Mrap - happy old idea

The anti-cumulative trellis armor has undergone major improvements over the past decade. This Cougar from Force Protection is all surrounded by a steel cage.

If the Mrap (Mine Resistant Ambush Protected - with enhanced mine protection) design is closely related to operations in Iraq and Afghanistan, then story tells us that this concept has actually been around for about 50 years. At that time, another Arab country was a long and bloody battlefield - Algeria. The French army tried out new tactics there, becoming the first army to use helicopters as highly mobile means of special forces that were trained and equipped to destroy the Katiba rebels in the highlands.

There were other innovations, including some surprisingly modified trucks that were part of French counterinsurgency tools. Algerian fighters tended to ambush, but they also made extensive use of mines and bombs hidden on the roads and frequently used trails.

The main vehicles of the French army consisted of American excesses of the Second World War, namely, half-tracked vehicles, GMC trucks, light reconnaissance vehicles M8 and jeeps. None of them was able to withstand the explosion and debris created by mines and roadside bombs. Thus, AMX received an offer to develop a mini-protected vehicle capable of better protecting troops and transport convoys.

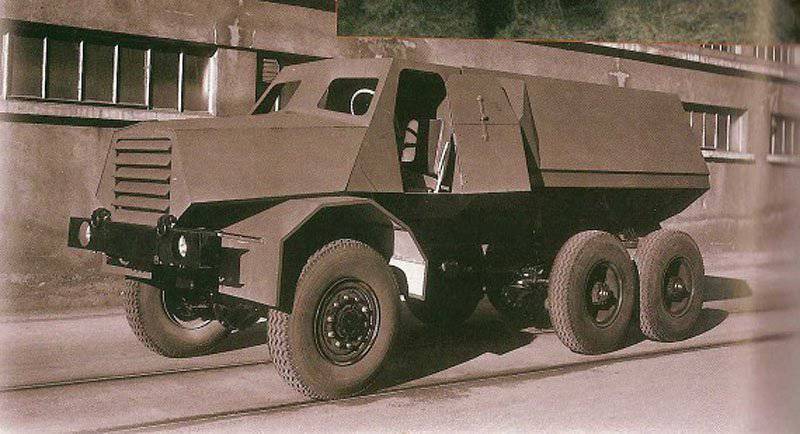

In collaboration with Berliet, a truck manufacturer known for its highly mobile Sahara trucks, AMX created an armored hull featuring an excellent V-profile. Someone may say, “nothing new in the military sphere,” and he will be right! The first cars were put into service in the 1959 year.

A decade later, small “Cold War related” conflicts began in southern Africa. The partisans supported by the Soviet Union were engaged in the destabilization of the so-called “colonial” regimes in South Africa, Namibia, Angola and Mozambique. Mines and roadside bombs became main again. weapons in the hands of irregular forces. It is time to start serious engineering work in the field of armored combat vehicles with mine protection.

The first experiments began in South Africa, there appeared cars with “long legs” and a V-shaped hull. These first cars looked like an ingenious “do-it-yourself” invention, combining light truck power drives, homemade frames and welded boxes to protect the driver and crew at the furthest point from the ground. So, an essential feature of these machines is the deployment of personnel as far as possible from the site of the explosion. The further the better.

Black and white photos reminiscent of the old story: at the end of the 50s, AMX and Berliet teamed up to create the first MRAP vehicle, which was intended for use in Algeria to escort convoys and transport infantry.

The photo clearly shows the V-shaped with the angle 90 ° the lower part of the body of the South African conveyor Ivema Gila

Ocelot from Force Protection won the LPPV program in the UK. It combines a V-shaped body and a composite structure reinforced with ceramics.

Such machines as Caspir, Ratel and Buffel went through all stages, from the experimental sample to the production. The South African armed forces used them extensively in their fight against SWAPO (Organization of the Peoples of South West Africa) and other insurgents and confirmed their sufficient effectiveness in protecting soldiers and weapons systems. Mine protection technology, mainly based on the concept of a V-shaped hull and “consumable” suspension elements, migrated to other means, such as supply trucks (for example, Samil) and even self-propelled howitzer G6.

