shortcomings were identified. Later we listed them to representatives of the pilot landfill site from Nakhabino and the plant of the manufacturer. The first is the dozer itself. On the frontal side, it had a welded steel sheet in 8-10 mm. To work in the soil of the earth was enough. And when it was necessary to dismantle the rubble of concrete, the latter often punched a frontal sheet of the blade, radiation graphite fell into the holes, and nobody took it out from there, and made holes. And, as a result, the radiation background of the machine is constantly growing. The second is the slow work of hydraulics, as a result of which more time is spent on a certain type of work, and radiation is around. The third is the inconvenience in working with the radio station, which was behind the right - it is better that it was on the left. Fourth, the GO-27 chemical reconnaissance device was located on the left side of the mechanic in the corner, and in order to remove the indicators from it, the mechanic had to lean to the side - and he was driving, and it was not advisable to be distracted. It is better to transfer the device to the operator’s cabin. Fifth - insufficient view from the mechanic's seat - when the blade is in working position, the dead zone for the review is about 5м. Because of this, - continues E. Starostin, - on the first day we almost fell into a deep ditch behind the station fence.

IMR-2. To work like a fight

From the end of May, upgraded vehicles began to arrive at the station with replacement. To enhance radiation protection on these machines, the operator's tower, the operator's hatch and the driver's mechanic were covered with 2-cm plates of lead. In addition, the driver got on his seat (under the fifth point) an additional lead sheet. It was the bottom of the car that was least protected. The machine was designed to quickly overcome the contaminated areas during the fighting, but here the slow work in small areas and therefore the effect of radiation from the ground was quite strong. Later, even more powerful cars appeared in the zone.

Another participant in the liquidation of the accident Medinsky V. A. recalls (for more details see the website Global catastrophe).

9 May he, along with his subordinates arrived at the Chernobyl NPP. WRI and WRI-2 immediately threw onto the station rowing graphite, uranium, concrete, and the like that flew out of the reactor. Spots of radioactive contamination were such, "...that the chemists were afraid to go there. Yes, by and large they had nothing to call in under the reactor. At the most protected of their machine RHM, the attenuation coefficient was just something about 14-20 times. In IMR-2 - 80 times. And this is the original version. When leaf lead came, we further strengthened the defense by placing, wherever possible, centimeters or two lead. At the same time, the track mine trawls and launchers of elongated demining charges with all the equipment were removed from the vehicles as completely unnecessary. Formally, the commander of the machine is the operator, but in that situation the main driver was the mechanic, since they had to work with bulldozer equipment, besides, the control units of the short-circuit systems and the hot spring tank are located with him. ” The fact is that the short circuit system (collective protection) was triggered by the command “A” - an atom! With a flash of a nuclear explosion, the automation switches off the supercharger for about 15 seconds, muffles the engine, puts the car on the brake, closes the blinds, the inlets for the supercharger and the gas analyzer, etc. (read above). When the shock wave passes (for these 15 seconds), then the gas analyzer and supercharger openings open, the supercharger starts, and all the thrust (high pressure fuel pump, brakes, blinds) are able to turn on for normal operation. “This is a nuclear explosion,” writes V. Medinsky, “when such a stream is short-lived. But then there is no explosion! The flow of such power continues to impact, and you can wait until everything returns to normal indefinitely. The car is muffled (and even not one, but in turn all)! And here in the first place is the qualification of the driver. Think about switching to the OPVT control unit (there is a tricky “OPVT-KZ” switch there), but not to panic, connect all the thrusts, start the engine of the machine and the supercharger and calmly continue working only a trained person. ” On the first day, all the dirt was scooped closer to the walls of the reactor, and sometimes in heaps. ” When there was a question about the removal of “radioactive” dirt from the site around the reactor to the burial grounds, a way out was found “in the form of containers for household waste (normal, standard), which were completely captured and lifted by the MHR-manipulator. They were installed on the PTS-2. PTS took them to the burial ground. There, another WRI containers unloaded into the actual repository. It feels good.

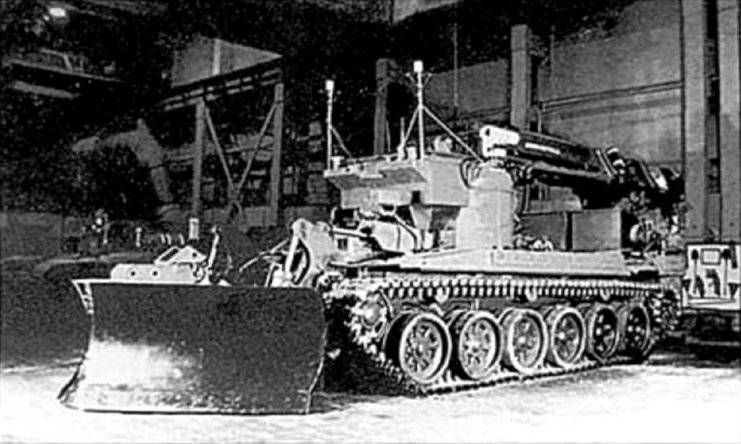

IMR-1 removes radioactive debris. Lead plates are clearly visible on the body.

But IMR-2 did not have a scraper ripper. Instead, it was launcher elongated charges of clearance. That is, there is nothing to fill the containers themselves. We decided to quickly this problem by boiling on the gripping arm of an ersatz grab from sheet steel. However, this led to the fact that the seizure stopped completely closing (normally, the ticks close with a decent, see 20 overlap) and because of this it was not possible to set it to a different position. The volume of the resulting grab was greater than the volume of the scraper, so it was decided to abandon the standard scraper-rippers from WRI. So within two days we received a “scraper” made from an excavator bucket. He very well went to the seizure, had a very not weak volume, but weighed about 2 tons, that is, as much as the entire carrying capacity of the stela. The fields took into account this case, and after about a week or two the machine came with the correct grab (and gripping ticks in the spare parts and tools). At about the same time, the first “dinosaur” arrived (IMR-2D)". V. Medinsky also describes in more detail the first IMR-XNUMHD: “The car has changed a lot. We must start with the fact that there were no windows on it. Instead, there are three television cameras and two monitors (one operator, second mechanics). Mekhvodu was reviewed by one camera (to the right of the hatch), the operator was two (one on the boom, the second on the arrowhead). The cameras of the mechanical input system and the one on the boom had rotational drives. The one on the tip, looked at the manipulator, turned with him and looked like a cylinder about half a meter long and 20 centimeters in diameter. Next to it was installed gammalokator. But the manipulator ... I don't know who and what the developers said, but the grab they put on the first dinosaur could be used somewhere on the moon or a gold mine, but for our business it was obviously small. His volume God forbid was liters 10! Truth and it was used very not weakly. Since the most active materials, as a rule, did not have a large volume, and the gamma-locator allowed them to be identified very accurately. Another feature of the first two IMR-2D was the absence of bulldozer equipment (the second copied the first one, but differed from it in a normal grab, came in two weeks). All had a very powerful air filtration system (a sort of hump on louvers based on an air filter from the T-80). The most important feature was the enhanced anti-radiation protection. And in different levels - different. On the bottom of the 15000 times, on the hatches (both) 500 times, on the levels of the driver's chest - 5000 times, etc. The mass of cars reached 57 tons. The third (came as early as July) differed from the previous two by the presence of windows (two pieces, forward and left-forward completely indecent, centimeters of 7 thickness, which made it look like an embrasure embrasure) at the mechanic drive. The operator still has cameras and a monitor". We add that the bulldozer equipment remained standard, the weight of the machine increased to 63 tons.

IMR-2D. The gamma-locator (white cylinder) is clearly visible on the head of the gripper. Also clearly visible is the attachment of the bucket to the grip pliers.