As for armor materials, only ordinary homogeneous rolled armor was used. There was no complicated ceramics, aramid fibers, composite materials, but only a skillful assembly as a result of new welding and bending processes, plus the clever use of space and isolated compartments. Interestingly, the Merkava Mk 1 was designed according to the same principles and at the same time!

Meanwhile, while the northern hemisphere froze at the stage of the Cold War, in the southern regions, endless ambushes, fights in the thickets, raids and the struggle to control areas caused great concern, all of which had their own ballistic consequences in the form of explosions and fragments. However, later a peacekeeping operation was carried out in the former Yugoslavia, completely changing the minds and strategies of developing military equipment.

German industry was among the first to understand the dramatic changes that still required an explanation, and in connection with these in the 1996, an ATV car from Krauss-Maffei Wegmann was released. This has led to a new generation of mine-protected machines with a more balanced design, incorporating new technologies, but retaining the concept of a truck. ATV received the designation Dingo and became one of the most successful industrial stories on the threshold of a new century.

Permali Gloucester is the main booking specialist. These two photos show the side and bottom panels for light and medium machines. Although the mine booking kit was made for Land Rover, it is interesting to note that the weld seam is not visible. Bending, bending and stamping are preferred to increase strength, and welding is avoided as much as possible.

The close-up of the stern of the BAE Systems RC-35 vehicle shows two interesting features of the armored structure. Firstly, the angle at “V” is rather large and reinforced with a small welded plate. Secondly, the welding seam between the V-shaped bottom and the sides of the body is clearly visible. The large overlap between the upper and lower structures ensures rigidity and proper insulation from the shock wave. The typical thickness of alloy steel sheets is approximately 18 mm. They provide the 3 Ballistic Level and the Mine Level 4a / 4b Level

Matador from Paramount has a direct genetic relationship with its famous South African predecessors Caspir and Buffel. V-shaped body is the basis of its design. Paramount has created a new machine, Mbombe, which is based on a new approach to protection.

To be V-shaped or not to be V-shaped?

V was a magical letter and a must-have point in talking about the designs of a mini-protected body, to the extent that no confidence in the car is possible if this letter is not its main element. Marketing was so effective that many armies demanded a “V” as the main solution for their planned purchases. The manufacturers of armored combat vehicles understood that without “V” many business opportunities would disappear. Therefore, the step from “purely theoretical V” to that offered on the market “V” was very short.

The beauty of “V” is that a single bent or correctly welded sheet of steel placed at the correct height provides mine protection without any additional elements. This is a functionally complete solution. Sheet thickness is also important, but less than the angle value. It was clearly demonstrated that the “flat V” does not behave in a calculated manner, in this case the blast wave is not reflected sufficiently. Wave deflection effectively occurs at an angle close to 90 °. However, when combined with high ground clearance, this automatically leads to a high silhouette — the weak point of all Mrap cars.

Counterinsurgency operations in Iraq began in 2004. Mrap became the response of the American industry to urgent operational requirements. Former South African engineers were invited by innovative and commercially aggressive companies, such as Force Protection or Navistar. In a very short time they were able to offer solutions for the American marines, which has always been the first to acquire the combat and auxiliary machines of the new generation. South African comrades came with a proven solution, which they knew, "V", the rest of course is already well known.

The American industry of heavy vehicles, taking into account martial law, for several years was able to put thousands of cars Mrap. Many models were produced, they became harder and harder as the threat increased. By the end of 2008, this deadly vicious circle had developed into an operational impasse. Indeed, the Mrap machines were not designed for cross-country driving, and as they became heavier, their mobility increasingly deteriorated. Thus, the rebels knew where to catch them.

Cougar from Force Protection differs thick and heavy armored blocks on the sides to prevent piercing the crew capsule with projectile warheads. As can be seen from the example of the Cougar, silencers and other means of REP have “succeeded” aboard all the Mrap machines in Iraq and Afghanistan, but have created problems for communication systems, crew safety and are contrary to medical standards.

Existing “V” solutions are the whole truth.

It was time to think differently and decide the paradigm of protection. Strategists suddenly realized or rediscovered that mobility was part of a holistic approach to survivability. At a recent symposium, the French army stated that not a single VBL was shot down from an RPG, although many of them were exposed to this threat and fired upon by insurgents in all theaters over the past 20 years. Simply the car is very small and very mobile.

The program was launched on M-ATV (off-road vehicle with enhanced mine protection), it was assumed that solutions to protect it can be very diverse. The goal was to create an all-terrain vehicle with more balanced ballistic protection. Reducing the silhouette in order to improve mobility led to the exclusion of the "V-shaped" bottom. At this stage of the story, it is necessary to emphasize that “V” is just a technical decision, and not a guide to action. Neither Merkava, nor Puma, nor VBCI and even light Mrap as, for example, Dingo or Aravis, are based on a V-shaped body. Thick and durable bottom or energy-absorbing modules are also very effective technical solutions.

However, some confusion was intentionally maintained for obvious marketing reasons. Indeed, anyone can notice that "V-shaped" or even "double V-shaped" bottom is mentioned in some programs, although the angle "V" is quite flat. The sole purpose of these so-called V-bottoms is to increase the rigidity of the bottom without the ability to deflect any explosion. This technology was applied in the modernization program for the Canadian Lav 3 machine, it can also be seen on the Oshkosh M-ATV, Piranha 5 or on some other 6xXNNXX and 6X8 combat vehicles.

It is interesting that in the technologies of “flatter” bottoms highly traditional materials are used, with rolled homogeneous armor and alloyed steels being preferred. Low silhouettes mean less distance between the bottom and the ground. Therefore, it is necessary to use materials with good ballistic and elastic properties. Good ballistic properties are necessary to stop the fragments and shrapnel created by mines and soil (since stones and pebbles can also be lethal at high speeds).

On the other hand, a good toughness ensures that the plate absorbs the shock wave without breaking or cracking. It turns out that good, good rolled homogeneous armor and its variations, alloyed or high-strength steels, do their job very well.

There is a lot of steel at the bottom of the M-ATV or Dingo machines. Nexter Aravis also uses well-designed energy-absorbing modules made of steel. To ensure the level of 4a / 4b's mine protection, they are combined with a bottom made of bent aluminum sheets. Also noteworthy is that some aluminum alloys are also very suitable, as they have a remarkable ability to stop splinters.

Based on the type of threat, other materials can also be integrated into the armored sandwich. Glass and polyethylene are among the favorites. They are very good at resisting small “shock core” mines (used in some mines, for example in the former Yugoslav TMRP-6).

The most important part in the design of a "flat" bottom is to ensure its integrity when exposed to a shock wave. Gearboxes, axles and other mechanical transmission components of the Mrap category of machines require holes in the casing and the main structure of the machine. Art minozaschischennyh machines is to seal these holes without impairing mobility.

The Universal Engineering Ranger was introduced as the final Mrap concept. It combines almost all of the available technologies that provide better protection with current mass limits. Despite the promising characteristics of the Ranger today could not find a single buyer

Getting the right product

At least three steps determine the development of threats in Iraq and Afghanistan.

• Step one: consists of mines and buried projectiles of all types that hit the lower part of Mrap.

• Step two: RPG attacks have become widespread in urban actions and in the protection of objects. The technical answer was stationary protection in the form of rails, grids and other similar solutions. Since most RPG launches were neutralized by this technology, the rebels began to think differently.

• the third step: cary-charge charges (or PPS) showed their terrible essence, they turned out to be a much more lethal threat compared to the RPG. In addition, they can be remotely controlled, which makes it difficult to detect the operator. They can also be operated by wire or by other devices. They are mainly made of old artillery shells: the body is cut into two parts and the spherical iron piece is attached directly to the explosive block. This spherical part is directly stamped from sheet metal. These handmade weapons have variable characteristics, one of which is that they can create many small projectiles, up to three, instead of one large one. Thus, they hit the car in one gulp and therefore armor protection should be designed accordingly.