Worked on these machines (IMR-XNUMHD) experts from the Institute NIKIMT. According to the memoirs of E. Kozlova (Ph.D., a participant in the liquidation of the consequences of accidents at the Chernobyl NPP in 2-1986), 1987 in May 6, the first group of specialists from the Research and Design Institute of Installation Technology (NIKIMT) on decontamination - B .N. Yegorov, N.M. Sorokin, I.Ya. Simanovskaya and B.V. Alekseev - went to the Chernobyl nuclear power plant to assist in the aftermath of the accident. The radiation situation at the station continuously deteriorated. Another, no less important task facing NIKIMT employees is to reduce the level of radiation around the 1986 unit to acceptable standards. One of its practical solutions was associated with the arrival of the IMR-4D stripping machines. By order of the ministry from 2, NIKIMT ordered the execution of a number of works, including the creation within extremely short periods of time of two robotic complexes based on the army machine IMR-07.05.86 to eliminate the consequences of the Chernobyl accident. All scientific management and organization of work on this issue was assigned to the deputy director A.A. Kurkumeli, the head of the department N.A. was appointed coordinator of the equipment layout at IMR-2. Sidorkin, and the responsible managers of various areas of work to accomplish this task were the leading specialists of the institute, who, working around the clock, were able to manufacture a new modernized IMR-2D for 21 day. At the same time, the engine was protected by filters from radioactive dust getting inside, a gamma-locator, a manipulator for collecting radioactive materials in a special collection, a grab that could remove soil up to 2 mm thick, special radiation-resistant television systems, a tank periscope, an operator’s life support system and driver, equipment for measuring radioactive background inside and outside the car. IMR-100D was coated with a special, well-deactivated paint. The machine was controlled by a television screen. 2 took tons of lead to radiation protection. Protection in real volume of the machine in real conditions was about 20 thousand times, and in some places reached 2 thousand times. On May 20, for the first time, NIKIMT's employees conducted tests of the IMR-31D in real conditions around the ChNPP 2 block from the machine room, which gave the management of the Chernobyl headquarters a true picture of the power distribution of gamma radiation. 4 June from NIKIMTa came the second machine, IMR-3D, and in the zone of greatest radiation, both machines began to work. The work carried out on this technology dramatically reduced the total radiation background around the 2 unit and made it possible to start building the Shelter using existing technology.

IMR-2 on the way to Chernobyl

One of the testers of IMR-XNUMHD was the designer of NIKIMT Valery Gamayun. He was destined to become one of the first who managed at IMR-2D, modified by the institute's specialists, to approach the destroyed 2 unit and make appropriate measurements in the radioactive zone, remove the cartogram of the area around the destroyed NPP. The results formed the basis of the plan of the Government Commission for the cleaning of contaminated areas.

As V. Gamayun recalls, May 4, he, together with the deputy director of NIKIMT A.A. Kurkumeli went to a military training ground in Nakhabino, where they participated in the selection of a military engineering vehicle. We stopped at the IMR-2 as the most satisfying requirements. The machine immediately entered NIKIMT for revision and modernization. WRI was equipped with a gamma locator (collimator), a manipulator for collecting radioactive materials, a grab that could remove the top layer, a tank periscope and other equipment. In Chernobyl, it was later called the thousand.

28 May V. Gamayun flew to Chernobyl, and the next day he met the first car IMR-2D, which arrived on the railway tracks consisting of two cars. The car was badly shabby after transportation, it was obvious that it was being transported at top speed. I had to put the WRI in order. To do this, opened a sealed plant of agricultural machinery, which was previously repaired milking machines. The necessary tools and machinery there remained in good order. After repairing the WRI, the trailer was sent to the Chernobyl NPP. It was 31 May. To Gamayun: “To 14. 00 our IMR stood on the road at the first block of the Chernobyl NPP. The radiation level at this initial position reached 10 p / h, but it was necessary to have time to make a move before flying around helicopters, which usually raised dust with their screws, and then the background radiation increased to 15-20 p / h. Worldwide, radiation dose in the amount of 5 X-rays that a person could receive during the year was considered a dose of safe radiation. At the time of the Chernobyl disaster, this rule was raised 5 times for the liquidators. At the initial position, much had to think out on the go. They decided to move in reverse because the driver's cabin was initially protected from radiation less than the operator’s position. They took off their shoes and, in order not to bring radiation dust into the cabin, sat in their socks in their socks. At that moment, the connection between the driver’s cab and the operator’s compartment worked normally. But some kind of intuition suggested that it could be interrupted, therefore, just in case, we agreed that, if it refused, we would be tapped. When they moved, the connection really disappeared. Because of the roar of the motor, the knock kicked by the key was barely distinguishable, and the connection with those who expected our return outside the danger zone was completely absent. And here we realized that in case of anything, for example, if the motor stalls, there will simply be no one to pull us out of here, and we will have to return on foot through the contaminated area, and in some socks. And at this time my collimator (dosimeter) was going off scale, and it was not possible to take readings from it. The car had to be finalized again. We did this at the same plant for the repair of milking machines. Only after this, regular exits to the affected area began around the destroyed reactor, as a result of which full radiation reconnaissance was made and the terrain cartogram was taken. Soon I was called to Moscow to prepare other machines for shipment to the Chernobyl NPP. ”

IMR-2D works on the 4 block

IMR-2 worked on 8-12 hours per day. At the very collapse of the block, the machines worked for no more than 1 hours. The rest of the time was spent on preparation and the road. This intensity of work led to the fact that despite all the protective measures, the radioactivity of the internal surfaces of all three IMR-2D, especially in the crew accommodation areas (under the legs), reached 150-200 mR / h. Therefore, soon the car had to be replaced with fully automated technology.

The Klin complex became such a technique. After the accident at the Chernobyl nuclear power plant, there was an urgent need to create automated equipment to eliminate the consequences of the accident and perform ground tasks without direct human participation. Work on such a complex began in April 1986 almost immediately after the accident. The complex was developed by the VNII-100 design bureau in Leningrad. Together with the Urals, by the summer of 1986, the Klin-1 robotic complex was developed and built, which consisted of a transport Robot and control machines based on IMR-2. The robot car was engaged in clearing rubble, pulling equipment, collecting radioactive debris and waste, and the crew of the control vehicle managed all these processes from a safe distance, while being in the middle of a protected vehicle.

According to the deadlines, the complex should have been developed in the 2 month, however, the development and manufacture amounted to the entire 44 day. The main objective of the complex was to minimize the presence of people in the zone with a high level of radioactivity. After doing all the work, the complex was buried in the burial ground.

The complex consisted of two cars, one controlled by a driver, the second was remotely controlled by the operator.

Machine control complex "Wedge-1"

Working, remotely controlled machine complex "Klin-1"

As a working machine was used "Object 032", created on the basis of the engineering machine lining IMR-2. Unlike the base machine, the 032 Object had additional equipment for decontamination, as well as a remote control system. In addition, the possibility of "habitability" of the machine remained. The engine compartment and chassis are modified to increase reliability when operating under conditions of exposure to ionizing radiation.

To control the crewless machine, the 033 Object Management Machine was manufactured. For the base was taken the main battle tank T-XNUMHA. The special compartment housed the crew of the car, consisting of the driver and operator, as well as all the necessary equipment for monitoring and controlling the machine. The body of the car was completely sealed and trimmed with lead sheets to enhance protection against radiation. In the center of the car were installed units to start the engine, as well as other specialized equipment.

In the liquidation zone, several WRI options were working, which differed in terms of the level of radiation attenuation. So, the first IMR-2 provided 80-fold attenuation of radiation. This was not enough. With the help of engineering troops, several WRI were equipped with lead protective screens, which ensured 100-multiple attenuation of radiation. Subsequently, in the factory, the WRI was made providing 200-500- and 1000-fold radiation attenuation: IMR-2В "sotnik" - up to 80-120 times; IMR-2 "dvuhotnik" - up to 250 times; IMR-2D "thousandth" - up to 2000 times.

Almost all IMRIs that then stood in the ranks, found themselves in Chernobyl, and they all remained there forever. During the operation of the machine, so much radiation was collected that the armor itself became radioactive.

IMRY on a cemetery of equipment in the area of Chernobyl

After the Chernobyl accident, there was a need for further modernization of the IMR-2. The subsequent modernization of the vehicle led to the appearance of the IMR-2М version, which was adopted by the decision of the Chief of Engineering Troops from 25 December 1987. On the new machine, the weight was reduced to 44,5 (45,7 in IMR-2); 72A. The car was removed set of launchers charge demining (due to the appearance of a special self-propelled launcher "Meteorit" (installation of mine clearance UR-77, Kharkov Tractor Plant), as well as the fact that during operation, this installation was very whimsical. Removed and machine gun installation, strengthened armor protection of hydraulic equipment.The scraper-ripper was returned (as on the first WRI), which made the machine more universal in terms of performing work in areas of destruction - the destruction of the crest of high blockages, hauling out large beams, debris, collecting debris, collapsing the crest of a crater, etc. The machine was produced from March 1987 to July 1990 and is known as an intermediate or transitional model of IMR-2М 1 of the second embodiment (conventionally IMR-2М1) .

IMR-2M first option. Kamenetz-Podolsk Engineering Institute. At the stern are visible frames to which PU demining charges were previously attached.

In 1990, the car went through another upgrade. The changes affected the tick-borne grab of the manipulator. It was replaced by a universal bucket-type working body that could hold objects comparable to a matchbox, work as a grab, reverse and straight shovel, scraper and ripper (the scraper-ripper as a separate piece of equipment was removed).

By 1996 (already in the independent RF), the IMR-2 and IMR-2М were created on the basis of the IMR-3 and IMR-3М based on the T-90 tank based on the IMR-3 and IMR-120М. In terms of equipment and tactical and technical characteristics, both machines are identical. But IMR-3 is designed to ensure the advancement of troops and the performance of engineering work in areas with a high level of radioactive contamination of the area. The gamma radiation attenuation ratio at crew locations is 80. IMR-XNUMXМ is designed to ensure the advancement of troops, including on radioactively contaminated areas, the multiplicity of attenuation of gamma radiation at crew locations - XNUMX.