At the turn of the century, with the appearance of mines and roadside bombs, doors and seats became high-tech elements. The doors of this car Dingo 2 are an example of the use of new technologies that prevent the crew from being hit by a shock wave, explosion or shrapnel.

Super Big Mac

PPS (slug charge) causes damage for three main factors: impact, penetration and fragmentation. It is not surprising that special armor protection mainly consists of various layers, combined in a kind of block. Each layer is carefully selected and placed to neutralize one of the above effects. It is worth noting that the standard industrial PPS is able to penetrate up to 100 mm rolled homogeneous armor, which means 780 kg of metal per square meter. meter! All side surfaces may be Mrap 15 m X NUMX, which may be 2 tons of steel.

In this regard, the Mrap constructors had to work with limited protected areas, but in the reservation laboratories they created reservation technologies with high mass efficiency (Em is the ratio of the surface density of the rolled homogeneous reservation to the total reservation area). Statistics say that PPSs mostly “fly” above the ground at a height of 0,8 - 2 meters, which means placing armor blocks between these heights on both sides of the vehicle.

Some so-called Super Big Mac armor plates are distinguished by the presence of up to eight layers of different materials. Steel is used to create the outer casing of the blocks. It provides the necessary rigidity and can be bolted or welded. The internal structure is made of aluminum, titanium, rubber, ceramics, glass and polyethylene. They interact with each other by combining their mechanical properties and thereby effectively stopping the projectiles and absorbing energy and debris.

Each armor developer has his own recipe, which he keeps at his heart, as any great chef would have done. The most sophisticated technology easily reaches Em = 1,5, which is equivalent to three tons of armor for large Mrap machines.

Up to one hundred kg of explosives (IEDs in a car) can be transported by vehicles. These cars are driven by suicide drivers who ram the coalition columns. Here, the best protection is the collection of information and the subsequent remote destruction of the car.

Let us return to the more classic threat of fixed bombs, here special attention was paid to the design of doors and hatches. It must be recalled that a large amount of explosive creates a double wave. The first directly affects the machine, but it is immediately followed by a cruel, so-called reverse vacuum, which seeks to tear off the doors and hatches. Both waves are equally lethal for the crew that is being hit and shaken, and here the whole article is not enough to describe in detail the technology of the mini-protected seats that are currently installed in the machines.

This BMC car has a very interesting solution, which consists in the fact that the entire body is connected to the chassis through a central bridge, which allows it to rotate in the event of a side attack. Powerful springs push the body back into place after reducing the force of the blast wave. A proud oak tree is uprooted in a storm, and a humble reed just bends down.

Transparent armor

More interesting are the significant improvements brought by the use of transparent armor. Due to the great needs of the US Mrap programs, manufacturers were financially in a favorable position and were eager to invest in these technologies.

The 2013 model's armored glasses are very different from ordinary thick glass plates manufactured in 90's. New compositional or transparent ceramics, for example, Saint Gobain Sapphire, is notable for even better Em compared to katana with homogeneous armor! Transparent armor is a key technology that provides the crew with immediate situational awareness - the most important operational requirement in counter-insurgency missions.

The booking technology has made a qualitative leap in the past fifteen years and it owes much to the Mrap programs. These technologies are currently migrating to other armored combat vehicles. For example, the promising French BTR VBMR included protection technologies developed for Mrap machines, but in it they are built into a more classic type of mechanical architecture characteristic of armored combat vehicles.

And remember ...

The concept of Mrap was on the verge of self-destruction when its poor mobility began to create strategic problems. M-ATV and advanced independent suspension solutions promoted, for example by Oshkosh, come to the rescue. However, the history of protection Mrap “rang the alarm” several times and once again showed how important the systems approach, where mobility, situational awareness, information sharing and active protection should all be combined into a single armored dome around the car. This is one of the most important lessons learned from recent hostilities. The best ballistic material will never replace it.

Materials used:

Armada International 2 / 2013

www.baesystems.com

www.ivema.co.za

www.gdls.com/

www.permali.co.uk

www.paramountgroup.biz

www.universalengineering.co.uk

http://www.bmc.com.tr/

Information