IMR-3 at work

Performance characteristics

Engineering Machinery Immobilization IMR-3

Length - 9,34 m, width - 3,53 m, height - 3,53 m.

Crew - 2 people.

Mass - 50,8 t.

Diesel engine В-84, hp power 750 (552 kW).

Power reserve - 500 km.

Maximum transport speed - 50 km / h.

Performance: with the device passes - 300-400 m / h, when laying roads - 10 - 12 km / h.

Productivity of earthworks: excavation works - 20 м3 / hour, bulldozer works - 300-400 м3 / hour.

Crane lifting capacity - 2 t.

Armament: 12,7-mm machine gun NSVT.

Maximum boom reach - 8 m.

WRIs are part of the engineering and road divisions and lodging units and are used as part of movement support teams and luggage groups along with demining installations and tank bridge stackers, ensuring the advance of tank and mechanized units of the first echelon. Thus, one IMR-2 is in the road equipment division of the engineering-platoon platoon of the ISR tank vehicle group’s (mechanized) brigade rally line, as well as the brigade-leveling platoon of the engineering company’s brigade detachment of the engineering regiment battalion.

IMR-2 (v. 637, 1980 g.) - engineering obstacle machine, equipped with a boom crane (carrying capacity of 2 t at full departure 8.8 m), dozer blade, mine sweep, PU demining charge. In serial production with 1982

IMR-2D (D - “Modified”) - IMR-2 with enhanced radiation protection, attenuation of radiation up to 2000 times. Worked in Chernobyl. At least 3-x built in June-July 1986 g.

IMR-2M1 is an upgraded version of the IMR-2 without PU charge clearance, range finder and PKT machine gun, but with enhanced armor. The boom crane is supplemented with a ripper scraper. Performance engineering equipment remained the same. Adopted in 1987, was produced from 1987 to 1990.

IMR-2М2 - a modernized version of the IMR-2М1 with more powerful multifunctional dozer equipment, the boom crane received a universal working body (URO) instead of a tick-held grip. URO has the capabilities of a manipulator, grapple, reverse and straight shovel, scraper and ripper. Adopted on 1990

"Robot" - IMR-2 with remote control, 1976 g.

Wedge-1 (v. 032) - IMR-2 with remote control. In June, 1986 was built an prototype.

Wedge-1 (v. 033)- the “object 032” control machine, also on the IMR-2 chassis. Crew - 2 people. (driver and operator).

IMR-3 - engineering lining machine, development of IMR-2. Diesel B-84. Dozer blade, hydraulic boom-manipulator, knife track mine sweep.

To date, the engineering fencing machine, in particular the IMR-2М (IMR-3), is the most advanced and promising engineering dispensing machine. It can produce all types of work in the conditions of radioactive contamination of the area, severe atmospheric damage by aggressive gases, vapors, toxic substances, smoke, dust, and direct fire exposure. Its reliability was confirmed in the course of eliminating the consequences of the most ambitious catastrophes of our time and in the combat conditions of Afghanistan. IMR-2М (IMR-3) is available not only to the military sphere, but also to the civilian, where the use of its universal capabilities ensures great benefits. It is equally effective both as an engineering lashing machine and as an emergency rescue vehicle.

The list of operations performed by WRI is wide. This, in particular, overlaying on sinter-terrain, in low forest, on virgin snow, on hillsides, uprooting stumps, felling trees, making walkways in forest and stone rubble, in minefields and non-explosive obstacles. It can be used to disassemble debris in populated areas, emergency buildings and structures. The machine carries out a fragment of trenches, pits, buried equipment and shelters, filling holes, ditches, ravines, preparing ditches, escarpes, dams, crossings through anti-tank ditches and escarpes. WRI allows you to install sections of bridges, to organize congresses and departures on water crossings. It is advisable to use it for work on soils of categories I-IV, in quarries and open workings, to fight forest and peat fires, to carry out lifting operations, to evacuate and tow damaged machinery.

Snow removal is a quite peaceful job for WRI. Volgograd, 1985

- Mikhail Feschuk

- Universal fighter engineering troops (engineering vehicle lining IMR-2)

Universal fighter engineering troops. Part two

Universal fighter engineering troops. Part three

Information